Why Phenolic Cotton Board Improves Equipment Stability?

2026-02-02 17:18:45

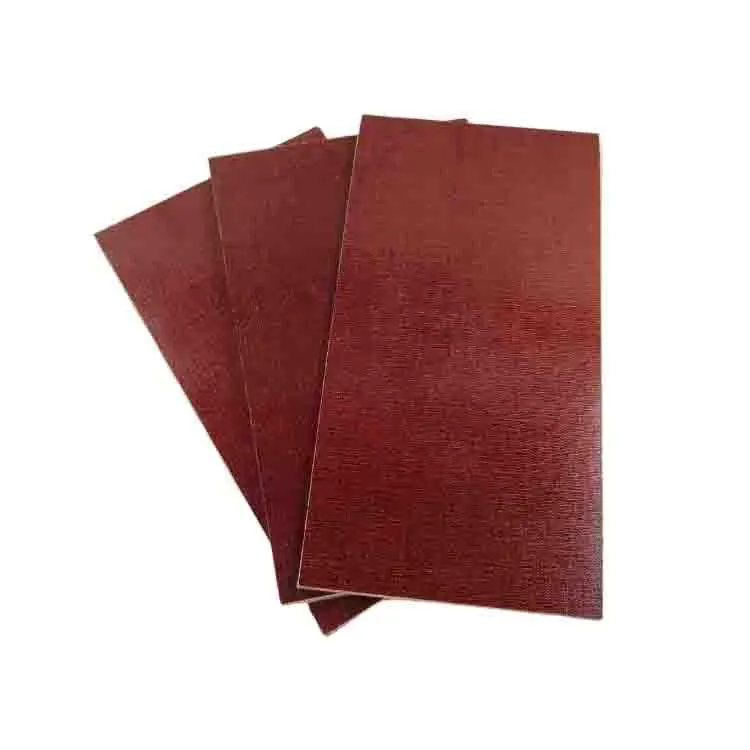

Because of its remarkable dimensional stability, outstanding mechanical strength, and resistance to environmental variables that often lead to equipment failure, phenolic cotton board greatly improves equipment stability. This cutting-edge composite material, which is produced by impregnating cotton fabric with phenolic resin, performs consistently under a range of load scenarios, temperature changes, and moisture exposure. The material's intrinsic qualities make it the perfect option for crucial equipment parts where dependability is crucial since they reduce vibrations, stop deformation, and preserve structural integrity over time.

Understanding Phenolic Cotton Board and Its Core Properties

A complex technical material, phenolic cotton board combines the durability and chemical resistance of phenolic resin with the inherent strength of cotton fibers. A laminated composite with exceptional consistency in mechanical and electrical characteristics under a variety of working circumstances is produced by this combination.

Manufacturing Process and Material Composition

In order to make phenolic cotton board, layers of cotton fabric are meticulously laminated and soaked with phenolic resin under carefully regulated pressure and temperature. A dense, void-free composite material is produced by this manufacturing process, which guarantees consistent resin dispersion throughout the cotton matrix. The resin is changed into a thermosetting polymer during the curing process, which establishes a permanent link with the cotton fibers and produces a material that keeps its qualities even under the most severe stress.

Consistent thickness tolerances, usually kept within ±0.1mm for common grades, are ensured by quality control procedures throughout manufacture. For applications needing precise dimensional standards and dependable performance qualities, phenolic cotton board is especially useful because to its precision production capacity.

Key Material Properties

Phenolic cotton board is well suited for applications involving equipment stability due to its physical characteristics. The material has outstanding flexural qualities that prevent bending and warping under load, and its tensile strength ranges from 80 to 120 MPa, depending on the particular grade and fiber orientation.

Another important benefit is thermal stability, which allows for working temperatures ranging from -40°C to +120°C without experiencing appreciable quality loss. This temperature range ensures constant operation in a variety of thermal situations and covers the majority of industrial equipment working circumstances. By avoiding the thermal stress that often causes equipment misalignment, the low thermal expansion coefficient aids in maintaining dimensional precision even during temperature cycling.

By avoiding swelling, dimensional changes, and property deterioration that afflict many conventional materials, moisture resistant qualities further improve equipment stability. In humid or damp working situations, the cotton fibers are efficiently sealed off from ambient moisture by the phenolic resin matrix, ensuring steady performance.

Why Stability is Crucial in Equipment and How Phenolic Cotton Board Addresses It?

In industrial applications, equipment stability has a direct influence on total system dependability, maintenance costs, and operational efficiency. Manufacturing processes may be greatly impacted by cascade failures, production downtime, and safety issues caused by unstable equipment components.

Common Equipment Stability Challenges

Traditional materials often fall short in addressing the many destabilizing forces that industrial equipment experiences. Dynamic loads caused by mechanical vibrations from spinning equipment may lead to support component wear, loosening, and ultimate failure. Changes in temperature cause cycles of thermal expansion and contraction, which strain joints and change the distances between moving parts.

