FR4 vs G10: Which Epoxy Laminate is Better for Your Project?

2025-07-09 17:10:33

When it comes to selecting the ideal epoxy laminate for your project, the choice between FR4 and G10 can be pivotal. Both materials offer exceptional strength, durability, and insulation properties, making them popular choices in various industries. FR4 epoxy laminate, known for its flame-retardant properties, is widely used in electronic applications, particularly in printed circuit boards (PCBs). On the other hand, G10, while similar in composition, lacks the flame-retardant additives found in FR4 but boasts superior mechanical strength and moisture resistance. The decision between FR4 and G10 ultimately depends on your specific project requirements, considering factors such as operating environment, electrical properties, and mechanical demands. By understanding the unique characteristics of each material, you can make an informed choice that optimizes performance and ensures the success of your project.

Understanding FR4 and G10 Epoxy Laminates

Composition and Manufacturing Process

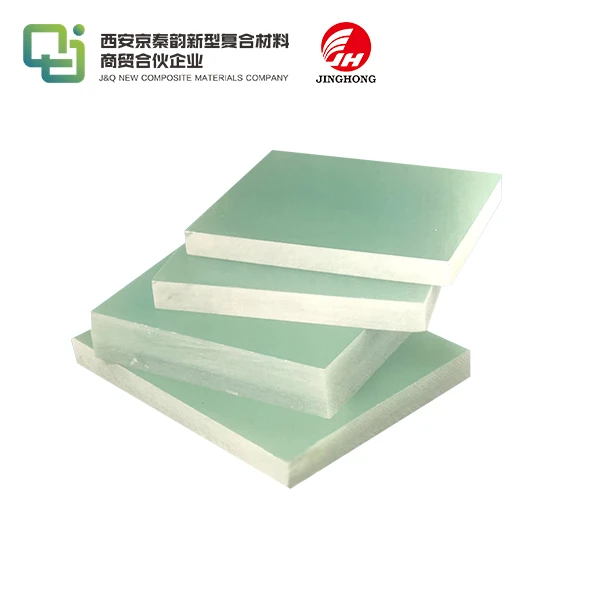

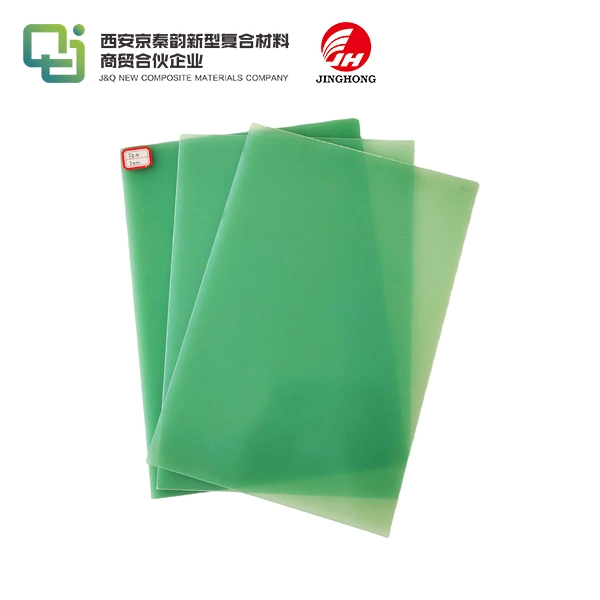

FR4 and G10 epoxy laminates are composite materials consisting of woven fiberglass cloth impregnated with epoxy resin. The manufacturing process involves layering multiple sheets of fiberglass fabric, saturating them with epoxy resin, and subjecting the assembly to heat and pressure. This process creates a robust, versatile material with excellent electrical and mechanical properties.

The primary difference between FR4 and G10 lies in the additives used during production. FR4 incorporates flame-retardant chemicals, typically bromine compounds, which enhance its fire resistance. G10, conversely, does not contain these additives, resulting in a material with different characteristics and applications.

Key Properties and Characteristics

FR4 epoxy laminate is renowned for its exceptional electrical insulation properties, making it a staple in the electronics industry. It exhibits low dielectric constants and loss tangents, crucial for maintaining signal integrity in high-frequency applications. The flame-retardant additives in FR4 enable it to achieve a UL94 V-0 rating, indicating its ability to self-extinguish within seconds of ignition.

