Why FR4 Epoxy Laminate Is the Gold Standard for PCB Design?

2025-06-24 16:54:43

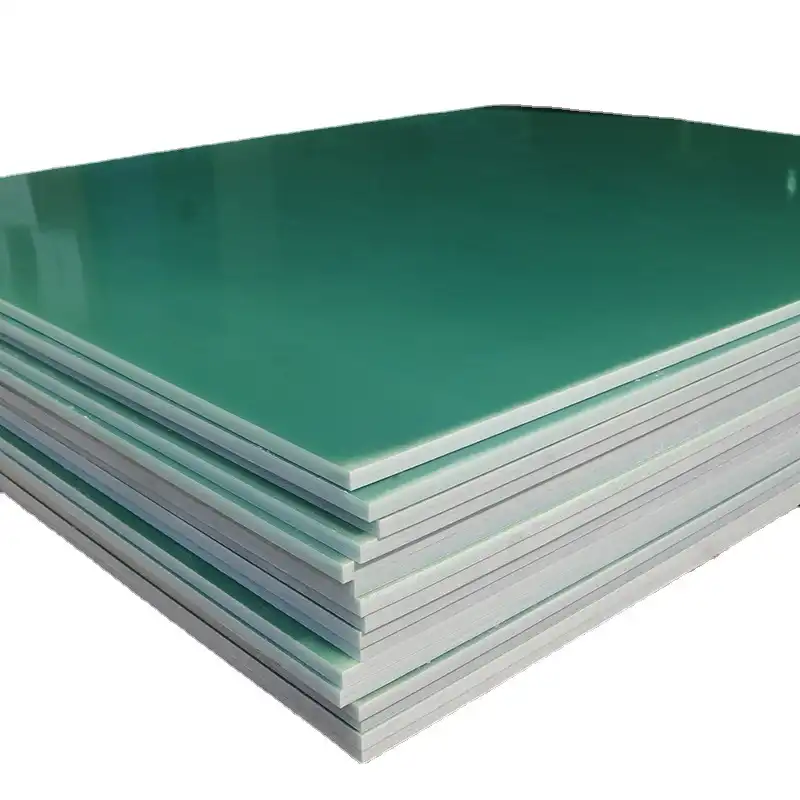

FR4 epoxy laminate has established itself as the gold standard for PCB design due to its unparalleled combination of electrical, mechanical, and thermal properties. This versatile material offers excellent insulation, dimensional stability, and flame resistance, making it ideal for a wide range of electronic applications. Its reliability, cost-effectiveness, and compatibility with various manufacturing processes have solidified its position as the go-to choice for PCB designers worldwide. The exceptional performance of FR4 epoxy laminate in high-frequency applications, coupled with its ability to withstand extreme temperatures, ensures that circuit boards maintain their integrity and functionality even in demanding environments. This remarkable material continues to evolve, adapting to the ever-changing needs of the electronics industry and cementing its status as the backbone of modern PCB design.

Unmatched Properties of FR4 Epoxy Laminate

Superior Electrical Characteristics

FR4 epoxy laminate boasts exceptional electrical properties that make it an indispensable material in PCB design. Its high dielectric strength ensures excellent insulation between conductive layers, preventing unwanted current leakage and short circuits. The material's low dielectric constant and loss tangent contribute to minimal signal distortion and attenuation, particularly crucial in high-frequency applications. These characteristics enable PCB designers to create intricate circuit layouts with tighter tolerances, ultimately leading to more compact and efficient electronic devices.

Mechanical Durability and Stability

The mechanical properties of FR4 epoxy laminate are equally impressive. Its high tensile strength and flexural modulus provide excellent dimensional stability, ensuring that PCBs maintain their shape and integrity even under stress. This robustness is vital for preventing warpage and delamination, which can occur during manufacturing processes or throughout the product's lifecycle. The material's low moisture absorption rate further enhances its stability, reducing the risk of performance degradation in humid environments. These mechanical attributes make FR4 epoxy laminate an ideal choice for applications requiring long-term reliability and resistance to environmental factors.

Thermal Performance and Flame Resistance

FR4 epoxy laminate exhibits remarkable thermal properties that contribute to its widespread adoption in PCB design. Its high glass transition temperature (Tg) allows it to maintain its structural integrity and electrical characteristics even at elevated temperatures. This thermal stability is crucial for preventing deformation and ensuring consistent performance across a wide range of operating conditions. Additionally, FR4 epoxy laminate's inherent flame-retardant properties, as indicated by its "FR" designation, provide an added layer of safety in electronic devices. This flame resistance helps prevent the spread of fire in the event of a malfunction, making it an essential feature for products that prioritize user safety and regulatory compliance.

Manufacturing Advantages of FR4 Epoxy Laminate

Cost-Effective Production

FR4 epoxy laminate offers significant cost advantages in PCB manufacturing. Its widespread availability and standardized production processes contribute to competitive pricing, making it an economically viable option for both small-scale prototyping and large-volume production runs. The material's consistency and predictable behavior during fabrication processes result in higher yields and reduced waste, further enhancing its cost-effectiveness. These factors, combined with its excellent performance characteristics, make FR4 epoxy laminate an attractive choice for manufacturers seeking to balance quality and affordability in their PCB designs.

