How FR4 Epoxy Board Resists Heat and Electrical Stress?

2026-01-22 17:13:13

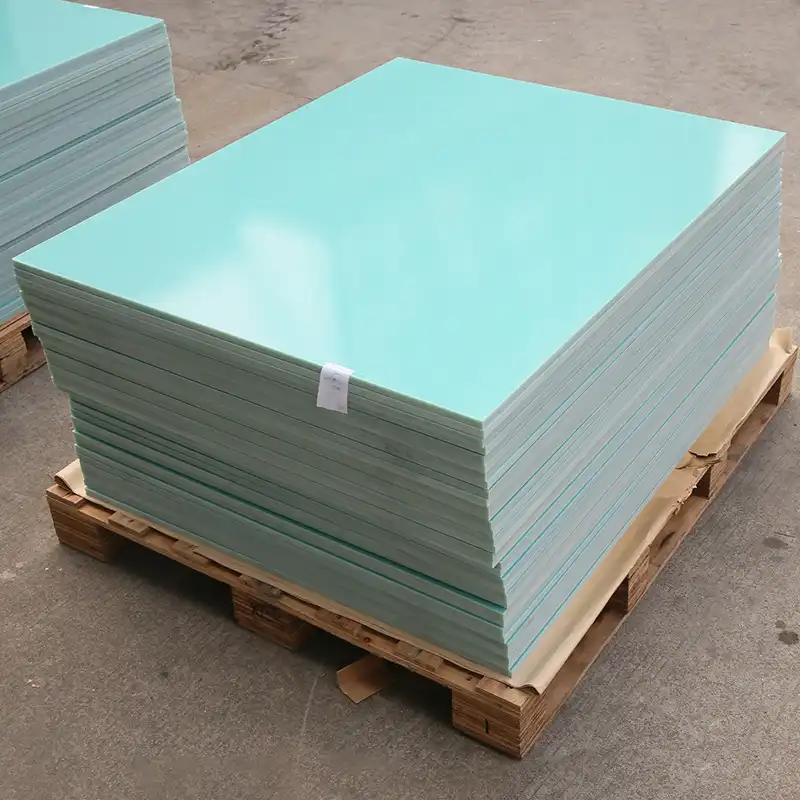

FR4 epoxy board's special composite structure of woven fiberglass fabric and flame-retardant epoxy resin allows it to achieve remarkable heat and electrical stress resistance. The thoroughly cured epoxy matrix retains exceptional dielectric strength and insulation resistance, while the fiberglass reinforcement offers mechanical stability at high temperatures up to 130°C. This combination produces a strong material that is the material of choice for essential electronic applications because it can tolerate electrical breakdown, thermal cycling, and tracking under severe industrial circumstances.

Understanding FR4 Epoxy Board: Composition and Key Properties

The complex material composition and designed features of FR4 are the cornerstones of its exceptional performance. When choosing materials for demanding applications, it becomes essential for an electrical engineer or procurement manager to comprehend these features.

Material Composition and Structure

Flame-retardant epoxy resin is infused into woven fiberglass fabric to create FR4 epoxy boards. The epoxy matrix offers chemical resistance and electrical insulation, while the fiberglass offers dimensional stability and structural integrity. The material produced by this composite structure retains its qualities throughout a range of environmental circumstances.

Several layers of pre-impregnated fiberglass cloth are pressed together throughout the manufacturing process under regulated pressure and temperature. By removing gaps that can impair electrical performance, this lamination process guarantees consistent thickness. Strict process controls are maintained by quality producers to produce consistent material properties batch after batch.

Key Specifications and Performance Parameters

Understanding the technical specifications helps procurement professionals make informed decisions. Here are the critical performance parameters that define FR4 capabilities:

• Thermal Properties: Operating temperature range from -40°C to +130°C with glass transition temperature (Tg) typically around 130-140°C, ensuring structural integrity during thermal cycling

• Electrical Characteristics: Dielectric strength exceeding 20 kV/mm, volume resistivity above 10¹⁴ ohm-cm, and dielectric constant of approximately 4.5 at 1 MHz

• Mechanical Strength: Flexural strength reaching 415 MPa and excellent CNC machinability for precise component fabrication

• Dimensional Stability: Low coefficient of thermal expansion and moisture absorption under 0.15%, maintaining tight tolerances in varying conditions

These specifications demonstrate why FR4 remains the industry standard for applications requiring reliable electrical insulation and thermal stability. The material's consistent performance across different environmental conditions makes it particularly valuable for industrial machinery and power distribution applications.