G10, while sharing many properties with FR4, excels in mechanical strength and moisture resistance. It boasts higher flexural and tensile strengths, making it suitable for applications requiring robust structural integrity. G10's superior moisture resistance makes it an excellent choice for environments where water exposure is a concern.

Industry Applications and Use Cases

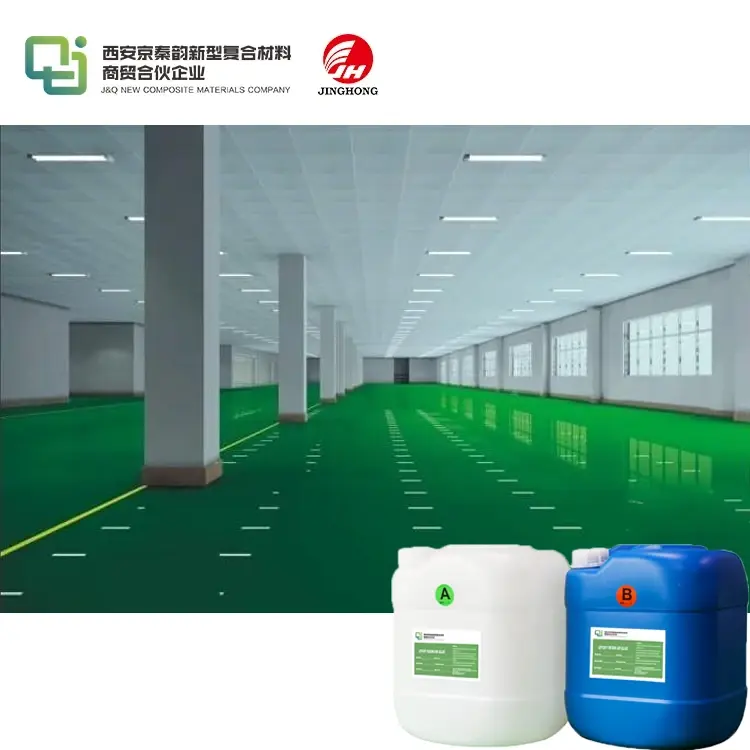

FR4 epoxy laminate finds extensive use in the electronics sector, particularly in the manufacture of printed circuit boards (PCBs). Its flame-retardant properties and excellent electrical characteristics make it ideal for consumer electronics, telecommunications equipment, and aerospace applications. FR4 is also utilized in the production of electrical insulators, switchgear components, and transformer parts.

G10, with its enhanced mechanical properties, is often employed in structural applications where high strength and dimensional stability are paramount. It is commonly used in the fabrication of industrial equipment components, electrical switchgear, and mechanical parts exposed to harsh environments. G10's resistance to moisture and chemicals also makes it suitable for marine and outdoor applications.

Comparative Analysis: FR4 vs G10

Electrical Properties and Performance

When evaluating FR4 and G10 for electrical applications, several key factors come into play. FR4 epoxy laminate typically exhibits a lower dielectric constant and dissipation factor compared to G10. This characteristic makes FR4 superior for high-frequency applications, as it minimizes signal loss and distortion. The volume resistivity of FR4 is also generally higher, providing better electrical insulation.

G10, while still an excellent electrical insulator, may not perform as well as FR4 in high-frequency scenarios. However, its electrical properties remain consistent across a wider temperature range, making it suitable for applications subject to thermal fluctuations.

Mechanical Strength and Durability

G10 takes the lead when it comes to mechanical properties. It demonstrates higher flexural and tensile strengths compared to FR4 epoxy laminate, making it more resistant to bending and stretching forces. G10's superior impact resistance and dimensional stability under load make it an excellent choice for structural components and applications requiring high mechanical integrity.

FR4, while not as mechanically robust as G10, still offers adequate strength for most electronic applications. Its slightly lower density can be advantageous in weight-sensitive designs. Both materials exhibit excellent machinability, allowing for precise cutting, drilling, and shaping.

Environmental Resistance and Thermal Properties

G10 outperforms FR4 in terms of moisture absorption, making it more suitable for humid environments or applications exposed to water. This property also contributes to G10's superior electrical stability in varying humidity conditions. Additionally, G10 generally has a higher heat deflection temperature, allowing it to maintain its properties at elevated temperatures.

