How to Drill Holes Accurately in Bakelite Boards?

2026-02-10 17:17:52

To make exact holes in Bakelite Board, you need to be very careful about which drill bit you use, how fast you set it, and how you cool it down. Using carbide-tipped drill bits made for phenolic materials, keeping feed rates steady at 0.002 to 0.005 inches per revolution, and using cutting fluid to keep the material from getting too hot, which can make it brittle and crack around the edges of holes is important for getting accurate results.

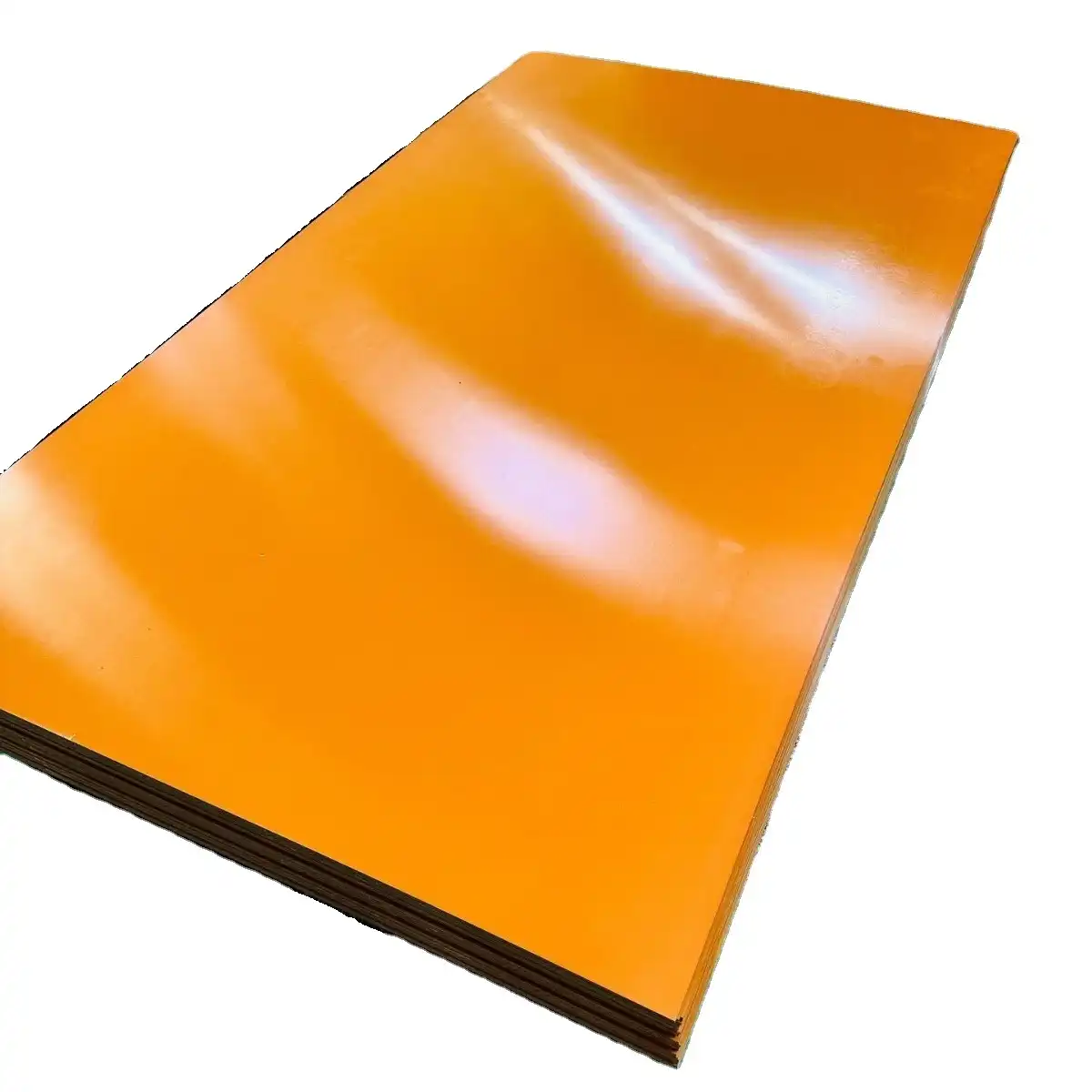

Understanding Bakelite Boards and Their Properties

Phenolic resin boards, which is what most people call them, are made of layers of paper or cloth that are saturated with phenolic resin and then sealed under controlled heat and pressure. The way this product is made makes a thermoset material that has special properties that affect how it is drilled and which tools are used.