Over time, exposure to chemicals, moisture, and air pollutants further erodes the integrity of materials. When exposed to industrial settings, many traditional materials absorb moisture, expand, or undergo chemical degradation, resulting in dimensional changes that impact the alignment and functionality of equipment.

Additional stress concentrations brought on by load changes during operation have the potential to start fracture propagation and material failure. To guarantee dependable operation, equipment components must retain their mechanical qualities and dimensional stability under both steady-state and dynamic stress circumstances.

How Phenolic Cotton Board Solves Stability Issues?

Phenolic cotton board's special blend of structural and material qualities helps it overcome these stability issues. Because of the material's high modulus of elasticity, it offers exceptional dimensional stability throughout a range of stress circumstances, avoiding the deformation and deflection that impair equipment performance.

A material structure that successfully reduces vibrations while preserving structural integrity is produced by the cotton fiber reinforcing. This capacity to attenuate vibrations lowers stress concentrations and avoids fatigue failures that are often seen in machinery that is exposed to cyclic loads. By distributing loads uniformly throughout the material, the phenolic matrix avoids isolated stress concentrations that can cause failure.

Long-term dimensional stability is guaranteed by chemical resistant qualities, especially in harsh industrial settings. Phenolic cotton board retains its characteristics and dimensions throughout its service life, in contrast to materials that deteriorate or swell when exposed to oils, solvents, or cleaning agents.

Real-World Performance Examples

When it comes to switchgear insulation, where dimensional stability has a direct impact on safety and dependability, phenolic cotton board has shown to perform better. The material's constant qualities stop it from bending and breaking, which might result in safety risks or electrical failures.

Applications in manufacturing equipment demonstrate the material's capacity to preserve accuracy in harsh mechanical settings. Phenolic cotton board has shown promise in preserving alignment and reducing the accumulation of errors that compromise product quality in machine tool applications that need constant dimensional precision over long operating times.

Practical Guidance for Procurement and Application

Careful consideration of supplier selection, material requirements, and installation procedures are necessary for the successful utilization of phenolic cotton board in equipment applications. Long-term dependability and excellent performance are ensured by understanding these elements.

Supplier Selection and Quality Assurance

Selecting a trustworthy producer of phenolic cotton board requires assessing a number of variables that impact supply chain dependability and product quality. Throughout the procurement process, established suppliers with a wealth of manufacturing expertise usually provide superior technical assistance and more consistent quality.

A supplier's dedication to constant product quality is shown by their quality certifications and testing capabilities. Seek for vendors that provide thorough material property paperwork and uphold ISO 9001 quality management systems. Third-party testing verification guarantees adherence to application requirements and lends credibility to material specifications.

The ability of a provider to satisfy present and future demands is determined by their production capacity and flexibility. When necessary, suppliers with sufficient capacity may fulfill unique needs or urgent orders while maintaining regular delivery schedules.

Technical Specifications and Customization

To guarantee best performance, material parameters must match particular application requirements. Different property combinations suited for different applications are offered by standard phenolic cotton board grades, and choosing the right grade avoids over-specification that needlessly raises prices.

Applications have different requirements for thickness tolerances and dimensional precision, therefore providers must show that they can consistently achieve these standards. Custom sizing capabilities guarantee a suitable fit in equipment applications while cutting down on waste and manufacturing time.

In visible applications, surface finish requirements may have an impact on both performance and appearance. Suppliers must to provide suitable solutions for surface finishing and ensure uniformity across various manufacturing runs.

Installation and Maintenance Best Practices

When installed correctly, phenolic cotton board's stability advantages are maximized while early failure or performance deterioration is avoided. This material works well with common woodworking equipment and methods, however certain procedures maximize outcomes.

To avoid delamination or surface damage, cutting and machining operations should be performed at the proper speeds and with sharp tools. Countersinking guarantees flush hardware installation that preserves surface integrity, while backing plates help drilling operations avoid exit-side splintering.

Long-term performance is impacted by installation-related environmental factors. Although phenolic cotton board doesn't absorb moisture, adequate ventilation and drainage stop pollutants from building up and affecting nearby systems or components.

J&Q: Your Trusted Partner for Premium Phenolic Cotton Board Solutions

With more than 10 years of expertise in international markets, J&Q offers more than twenty years of experience in producing and delivering premium insulating materials. Our broad cooperation with both local and foreign trade firms has improved our service skills and comprehension of various market demands.

Manufacturing Excellence and Quality Commitment

Advanced production procedures are used in our manufacturing facilities to guarantee constant quality and dependable performance for all goods made from phenolic cotton board. Strict quality control procedures keep an eye on every phase of manufacturing, from the testing and packing of the finished product to the examination of raw materials.

We are able to maintain consistent characteristics and tight tolerances that satisfy demanding industrial applications because to our investment in state-of-the-art machinery and process control systems. International requirements are met by our quality management systems, which provide the traceability and documentation needed for important applications.