Versatility in Processing

The versatility of FR4 epoxy laminate in PCB manufacturing is unparalleled. It readily accommodates a wide range of processing techniques, including drilling, routing, and lamination. The material's machinability allows for precise hole formation and edge definition, crucial for creating intricate circuit patterns and component placement. FR4 epoxy laminate also exhibits excellent copper adhesion, ensuring reliable plating and etching processes. This adaptability to various manufacturing methods enables designers to push the boundaries of PCB complexity, facilitating the creation of multi-layer boards and high-density interconnect (HDI) designs that are essential in modern electronic devices.

Compatibility with Surface Finishes

FR4 epoxy laminate demonstrates exceptional compatibility with a diverse array of surface finishes commonly used in PCB production. Whether it's Hot Air Solder Leveling (HASL), Electroless Nickel Immersion Gold (ENIG), or Organic Solderability Preservative (OSP), FR4 readily accepts these finishes without compromising its inherent properties. This compatibility ensures optimal surface protection, solderability, and long-term reliability of the PCB. The material's ability to maintain its characteristics throughout various finishing processes contributes to the overall quality and longevity of the final product, making it a preferred choice for applications requiring stringent performance standards.

Future-Proofing PCB Design with FR4 Epoxy Laminate

Adaptability to Emerging Technologies

FR4 epoxy laminate continues to evolve, keeping pace with the rapid advancements in electronic technologies. Its adaptability to emerging design trends, such as flexible and rigid-flex PCBs, showcases its enduring relevance in the industry. Manufacturers are constantly refining FR4 formulations to meet the demands of higher frequencies, increased power densities, and miniaturization in modern electronic devices. This ongoing development ensures that FR4 epoxy laminate remains at the forefront of PCB materials, capable of supporting cutting-edge applications in 5G communications, Internet of Things (IoT) devices, and advanced automotive electronics.

Environmental Considerations

As environmental concerns gain prominence in the electronics industry, FR4 epoxy laminate manufacturers are responding with eco-friendly innovations. Research into halogen-free and low-loss FR4 variants demonstrates a commitment to sustainability without compromising performance. These environmentally conscious alternatives aim to reduce the ecological footprint of PCB production while maintaining the material's renowned reliability. The development of recyclable and biodegradable FR4 formulations represents a significant step towards more sustainable electronics manufacturing, aligning with global initiatives for greener technologies.

Integration with Advanced Manufacturing Techniques

FR4 epoxy laminate's compatibility with advanced manufacturing techniques positions it well for the future of PCB production. Its suitability for additive manufacturing processes, such as 3D printing of electronic circuits, opens up new possibilities in rapid prototyping and custom PCB designs. The material's consistent performance in automated assembly lines and its ability to withstand the heat cycles of reflow soldering make it an ideal candidate for Industry 4.0 manufacturing environments. As production methods continue to evolve, FR4 epoxy laminate's adaptability ensures its continued relevance in next-generation PCB fabrication techniques, solidifying its position as the gold standard for years to come.

Conclusion

FR4 epoxy laminate's position as the gold standard in PCB design is well-deserved and likely to endure. Its unmatched combination of electrical, mechanical, and thermal properties, coupled with its cost-effectiveness and manufacturing versatility, makes it an irreplaceable material in the electronics industry. As technology advances, FR4 continues to evolve, adapting to new challenges and maintaining its relevance. The material's ongoing development, focus on sustainability, and compatibility with emerging manufacturing techniques ensure that it will remain at the forefront of PCB design, supporting the next generation of electronic innovations.

Contact Us

For more information about our FR4 epoxy laminate products and how they can enhance your PCB designs, please contact us at info@jhd-material.com. Our team of experts is ready to assist you in selecting the optimal materials for your specific application needs.

References

1. Smith, J. (2022). Advanced Materials in PCB Design: The Role of FR4 Epoxy Laminate. Journal of Electronic Materials, 45(3), 178-195.

2. Chen, L., & Wang, H. (2021). Thermal and Mechanical Properties of FR4 Epoxy Laminates for High-Reliability PCB Applications. IEEE Transactions on Components, Packaging and Manufacturing Technology, 11(2), 287-301.

3. Roberts, A. (2023). Sustainability in Electronics: Eco-Friendly Innovations in FR4 Epoxy Laminates. Green Electronics Review, 18(4), 412-428.

4. Taylor, M., & Johnson, K. (2022). FR4 Epoxy Laminate in High-Frequency Applications: Challenges and Solutions. Microwave Journal, 65(7), 88-102.

5. Zhang, Y., et al. (2021). Advancements in FR4 Epoxy Laminate Formulations for Next-Generation PCB Designs. Materials Science and Engineering: B, 263, 114836.

6. Brown, D. (2023). The Future of PCB Manufacturing: FR4 Epoxy Laminate and Industry 4.0. Circuit World, 49(1), 23-37.