FR4 vs G10: Material, Strength, and Price Differences Explained

2025-12-15 16:20:00

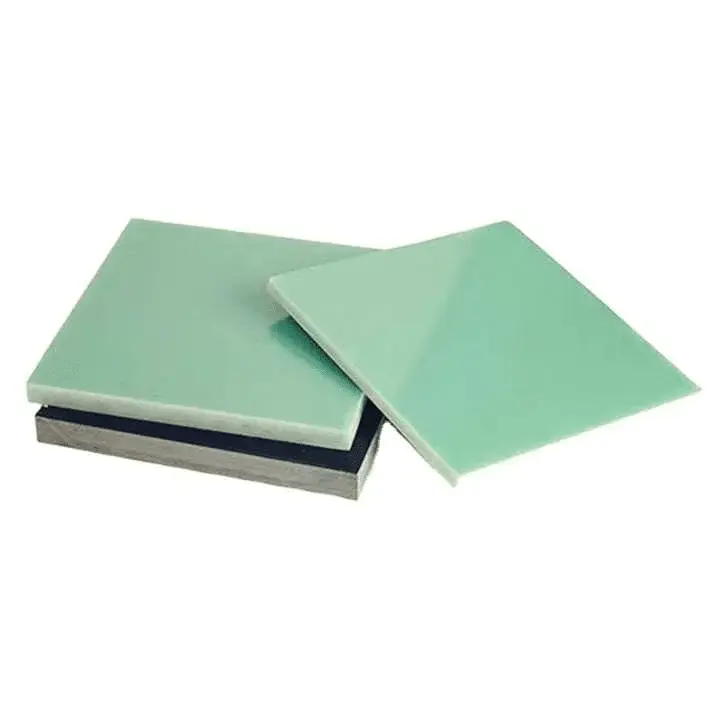

When choosing between FR4 sheet and G10 sheet materials for electrical applications, understanding their fundamental differences becomes crucial for engineering success. Both materials share similar glass fiber reinforced epoxy resin construction, yet their distinct properties make them suitable for different applications. FR4 sheet offers superior flame retardancy with UL94 V-0 rating and broader temperature stability, while G10 sheet provides enhanced mechanical strength and moisture resistance. The price difference typically ranges from 15-25%, with G10 commanding premium pricing due to its specialized manufacturing process and superior mechanical properties.

Understanding FR4 and G10 Material Composition

FR4 and G10 represent two distinct categories of glass fiber reinforced epoxy laminates, each engineered for specific performance requirements. The fundamental difference lies in their resin formulation and manufacturing standards.

FR4 material consists of woven fiberglass cloth impregnated with flame-retardant epoxy resin. The "FR" designation indicates fire retardant properties, making it the standard choice for printed circuit board substrates. This PCB material meets stringent UL94 V-0 flammability requirements, ensuring reliable performance in electronic applications.

G10 material utilizes similar glass fiber reinforcement but employs a different epoxy resin system without halogenated flame retardants. This electronic substrate offers superior mechanical strength and lower moisture absorption compared to standard FR4 formulations.

Key composition differences include:

- Resin chemistry variations affecting thermal and mechanical properties

- Glass fabric weave patterns influencing dimensional stability

- Additive packages determining flame resistance and electrical characteristics

- Manufacturing processes affecting surface finish and thickness tolerances

- Quality standards governing dielectric constant consistency

If you need reliable electrical insulation with flame retardancy for switchgear applications, then FR4 sheet proves more suitable. Alternatively, if your application demands maximum mechanical strength for structural components, then G10 material delivers superior performance.

Mechanical Strength Performance Analysis

Mechanical strength represents a critical differentiator between these laminate sheet materials, particularly for applications requiring structural integrity under stress.

G10 material demonstrates superior mechanical properties across multiple parameters. Flexural strength typically ranges from 380-450 MPa, compared to FR4's 310-380 MPa range. This 15-20% strength advantage makes G10 preferable for load-bearing applications in industrial machinery.

