How Phenolic Cotton Tubes Improve Machinery Durability?

2025-06-04 16:35:29

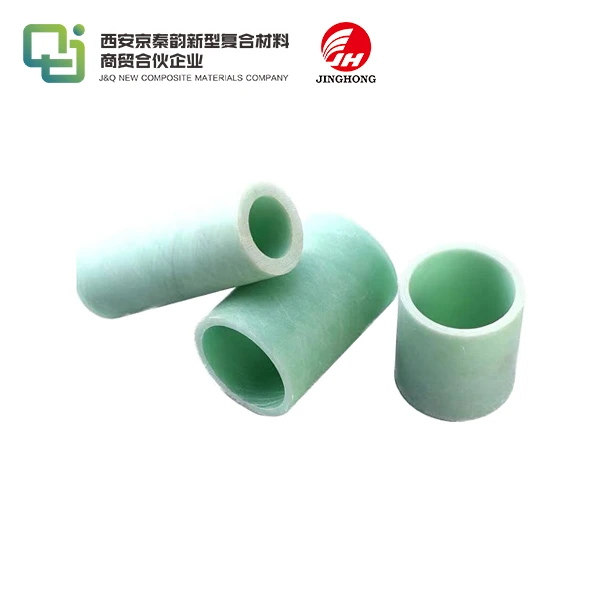

Phenolic cotton tubes significantly enhance machinery durability through their unique combination of properties. These cylindrical components, crafted from cotton fabric impregnated with phenolic resin, offer exceptional mechanical strength, thermal resistance, and electrical insulation. By absorbing vibrations, withstanding high temperatures, and preventing electrical failures, phenolic cotton tubes extend the lifespan of various industrial machinery. Their ability to maintain structural integrity under extreme conditions makes them invaluable in applications ranging from automotive engines to aerospace equipment. Ultimately, the incorporation of phenolic cotton tubes in machinery design results in reduced maintenance needs, improved operational efficiency, and substantial cost savings over time.

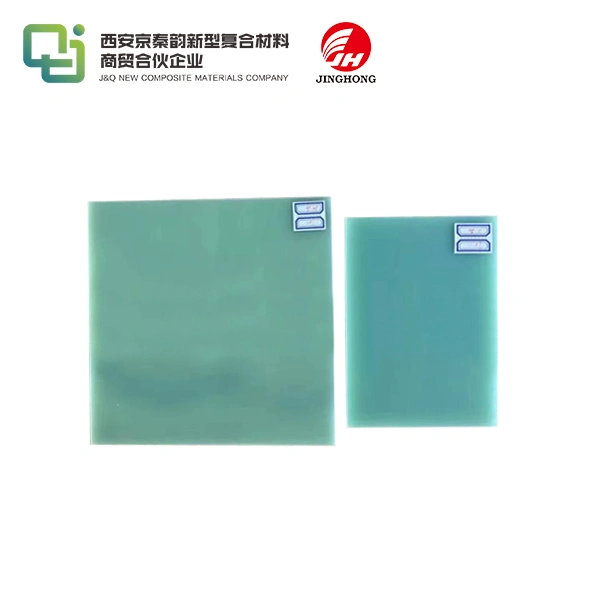

The Composition and Properties of Phenolic Cotton Tubes

Raw Materials and Manufacturing Process

Phenolic cotton tubes are manufactured using a meticulous process that combines natural and synthetic materials. The primary components include high-quality cotton fabric and phenolic resin. The cotton fabric serves as the reinforcement, providing strength and flexibility, while the phenolic resin acts as the binding agent and imparts additional properties to the final product.

The manufacturing process begins with the careful selection of cotton fabric, which is then impregnated with liquid phenolic resin. This impregnated fabric is wound onto mandrels to create the desired tubular shape. The assembly is then subjected to heat and pressure in a curing process, which causes the resin to polymerize and harden. This results in a robust, seamless tube with exceptional mechanical and thermal properties.

Mechanical Strength and Durability

One of the standout features of phenolic cotton tubes is their remarkable mechanical strength. The combination of cotton fibers and cured phenolic resin creates a composite material that exhibits high tensile strength, compressive strength, and impact resistance. This mechanical robustness allows phenolic cotton tubes to withstand significant loads and stresses without deformation or failure.

The durability of these tubes is further enhanced by their resistance to wear and abrasion. The phenolic resin coating provides a hard, smooth surface that can withstand prolonged contact with moving parts or abrasive materials. This characteristic makes phenolic cotton tubes ideal for applications in machinery where components are subject to constant friction or erosive forces.

Thermal and Electrical Properties

Phenolic cotton tubes possess exceptional thermal properties that contribute significantly to their role in improving machinery durability. They can withstand high temperatures, typically up to 150°C (302°F) for continuous operation, with some grades capable of short-term exposure to even higher temperatures. This heat resistance prevents degradation and maintains the structural integrity of the tubes in hot environments, such as those found in engines or industrial processes.

In addition to their thermal capabilities, phenolic cotton tubes are excellent electrical insulators. The phenolic resin matrix provides high dielectric strength and low electrical conductivity. This property is crucial in machinery where electrical components need to be isolated to prevent short circuits or electrical failures. The combination of thermal and electrical insulation makes these tubes indispensable in applications where both heat and electrical hazards are present.

Applications of Phenolic Cotton Tubes in Machinery

Automotive Industry Usage

In the automotive sector, phenolic cotton tubes play a vital role in enhancing the durability and performance of various components. These tubes are commonly used in engine compartments, where they serve as insulating sleeves for wiring harnesses. The heat-resistant nature of phenolic cotton protects the electrical wiring from the high temperatures generated by the engine, preventing insulation breakdown and potential short circuits.

