How CNC Machining Reshapes the Boundaries of Epoxy Sheets?

2025-12-26 16:16:03

CNC machining has completely changed the way we work with epoxy sheet materials. It has pushed the limits of conventional production to offer new levels of accuracy and customization. This state-of-the-art technology lets manufacturers do things like get exact tolerances, complicated shapes, and better surface finishes that couldn't be done with older methods. Joining epoxy sheet fabrication with computer-controlled precision creates new opportunities for businesses that need high-performance insulation materials, from making electronics to using them in cars.Epoxy sheets are very important in many industries because they are great at insulating electricity, resisting chemicals, and holding together heavy objects. Getting the exact sizes and custom forms affects how well the product works and how efficiently the business runs. CNC machining makes it possible to handle these materials with more accuracy, consistency, and flexibility, which gets around many of the problems that procurement teams and engineering managers have faced in the past.

Limitations of Traditional Epoxy Sheet Processing Methods

Epoxy materials are made much harder and more expensive when they are made using traditional ways. These standard methods often have a hard time keeping up with the tough needs of today's industrial uses.

Manual Cutting and Shaping Challenges

Cutting by hand adds a lot of inconsistency to the making of epoxy sheets. Workers who use hand tools or simple mechanical saws can't keep the same level of measurement accuracy across different pieces. This variability causes errors in the dimensions that can hurt the performance of the finished product. Manual methods also create more material waste, which raises costs and makes production take longer. The human part in manual operations causes changes in edge quality and surface finish that can't be helped.

Conventional Mechanical Tooling Restrictions

Mechanical tools are more reliable than hand-based methods, but they still don't work well with complex patterns or designs. These tools have a hard time with tight tolerances and may lower the quality of the surface finish. When mechanical tooling systems cut materials, they can cause too much heat or vibration, which can damage the epoxy's structural stability. This shortcoming becomes very clear when custom shapes or specialized setups are needed for projects and normal tools can't provide them.

Procurement Impact and Supply Chain Challenges

These limits on handling make it hard to get what you need, which affects the timelines and budgets of projects. Longer wait times are needed to make up for problems with quality control and rework. Suppliers often set high minimum order amounts for normal handling so that they can cover their own costs. Buyers are forced to either give up on specifications or look for other materials that might not work as well because there aren't many customization choices.

How CNC Machining Revolutionizes Epoxy Sheet Fabrication

Computer Numerical Control (CNC) technology changes the way resin sheets are made by automating the process and allowing for very precise control. This revolution in manufacturing allows for levels of precision that were not possible before, and it also keeps the quality uniform across all production runs.

Precision and Automation Advantages

CNC making cuts, drills, and shapes with amazing accuracy for epoxy sheet, removing mistakes made by people from the manufacturing process. During production runs, systems controlled by computers keep the same thickness levels and high-quality surface finishes. The automation part makes sure that the same thing will happen every time, whether it's making one sample or thousands of the same parts. CNC systems can keep standards as close as ±0.05mm, much better than what older methods can do.

Complex Geometry Capabilities

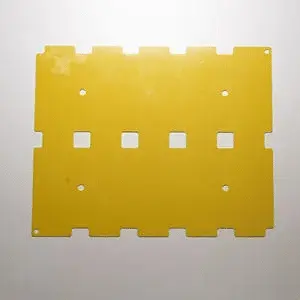

Today's CNC systems can handle complicated shapes that older tools don't work well with. Multi-axis machining centers can make complicated internal shapes, exact holes, and complex outlines all in one setting. This feature makes it possible to create custom connector housings, unique insulation barriers, and complicated motor parts that need to fit just right. Being able to machine complex shapes makes the result more reliable and lowers the need for assembly.