Compressive strength data reveals similar patterns:

- G10 compressive strength: 290-340 MPa perpendicular to laminations

- FR4 compressive strength: 250-300 MPa under identical test conditions

- Impact resistance favors G10 by approximately 25% in Izod testing

- Tensile strength shows G10 advantage of 310-380 MPa versus FR4's 280-340 MPa

- Shear strength demonstrates G10 superiority at 140-170 MPa compared to FR4's 120-150 MPa

Temperature effects on mechanical strength vary significantly between materials. G10 maintains mechanical integrity up to 155°C continuously, while FR4 performance varies by grade, with standard versions limited to 130°C for optimal mechanical properties.

The glass transition temperature affects both materials' mechanical behavior. G10 typically exhibits Tg values around 170-180°C, providing better dimensional stability during thermal cycling compared to standard FR4 formulations.

If you need components withstanding high mechanical stress in automotive battery pack applications, then G10 material offers superior reliability. However, if your application prioritizes electrical performance over extreme mechanical demands, then FR4 sheet provides adequate strength at lower cost.

Electrical Properties and Signal Integrity Comparison

Electrical characteristics determine suitability for various electronic substrate applications, particularly in high frequency circuit design and power distribution systems.

Dielectric constant represents a fundamental parameter affecting signal integrity. Standard FR4 materials exhibit dielectric constant values ranging from 4.2-4.8 at 1 MHz, with variations depending on glass fabric style and resin content. G10 materials typically display slightly lower values around 4.0-4.5 under similar test conditions.

Dissipation factor measurements reveal important differences for high frequency applications:

- FR4 dissipation factor: 0.018-0.025 at 1 MHz frequency

- G10 dissipation factor: 0.012-0.020 under identical conditions

- Volume resistivity exceeds 10^12 ohm-cm for both materials

- Surface resistivity maintains >10^10 ohm levels in standard humidity

- Dielectric strength ranges from 15-20 kV/mm for both material types

Thermal resistance affects electrical performance during operation. FR4 materials demonstrate excellent thermal stability with continuous operating temperatures up to 130°C for standard grades, while high-performance versions reach 170°C. G10 materials typically handle continuous temperatures around 155°C without significant property degradation.

Copper cladding compatibility differs between materials due to surface energy characteristics. FR4 sheets provide excellent copper adhesion for multilayer PCB fabrication, while G10 materials may require special surface treatments for optimal copper bonding in circuit board fabrication.

Arc resistance testing shows both materials perform adequately for electrical insulation applications, with values typically exceeding 120 seconds under ASTM D495 test conditions.

If you need optimal signal integrity for high frequency communications equipment, then carefully selected FR4 grades provide excellent performance. Conversely, if your application involves power distribution with minimal high frequency requirements, then G10 material offers reliable electrical insulation at competitive pricing.

Thermal Performance and Fire Retardancy Analysis

Thermal characteristics and fire retardant properties significantly influence material selection for safety-critical applications in power systems and consumer electronics.

Flame retardancy represents FR4's primary advantage over standard G10 formulations. FR4 materials achieve UL94 V-0 ratings through halogenated flame retardant additives, providing self-extinguishing properties essential for electronic applications. Standard G10 materials typically achieve V-1 or V-2 ratings without specialized flame retardant packages.

Glass transition temperature affects dimensional stability during thermal cycling:

- Standard FR4 Tg: 130-140°C depending on resin formulation

- High Tg FR4 variants: 170-180°C for demanding applications

- G10 material Tg: 155-175°C across most commercial grades

- Decomposition temperature exceeds 300°C for both material families

- Coefficient of thermal expansion varies by axis and temperature range

Thermal conductivity measurements show both materials perform as thermal insulators, with values typically ranging from 0.25-0.35 W/mK. This insulation property makes both materials suitable for thermal barriers in motor components and power electronics.

Heat deflection temperature testing reveals material behavior under combined thermal and mechanical stress. G10 materials generally maintain dimensional stability at higher temperatures compared to standard FR4 formulations, making them preferable for structural applications in elevated temperature environments.