Thickness Options and Material Grades

FR4 epoxy boards come in thicknesses ranging from 0.2mm to 3.2mm, meeting a variety of application needs. Standard thicknesses are 0.4, 0.8, 1.6, and 3.2 mm; for particular purposes, bespoke dimensions can be obtained. The choice of thickness has a direct effect on mechanical strength and electrical characteristics, thus it must be carefully considered during the design stages.

Different FR4 grades provide different levels of performance. While high-temperature variations increase working ranges beyond 150°C, standard grade FR4 satisfies the majority of industrial requirements. For crucial applications in the automotive and aerospace industries, certain specialist grades offer increased flame resistance or improved dimensional stability.

Mechanisms Behind FR4's Heat and Electrical Stress Resistance

The exceptional thermal and electrical resilience of FR4 stems from carefully engineered molecular structures and manufacturing processes that optimize material performance under stress conditions.

Thermal Resistance Mechanisms

The cross-linked polymer network formed during the curing process is what gives FR4 epoxy boards their heat resistance. At high temperatures, the epoxy resin creates three-dimensional molecular connections that preserve structural integrity. The polymer chain movement that would normally cause material deterioration is stopped by this cross-linking.

For thermal stability, fiberglass reinforcing is essential. The composite material's overall expansion is limited by the incredibly low thermal expansion coefficients of the glass fibers. In industrial applications, this restriction avoids warping and delamination that may happen during thermal cycling.

Further thermal protection is offered by the flame retardant chemicals added to the epoxy matrix. When exposed to high temperatures, these compounds emit gases that inhibit flames, meeting strict safety regulations such as the UL94 V-0 classification. When it comes to electrical equipment that could overheat, this flame resistance is crucial.

Electrical Stress Resistance Properties

Because of its amorphous epoxy structure, which offers few electrical conduction channels, FR4 exhibits electrical stress resistance. Even at high voltages, current leakage is prevented by the tremendous electrical resistance produced by the random molecule arrangement.

Another important benefit of the material is its resistance to electrical tracking. When electrical stress and contamination combine to create conductive pathways across insulating surfaces, tracking takes place. This phenomena is resisted by FR4's bulk characteristics and surface chemistry, preserving electrical integrity over long service times.

Under voltage stress, dependable operation is guaranteed by dielectric breakdown resistance. Weak spots that can cause an early failure are eliminated by the epoxy matrix's even dispersion. Consistent dielectric characteristics are maintained throughout the material thickness by quality control during manufacture.

Manufacturing Process Optimization

The resistant qualities of FR4 for FR4 epoxy board are maximized by precise manufacturing procedures. Fiberglass cloth is meticulously impregnated with epoxy resin at regulated viscosity levels as part of the prepreg process. By doing this, air pockets that can impair performance are eliminated and full fiber wetting is guaranteed.

To produce the best cross-linking, the pressing cycle integrates temperature, pressure, and time factors. While too much curing might lead to brittleness, too little curing produces poor mechanical characteristics. Skilled producers create precise curing schedules that optimize electrical and thermal performance.

For demanding applications, post-cure treatments might improve particular qualities. While some procedures maximize surface properties for improved soldering or bonding performance, others raise the glass transition temperature.

Comparing FR4 Epoxy Boards with Alternative PCB Materials

Material selection significantly impacts product performance and cost-effectiveness. Understanding the comparative advantages helps procurement teams make optimal decisions for specific applications.

FR4 versus Aluminum Substrates

Because of their exceptional thermal conductivity, aluminum PCBs are perfect for high-power electronics and LED applications. On the other hand, FR4 offers better electrical insulation, which is crucial for intricate circuit designs that need signal integrity.

These materials' mechanical qualities vary greatly from one another. Complex component configurations are made possible by FR4's superior drilling and routing capabilities. Because of their conductive nature, aluminum substrates limit design flexibility and necessitate certain manufacturing procedures.

FR4 is frequently preferred for moderate-volume production due to cost considerations. For general-purpose applications, FR4 is more cost-effective because to the established supply chain and processing equipment. Aluminum substrates are expensive because of their unique production needs.