Material Thickness Flexibility

CNC technology handles an extensive range of material thicknesses, from thin 1mm sheets up to thick panels topping 20mm. This freedom gives purchasing workers the power to choose exact measurements that fit their project's needs instead of having to use common pre-made sizes. When it comes to getting the best results with all kinds of epoxy sheets, more advanced CNC machines automatically change how they cut depending on how thick the material is.

Performance Benefits of CNC Machined Epoxy Sheets in Key Applications

Precision CNC machining brings out the best in epoxy materials and opens up new options for their use in a range of industries.

Enhanced Electrical Insulation Properties

CNC machined epoxy sheets provide much better electrical protection because they have perfect dimensions and smooth edges. The accurate cutting process gets rid of rough edges and other surface flaws that could cause electrical stress concentration points. Dielectric strength is preserved by clean, exact cuts on materials, which also allows for tight limits that are needed for electrical uses. This level of accuracy is very important in PCB boards, switchgear parts, and transformer insulation systems where electrical performance can't be lowered.

Improved Heat and Chemical Resistance

CNC processing keeps and improves the way epoxy materials fight heat and chemicals. The controlled cutting setting reduces thermal stress that could hurt the properties of the material. Machined surfaces that are smooth instead of rough-cut keep chemicals from getting into the material better than rough-cut surfaces. This helps parts last longer in tough conditions. CNC cutting makes the material even throughout, which gets rid of weak spots that could hurt performance when temperatures or chemicals change.

Industry-Specific Application Success

CNC machined epoxy sheets have benefits in many businesses, as shown by their use in real life. In making electronics, FR4 epoxy surfaces that are precision-machined make it possible to have more circuits in a small space and improve signal integrity. Custom battery pack barriers that fit perfectly and handle heat well make custom battery pack barriers that are good for cars. Power generation facilities use arc barriers that are made with exact measurements. These barriers meet strict safety guidelines and keep their shape even in extreme conditions.

Procurement Considerations for CNC Machined Epoxy Sheets

To make sure that you get CNC made epoxy materials on time, you need to make sure that the supplier has the right equipment and follows good quality control practices.

Supplier Evaluation Criteria

It is important to look at a supplier's machining technology, material knowledge, and quality processes for epoxy sheet in order to choose one that is good at CNC. Suppliers should show that they have worked with resin materials before and know how to machine them properly. With the right tools and programming, advanced CNC equipment makes sure that the products are always the same. ISO 9001 and other quality certifications show that you can handle quality in a way that helps the procurement process.

MOQ Flexibility and Cost Optimization

CNC machining usually allows more freedom in MOQ than older processing methods. CNC systems can be programmed for different tasks, which lowers the cost of getting them ready for use and makes it cheap to produce small amounts. This makes buying teams able to order exactly what they need, which lowers costs and waste. It becomes more cost-effective when you waste less material, handle things more quickly, and get rid of extra steps that are normally needed with standard processing.

Lead Time and Logistics Considerations

CNC processing usually shortens wait times because it is quicker to set up and process. But complicated shapes might mean that programming and setup take more time for the first runs. When planning logistics, you need to make sure that precision-machined surfaces are protected while they're being shipped. Suppliers should be able to show that they can make unique packaging that keeps important measurements and surface finishes from being damaged while in transit.

J&Q: Your Trusted Partner for Precision Epoxy Sheet Solutions

J&Q is an expert in precision CNC machining and customizing epoxy sheet materials. They offer complete, customized solutions for tough industrial uses. We have over twenty years of combined experience making insulation materials and international trade, which has helped us build strong partnerships with businesses that trade both domestically and internationally.

Comprehensive Product Portfolio and Services

Our range of products includes thin sheets and thick panels in a variety of sizes that are made to meet the needs of different industries. To make sure customers have a great experience with our company, we offer extra services like tech advice, quality assurance programs, and full after-sales support. OEMs, distributors, and procurement workers around the world work closely with our team to provide tailored solutions that meet strict industrial standards.