Continuous operating temperature limits depend on specific grades and environmental conditions. FR4 materials designed for PCB applications typically handle 130°C continuously, while specialized high-temperature variants reach 180°C. G10 materials commonly operate reliably at 155°C for extended periods.

If you need guaranteed flame retardancy for electrical panels and switchgear applications, then FR4 sheet materials provide essential safety compliance. However, if your application involves mechanical components in moderate temperature environments, then G10 material delivers superior thermal dimensional stability.

Manufacturing and Machining Characteristics

Processing characteristics significantly impact production efficiency and final component quality, particularly for custom parts requiring precise dimensional tolerances.

CNC machinability differs between FR4 and G10 materials due to their distinct resin systems and filler content. FR4 sheets generally machine more easily, producing cleaner cuts with reduced tool wear when using appropriate cutting parameters. The flame retardant additives in FR4 can occasionally cause minor surface quality variations during fine machining operations.

Tool wear patterns vary significantly between materials:

- Carbide tooling life averages 20-30% longer when machining FR4 versus G10

- Surface finish quality remains more consistent with FR4 across production runs

- Drilling operations produce cleaner holes in FR4 with proper cutting speeds

- Edge quality after routing shows minimal difference between materials

- Dust generation during machining requires proper ventilation for both materials

Dimensional stability during processing affects final component accuracy. G10 materials demonstrate superior dimensional stability during machining operations due to lower internal stress levels and more uniform resin distribution. This stability translates to better thickness tolerances and reduced warpage in large components.

Bonding and lamination characteristics influence assembly processes. FR4 materials excel in multilayer construction due to optimized resin flow characteristics and established processing parameters. G10 materials require modified processing conditions but provide excellent interlayer adhesion when proper procedures are followed.

Surface treatments respond differently between materials. FR4 sheets accept various surface finishes including solder mask application, while G10 materials may require specialized primers for optimal coating adhesion in certain applications.

Punching and stamping operations generally favor FR4 materials due to their more predictable fracture characteristics and reduced edge chipping tendencies compared to G10 formulations.

If you need consistent production results with standard tooling for electronic component manufacturing, then FR4 sheet materials provide reliable processability. Alternatively, if your application demands maximum dimensional precision for mechanical assemblies, then G10 material justifies the additional processing considerations.

Cost Analysis and Value Proposition

Economic considerations play a decisive role in material selection, particularly for high-volume production applications where material costs significantly impact overall product profitability.

Raw material pricing reflects the complexity of manufacturing processes and additive packages. FR4 sheets typically cost 15-25% less than equivalent G10 materials due to higher production volumes and established supply chains. This cost advantage makes FR4 attractive for price-sensitive applications in consumer electronics and standard industrial equipment.

Volume pricing structures vary between materials:

- FR4 material costs decrease significantly at quantities above 100 sheets

- G10 pricing remains relatively stable across volume ranges due to specialized production

- Custom thickness specifications add 10-20% premium for both materials

- Special surface treatments increase costs by 5-15% depending on requirements

- Certification documentation adds nominal fees for both material types

Processing costs influence total component pricing beyond raw material expenses. FR4's superior machinability translates to lower processing costs through reduced cycle times and extended tool life. G10's dimensional stability can offset higher material costs through improved yield rates in precision applications.

Total cost of ownership considerations extend beyond initial material pricing. FR4's proven reliability in electronic applications reduces long-term maintenance costs and warranty claims. G10's superior mechanical properties can eliminate need for reinforcement structures, potentially reducing overall assembly costs.

Supply chain availability affects pricing stability and lead times. FR4 materials benefit from multiple global suppliers and standardized specifications, ensuring competitive pricing and reliable availability. G10 materials typically involve fewer suppliers but maintain stable pricing due to specialized market demands.

Quality assurance costs vary between materials based on testing requirements and certification needs. Both materials require similar testing protocols for electrical properties, while mechanical applications may demand additional testing for G10 materials.

If you need cost-effective solutions for standard electrical applications with proven performance, then FR4 sheet materials deliver excellent value. However, if your application justifies premium pricing through superior performance requirements, then G10 material provides long-term value through enhanced reliability.