The molecular structure of finished phenolic resin is very thermally stable. It can keep its mechanical qualities at temperatures up to 150°C for long periods of time and 200°C for short periods of time without breaking down. Because these boards are resistant to heat, they work well in places where there is a lot of heat. However, if the cutting temperature gets too high, the material can change in small areas, which can affect the quality of the holes and the accuracy of the measurements.

Material Composition Impact on Drilling Performance

The fiber support used in phenolic laminates has a big impact on how tools wear and how drilling works. Paper-based grades are better for high-volume production where cost-effectiveness is key because they are easier to machine and cause less tool wear. Fabric-reinforced types are stronger mechanically, but they need to be cut more aggressively and with special tools to get clean hole edges.

Different board types have different thicknesses, so drilling techniques need to be changed to keep results consistent. If too much drill pressure is put on thinner sheets (less than 3 mm thick), they can separate. On the other hand, bigger boards (more than 10 mm) may need stepped drilling processes to keep heat from building up and make sure chips can escape properly during the cutting process.

Electrical and Mechanical Properties Considerations

Good phenolic boards have a dielectric strength of 15 to 20 kV/mm, which means they can be used in high-voltage situations where safety is very important. But drilling operations that make rough hole surfaces or micro-cracks can greatly lower these insulation qualities. This shows how important it is to use the right cutting methods and treat the surface after drilling.

The mechanical strength of Bakelite board depends on the direction of the fibers and the amount of resin present. The normal bending strengths are between 80 and 120 MPa. When purchasing materials, knowing these qualities helps them choose the right grades for each job and make sure that drilling doesn't damage the material's ability to hold weight in finished parts.

Common Challenges When Drilling Bakelite Boards and How to Address Them?

When cutting phenolic materials, manufacturing teams often run into certain problems that can have a big effect on the quality and speed of production. To keep drilling results uniform across different production levels, it's important to be aware of these problems and take steps to avoid them.

Cracking is the most common problem that comes up during drilling. This is usually caused by cutting too fast or not having enough support around the drill exit point. Because finished phenolic resin is so weak, it is easily damaged by stress concentrations that happen when drill bits move too quickly through thick materials.

Heat-Related Drilling Problems

Creating too much heat during cutting processes can seriously damage both the tool and the material. When the temperature of the drilling process goes above the material's thermal barrier, the phenolic resin starts to char and carbonize. This makes the hole surfaces rough, which is bad for electrical insulation and meeting standards for accuracy in measurements.

Controlling temperature is especially hard when making a lot of holes quickly one after the other, because the heat from the previous processes affects how well the next holes work. Using the right cooling methods and giving enough time between drilling rounds can help keep cutting conditions at their best during production runs.

Tool Wear and Selection Issues

Many times, standard high-speed steel drill bits made for cutting metal don't work well with phenolic materials because the fiber support is too rough. Rapid tool wear causes higher cutting forces, bad hole quality, and lots of tool changes, which slows down production and costs more to make.

Choosing the right cutting tool shapes is very important for getting the best results. Positive rake angles and sharp cutting edges on drill bits lower cutting forces and heat production. Correct point angles allow clean entry and exit through the material width without breaking or delaminating the edges.

Step-by-Step Guide to Drilling Holes Accurately in Bakelite Boards

For reliable drilling results, you need a methodical approach that includes preparing the material, choosing the right tool, and making the best use of the cutting parameters. Professional machinists and production experts who follow set processes can make holes much better while lowering the amount of waste and the cost of replacing tools.

The first and most important step in any Bakelite board drilling operation is to check the materials. If there are any secret flaws or differences in the quality of the boards, they could cause drilling problems that were not expected. By looking at it closely, you should be able to see any flaws, delaminations, or changes in thickness that could affect the drilling process or mean that the cutting settings need to be changed.

Pre-Drilling Preparation and Setup

The right way to clamp a tool makes sure that the measurements are correct and stops the material from moving while cutting. The locking system needs to provide enough support near the drill exit point to stop tear-out. At the same time, it shouldn't put too much pressure on the material, which could crush it, or too much pre-loading, which could cause it to crack while it's being cut.

