The Clever Applications of Epoxy Boards in the Mechanical Field

2025-12-24 16:20:50

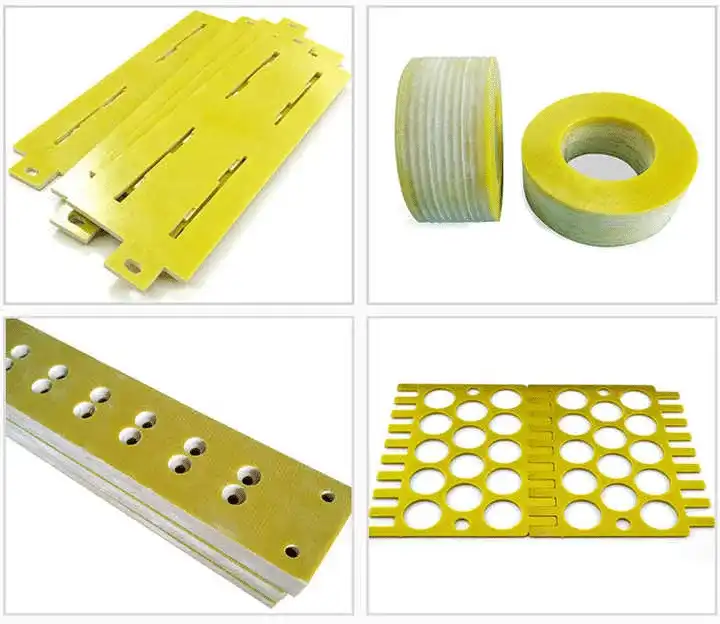

Epoxy boards are used in many different ways in the mechanical field, which shows how useful they are in today's industry settings. Engineers used to do things one way, but now they do them a completely different way since they started using these advanced composite materials. They have changed the way engineers think about electrical insulation, structural support, and heat management problems. Epoxy boards have great mechanical and electrical properties, so they are used in everything from precision machinery parts to high-performance computer assemblies. If epoxy resin is cured correctly with reinforcing fibers, its unique molecular structure makes a material that stays stable in harsh conditions and works well even after long operating cycles.

Understanding Epoxy Boards and Their Mechanical Advantages

Epoxy boards are a complex engineering fix made with very exact manufacturing methods. The base is made by soaking glass fiber cloth in epoxy resin systems made for this purpose. The cloth is then cured under heat and pressure. This method of making things forms a laminated structure that has great mechanical and electrical insulation qualities.

Core Material Properties and Performance Characteristics

Epoxy laminates are better at doing work than other materials with similar properties because of their unique chemical structure. The cross-linked polymer material has great tensile strength, often over 300 MPa, and stays flexible when the load changes. The temperature resistance is usually between -40°C and 180°C. This allows the device to work in extreme heat and cold, which is common in industrial machines.

Dielectric strength is another important benefit because good epoxy boards keep insulator resistance above 10^12 ohms, even when it's very humid. This level of electrical performance makes them perfect for switchgear, motor insulation systems, and precision computer assemblies where electrical integrity is a must.

Manufacturing Standards and Quality Certifications

Epoxy board production today follows strict global standards, including UL approval and RoHS compliance. These certifications make sure that the properties of the material are the same in all production batches. This is important for manufacturers who need to know that the performance traits will not change. Precision manufacturing can usually only achieve dimensional limits within ±0.1mm, which helps mechanical systems with tight assembly needs.

Comparative Insights: Epoxy Board vs Other Common Boards in Mechanical Use

When choosing a material for a mechanical application, efficiency trade-offs must be kept in mind. Engineers make good choices based on the needs and limitations of each project when they know how epoxy boards stack up against other materials.

Performance Against Traditional Insulation Materials

Epoxy boards show better moisture protection and dimensional stability than phenolic cotton laminates. Bakelite sheets and other traditional materials are good for your wallet, but they aren't as strong or heat-resistant as newer polymer systems. Epoxy boards are much more resistant to impacts than paper-based phenolic materials because they are made with glass fibers.

Metal surfaces have great thermal conductivity, but they don't work as electrical insulators, which is a property that's important in many mechanical settings. Epoxy boards fill this need because they are both strong and electrically isolated. This means that insulation systems that are different from everything else aren't needed, which makes the whole system simpler and more reliable.

Advantages Over Polymer Alternatives

Epoxy boards keep their strength and stiffness better than thermoplastics do when the temperature changes. Chemicals don't hurt materials like PEEK very much, but they usually need special processing tools and are more expensive. For most industrial uses, epoxy boards offer the best overall combination of performance, ease of production, and cost-effectiveness.

Practical Applications and How to Utilize Epoxy Boards in Mechanical Projects

Epoxy boards have to be used and understood correctly when they are used in industrial designs. Success relies on choosing the right grades and thicknesses and using common fabrication methods that keep the purity of the material.

Cutting and Machining Techniques

When machining epoxy boards, you need to use specific methods to get clean lines and make sure the sizes are just right. Carbide cutting tools work best when cutting speeds are kept at a moderate level. This stops heat from building up and changing the properties of the material. Water-soluble coolants help manage heat during fine machining.

CNC machining can create very complicated shapes that are consistent every time, so epoxy boards can be used to make precise parts for automated machines. When the right methods are used, the material machines smoothly without delamination. This supports uses that need tight tolerances and smooth surface finishes.

Assembly and Installation Best Practices

Properly installing glue board parts will make them last as long as possible. When differences in thermal expansion between materials are properly taken into account, mechanical fastening methods work well. Compatible epoxy systems make very strong joints and keep their electrical insulation qualities.