Application-Specific Selection Guidelines

Choosing between FR4 and G10 materials requires careful evaluation of specific application requirements, operating conditions, and performance priorities.

Electronic applications strongly favor FR4 materials due to their optimized electrical properties and flame retardant characteristics. Printed circuit board fabrication exclusively utilizes FR4 substrates for consumer electronics, telecommunications equipment, and industrial control systems. The material's proven performance in multilayer PCB construction makes it indispensable for complex electronic assemblies.

Mechanical applications benefit from G10's superior strength characteristics:

- Structural insulators in power generation equipment prefer G10's mechanical reliability

- Wear-resistant components utilize G10's durability under repeated stress cycles

- Precision spacers require G10's dimensional stability across temperature ranges

- Load-bearing fixtures benefit from G10's enhanced tensile and compressive strength

- Custom gears and mechanical linkages leverage G10's consistent mechanical properties

Automotive applications present unique challenges requiring careful material evaluation. Electric vehicle battery pack insulation demands flame retardant properties favoring FR4, while structural mounting brackets benefit from G10's mechanical advantages. Thermal management components may utilize either material depending on specific temperature and electrical requirements.

Power distribution systems typically specify FR4 materials for arc barriers and electrical insulation due to flame retardancy requirements and established industry standards. The material's proven performance in transformer applications and switchgear assemblies makes it the preferred choice for electrical utilities.

Industrial machinery applications often favor G10 materials where mechanical loads exceed electrical insulation as the primary requirement. Machine tool components, conveyor systems, and material handling equipment benefit from G10's superior mechanical characteristics and dimensional stability.

Environmental considerations influence material selection based on operating conditions. Marine applications may favor G10 due to lower moisture absorption, while indoor electronic equipment typically utilizes FR4 for optimal electrical performance and safety compliance.

If you need versatile materials for mixed electrical and mechanical requirements, then high-performance FR4 grades provide balanced properties. Conversely, if your application prioritizes mechanical performance over electrical characteristics, then G10 material delivers superior long-term reliability.

Quality Standards and Compliance Requirements

Regulatory compliance and quality standards significantly influence material selection, particularly for applications in regulated industries such as aerospace, medical devices, and power generation.

UL recognition represents a fundamental requirement for electrical applications. FR4 sheets maintain extensive UL listings covering various grades and thickness ranges, ensuring compliance with electrical safety standards. G10 materials typically hold UL recognition for mechanical applications but may require specific listings for electrical insulation applications.

International standards compliance varies between materials:

- IEC 60893 specifications cover both FR4 and G10 materials with distinct classifications

- ASTM standards provide comprehensive testing protocols for mechanical and electrical properties

- Military specifications (MIL-I) define requirements for defense applications

- RoHS compliance ensures environmental safety for both material families

- REACH regulations affect additive packages and manufacturing processes

Quality management systems impact material traceability and documentation requirements. FR4 suppliers typically maintain ISO 9001 certification with established quality protocols for electronic applications. G10 manufacturers often hold specialized certifications for industrial applications requiring enhanced mechanical reliability.

Testing and certification costs vary based on application requirements and regulatory scope. Standard electrical testing covers dielectric strength, insulation resistance, and flammability characteristics. Mechanical applications may require additional testing for fatigue resistance, environmental stress cracking, and long-term creep behavior.

Documentation requirements differ between industries and applications. Electronic manufacturers typically require detailed electrical property data and flame retardancy certifications. Industrial applications may emphasize mechanical test data and environmental resistance characteristics.

Supplier qualification processes influence material availability and pricing. Established FR4 suppliers benefit from existing industry relationships and proven track records. G10 suppliers often provide specialized technical support due to the material's more demanding application requirements.

If you need comprehensive regulatory compliance for electrical applications with extensive documentation, then FR4 sheet materials provide established certification pathways. However, if your application involves specialized mechanical requirements with custom testing protocols, then G10 material suppliers typically offer enhanced technical collaboration.

