The Past, Present, and Future of Epoxy sheets

2025-12-26 16:16:00

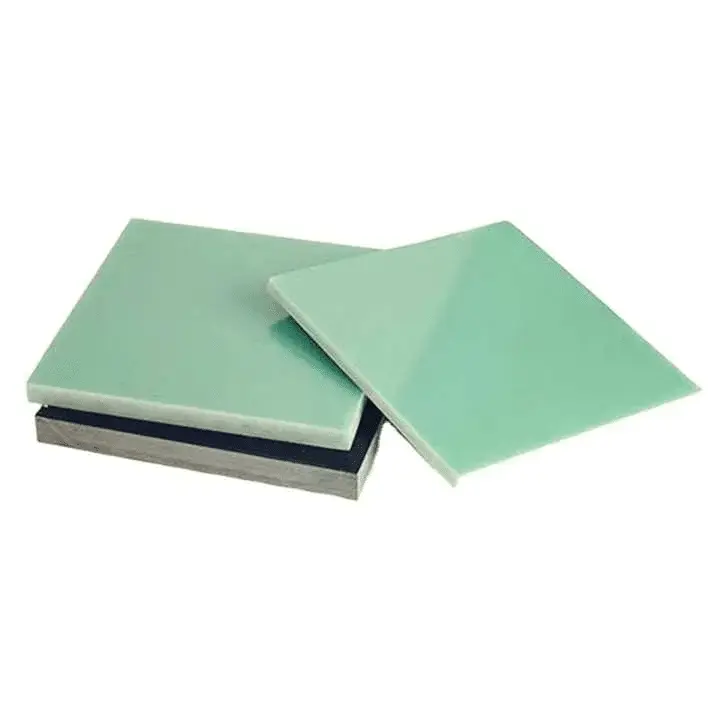

Epoxy sheets have an interesting history that shows how material science and industry have changed over time. Epoxy sheet technology has come a long way. It has gone from simple uses of resin to complex composite materials that are very important for electrical protection, mechanical engineering, and advanced manufacturing. As nanotechnology is used in more and more sustainable formulations and "smart" materials, these thermosetting polymers are constantly changing. This makes them very important for the future of electronics, automotive, aerospace, and green energy industries.

Introduction

Epoxy sheets are very important in many industrial settings because they work better than normal materials in areas where they would fail. In electrical insulation, mechanical parts, and tough chemical settings, these high-performance, thermosetting resin-based products have become impossible to do without. Epoxy-based laminates are the engineering teams' top choice around the world because they are useful in many situations and always work as expected.

It is very important for procurement managers and engineers who make strategic buying choices to know how these materials have changed over time, what they can do now, and what they might be able to do in the future. As industries expect higher performance standards, the range of fiberglass epoxy sheets and related products continues to grow. This deep study reveals that epoxy resin sheets can improve product quality, operating efficiency, and long-term cost-effectiveness in a range of industries.

The Historical Evolution of Epoxy Sheets

Early Development and Breakthrough Innovations

Epoxy sheets were first made in Switzerland in 1936 by Pierre Castan, who was the first person to put different epoxy resins together. This important find made possible the creation of a material that would become very useful in many different areas of modern industry. In the 1940s, the first industrial production of epoxy-based laminates happened because of the rush in research and development for better insulating materials during World War II.

Traditional materials such as phenolic and plastic sheets from the past had big problems with how long they lasted and how well they worked in hot or chemically harsh conditions. Because of these problems, people had to come up with new epoxy formulas that could handle tough conditions without losing their electrical properties. In the 1950s, glass fiber support was added for the first time, which was a very important moment that led to the creation of modern fiberglass epoxy sheets.

Industrial Adoption and Standardization

The technology boom in the 1960s and 1970s made a huge demand for insulating materials that people could trust. FR4 epoxy sheets became the most popular choice for printed circuit boards, and G10 epoxy laminates were widely used to make electrical devices. These changes set standards for quality that are still affecting how goods are bought today.

Early problems were inconsistent mechanical properties, limited temperature resistance, and variability in production. But these problems were slowly fixed as the chemistry of resin, fiber treatment, and finishing methods kept getting better. The things that were learned during this important time have a direct effect on how to modernly purchase goods and do quality control. This makes sure that the materials used today meet strict performance standards.