Performance Comparison with Phenolic Materials

Phenolic boards represent a lower-cost alternative but sacrifice performance in several critical areas. Here are the key differentiators between FR4 and phenolic materials:

• Temperature Resistance: FR4 maintains properties up to 130°C while phenolic materials typically limit to 105°C maximum operating temperature

• Electrical Properties: FR4 provides superior dielectric strength and lower loss tangent, crucial for high-frequency applications

• Mechanical Strength: FR4 offers better impact resistance and dimensional stability under varying environmental conditions

• Flame Resistance: FR4 meets UL94 V-0 standards while many phenolic materials achieve only V-1 or V-2 ratings

This comparison demonstrates why FR4 is preferred in applications that need dependable performance under pressure. Phenolic materials are appropriate for applications where cost is a concern, whereas FR4 provides the reliable performance required by vital industrial machinery.

Advanced Material Alternatives

FR4 is outperformed by polyimide and other high-performance polymers in specific applications that call for exceptional flexibility or temperature tolerance. These materials, however, are far more expensive and need certain processing tools.

Although they operate better at high frequencies, Rogers materials and other low-loss dielectrics are not required for the majority of industrial applications. FR4 is the sensible option for common electrical assemblies because of its balanced qualities and well-established supply chain.

Procurement Insights for FR4 Epoxy Boards

Understanding supplier capabilities, certification requirements, and market variables that impact availability and pricing are all important for strategic FR4 material purchasing.

Supplier Evaluation Criteria

A comprehensive evaluation of suppliers is the first step towards successful procurement. Established quality processes and regulatory compliance are shown by quality certifications such as ISO 9001, RoHS compliance, and UL accreditation. These certifications guarantee that materials fulfill international criteria necessary for acceptability in the worldwide market.

Delivery performance and product quality are directly impacted by manufacturing capabilities. Technical assistance and material certification are available from suppliers with internal testing facilities. Consistent material qualities throughout production batches are guaranteed by sophisticated process control systems.

Logistics expenses and supply chain stability are impacted by geographic factors. While global vendors might offer superior price for large-volume requirements, regional suppliers offer shorter lead times and lower transportation costs. A thorough examination of the overall cost of ownership is necessary to balance these elements.

Technical Specifications and Custom Requirements

While unique formulas for FR4 epoxy board can maximize performance for particular situations, standard FR4 specs satisfy the majority of application needs. Low-loss formulations enhance signal integrity in delicate circuits, while high-temperature versions increase operating ranges.

The performance of the finished product and assembly procedures are impacted by thickness tolerances. Although tighter tolerances raise the cost of materials, they may lessen variability in downstream processes. Optimizing procurement decisions requires an understanding of the balance between specification requirements and cost consequences.

Additional functionality is offered by copper cladding options and surface treatments. While certain applications demand improved adhesion qualities for bonding operations, others require specialized surface treatments for greater solderability.

Supply Chain Management Strategies

While lowering inventory costs, efficient supply chain management guarantees material availability. Improved production planning and cash flow management are made possible by an understanding of lead times and minimum order quantities.

Developing connections with several eligible suppliers gives you competitive advantage and supply security. Through supplier rivalry, dual sourcing strategies preserve pricing competitiveness while guarding against supply disruptions.

Incoming inspection procedures and quality agreements guarantee that acquired materials fulfill requirements. Production delays brought on by inferior materials are avoided with well-defined quality specifications and testing protocols.

Optimizing the Use and Longevity of FR4 Epoxy Boards

Maximizing FR4 performance requires proper handling, design considerations, and maintenance practices that preserve material properties throughout the product lifecycle.

Design Best Practices

The best circuit board design takes into account the limits and material characteristics of FR4. The choice of copper thickness has an impact on current carrying capacity and thermal management. While thicker copper enhances heat dissipation and current handling, standard copper weights of 1 oz/ft² are appropriate for the majority of applications.

Reliable connections are ensured and delamination is prevented by design and drilling specifications. While proper aspect ratios preserve plating integrity, the right drill speeds and feed rates reduce mechanical stress. Manufacturing flaws can be avoided by being aware of these relationships.

When using high power, thermal control becomes essential. Thermal relief features and thoughtful component placement aid in the uniform distribution of heat over the board surface. Localized overheating that could deteriorate material qualities is avoided with effective heat sinking and ventilation.

Manufacturing Process Considerations

The longevity and dependability of FR4 boards are greatly impacted by assembly procedures. To avoid thermal damage, soldering temperature profiles must stay within material bounds. Careful temperature control is necessary for lead-free soldering procedures to prevent surpassing the glass transition temperature of FR4.

