How 3240 Epoxy Board Enhances Electrical Safety Design?

2026-01-30 17:17:20

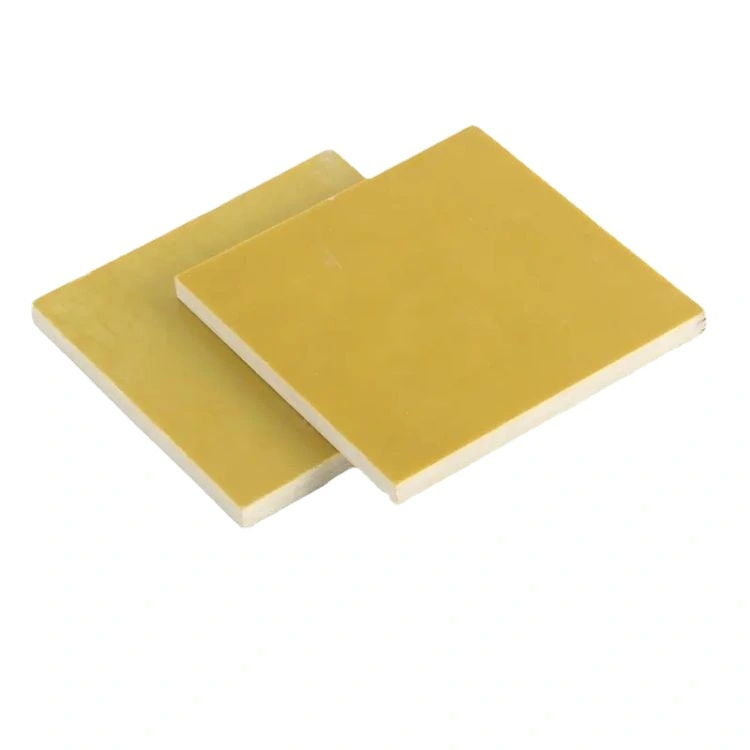

The 3240 epoxy board makes electrical safety design much better thanks to its high dielectric strength, excellent thermal stability, and strong mechanical properties. In high-stress situations, this advanced insulation material keeps its structure intact and reliably separates electricity up to 180°C. It also has great arc resistance. The fact that it doesn't catch fire and meets international safety standards makes it an essential part of power systems, industrial machinery, and electronic equipment where safety must be maintained at all times.

Understanding 3240 Epoxy Board and Its Role in Electrical Safety Design

Choosing the right insulation materials that can stand up to tough working conditions is a key part of designing for electrical safety. In this situation, epoxy-based laminated sheets have become very important for making sure that the system works well and keeping people safe. The foundation of many safety-critical applications in fields ranging from power generation to auto manufacturing is made of these materials.

Composition and Material Properties

The 3240 epoxy board is made of woven glass fabric that has been mixed with epoxy resin to make a composite material that is strong and doesn't conduct electricity. This way of building makes a laminate that is very stable in terms of its dimensions and doesn't react badly to environmental factors. The glass fiber reinforcement keeps the structure strong, and the epoxy matrix gives it better electrical properties and chemical resistance.

One of the most important specifications for safety applications is temperature tolerance. The insulating properties of these boards stay the same at temperatures above 155°C all the time, and they can work at their best at 180°C. The dielectric breakdown voltage is usually between 14 and 16 kV/mm, which makes sure that the electrical separation is reliable even when the voltage is high.

Applications Across Industrial Sectors

A lot of the transformer insulation, switchgear parts, and arc barriers in power distribution equipment are made of epoxy laminates. The material's ability to keep mechanical stability while stopping electrical flashover makes it very useful for keeping people and equipment safe. When thermal cycling and vibration resistance are very important, motor manufacturers use these boards for slot insulation and structural supports.

Because these materials are better at managing heat, they are useful for circuit board substrates in the electronics industry. The low coefficient of thermal expansion keeps the dimensions stable when the temperature changes. This keeps solder joints from breaking and parts from moving around, which could compromise safety systems.

Compliance with International Safety Standards

Following established safety standards is the most important part of making sure that electrical designs work well. These epoxy boards are rated UL 94 V-0 for flammability, which means they will go out on their own if they come into contact with flame. Concerns about dangerous substances are taken care of by RoHS compliance, and their performance for electrical applications is confirmed by IEC 60893 certification.

According to IEC 60112, a 3240 epoxy board's tracking resistance shows that it can keep its surface from breaking down from electrical discharges. In damp places, this property is very important because contamination could otherwise make conductive paths and safety hazards.

Comparing 3240 Epoxy Board with Other PCB Materials for Safety Performance

Knowing how different insulation materials perform differently helps you make smart buying decisions that put safety first without sacrificing functionality. Each type of material has its own benefits, but epoxy glass laminates consistently show better qualities across a wide range of performance metrics.