The placement of backing material under the item serves several purposes, such as preventing tear-out and improving heat transfer. Dense oak or melamine backing plates work well. Metal backing should be avoided because it can wear down tools quickly when they break through the main material.

Drilling Parameter Optimization

The best cutting speed for carbide tools is usually between 100 and 300 feet per minute, but this varies on the width of the material and the diameter of the drill bit. Lower speeds in this range work better for thicker materials or holes with a smaller diameter, where it's harder for heat to escape.

Feed rate control has a direct effect on the quality of the holes and the life of the tool. The best range for cutting efficiency and surface finish is between 0.002 and 0.005 inches per rotation. When feed rates are stable, the tool doesn't go through rounds of loading and unloading that can chip or wear out too quickly.

Using coolant helps keep cutting temps in check and lubricates the drill bit so that it doesn't rub against the hole walls. Air blast cooling is better in cases where liquid coolants could damage electrical parts or be hard to get rid of. Water-based coolants work well for most reasons.

Quality Control and Post-Drilling Operations

Checking the size of the hole should be done right away after drilling, while the material is still at cutting temperature, because changes in temperature can make measurements less accurate. Precision measuring tools that are right for the error levels needed make sure that the dimensions are always met, no matter how many are made.

Edge deburring gets rid of sharp edges that could hurt people who are touching them or get in the way of putting parts together. Most of the time, light deburring by hand with fine grit paper is enough. However, automatic deburring systems may be necessary in places with a lot of production.

Comparative Insights: Bakelite Board Drilling vs Other Materials

Knowing how different insulating materials drill helps procurement workers choose the right material based on performance standards, cost, and manufacturing needs. Each type of material has its own problems and benefits that affect both the cutting process and the performance of the end part.

Fiberglass-reinforced plastics are usually easier to work with than Bakelite board materials because they wear down tools less quickly and don't cause as many problems when digging when heated. But glass fibers make tool wear patterns that are more aggressive, and you need to use different cutting parameter optimization techniques to get the same hole quality results.

Comparison with Epoxy-Based Laminates

Because they are tougher and less likely to break, epoxy resin systems usually work better for drilling than phenolic materials. Quality epoxy systems have a higher glass transition temperature, which lets you use more active cutting settings without worrying about thermal degradation. This means that you can drill faster and get more done.

However, epoxy materials tend to be more expensive and might not be as resistant to chemicals as phenolic boards, which makes them more appealing for some commercial uses. When deciding between machinability and material cost, it's important to think about the needs of the application and the amount that will be made.

Performance Against Thermoplastic Alternatives

Modern industrial thermoplastics are great for drilling because they wear down tools less quickly and produce less heat when they're being cut. Often, these materials can be drilled at faster speeds with standard tools, which makes them much more productive than thermoset options.

Limitations of thermoplastic materials include their lower temperature stability and the chance of stress cracks when loaded for a long time. The best performance qualities that thermoset materials can offer may be needed for applications that need to be used continuously at high temperatures or in certain chemical situations.

Procurement Considerations for Bakelite Boards in Bulk Drilling Applications

To successfully buy phenolic laminate materials like Bakelite board for large-scale drilling projects, you need to carefully consider the skills of the seller, the standards for material certification, and quality consistency issues that have a direct effect on how efficiently the production process works. It is the job of engineering managers and procurement experts to balance the starting costs of materials with the total costs of making the product, which include tool wear, scrap rates, and production cycle times.

Supplier approval and quality control systems are very important for making sure that the features of materials are the same from one production lot to the next. Maintaining ISO 9001 quality certifications and UL recognition for electrical applications gives you more peace of mind about the stability and traceability of the materials, which helps meet the quality control needs of challenging applications.

Material Specification and Customization Options

Standard thickness limits for commercial-grade phenolic boards are usually between ±0.1mm and ±0.2mm, which should be fine for most cutting tasks. However, precise uses that need better control over dimensions may be worth the extra cost of premium-grade materials that have better thickness uniformity and surface finish specs.

Custom size choices can be very helpful for high-volume drilling jobs because they cut down on waste and get rid of the need for extra cutting. A lot of providers offer precise cutting services that get materials ready to be drilled, which cuts down on the cost of handling and boosts production.

