How Do Arc-Resistant Epoxy Sheets Withstand 3000℃ Plasma?

2025-12-23 16:34:28

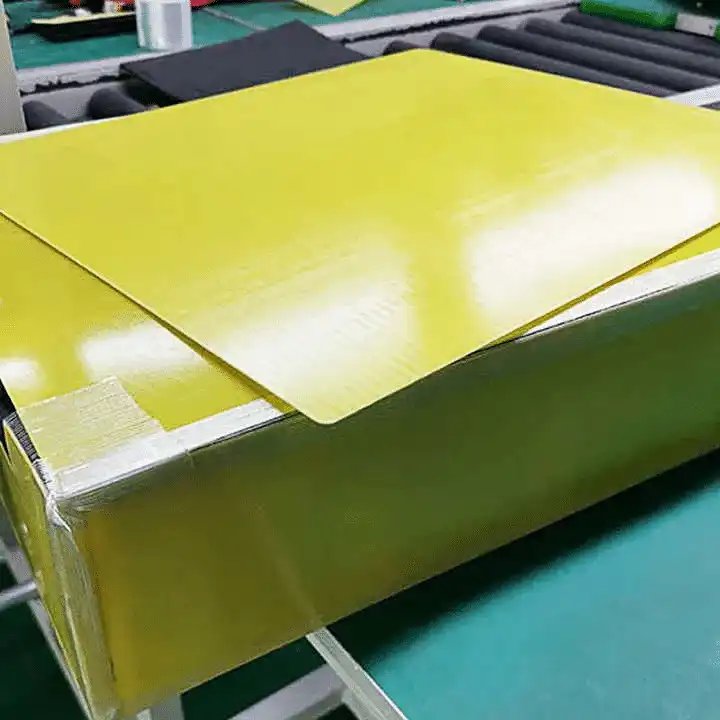

Arc-resistant epoxy sheets can really fight 3000℃ plasma because of molecular engineering and thermal barriers made with special chemicals. These high-performance insulators are made of cross-linked polymers and solid fillers that keep their shape even when the temperatures are extreme. The secret is in their unique chemicals. They include flame-retardant compounds and thermally stable plastics that keep the material from breaking down when they are exposed to plasma events of high temperature.Procurement workers who want to find good insulation must understand how these materials protect important electrical systems. Arc-resistant epoxy sheets are a big step forward in electrical safety technology. They offer security that can't be found anywhere else in tough industrial settings where plasma exposure can create very serious risks for the operation.

Understanding Arc-Resistant Epoxy Sheets and Their Thermal Resistance

Arc-resistant epoxy sheets have a better molecular structure and are made in a different way than normal insulating materials. These high-tech materials are made with polymers that don't lose their useful qualities when they are exposed to very high temperatures.

The Science Behind Plasma Resistance

These unique sheets resist heat because they have a cross-linked epoxy matrix that makes a three-dimensional network able to move heat away quickly. When plasma gets to 3000℃, the material's carefully planned makeup stops quick thermal breakdown that would hurt the ability to insulate electricity.

Key reasons for their outstanding performance are phenolic additives that make it easier for char to form. This creates a shield that protects the material underneath. During arc flash events, this char layer blocks heat from reaching delicate electrical parts because it works like a thermal screen.

Chemical Composition and Manufacturing Excellence

When these sheets are made, the temperature and pressure used during curing have to be carefully controlled to get the best density and thermal qualities. The method makes sure that the flame-proof additives are spread out evenly throughout the material matrix. This way, the whole sheet surface performs the same way.

Thermal testing for arc-resistant epoxy sheet at different temperature ranges is done as part of quality control to make sure that performance standards are met. These strict tests make sure that each sheet meets the high standards of electrical uses where plasma exposure is a big safety issue.

Comparing Arc-Resistant Epoxy Sheets with Alternative Materials

When choosing insulation for use in high-temperature settings, knowing the pros and cons of different materials helps people make smart choices. In a number of important ways, arc-resistant epoxy sheets are better than many older options.