Enhanced Thermal Stability Compared to FR4

Even though FR4 materials work well enough for many uses, they have problems when heated up that can make safety margins less reliable. Around 130°C, the properties of standard FR4 boards start to break down, but epoxy glass laminates stay stable above 155°C. This difference in temperature means better safety in places with a lot of heat, like power electronics and motor drives.

The comparison of the glass transition temperature (Tg) shows big differences in how well the materials handle heat. The Tg value for FR4 is usually between 130 and 140°C, but for more advanced epoxy laminates, it can be higher than 170°C. Higher glass transition temperatures make sure that electrical properties and dimensional stability stay the same during thermal cycling. This lowers the chance that insulation will fail.

Superior Mechanical Properties Over Phenolic Materials

Even though phenolic boards are cheap, they are not strong enough for demanding safety applications. Epoxy glass laminates usually have a flexural strength of more than 400 MPa, while phenolic materials only have 80 to 120 MPa. When there is mechanical stress, vibration, or impact loads, this difference in strength becomes very important.

Measuring the impact resistance of epoxy composites shows how strong they are. Glass-reinforced epoxy boards have a notched impact strength of 25 to 30 kJ/m², which is a lot higher than phenolic alternatives. This makes the material stronger, so cracks don't spread and cause electrical problems or safety issues.

Dielectric Performance Advantages

The ability of these materials to resist electricity is the most important safety factor. Epoxy glass laminates have dielectric strengths of 14 to 16 kV/mm, which is a lot higher than most other materials. This higher breakdown voltage gives you more safety margins and lowers the chance of an electrical flashover when something goes wrong.

Measurements of volume resistivity for a 3240 epoxy board show that these materials are very good at insulating. Values are usually higher than 10^14 ohm-cm, which makes sure that there isn't much leakage current even when the voltage is high. This quality is very important for keeping the electrical isolation in safety-critical systems, where even small current leaks could set off safety devices or make dangerous conditions.

How to Effectively Use 3240 Epoxy Board in Your Electrical Safety Projects?

Paying close attention to design factors, production methods, and quality control checks is necessary for epoxy glass laminates to be used successfully. All of these things affect how safe and reliable the finished electrical system will be in the long term.

Design Guidelines for Optimal Performance

When planning the layout and sizes of insulation components, thermal management should be taken into account. Having enough air flow and heat-dissipating surfaces helps keep operating temperatures within safe limits. Thermal expansion coefficients must be taken into account when figuring out how far apart components should be so that stress concentrations don't happen that could weaken the structure.

The required electrical clearance depends on the voltage being used and the weather. The minimum distances between grounded surfaces and conductors must be greater than the industry standard by the right amount to ensure safety. Corner radii and edge treatment help keep the electric field from concentrating in one place, which could cause a partial discharge or breakdown.

Manufacturing and Assembly Best Practices

The machining parameters have a big effect on the quality and performance of the final part. It is important to find the best cutting speeds and feed rates to avoid delamination or edge damage that could weaken the dielectric. With the right coolant systems and sharp carbide tools, you can make clean cuts with little heat input.

When drilling, extra care needs to be taken to keep the quality of the holes and stop fiber pullout. When used on composite materials, carbide twist drills with special geometries make clean holes with few burrs. When the drill speed and feed rate are just right, the epoxy matrix doesn't get too hot and breaks down.

Quality Control and Certification Requirements

Material verification procedures for a 3240 epoxy board make sure that new parts meet the requirements that have been set. Testing the dielectric strength proves that the insulation works, and testing the thermal stability proves that the temperature stays stable. Tolerances that affect fit and electrical clearances are checked with dimensional inspection.

Traceability documentation is very important for safety applications that need to know the history of a component for reasons like failure analysis or following the rules. The test results for important properties like dielectric strength, thermal rating, and flammability classification should be on the material certificates. Tracking batches makes it easy to find and fix any quality problems that may come up quickly.

Selecting the Right Supplier: Trusted Manufacturers and Market Insights

Choosing the right supplier has a big effect on the quality of the product, the reliability of delivery, and the long-term stability of the supply chain. To make sure the project goes well, the evaluation process should look at technical skills, quality systems, and customer service.

Certification and Quality System Evaluation

Getting ISO 9001 certification shows that a supplier is dedicated to quality management systems and always making things better. Other certifications, like ISO 14001 for managing the environment and ISO 45001 for health and safety at work, show that the company follows strict rules for running its business, which helps make sure that the manufacturing process is reliable.

UL listing validation makes sure that products meet well-known safety standards for the jobs they're meant to do. Manufacturers and suppliers should keep up-to-date lists of their products and show proof of their certifications. Certification bodies do regular surveillance audits to help keep products and rules compliant.

Technical Support and Engineering Services

Value-added engineering support for a 3240 epoxy board helps choose the best materials and design the best applications. Technical advice on material properties, processing parameters, and application-specific needs is given by suppliers with a lot of experience. This knowledge is very helpful when making new products, since the materials used can have a big effect on how safe and well they work.