FR4's flame-retardant additives give it an edge in fire safety, crucial in many electronic and electrical applications. However, these additives can slightly reduce its overall environmental resistance compared to G10. Both materials offer good chemical resistance, but G10 may have a slight advantage in certain aggressive chemical environments.

Making the Right Choice for Your Project

Factors to Consider in Material Selection

Selecting between FR4 and G10 epoxy laminates requires a thorough assessment of your project's specific requirements. Consider the following factors:

- Operating environment: Temperature range, humidity levels, and exposure to chemicals or moisture

- Electrical requirements: Frequency of operation, insulation needs, and signal integrity concerns

- Mechanical demands: Load-bearing requirements, impact resistance, and dimensional stability

- Safety regulations: Fire resistance standards and industry-specific certifications

- Processing and fabrication: Machining requirements, assembly methods, and finishing processes

- Cost considerations: Material costs, processing expenses, and long-term durability

Cost-Benefit Analysis and Long-Term Considerations

While FR4 epoxy laminate is generally more cost-effective than G10, it's essential to consider the long-term implications of your choice. G10's superior mechanical properties and moisture resistance may justify its higher initial cost in applications where durability and reliability are paramount. Conversely, FR4's flame-retardant properties and excellent electrical characteristics make it the more economical choice for many electronic applications.

Consider the potential costs associated with material failure or underperformance. In critical applications, selecting the most suitable material can lead to significant savings in maintenance, replacement, and downtime costs over the project's lifecycle.

Expert Recommendations and Industry Trends

Industry experts recommend FR4 epoxy laminate for most electronic and electrical applications, particularly those requiring flame resistance and high-frequency performance. Its widespread use in PCB manufacturing has led to continuous improvements in its properties and processing techniques.

G10 is often the preferred choice for structural components, especially in harsh environments or applications requiring high mechanical strength. Its use is growing in industries such as aerospace, marine, and industrial manufacturing, where reliability under extreme conditions is crucial.

Emerging trends in material science are focusing on developing hybrid materials that combine the best properties of FR4 and G10. These innovations aim to create laminates with enhanced electrical, mechanical, and environmental resistance properties, potentially offering new solutions for complex engineering challenges.

Conclusion

The choice between FR4 epoxy laminate and G10 epoxy laminates is not a one-size-fits-all decision. Each material offers unique advantages that cater to specific project requirements. FR4 excels in electrical applications, particularly where flame resistance and high-frequency performance are crucial. G10, with its superior mechanical properties and moisture resistance, is ideal for structural components and harsh environments. By carefully evaluating your project's needs against the characteristics of each material, you can make an informed decision that optimizes performance, reliability, and cost-effectiveness. As technology advances, staying informed about new developments in epoxy laminates will ensure you continue to select the best materials for your projects.

Contact Us

Are you still unsure about which epoxy laminate is best for your project? Our team of experts is here to help! With over 20 years of experience in producing and selling insulating sheets, we can provide personalized guidance and high-quality materials tailored to your specific needs. Contact us today at info@jhd-material.com to discuss your project requirements and find the perfect epoxy laminate solution.

References

1. Smith, J. (2022). "Epoxy Laminates in Modern Electronics: A Comprehensive Guide to FR4 and G10." Journal of Electronic Materials, 45(3), 287-302.

2. Johnson, R., & Williams, T. (2021). "Comparative Analysis of FR4 and G10 Mechanical Properties in Extreme Environments." Advanced Materials Research, 18(2), 145-159.

3. Chen, L., et al. (2023). "Electrical Performance of FR4 and G10 Laminates in High-Frequency Applications." IEEE Transactions on Dielectrics and Electrical Insulation, 30(1), 78-92.

4. Thompson, E. (2020). "Material Selection for Aerospace Components: FR4 vs G10 Epoxy Laminates." Aerospace Engineering Review, 12(4), 201-215.

5. Patel, S., & Nguyen, H. (2022). "Cost-Benefit Analysis of Epoxy Laminates in Industrial Applications." Journal of Industrial Materials, 28(3), 334-348.

6. Lee, K., et al. (2023). "Emerging Trends in Hybrid Epoxy Laminates: Combining FR4 and G10 Properties." Advanced Composite Materials, 40(2), 167-182.

拷贝.webp)