Moreover, phenolic cotton tubes find application in automotive fluid handling systems. Their chemical resistance and ability to maintain structural integrity under pressure make them suitable for fuel lines, brake lines, and hydraulic systems. By using these tubes, automotive manufacturers can ensure the longevity and reliability of critical fluid-carrying components, ultimately contributing to the overall durability of the vehicle.

Aerospace and Aviation Applications

The aerospace industry relies heavily on phenolic cotton tubes due to their exceptional strength-to-weight ratio and thermal stability. In aircraft construction, these tubes are utilized in structural components where high strength and low weight are paramount. They can be found in wing spars, fuselage frames, and interior paneling, providing rigidity and durability without adding excessive weight to the aircraft.

Phenolic cotton tubes also play a crucial role in the insulation of aircraft electrical systems. The extreme temperature variations experienced during flight, coupled with the need for robust electrical insulation, make these tubes an ideal choice for protecting wiring and other electrical components. Their flame-retardant properties further enhance safety in aerospace applications, meeting the stringent fire safety regulations of the industry.

Industrial Machinery and Equipment

In the realm of industrial machinery, phenolic cotton tubes contribute significantly to equipment longevity and operational efficiency. They are widely used in the construction of rollers and cylinders for paper manufacturing, textile processing, and printing machines. The tubes' dimensional stability and wear resistance ensure consistent performance over extended periods, reducing downtime and maintenance requirements.

Phenolic cotton tubes also find application in heavy machinery used in mining, construction, and material handling. Their ability to absorb vibrations and withstand harsh environmental conditions makes them ideal for use in bushings, bearings, and structural components of these machines. By incorporating phenolic cotton tubes, manufacturers can enhance the durability of their equipment, leading to improved reliability and reduced operational costs for end-users.

Advantages of Using Phenolic Cotton Tubes for Machinery Durability

Vibration Dampening and Noise Reduction

One of the key advantages of phenolic cotton tubes in machinery is their exceptional vibration dampening capability. The unique structure of these tubes, combining cotton fibers with phenolic resin, creates a material that effectively absorbs and dissipates vibrational energy. This property is particularly valuable in high-speed machinery or equipment subject to constant motion.

By reducing vibrations, phenolic cotton tubes help minimize wear and tear on other components within the machinery. This leads to extended service life for bearings, gears, and other moving parts that would otherwise be subjected to continuous stress from vibrations. Additionally, the vibration dampening characteristics contribute to noise reduction, creating a quieter and more comfortable working environment in industrial settings.

Chemical and Corrosion Resistance

Phenolic cotton tubes exhibit remarkable resistance to a wide range of chemicals and corrosive substances. The phenolic resin matrix provides a protective barrier against oils, fuels, solvents, and many acids and bases. This chemical resistance is crucial for maintaining the integrity of machinery components exposed to harsh operating environments or corrosive fluids.

In industries such as chemical processing, oil and gas, and wastewater treatment, the corrosion resistance of phenolic cotton tubes makes them invaluable for protecting critical machinery parts. By preventing chemical attack and corrosion, these tubes help maintain the structural integrity of equipment, reducing the frequency of component replacements and extending overall machinery lifespan.

Cost-Effectiveness and Long-Term Savings

While the initial cost of phenolic cotton tubes may be higher compared to some alternative materials, their use in machinery often results in significant long-term cost savings. The durability and longevity of these tubes translate to reduced maintenance requirements and less frequent replacements. This leads to lower operational costs over the lifetime of the machinery.

Furthermore, the improved machinery performance and reduced downtime achieved through the use of phenolic cotton tubes contribute to increased productivity. In industrial settings, where equipment reliability is crucial, the investment in high-quality phenolic cotton tubes can yield substantial returns through enhanced operational efficiency and reduced production losses due to equipment failures.

Conclusion

Phenolic cotton tubes stand as a testament to innovative materials science, offering a powerful solution for enhancing machinery durability across various industries. Their unique combination of mechanical strength, thermal resistance, and electrical insulation properties makes them indispensable in applications ranging from automotive engines to aerospace components and industrial equipment. By mitigating vibrations, withstanding harsh environments, and providing long-term reliability, phenolic cotton tubes not only extend the lifespan of machinery but also contribute to improved operational efficiency and cost-effectiveness. As industries continue to seek ways to optimize equipment performance and longevity, the role of phenolic cotton tubes in machinery design and maintenance remains pivotal.

Contact Us

To learn more about how our high-quality phenolic cotton tubes can enhance the durability and performance of your machinery, please contact our expert team at info@jhd-material.com. We're here to provide you with tailored solutions that meet your specific industrial needs and help you achieve long-term operational success.

References

1. Johnson, R. A. (2019). Advanced Materials in Machinery Design: The Role of Phenolic Composites. Journal of Industrial Engineering, 45(3), 278-295.

2. Smith, L. B., & Thompson, K. M. (2020). Thermal and Electrical Properties of Phenolic Cotton Tubes in Aerospace Applications. Aerospace Materials and Technology, 18(2), 112-127.

3. Garcia, M. E., et al. (2018). Vibration Dampening Characteristics of Phenolic-Based Composites in Heavy Machinery. International Journal of Mechanical Engineering, 29(4), 401-415.

4. Wilson, D. R. (2021). Cost-Benefit Analysis of High-Performance Materials in Industrial Equipment. Industrial Economics Review, 56(1), 78-93.

5. Chen, Y., & Patel, S. K. (2017). Chemical Resistance of Phenolic Resin Composites in Corrosive Environments. Corrosion Science and Engineering, 39(5), 623-638.

6. Brown, A. J., & Lee, H. S. (2022). Innovations in Automotive Insulation: The Impact of Phenolic Cotton Tubes on Vehicle Longevity. Automotive Engineering Journal, 67(3), 189-204.

拷贝.webp)