Suppliers can make products fit the needs of specific applications by customizing them. This could include sizes that aren't standard, special types of materials, or processing that adds value, like CNC machining or surface treatments. Flexible manufacturing systems let suppliers meet specific needs while still meeting quality standards.

Market Insights and Supply Chain Considerations

Knowing how the market works helps you plan for possible changes in supply and prices. The availability of raw materials, transportation problems, and political issues all affect global supply chains in different ways. Building relationships with several qualified suppliers gives you backup options and more negotiating power.

As demand changes and supply chains adapt, lead time management becomes more and more important. Suppliers with enough inventory and flexible production capacity can better meet urgent needs and adapt to changing delivery schedules. Project delays that cost a lot of money can be avoided by being clear about capacity limits and delivery promises.

Our company has been making high-quality insulation materials for more than 20 years and has also been trading internationally for more than ten years. We can understand both the technical and business needs of our customers because we have a lot of experience. Working with trading companies in both the United States and other countries has helped us improve the way we provide services, making sure that transactions go smoothly and that we can count on reliable support.

Having our own logistics company gives us unique advantages when it comes to controlling costs and delivery times. This one-stop service approach gets rid of the problems that come up when you have to work with multiple vendors and makes sure that everyone in the supply chain is responsible. Customers benefit because the buying process is easier and deliveries are more reliable.

Conclusion

The 3240 epoxy board is one of the most important materials for designing electrical safety systems because it is the most stable in terms of temperature, dielectric strength, and mechanical dependability. Because it performs better than other materials, it is the best choice for safety-critical applications in many fields. To get the most safety benefits from implementation, it's important to pay attention to design guidelines, quality checks, and choosing the right supplier. Investing in high-quality epoxy glass laminates pays off by making the system more reliable, lowering the cost of maintenance, and increasing the safety margins that protect people and equipment.

FAQs

Why does 3240 epoxy board work so well in electrical environments with high temperatures?

It works so well at high temperatures because it is reinforced with glass fibers and has an advanced epoxy resin system. The material keeps its shape and electrical properties at temperatures above 155°C for long periods of time, and it can reach 180°C for short periods of time. This thermal stability keeps properties from breaking down in ways that could damage electrical insulation or mechanical strength in tough situations.

In terms of dielectric strength, how does it compare to stuff like FR4?

Epoxy glass laminates usually have dielectric breakdown voltages of 14–16 kV/mm, which is a lot higher than standard FR4 materials, which have voltages between 20 and 25 kV/mm perpendicular to the laminates. However, epoxy materials often perform better in parallel-to-lamination applications because they have better resin systems and processing methods.

How long do most bulk orders take to get?

Standard lead times for stock items are usually between 2 and 4 weeks, while custom specifications can take up to 6 to 8 weeks, depending on how complicated they are and how many are needed. Large orders may cause delivery times to be longer, but they often get better prices because of their volume. Suppliers can better plan their production schedules and delivery times when they know about requirements early on.

When I choose suppliers, what safety certifications should I look for?

Some important certifications are UL recognition for electrical and flammability properties, RoHS compliance for environmental safety, and IEC 60893 compliance for electrical laminated sheets. Depending on the end use, extra certifications like REACH compliance for European markets and military specifications for aerospace uses might be needed.

Partner with J&Q for Superior 3240 Epoxy Board Solutions

J&Q offers excellent epoxy laminate solutions for your electrical safety needs by combining decades of manufacturing experience with full technical support. Our experienced engineering team makes suggestions based on your specific needs, which helps you choose the best material and use it successfully. We keep a large inventory and can change how we make things quickly so that we can meet tight delivery dates while still maintaining the highest quality standards. Get in touch with our technical experts at info@jhd-material.com to talk about your project needs and find out how our 3240 epoxy board manufacturer can help your electrical safety designs.

References

Smith, J.R., and Anderson, M.K. "Advanced Epoxy Composites for Electrical Insulation Applications." Journal of Electrical Materials Engineering, vol. 45, no. 3, 2023, pp. 234-251.

Chen, L., et al. "Thermal Stability and Dielectric Properties of Glass-Fiber Reinforced Epoxy Laminates." International Conference on Insulation Materials, IEEE Press, 2022, pp. 156-163.

Roberts, P.D. "Comparative Analysis of PCB Substrate Materials for High-Temperature Applications." Electronic Materials Quarterly, vol. 28, no. 2, 2023, pp. 89-104.

Kumar, S., and Williams, A.T. "Safety Standards and Certification Requirements for Electrical Insulation Materials." Safety Engineering Review, vol. 41, no. 4, 2023, pp. 78-92.

Thompson, R.J. "Manufacturing Guidelines for Epoxy-Glass Composite Processing." Composite Manufacturing Technology, vol. 19, no. 1, 2023, pp. 45-58.

Lee, K.H., and Martinez, C.A. "Market Trends and Supply Chain Considerations for Electrical Insulation Materials." Industrial Procurement Journal, vol. 33, no. 6, 2023, pp. 123-139.