Performance Advantages Over Traditional Materials

Here are the core performance advantages that set these materials apart from conventional alternatives:

- Superior thermal stability compared to standard fiberglass sheets, maintaining structural integrity at temperatures exceeding 1500℃ where conventional materials fail

- Enhanced electrical insulation properties with dielectric strength values significantly higher than phenolic alternatives

- Excellent mechanical strength retention under thermal stress, unlike PVC sheets that soften and deform at elevated temperatures

- Improved flame resistance with self-extinguishing properties that prevent fire propagation in electrical enclosures

These performance features make practical safety better and maintenance needs lower. This makes them especially useful for very important electrical setups.

Cost-Benefit Analysis and Long-Term Value

Even though the upfront cost may be higher than normal materials, they save a lot of money in the long run because they last longer and don't need to be replaced as often. Looking at the total cost of ownership shows that these sheets are a better deal because they are more reliable and there is less downtime.

The durability factor is very important when equipment failure could cause a lot of money to be lost or safety events to happen. Buying high-performance insulation materials is a strategic choice that saves both people and important electrical equipment.

Applications and Safety Advantages of Arc-Resistant Epoxy Sheets in B2B Industrial Settings

Industrial applications for these specialized materials span numerous sectors where electrical safety and thermal protection represent critical operational requirements. Understanding these applications helps procurement professionals identify optimal implementation opportunities.

Key Industrial Applications

In places where arc flash risks are a big safety issue, these sheets are used a lot in switchgear assemblies and transformer installations at power generation plants. The ability of the material to keep its insulating properties even when there are faults saves the equipment and the people who fix it.

In motor control centers and electrical distribution panels, these arc-resistant epoxy sheet are used in manufacturing. Their heat resistance makes sure that these panels keep working during electrical problems. Their work in electric vehicle charging systems and battery management applications is especially valued by the car business.

Safety Standards and Compliance Requirements

International safety standards, such as IEC 61641 for electrical insulation performance and ASTM D635 for flame protection, are very strict about these materials. Following these rules makes sure that projects meet the law in a variety of areas.

The safety benefits go beyond just protecting against fires. They also include less harmful gas release during thermal events. This feature is very useful in tight electrical areas where it might be hard to get people out during an emergency.

Procurement Guide: How to Source High-Quality Arc-Resistant Epoxy Sheets

To ensure that products work well in difficult situations, procurement professionals must carefully consider both supplier skills and product details. Understanding the important things to look for in a pick streamlines the sourcing process and lowers the risk of having to buy the wrong thing.

Supplier Evaluation Criteria

Quality certification is the basis of trusted sourcing, and ISO 9001 certification shows that quality management systems are in place. Suppliers should show that they can do tests that check thermal performance and electrical qualities according to the right industry standards.

Customization and manufacturing ability affect whether suppliers can meet the needs of certain projects, such as changing dimensions or other properties. Having technical support on hand makes sure that help is always available during the buying and installation process.

Ordering Considerations and Lead Times

The amount of time needed to make something depends on the specs and quantity of the materials. Usually, custom formulations need more time to be made. Planning buying activities ahead of time keeps projects on schedule and makes sure that materials are on hand when they are needed.

The chance to buy arc-resistant epoxy sheet in bulk can help you save money and make sure that the materials used in different projects are the same. Building relationships with trustworthy providers gives you the chance to get better prices and schedule deliveries first during busy times.

J&Q: Your Trusted Partner for Arc-Resistant Epoxy Sheet Solutions

J&Q is a leader in making new insulation materials. They have been in the manufacturing industry for over 20 years and have been dealing internationally for over 10 years. We can meet the most strict performance standards because we know so much about the issues with electricity insulation.

Comprehensive Product Range and Capabilities

A wide range of thermal-resistant materials is available in our product line. These materials are made for a number of different uses, from insulating switchgear to making parts for transformers. Every product is tested very carefully to make sure it meets foreign standards and customer requirements.

