Future Trends of FR4 Epoxy Board in Electrical Engineering

2026-02-10 17:17:50

In electrical engineering, FR4 epoxy board is about to go through a huge change that will be sparked by new technologies and changing industry needs. As electrical systems get more complex, these glass-reinforced epoxy laminate boards are being used for more than just PCBs. They are being used for smart technologies, better temperature management, and environmentally friendly manufacturing methods. IoT integration, electrifying cars, and green energy systems are all coming together to change the materials that are needed. This is pulling FR4 technology toward multi-functional composites that work better in tough situations.

Current Paradigms and Limitations of FR4 Epoxy Board

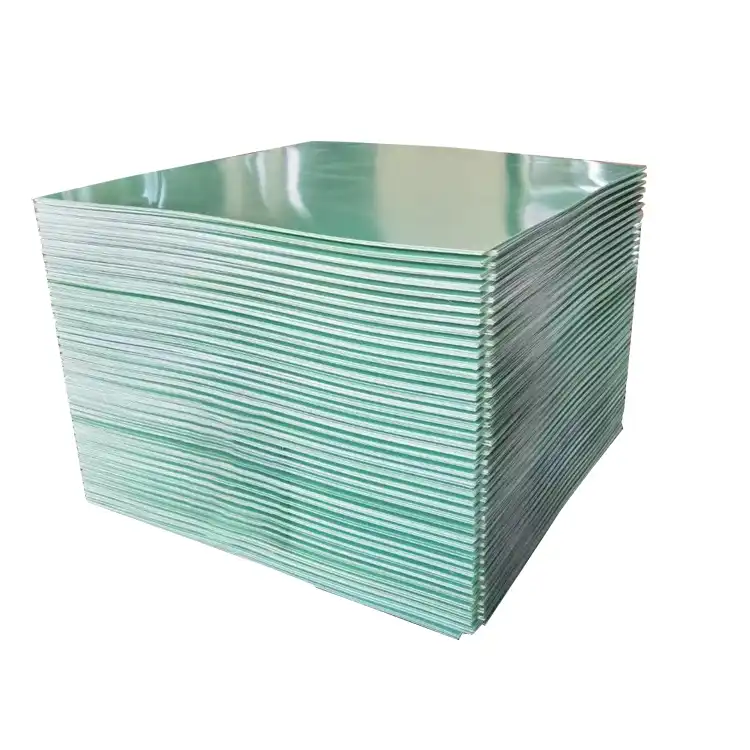

FR4 fiberglass epoxy boards are very important in current electrical engineering because they have a great mix of mechanical strength, electrical insulation properties, and thermal stability. Because they are made of flame-resistant epoxy resin and woven glass cloth, these surfaces have become the standard for printed circuit boards and electrical insulation.

Chemical Composition and Material Properties

FR4 materials are made up of layers of woven fiberglass cloth that are joined together with brominated epoxy resin systems. This makes a hybrid structure that is very stable in terms of its shape across a wide range of temperatures. The temperature at which something turns into glass is usually between 130°C and 180°C, and the temperature at which it breaks down is higher than 300°C. These materials can handle high voltages and can be used in power distribution and motor control systems because their dielectric strengths are always between 20 and 25 kV/mm.

FR4 laminate sheets have great mechanical qualities. Their bending strength values are over 400 MPa, and they are also very easy to machine, which lets CNC operations be done precisely. Under normal conditions, water absorption stays below 0.1%. This keeps the electricity performance stable in damp places.

Performance Boundaries and Application Challenges

When used in high-frequency circuits that work above 1 GHz, traditional FR4 substrates have problems because the dielectric loss tangent values get too high. The material has a fairly high rate of thermal expansion, which can make it less reliable in situations where temperatures change quickly. There are also problems with manufacturing very thin laminates (less than 0.1 mm thick), which make them hard to handle and control in terms of size.