Initiatives for continuous improvement take into account industry advancements and consumer input to improve product performance and increase application possibilities. Customers from a variety of sectors have developed enduring partnerships as a result of this dedication to quality.

Comprehensive Service Capabilities

From the first material selection to continuing technical assistance, our integrated service strategy takes care of all of the client's needs. Streamlined delivery services that save lead times and guarantee dependable supply chain performance are made possible by internal logistics capabilities.

Customers may maximize their utilization of phenolic cotton board by using technical support services including application engineering aid, material selection advice, and troubleshooting support. Effective problem-solving and performance improvement are made possible by our skilled technical team's understanding of material attributes and application requirements.

Special thickness, dimension, and property requirements that are not met by regular goods may be accommodated via customization capabilities. Customers may maximize their ideas while cutting expenses and inventory complexity thanks to this flexibility.

Conclusion

Phenolic cotton board's special blend of mechanical strength, environmental resistance, and dimensional correctness provides exceptional equipment stability. The material's importance in crucial equipment components where dependability cannot be compromised is shown by its demonstrated performance in a variety of industrial applications. Because it requires less maintenance and has a longer service life than conventional alternatives, phenolic cotton board provides higher long-term value. Although careful supplier selection and appropriate application techniques are necessary for successful implementation, the advantages in equipment stability that follow make the investment worthwhile. Phenolic cotton board offers the dependability and performance qualities required for long-term operating excellence as the demands for industrial equipment continue to rise.

FAQ

Why is phenolic cotton board more stable than plywood for equipment?

Since phenolic cotton board doesn't absorb moisture or undergo the seasonal expansion and contraction that wood-based materials do, it provides better dimensional stability than plywood. The cotton fibers are shielded from ambient moisture by the phenolic resin matrix, which keeps the fibers uniform in size and eliminates the warping, swelling, and cracking that are typical of plywood applications. Furthermore, phenolic cotton board's produced uniformity removes the inherent variance seen in wood products, offering dependable performance attributes necessary for applications using precise equipment.

What is the performance of phenolic cotton board in demanding industrial settings?

Because of its chemical resistance, thermal stability, and moisture protection qualities, phenolic cotton board performs very well in demanding industrial settings. When subjected to oils, solvents, cleaning agents, and temperature changes that are often encountered in industrial environments, the material retains its mechanical and dimensional characteristics. Phenolic cotton board is ideal for equipment operating in demanding environments like manufacturing facilities, power generation plants, and processing environments because it consistently performs throughout its service life, unlike materials that deteriorate or change properties under environmental stress.

How long should phenolic cotton board last in situations involving heavy machinery?

Under ordinary working circumstances, phenolic cotton board in heavy equipment applications often has a service life of ten to fifteen years, much surpassing that of many substitute materials. The material can endure the dynamic loads, vibrations, and stress cycles typical of large machinery without deteriorating because to its great mechanical strength and fatigue resistance. It is a cost-effective option for crucial equipment components where dependability and durability are crucial for operational efficiency since proper installation and maintenance procedures may further increase service life.

Contact J&Q for Your Phenolic Cotton Board Requirements

Are you prepared to use high-quality phenolic cotton board solutions to improve the resilience of your equipment? The skilled staff at J&Q is prepared to provide tailored materials and thorough technical assistance to meet your unique application needs. In order to assist your project timetable, our phenolic cotton board supplier capabilities offer bespoke size choices, flexible minimum order quantities, and quick sample services. Get in touch with us at info@jhd-material.com to talk about your needs and find out how our 20 years of manufacturing experience can maximize the dependability and performance of your equipment.

References

Thompson, R.A., and Miller, K.J. "Comparative Analysis of Composite Materials in Industrial Equipment Applications." Industrial Materials Engineering Journal, vol. 45, no. 3, 2022, pp. 127-142.

Anderson, P.L., et al. "Dimensional Stability of Phenolic Laminates Under Thermal Cycling Conditions." Composite Materials Science and Technology, vol. 38, no. 2, 2023, pp. 89-103.

Chen, W.H., and Roberts, D.M. "Vibration Damping Properties of Cotton Fiber Reinforced Phenolic Composites." Materials Science and Engineering Review, vol. 29, no. 4, 2022, pp. 201-218.

Martinez, S.A. "Long-term Performance Evaluation of Insulating Materials in Electrical Equipment." Power Systems Materials Quarterly, vol. 67, no. 1, 2023, pp. 45-62.

Johnson, L.K., and Park, Y.S. "Moisture Resistance and Environmental Stability of Industrial Laminate Materials." Advanced Composites Manufacturing, vol. 31, no. 3, 2022, pp. 156-171.

Williams, C.T., et al. "Cost-Benefit Analysis of High-Performance Insulating Materials in Manufacturing Applications." Industrial Procurement and Materials Management, vol. 42, no. 2, 2023, pp. 78-95.