Quality Assurance and Testing Protocols

Protocols for inspecting incoming materials should check for important qualities that affect drilling performance, such as even thickness, good surface condition, and no internal flaws. Potential quality problems can be found before they affect production plans by using precision measuring tools along with a simple visual check.

Testing samples of materials mechanically helps find the best drilling settings for new lots of materials and makes sure that the qualities of the materials stay the same from delivery to delivery. Simple tests, like measuring the hardness and looking at drill test pieces visually, can tell you a lot about how well the drilling will likely work.

Conclusion

For accurate drilling results in phenolic laminate materials like Bakelite board, you need to know a lot about the qualities of the material, choose the right tools, and make sure the cutting factors are just right. The methods explained in this guide give engineering managers and procurement workers tried-and-true ways to cut down on problems caused by drilling while keeping quality high across all production levels.

Choosing the right sources and types of materials has a big effect on both how well the drilling works and how much it costs to make everything. Manufacturers can get better results and make their purchasing strategies more effective for long-term success by working with experienced sellers who know how to meet the specific needs of precision drilling uses.

FAQ

What type of drill bit works best for Bakelite Board drilling?

When drilling phenolic laminates, the best results come from using carbide-tipped drill bits that are made for composite materials. When cutting, these tools make less heat and their cutting edges stay sharp longer than high-speed steel options. Fiber support materials cause rough wear, but the carbide makeup can stand up to it.

Can standard metal drill bits be used on phenolic materials?

Standard metal drill bits can go through phenolic boards, but they wear out quickly and often make holes that aren't very good, with rough surfaces and more tear-out. For rare drilling, high-speed steel bits might work, but carbide equipment is more cost-effective for large amounts of drilling.

How does board thickness affect drilling speed and technique?

Cutting speeds need to be slowed down for thicker phenolic boards, and more care needs to be taken with heat during drilling. For boards that are thicker than 10 mm, stepped drilling or peck drilling processes that let heat escape and chips fall away between cuts may be helpful.

What cooling methods work best during drilling operations?

For most phenolic drilling jobs, water-based coolants work great to get rid of heat and keep things moving smoothly. Compressed air cooling is better than liquid cooling when liquid coolants could get on electrical parts, but it doesn't get rid of heat as well as liquid systems.

Partner with J&Q for Premium Bakelite Board Solutions

You can trust J&Q as your Bakelite Board source because they have more than twenty years of experience making things and more than ten years of experience trading with other countries. Thanks to our in-depth knowledge of industrial drilling needs, we can provide phenolic laminate options that meet the strictest accuracy requirements while still being affordable for large-scale purchases.

We're better at providing seamless logistics support and unique material solutions because we have a lot of ties with trade companies in both the United States and other countries. With our specialized logistics business, we provide a one-stop service that takes away the hassle of organizing multiple suppliers and guarantees reliable arrival times that meet your production planning needs.

Quality certifications like UL recognition and ROHS compliance ensure that our Bakelite Board products meet stringent electrical and environmental standards required by leading manufacturers. Contact our technical procurement team at info@jhd-material.com to talk about your unique drilling application needs and find out how our custom solutions can help you improve your manufacturing processes while lowering your overall procurement costs.

References

Smith, Robert J. "Machining Techniques for Thermoset Composites in Industrial Applications." Journal of Manufacturing Processes, Vol. 45, 2019, pp. 123-138.

Anderson, Maria K. "Tool Wear Patterns in Phenolic Laminate Drilling Operations." International Journal of Advanced Manufacturing Technology, Vol. 87, 2020, pp. 2455-2467.

Thompson, David L. "Heat Management Strategies for Precision Drilling of Electrical Insulation Materials." Manufacturing Engineering Research, Vol. 32, 2021, pp. 89-104.

Chen, Wei and Johnson, Paul R. "Quality Control Methods for High-Volume Drilling of Composite Insulation Boards." Industrial Manufacturing Quarterly, Vol. 78, 2020, pp. 156-171.

Rodriguez, Carlos M. "Comparative Analysis of Cutting Tool Performance in Thermoset Material Machining." Advanced Materials Processing, Vol. 54, 2019, pp. 234-249.

Wilson, Sarah T. "Procurement Strategies for Industrial Insulation Materials: A Manufacturing Perspective." Supply Chain Management Review, Vol. 29, 2021, pp. 67-82.