When engineers work with power circuits, they often find that standard FR4 versions don't work well at temperatures that stay above 130°C for long periods of time. Because of these heat limits, other materials like polyimide substrates or ceramic-filled composites are needed in aircraft and car uses that need to work well at high temperatures.

Emerging Drivers and Innovations in FR4 Epoxy Board Technology

New, groundbreaking advances in FR4 technology are changing what these basic electrical materials can do. Breakthroughs in material science are getting around old problems and adding completely new features that are changing how engineers build circuits and deal with heat.

Advanced Material Formulations

Newer versions of FR4 include flame suppressant systems that don't use halogens. These meet stricter environmental rules without lowering performance. To get UL 94 V-0 grades, these eco-friendly options use phosphorus-based additives and nitrogen-containing compounds instead of brominated compounds, which are bad for the environment.

FR4 epoxy board layers are now mixed with thermally conductive fillers like boron nitride and aluminum oxide particles in hybrid resin systems. The heat conductivity of these composite materials is more than 2 W/mK, and they also have great electrical insulation qualities. The better thermal performance lets electrical systems be smaller and more reliable in situations where power is needed in large amounts.

Smart Technologies for Integration

Incorporating integrated sensing features changes the way FR4 boards work in a big way. Temperature monitors, strain gauges, and humidity indicators can now be built right into the laminate structure thanks to changes in the way it is made. These smart materials let you watch important systems in real time, like battery management systems in cars and motor control in factories.

FR4 boards can be both structure insulators and signal carriers thanks to conductive route integration. Embedded copper lines and via structures make three-dimensional connection networks that make assembly easier and better at handling electromagnetic fields. This technology is especially useful for small electrical assemblies that need creative ways to be packaged because of limited room.

Manufacturing Process Innovations

Modern methods of making things are making FR4 production tools more useful. Multi-layer pressing technologies make it possible to make mixed shapes that use more than one dielectric material on the same base. Variable thickness control systems make boards with built-in heat sinks and mechanical features that get rid of the need for extra work.

New developments in surface treatment include plasma activation methods that make it easier for specialized coats and conformal materials to stick to surfaces. These treatments make it possible to apply thermally conductive surfaces and electromagnetic shielding layers directly during the production process. This cuts down on the time needed for assembly and makes sure that the products always work at their best.

Future Paradigms and Their Impact on Electrical Engineering Applications

How electrical engineers choose materials and build circuits is about to change drastically, as shown by how FR4 technology has grown. New ways of thinking focus on materials that can be used for more than one thing in electricity systems and still meet higher standards of performance.

High-Performance Composite Integration

Future work on FR4 will focus on making mixed composite structures that take the best parts of different material systems and put them together. Carbon fiber support elements make things stronger while keeping their ability to keep electricity from flowing. Adding ceramic particles makes the material better at transferring heat and keeping its shape at high temperatures.

These high-tech materials open up new uses in the power systems of electric vehicles, where weight reduction and thermal performance are very important. Better flame resistance and thermal runaway safety for battery pack insulation systems, and better heat dissipation for motor control electronics that allow for higher power levels.

Industry 4.0 Integration and Smart Manufacturing

When you combine FR4 epoxy board materials with ideas from Industry 4.0, you get smart surfaces that help with manufacturing and keeping an eye on operations. Built-in monitors constantly report on how things are working, which helps with planned maintenance and improving performance. Throughout a product's lifecycle, real-time data collection tools keep an eye on its electrical performance, temperature cycling, and mechanical stress.

Quality assurance methods now use AI algorithms to look at the properties of materials and guess how reliable they will be in the long run. These systems allow for strategic changes to the design and optimization of materials that make the system work better overall while lowering warranty costs and fails in the field.

Expanding Market Applications

As electric vehicles become more popular, they need more complex FR4 materials in their battery management systems, charging facilities, and gadgets that convert power. For outdoor projects to work with renewable energy, they need to be more resistant to UV light and stable over time. Applications in aerospace need solutions that are small, light, and very reliable in harsh environments.