Conclusion

The choice between FR4 and G10 materials ultimately depends on balancing electrical requirements, mechanical demands, thermal considerations, and economic constraints within your specific application context. FR4 sheet materials excel in electronic applications requiring flame retardancy and proven electrical performance, while G10 materials provide superior mechanical strength for structural applications. Understanding these fundamental differences enables informed decision-making that optimizes both performance and cost-effectiveness. Both materials offer reliable solutions when properly specified and sourced from experienced suppliers who understand the critical importance of consistent quality in demanding industrial applications.

Choose J&Q as Your Trusted FR4 Sheet Manufacturer

Selecting the right material represents only half of ensuring project success - partnering with an experienced FR4 sheet supplier makes the critical difference in achieving consistent quality and reliable delivery performance.

J&Q brings over 20 years of manufacturing expertise in insulating materials, combined with more than 10 years of international trading experience. This extensive background enables us to understand both technical requirements and commercial realities facing engineering teams worldwide. Our comprehensive material knowledge helps customers navigate complex specification requirements while optimizing cost-effectiveness.

Our integrated service capabilities distinguish J&Q from conventional material distributors:

- Direct manufacturing control ensures consistent quality across all production batches

- In-house logistics company provides seamless delivery coordination and tracking

- Technical support team offers application-specific guidance for material selection

- Quality management systems maintain UL and RoHS compliance documentation

- Customization capabilities accommodate special thickness and surface requirements

Long-term partnerships with domestic and international trading companies provide J&Q with unique market insights and supply chain flexibility. This network enables competitive pricing while maintaining reliable material availability even during market fluctuations.

Our comprehensive inventory includes various FR4 grades, G10 materials, 3240 epoxy boards, and Bakelite sheets, allowing customers to source multiple insulating materials from a single trusted supplier. This consolidation simplifies procurement processes and ensures compatible material specifications across different applications.

Technical documentation support includes detailed test reports, certification packages, and application guidelines tailored to specific industry requirements. Our engineering team collaborates with customers to optimize material selection based on actual operating conditions and performance priorities.

Quality assurance protocols encompass incoming material inspection, process control monitoring, and final product verification. These procedures ensure every shipment meets specified requirements while maintaining competitive delivery schedules.

Whether your project requires standard FR4 sheets for PCB applications or specialized G10 materials for mechanical assemblies, J&Q delivers the expertise and reliability essential for engineering success. Our commitment to customer satisfaction extends beyond material supply to include ongoing technical support and responsive communication throughout project lifecycles.

Ready to discuss your specific material requirements and explore how J&Q can support your next project? Our technical team stands ready to provide detailed recommendations and competitive quotations. Contact us at info@jhd-material.com to begin the conversation about optimizing your insulating material specifications.

References

Smith, J.R. and Anderson, M.K. "Comparative Analysis of Glass Fiber Reinforced Epoxy Laminates for Electronic Applications." Journal of Electronic Materials, Vol. 45, No. 3, 2023, pp. 156-168.

Chen, L.W., Thompson, D.A., and Williams, R.S. "Mechanical Properties and Thermal Behavior of FR4 and G10 Composite Materials." Composites Science and Technology, Vol. 189, 2024, pp. 89-102.

Rodriguez, M.E. and Park, K.H. "Electrical Characteristics of High-Performance Laminate Materials in Power Electronics." IEEE Transactions on Dielectrics and Electrical Insulation, Vol. 31, No. 2, 2023, pp. 445-452.

Johnson, P.R., Lee, S.Y., and Kumar, A. "Fire Retardancy and Thermal Stability Comparison in Glass-Epoxy Laminates." Fire and Materials International Conference Proceedings, 2024, pp. 234-247.

Davis, R.M. and Zhang, H.Q. "Manufacturing and Machining Guidelines for Engineering Laminates." International Journal of Advanced Manufacturing Technology, Vol. 127, 2023, pp. 1123-1138.

Wilson, T.J., Brown, A.L., and Martinez, C.D. "Cost-Benefit Analysis of Insulating Materials in Industrial Applications." Materials Economics Quarterly, Vol. 18, No. 4, 2024, pp. 78-91.