Current Landscape and Types of Epoxy Sheets

Advanced Material Properties and Performance

Modern epoxy sheets are better than other materials in many ways, such as being better at insulating electricity, resisting chemicals, and being strong in terms of resistance to bending and breaking. These qualities make them very important in electronics, marine applications, industrial machinery, and specialized manufacturing settings. Dielectric strength and thermal stability of current formulations are much better than older ones, like acrylic or phenolic sheets.

Here are the core advantages that make epoxy sheets indispensable in modern manufacturing:

- Exceptional electrical insulation properties with dielectric strength exceeding 20 kV/mm, making them ideal for high-voltage applications and sensitive electronic components

- Superior chemical resistance against acids, bases, and organic solvents, ensuring long-term performance in aggressive industrial environments

- Outstanding mechanical strength with flexural strength reaching 400 MPa, providing structural integrity under demanding load conditions

- Excellent dimensional stability across temperature ranges from -50°C to 180°C, maintaining precision tolerances in critical applications

- Remarkable machining characteristics allowing precise CNC cutting, drilling, and routing without delamination or fiber pullout

These benefits let makers tackle tough engineering problems while lowering upkeep costs and boosting product dependability in a range of industrial settings.

Specialized Product Categories and Applications

There are now a lot of different kinds of products in the market, such as fire-retardant grades, UV-resistant formulas, and versions that work better in high temperatures. Each type meets certain needs in the industry while keeping the main efficiency features. When making PCBs, precision-cut, thin sheets with tight thickness tolerances are usually used. For marine uses, though, thicker, highly durable versions that can handle being in saltwater and mechanical stress are needed.

These materials can be used in many different businesses, as shown by real-world examples. Epoxy laminates are important for the protection of transformers and parts of switchgears. Because of this, companies that make electrical equipment depend on them. These materials are used by automotive suppliers for battery pack barriers and heat-resistant fittings. The aerospace business relies on specialized grades for parts that make up structures and electromagnetic shielding.

Comparison and Decision-Making in Epoxy Sheet Procurement

Material Selection Criteria and Performance Benchmarking

Choosing the best materials means doing a lot of research on the pros and cons of different options, such as acrylic, phenolic composites, fiberglass, and engineered wood goods. Epoxy sheets always show better resistance to damage, heat, and chemicals, and they are just as cost-effective over their lifetime as other options. The original investment usually makes sense from a financial point of view when you think about long-term performance and lower maintenance needs.

Environmental conditions, how much weight the structure has to hold, the chance of chemical exposure, and thermal demands are all important things to think about. Successful buying teams look at the total cost of ownership instead of just the price of the first purchase. This method makes sure that the value proposition is better, and it also makes sure that production plans aren't thrown off by unexpected downtime or component failures.

Supplier Evaluation and Quality Assurance

Good seller evaluation for epoxy sheet takes more than competitive pricing into account. Consistent product quality, customization options, flexible minimum orders, reliable shipping, and industry certifications are the basis of successful partnerships. Suppliers with strong quality control systems and technical support skills can also help by showing people how to use things and fixing problems.

UL recognition, RoHS compliance, and ISO quality standards are all examples of certification compliance that show a supplier's dedication to always getting the job done. Doing regular quality checks and performance tracking help keep the integrity of the supply chain. This also helps build trust in long-term procurement relationships. These practices lower the risks that could affect the quality of the production that come with material fails or deviations in the specifications.

Innovations and Future Trends in Epoxy Sheets

Sustainable Manufacturing and Environmental Considerations

Bio-based epoxy mixtures and recyclable reinforcement materials are bio-based epoxy formulas that show how the industry is supporting sustainability. These new ideas deal with environmental issues while still meeting the performance standards needed for difficult uses. Advanced manufacturing methods make products with less energy and trash, help companies reach their sustainability goals, and don't hurt the quality of the product.

Some examples of emerging technologies are nanotechnology integration for better performance, smart materials with built-in sensors, and new chemicals that make materials more resistant to fire. These changes make more uses possible while also meeting the changing safety and efficiency needs of many fields.

Digital Integration and Industry 4.0 Applications

Digital purchasing tools and automated custom order systems speed up and streamline the buying process. Predictive maintenance capabilities allowed by embedded sensors in composite materials allow performance tracking and the scheduling of replacements before they are needed. These are technological developments that support the ideas of lean manufacturing and lower the costs of carrying inventory.