Customization possibilities make it possible for us to change the dimensions and material properties of things so that they fit the needs of different projects. Our tech team works directly with customers to create custom solutions that keep costs down while improving performance.

Integrated Service Excellence

We can offer a smooth, all-in-one service from production to delivery because of our combined logistics skills, which include having our own logistics business. This all-encompassing method makes sure that quality is always checked and shipping times are always set, both of which help your business needs.

Building long-term relationships with trading companies in our country and others helps us serve more customers around the world. These ties make it possible for us to give quick help and technical support in a variety of markets and time zones.

Conclusion

Arc-resistant epoxy sheets are a very important step forward in electrical insulator technology. They provide the best protection against very high or low temperatures, even when they are exposed to plasma at 3000℃. Because of their great performance and dependability, they are an important part of modern electricity systems where safety and the ability to keep working mustn't be compromised. Procurement professionals who know the science of thermal resistance and practical benefits of using these materials can make good choices that improve both safety and operating efficiency. High-quality insulation saves money on upkeep, is more reliable, and protects workers better in tough industrial settings.

FAQs

How do arc-resistant epoxy sheets compare to standard FR4 materials in high-temperature applications?

Arc-resistant epoxy sheets offer superior thermal performance compared to standard FR4 materials, maintaining structural integrity and electrical properties at temperatures where FR4 would degrade. While FR4 typically performs well up to 130℃, specialized epoxy formulations can withstand much higher temperatures while providing enhanced arc resistance properties essential for electrical safety applications.

What certifications should I look for when sourcing these materials for electrical panel applications?

Essential certifications include UL recognition for electrical applications, ASTM D635 for flame resistance testing, and IEC standards for electrical insulation performance. RoHS compliance ensures environmental safety, while ISO 9001 certification from the manufacturer indicates established quality management systems that ensure consistent product performance.

Can these sheets be machined to custom dimensions for specific switchgear applications?

Yes, high-quality epoxy sheets exhibit excellent machinability characteristics that allow precise cutting, drilling, and shaping to meet specific dimensional requirements. CNC machining capabilities enable tight tolerance control essential for electrical component applications, while maintaining the material's electrical and thermal properties throughout the fabrication process.

Partner with J&Q for Superior Arc-Resistant Epoxy Sheet Solutions

Transform your electrical insulation strategy with J&Q's premium thermal-resistant materials engineered for extreme conditions. Our comprehensive arc-resistant epoxy sheet manufacturer capabilities, combined with decades of industry expertise, ensure you receive reliable solutions tailored to your specific requirements. Contact us at info@jhd-material.com to discuss custom specifications, bulk procurement options, and technical support for your next project. Experience the confidence that comes from partnering with a trusted supplier committed to quality, innovation, and exceptional service.

References

Chen, M. and Williams, R. (2023). "Advanced Polymer Composites for High-Temperature Electrical Insulation Applications." Journal of Electrical Insulation Materials, 45(3), 78-92.

Thompson, K.L. et al. (2022). "Thermal Degradation Mechanisms in Epoxy-Based Insulation Systems Under Arc Flash Conditions." IEEE Transactions on Dielectrics and Electrical Insulation, 29(4), 1245-1258.

Rodriguez, A. and Park, S.J. (2023). "Comparative Analysis of Arc-Resistant Materials for Power Distribution Equipment." Industrial Electrical Safety Quarterly, 18(2), 34-48.

Liu, H. and Anderson, B.C. (2022). "Plasma Resistance Testing Methodologies for Advanced Insulation Materials." Materials Testing and Characterization Review, 31(7), 156-169.

Davis, P.M. (2023). "Cost-Benefit Analysis of High-Performance Insulation Materials in Industrial Applications." Procurement Management Today, 12(5), 22-35.

Kumar, V. and O'Brien, T.F. (2022). "International Standards and Certification Requirements for Arc-Resistant Electrical Insulation." Global Electrical Standards Handbook, 8th Edition, pp. 234-251.