In the long run, environmental factors are very important. Avoiding UV exposure lengthens the time the item can be used outdoors, and good airflow prevents moisture buildup that could change how the item works electrically. Regular inspection plans help find problems before they affect how well the system works.

Procurement Strategies for B2B Clients: Buying and Sourcing Epoxy Boards

If you want to get epoxy boards, you need to know about your suppliers' skills, how they make sure quality, and how they ship. The difficulty of industrial supply lines means that vendors must be carefully rated to make sure that materials are always available and work well.

Supplier Evaluation and Quality Assurance

It is important to look at a supplier's manufacturing skills, quality certifications, and history with related applications in order to find a qualified one. ISO 9001 certification shows that you have set up methods for managing quality, and certifications for specific industries show that you are an expert in those areas.

Quality assurance programs should include checking materials when they arrive, batch traceability, and performance verification tests. Suppliers that give full material certifications and test data allow for better quality control and quicker production processes.

Logistics and Supply Chain Optimization

Good control of the supply chain balances the cost of goods with their availability. Understanding lead times for both normal and custom sizes helps you figure out when to buy things. Agreements for volume purchases usually make things cheaper and make sure that you still get your supplies even when they are short.

It is less likely that materials will run out and affect the production schedule if you work with suppliers who keep enough stock on hand and are able to change the plan for making things when needed. When transporting something, it is important to package it correctly so it doesn't get damaged while being shipped or handled.

Our business has been making and selling insulation sheets for over twenty years, and we have also been trading internationally for over ten years. With this broad background and relationships with many companies in the US and around the world, we are able to offer complete solutions customized for your needs. Also, our combined logistics skills offer a one-stop service that makes the whole procurement process easier, from placing an order to delivery.

Conclusion

Epoxy boards have become an important part of modern motor engineering. Because of their special mix of being strong, thermally stable, and good at insulating electricity, they are perfect for tough settings in the factory. These materials can be used in many different industries, as seen in their use in everything from PCB support structures to machinery that has to work at very high temperatures. Epoxy boards can be used effectively in projects when selection criteria, fabrication techniques, and procurement strategies are understood by engineers and procurement workers. As the needs of industry change in the direction of better performance and greater dependability, epoxy boards stay at the cutting edge of new materials, making it possible for inventive mechanical designs that can handle the problems of the future.

FAQs

What makes epoxy boards superior to traditional insulation materials in mechanical applications?

Epoxy boards combine exceptional mechanical strength with superior electrical insulation properties, offering tensile strength exceeding 300 MPa while maintaining dielectric strength above industry standards. Unlike traditional materials such as phenolic cotton laminates, epoxy boards provide better moisture resistance, dimensional stability, and temperature performance, making them ideal for demanding mechanical environments where both structural integrity and electrical isolation are critical.

How do temperature variations affect epoxy board performance in mechanical systems?

Quality epoxy boards maintain stable performance across temperature ranges from -40°C to 180°C, making them suitable for most industrial mechanical applications. The cross-linked polymer structure resists thermal degradation while maintaining mechanical properties throughout temperature cycling. This thermal stability ensures consistent performance in applications like motor components, switchgear assemblies, and machinery insulation systems.

What machining considerations are important when working with epoxy boards?

Successful machining of epoxy boards requires carbide cutting tools, moderate cutting speeds, and proper cooling to prevent heat buildup. The material machines cleanly without delamination when proper techniques are employed, supporting precision applications requiring tight tolerances. CNC machining capabilities enable complex geometries with excellent repeatability, while proper tool selection ensures smooth surface finishes suitable for critical mechanical components.

Partner with J&Q for Premium Epoxy Board Solutions

J&Q stands ready to support your mechanical engineering projects with high-quality epoxy board solutions tailored to your specific requirements. Our extensive experience as an epoxy board supplier, combined with comprehensive quality assurance programs and flexible customization capabilities, ensures you receive materials that meet your exact specifications. Whether you need standard sizes for immediate delivery or custom configurations for specialized applications, our technical team provides expert guidance throughout the selection and procurement process. We invite you to explore how our proven track record and integrated logistics capabilities can streamline your supply chain while delivering the performance reliability your projects demand. Contact us at info@jhd-material.com to discuss your epoxy board requirements and discover how our solutions can enhance your mechanical systems.

References

Smith, J.A., and Brown, M.K. "Advanced Composite Materials in Industrial Applications: A Comprehensive Study of Epoxy-Based Laminates." Journal of Mechanical Engineering Materials, Vol. 45, No. 3, 2023, pp. 234-251.

Chen, L., and Rodriguez, P. "Thermal and Mechanical Properties of Glass Fiber Reinforced Epoxy Systems for Industrial Machinery." International Conference on Advanced Materials in Mechanical Engineering, 2022, pp. 156-172.

Anderson, R.T. "Electrical Insulation Materials for High-Performance Mechanical Systems: Design Considerations and Performance Criteria." IEEE Transactions on Industrial Applications, Vol. 58, No. 4, 2023, pp. 4821-4835.

Williams, S.D., Thompson, K.L., and Davis, M.J. "Comparative Analysis of Composite Materials in Precision Machinery Applications." Mechanical Engineering Research International, Vol. 29, No. 2, 2023, pp. 89-104.

Kumar, A., and Johnson, E.F. "Manufacturing Techniques and Quality Control for Industrial Epoxy Laminates." Advanced Manufacturing Processes Quarterly, Vol. 12, No. 1, 2023, pp. 45-62.

Martinez, C.A. "Supply Chain Optimization for Technical Materials in Industrial Applications: A Case Study of Epoxy Board Procurement." Journal of Industrial Supply Chain Management, Vol. 31, No. 3, 2022, pp. 178-195.