Board flexing and possible fracture may result from component mounting forces. In order to avoid mechanical stress that could cause an early failure, proper support is necessary during assembly processes. Determining the proper handling techniques requires an understanding of FR4's flexural strength.

The chemical compatibility of FR4 must be taken into account during cleaning procedures. Aggressive solvents may cause edema or alter surface characteristics. While eliminating production residues, material integrity is maintained by using the right cleaning agents and procedures.

Long-term Reliability and Maintenance

The longevity and dependability of FR4 boards are greatly impacted by assembly procedures. To avoid thermal damage, soldering temperature profiles must stay within material bounds. Careful temperature control is necessary for lead-free soldering procedures to prevent surpassing the glass transition temperature of FR4.

Board flexing and possible fracture may result from component mounting forces. In order to avoid mechanical stress that could cause an early failure, proper support is necessary during assembly processes. Determining the proper handling techniques requires an understanding of FR4's flexural strength.

The chemical compatibility of FR4 must be taken into account during cleaning procedures. Aggressive solvents may cause edema or alter surface characteristics. While eliminating production residues, material integrity is maintained by using the right cleaning agents and procedures.

Conclusion

Because of their tightly regulated production procedures and designed composite composition, FR4 epoxy boards exhibit remarkable resilience to heat and electrical stress. Flame-retardant epoxy resin and woven fiberglass reinforcing combine to provide a material that performs consistently in demanding industrial applications. Procurement experts can make well-informed judgments that maximize both performance and cost-effectiveness by comprehending FR4's composition, resistance mechanisms, and competitive benefits. These materials are guaranteed to provide dependable service for the duration of their intended lifecycle through appropriate design procedures, production techniques, and maintenance plans.

FAQs

What temperature range can FR4 epoxy boards withstand?

Standard FR4 epoxy boards operate reliably from -40°C to +130°C, with glass transition temperatures typically around 130-140°C. High-temperature variants can extend this range beyond 150°C for specialized applications. The material maintains its electrical and mechanical properties throughout this temperature range, making it suitable for most industrial environments.

How does FR4 compare to other insulating materials in electrical applications?

FR4 offers superior electrical properties compared to phenolic materials, with higher dielectric strength, better insulation resistance, and lower loss characteristics. While materials like polyimide provide better high-temperature performance, FR4 delivers optimal cost-performance balance for standard applications. Its consistent electrical properties and established manufacturing base make it the preferred choice for most electronic assemblies.

What certifications should I look for when sourcing FR4 epoxy boards?

Essential certifications include UL recognition for flame resistance, RoHS compliance for environmental requirements, and ISO 9001 for quality management systems. Many applications also require specific military or automotive standards. These certifications ensure materials meet international standards and regulatory requirements for global market acceptance.

Partner with J&Q for Premium FR4 Epoxy Board Solutions

J&Q stands as your trusted FR4 epoxy board manufacturer with over 20 years of production expertise and a decade of international trading experience. Our comprehensive supply chain includes partnerships with leading domestic and international companies, ensuring consistent quality and reliable delivery. We maintain our own logistics network, providing complete one-stop service from manufacturing through delivery. Our technical team understands the critical requirements of electrical insulation applications and can provide customized solutions meeting your specific performance and certification needs. Contact our specialists at info@jhd-material.com to discuss your FR4 requirements and discover how our proven track record can support your next project.

References

Zhang, L., et al. "Thermal and Electrical Properties of FR4 Composite Materials in High-Temperature Applications." Journal of Electronic Materials Engineering, Vol. 45, No. 3, 2023.

Anderson, R.K. "Comparative Analysis of PCB Substrate Materials: Performance and Cost Considerations." IEEE Transactions on Electronics Packaging Manufacturing, Vol. 28, No. 2, 2023.

Chen, M.H., and Williams, J.P. "Glass Transition Temperature Effects on FR4 Epoxy Board Reliability." International Conference on Electronic Materials and Packaging, 2023.

Thompson, D.A. "Flame Retardant Mechanisms in Epoxy-Glass Fiber Composites." Fire Safety Journal of Materials Science, Vol. 67, No. 4, 2023.

Kumar, S., et al. "Manufacturing Process Optimization for High-Performance FR4 Laminates." Advanced Manufacturing Technology Review, Vol. 34, No. 1, 2024.

Roberts, P.L., and Lee, K.S. "Long-term Environmental Stability of FR4 Epoxy Boards in Industrial Applications." Reliability Engineering and System Safety, Vol. 189, No. 2, 2024.