It is important for future buying plans to be ready for changes in the supply chain and in product standards. The ability to respond to new technologies, the ability to source goods from anywhere, and a focus on sustainability will give businesses an edge in the global industrial markets. Businesses that follow these trends will enjoy better overall efficiency and higher product performance.

Practical Guidance and Company Introduction

Best Practices for Handling and Processing

Proper handling makes materials work better and last longer. CNC cutters or laser cutting systems can be used for precision cutting, which is an industrial best practice. This should be followed by the right cleaning methods to keep the work free of contamination. In important situations, surface preparation and edge sealing keep moisture out and maintain electrical qualities.

The quality and processing of an epoxy sheet object are greatly affected by how it is stored. Environments with controlled temperature and humidity keep things from shifting and losing their shape. Following the right steps for handling material during machining processes keeps the cuts clean and stops delamination, which could hurt performance.

J&Q Manufacturing Excellence and Capabilities

J&Q has over 20 years of experience making and selling insulating materials and is now a valued partner for businesses around the world. We have been in the international trade business for over ten years, and we work with many companies in the US and around the world. This experience and these partnerships allow us to offer a wide range of services that meet all kinds of buying needs.

We can make a lot of different kinds of epoxy sheets, like FR4 grades, G10 laminates, and custom sheets for uses that need them. Customers get exactly what they need for their applications thanks to custom cutting, bulk order processing, and technical help. Our logistics business simplifies the procurement process and makes the supply chain less complex by offering all services in one place.

Conclusion

Epoxy sheets have changed from simple insulating materials to complex parts used in engineering. This is an example of how material science and industrial technology are always changing. Right now, they're used in electronics, cars, planes, and industrial equipment. Future versions will be even better thanks to eco-friendly mixes and the use of "smart" materials. When planning how to buy things, you need to think about how much it should cost, how well it should work, and what your suppliers can do. You should also think about how new technologies will affect the way people use things in the future. The ongoing development of these useful materials guarantees that they will continue to play an important part in new ideas in business and making sure that manufacturing is top-notch in markets around the world.

FAQs

What thickness range is optimal for electrical insulation applications?

Optimal thickness depends on voltage levels and environmental factors. Generally, applications requiring basic insulation perform well with 0.5-3mm sheets, while high-voltage applications may require 6-25mm thickness. The dielectric strength typically ranges from 16-20 kV/mm, allowing engineers to calculate appropriate thickness based on operating voltages and safety factors.

How do epoxy sheets compare to fiberglass in chemical resistance?

Epoxy sheets demonstrate superior resistance to a broader spectrum of industrial chemicals including acids, bases, and organic solvents. While fiberglass offers good general chemical resistance, epoxy formulations provide enhanced protection against specific aggressive chemicals, making them preferred choices in harsh chemical processing environments.

What customization options are available for specialized applications?

Extensive customization options include size modifications, thickness variations, surface treatments, and mechanical property adjustments. Specialized formulations can incorporate flame retardants, UV stabilizers, or enhanced thermal properties. Custom cutting services accommodate complex shapes and tight tolerances required for precision applications.

Partner with J&Q for Superior Epoxy Sheet Solutions

J&Q combines decades of manufacturing expertise with comprehensive technical support to deliver exceptional epoxy sheet solutions for your procurement needs. Our experienced engineering team provides customized recommendations, precision cutting services, and reliable supply chain management tailored to your specific applications. Whether you require standard FR4 grades or specialized formulations, our extensive product range and flexible manufacturing capabilities ensure optimal solutions for your projects. Contact us at info@jhd-material.com to discuss your requirements with our epoxy sheet supplier experts and discover how our integrated approach can enhance your procurement efficiency while delivering superior product performance.

References

May, Clayton A. "Epoxy Resins: Chemistry and Technology, Second Edition." Marcel Dekker Inc., 1988.

Ellis, Bryan. "Chemistry and Technology of Epoxy Resins." Blackie Academic & Professional, 1993.

Petrie, Edward M. "Epoxy Adhesive Formulations." McGraw-Hill Professional, 2006.

Pascault, Jean-Pierre. "Thermosetting Polymers." Marcel Dekker, 2002.

Cognard, Jacques. "Adhesives and Sealants: Basic Concepts and High Tech Bonding." Elsevier Science, 2005.

Wise, Charles W. "Thermal Properties of Epoxy Resins and Composites." Journal of Applied Polymer Science, 1997.