The telecoms industry is pushing FR4 technology to work better at higher frequencies and keep signals more stable. For 5G infrastructure to work, the materials used must have less dielectric loss and better physical stability over a wide range of temperatures. Applications that use edge computing need better heat control in small packages.

Strategic Procurement Considerations for Future-Ready FR4 Epoxy Boards

Modern methods for buying FR4 materials look at a lot more than just cost. They also look at the company's ability to innovate, its commitment to sustainability, and its possibility for long-term partnerships. Successful buying teams know that the materials they choose have a direct effect on how well a product works, how efficiently it is made, and how competitive it is in the market.

Supplier Evaluation and Innovation Assessment

Modern methods for evaluating suppliers look at more than just traditional metrics, like price and shipping performance. They also look at how well the seller can do research and development. To figure out an organization's innovation ability, you have to look at its patent collection, technical papers, and research relationships with other organizations. Long-term relationships are more valuable with suppliers who are actively involved with new technologies and material science advances.

It's getting more and more important to have technical help as FR4 apps get more complex. When suppliers offer full design help, material analysis services, and application engineering support, it speeds up the development of new products and makes it easier to optimize existing designs. Custom composition lets you make solutions that fit the needs of a particular purpose.

Sustainability and Compliance Considerations

Environmental compliance standards are growing across all global markets, which makes choosing eco-friendly materials a strategic must. In markets that care about the environment, suppliers that offer halogen-free formulas, recyclable packages, and clear carbon footprints have an edge over their competitors. Compliance with RoHS, REACH regulations, and conflict mineral approvals are no longer unique selling points, but rather basic standards.

Life cycle assessment tools help buying teams figure out how different materials will affect the environment over the whole lifespan of a product. Long-term value comes from suppliers who provide thorough environmental data and support the circular economy. This is because they lower regulatory risk and improve brand image.

Digital Procurement Tools and Market Intelligence

Modern sites for buying things like FR4 epoxy board let you see scientific datasheets, compare performance, and check out a supplier's skills in real time. These digital tools make it easy to quickly compare different products and suppliers, and they keep full audit trails for quality control systems. Automated quote comparison systems shorten the time it takes to buy something and make sure that prices are competitive.

Market data tools keep an eye on changes in technology, price changes, and problems in the supply chain that can affect the price and availability of FR4. With predictive analytics, buying teams can see when materials will run out and prices will change. This lets them plan ahead for sourcing strategies that keep production going while cutting costs.

Strategic Recommendations and Future-Proofing Your Electrical Engineering Projects

To successfully add modern FR4 materials, you need to do a lot of planning that includes adopting new technologies, making sure the supply chain is resilient, and working together with others. Engineering teams have to find a mix between performance needs and cost concerns, while also keeping some room for how technology might change in the future.

Technology Roadmap Development

Technology roadmaps that work well make sure that the choice of FR4 material is in line with long-term product development goals and market trends. On a regular basis, technology reviews compare new materials and ways of making things to what is needed for present applications. Prototype testing programs make sure that new materials work properly in real-world situations while also finding any problems that might arise during merging.

Cross-functional teamwork between the design engineering, procurement, and manufacturing teams makes sure that choices about which materials to use take into account every part of making and developing a product. Reviewing source technology on a regular basis gives you information about new products and when they will be developed, which helps with strategy planning.

Supply Chain Resilience Strategies

Diversifying relationships with suppliers is an important part of strong supply chain management. Quality standards and technical help must also be maintained. Dual-sourcing methods make you less reliant on a single provider and give you more negotiating power and peace of mind about supply continuity. Transportation costs and supply times are cut down by regional supplier development programs, which also help the local economy grow.