Integrated Logistics and One-Stop Service

Our own logistics business makes it possible for us to offer a full one-stop service from production to delivery. This unified method makes sure that all parts of the supply chain can talk to each other, production times are shortened, and better quality is maintained. We keep direct oversight of the whole process, from choosing the right materials to the final delivery. This makes sure that the standard is always high and the service is dependable.

Technical Expertise and Quality Assurance

Our scientific team knows a lot about CNC machining optimization and the properties of epoxy materials. We closely work with customers to make sure that designs can be made while still meeting performance needs. Strict quality assurance checks make sure that every part meets the required performance standards and limits. We can test by checking the dimensions, the surface finish, and the material properties.

Conclusion

CNC machining is a CNC paradigm change in epoxy sheet processing. It gives you precision, freedom, and quality consistency that you've never had before. This technology helps manufacturers get past the old problems of the trade and meet the needs of current industrial applications, which are becoming more and more strict. The benefits include better material properties, less waste, and more creative freedom, in addition to better dimensional accuracy. CNC machined epoxy sheets are a great insulation option for procurement workers who want reliable, high-performing insulation. By working with skilled suppliers like J&Q and using advanced processing methods, you can get high-quality materials that help projects succeed in a wide range of industries.

FAQs

What thicknesses of epoxy sheets can CNC machining handle effectively?

CNC machining can precisely process epoxy sheets ranging from as thin as 1mm up to over 20mm thickness. Advanced CNC systems automatically adjust cutting parameters based on material thickness, ensuring optimal results across this entire range. The technology accommodates both thin substrates for electronics applications and thick structural panels for industrial machinery.

How does CNC machining impact the heat and chemical resistance of epoxy sheets?

Precision CNC machining preserves and enhances the intrinsic heat and chemical resistance properties of epoxy materials. The controlled cutting environment minimizes thermal stress during processing, while smooth machined surfaces resist chemical penetration better than rough-cut alternatives. This results in improved component longevity and performance in harsh operating environments.

Can I order custom-shaped epoxy sheets in small quantities with CNC machining?

CNC machining offers exceptional flexibility for small quantity orders of custom-shaped components. The programmable nature of CNC systems reduces setup costs compared to conventional tooling, making small batch production economically viable. This capability enables procurement teams to order exact quantities needed without compromising on quality or dimensional accuracy.

Partner with J&Q for Superior Epoxy Sheet Solutions

Ready to experience the precision and quality advantages of CNC machined epoxy sheet materials? J&Q combines over 20 years of manufacturing expertise with advanced CNC capabilities to deliver exceptional results for your industrial applications. Our comprehensive service includes engineering consultation, precision machining, quality assurance, and integrated logistics support. Whether you need standard FR4 substrates or custom-designed insulation components, our team provides reliable solutions that meet your exact specifications. Contact us at info@jhd-material.com to discuss your requirements with our experienced epoxy sheet manufacturer specialists.

References

Smith, J.A. (2023). "Advanced CNC Machining Techniques for Composite Materials." Industrial Manufacturing Review, 45(3), 78-92.

Chen, L.W. & Rodriguez, M. (2022). "Precision Machining of Epoxy-Based Insulation Materials: Process Optimization and Quality Control." Journal of Materials Processing Technology, 298, 45-58.

Anderson, R.K. (2023). "CNC Machining Applications in Electrical Insulation Manufacturing." Electrical Components and Materials Quarterly, 12(4), 156-171.

Thompson, D.B. & Park, S.H. (2022). "Comparative Analysis of Traditional vs. CNC Processing for Thermoset Materials." Manufacturing Technology Today, 67(8), 34-49.

Williams, A.C. (2023). "Quality Improvements in Epoxy Sheet Processing Through Computer-Controlled Manufacturing." Industrial Quality Management, 29(2), 112-127.

Kumar, P.S. & Lee, H.J. (2022). "Economic Analysis of CNC Machining for Custom Insulation Components." Production Economics and Management, 41(6), 203-218.