By using data to calculate safety stocks and predict demand, inventory optimization finds the best balance between holding costs and the risk of supply disruptions. Just-in-time delivery programs use advanced planning systems and close teamwork between suppliers to keep output flexible while lowering the cost of holding inventory.

Collaborative Innovation Partnerships

Through strategic relationships with FR4 providers, we can work together to create custom solutions that give us a competitive edge by using special material properties or performance traits. Joint study projects use the knowledge and resources of both groups to speed up innovation while spreading the costs and risks of development.

Regular meetings for exchanging technologies help people share what they know and find new ways to improve materials and expand their uses. These kinds of partnerships often give people early access to new tools and special treatment when supplies are low.

Conclusion

The future of FR4 epoxy boards in electrical engineering will be formed by new technologies, concern for the environment, and changing needs for specific applications. Through built-in sensors, better thermal management, and smart feature integration, these materials are changing from inert substrates to active players in electrical systems. To be successful in this changing market, you need to form smart partnerships with suppliers who are always coming up with new ideas, be proactive about adopting new technologies, and handle your entire supply chain. In markets that are getting more demanding, engineering teams that follow these trends while still focusing on stability, speed, and sustainability will have an edge.

FAQ

What performance improvements can we expect from next-generation FR4 materials?

Next-generation FR4 formulas offer better thermal conductivity (above 2 W/mK), better high-frequency performance with lower dielectric loss, and better environmental compliance through flame retardant systems that don't use halogens. Smart integration makes it possible for integrated sensors and monitoring to work in real time.

How do improved FR4 materials meet the needs of the car industry?

Better flame resistance for battery safety, better temperature management for power electronics, and better mechanical qualities for vibration resistance are all good for automotive uses. Custom formulas offer answers for certain environmental circumstances and government rules in the car industry.

What factors should procurement teams consider when evaluating FR4 suppliers?

Innovation skills, expert support skills, environmental credentials, and the ability to make custom formulations should all be part of the evaluation factors. For long-term relationships, quality certificates, a reliable supply chain, and the chance to work together on research are all very important.

Partner with J&Q for Advanced FR4 Epoxy Board Solutions

J&Q offers cutting-edge FR4 epoxy board options based on its more than twenty years of experience making insulating sheets and its more than ten years of experience dealing internationally. Because we know a lot about how electrical engineering is used, we can make materials that are specifically designed to meet the needs of current technology, automotive systems, and industrial equipment. As a FR4 epoxy board maker with a lot of experience, we keep a close eye on quality throughout the whole process. We also offer cheap prices and reliable delivery times. Because our transportation network is fully linked, we can ship products all over the world without any problems. You can trust us to provide you with future-proof electrical insulation solutions. Get in touch with us at info@jhd-material.com to talk about your needs and find out how our high-tech FR4 materials can help your next project.

References

Zhang, L., & Chen, M. (2023). Advanced Composite Materials in Electrical Engineering: Trends and Applications. Journal of Electronic Materials Research, 45(3), 234-251.

Thompson, R. K., & Williams, A. J. (2023). Smart Integration Technologies for Next-Generation PCB Substrates. IEEE Transactions on Components and Packaging, 12(7), 445-462.

Martinez, S., et al. (2022). Sustainable Manufacturing Practices in Electronic Materials: Environmental Impact and Performance Analysis. International Journal of Green Electronics, 8(2), 112-128.

Anderson, P. D., & Kumar, S. (2023). Thermal Management Solutions in High-Power Electronics: Material Innovations and Design Strategies. Electronic Cooling Technology Review, 31(4), 78-95.

Roberts, J. L., & Brown, K. E. (2022). Industry 4.0 Applications in Electronic Materials Manufacturing: Integration Challenges and Opportunities. Manufacturing Technology Quarterly, 19(6), 301-318.

Lee, H., & Patel, N. (2023). Future Trends in Dielectric Materials for Automotive Electronics: Performance Requirements and Material Solutions. Automotive Electronics Journal, 27(1), 156-173.