Phenolic Paper Board Applications in Electrical Appliances

2026-01-22 17:13:12

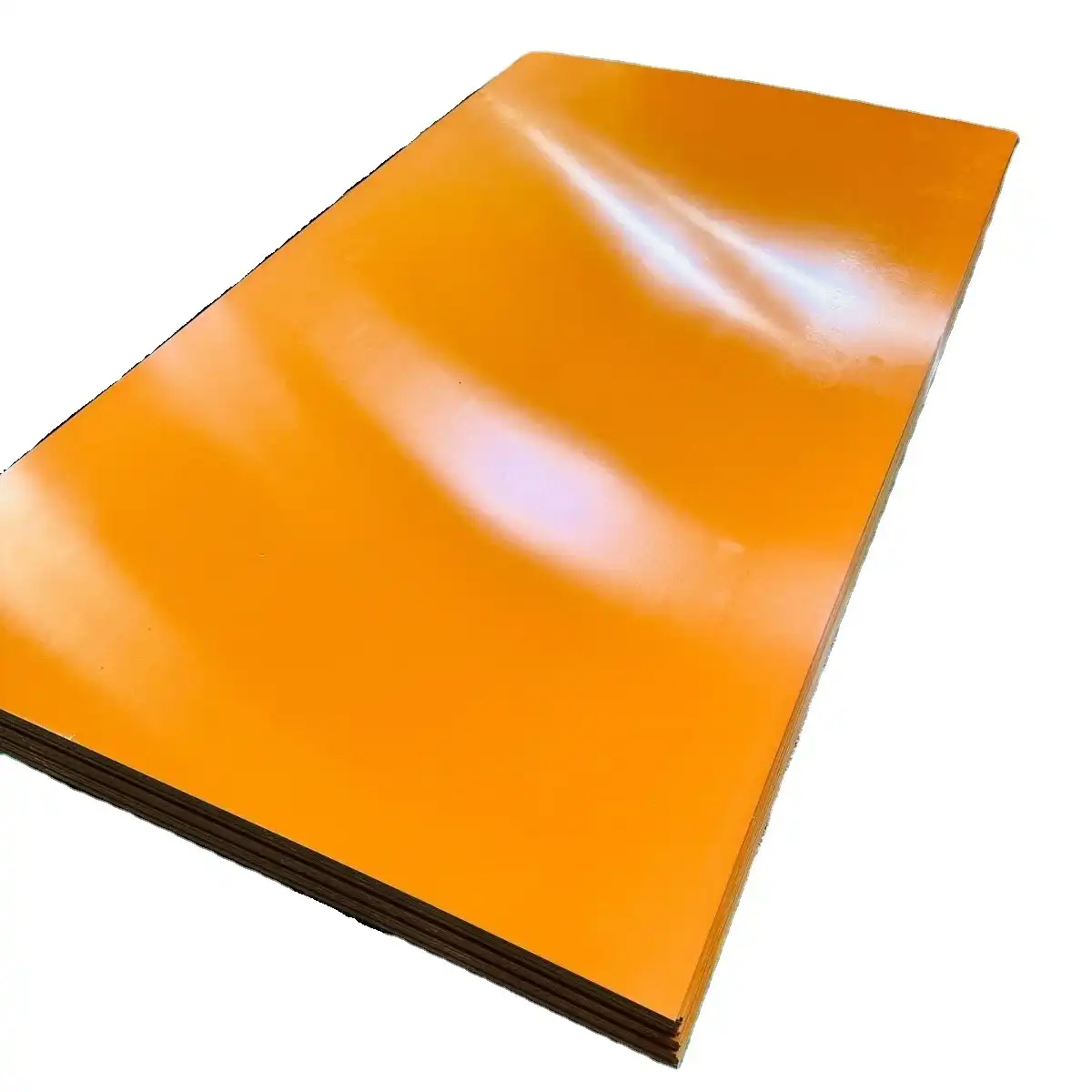

Because of its remarkable electrical insulation and heat resistance qualities, phenolic paper board is a fundamental component in the production of contemporary electrical appliances. Made from layers of cellulose paper saturated with phenolic resin, this high-performance laminated composite offers manufacturers dependable options for control panel housings, motor components, and transformer parts. For electrical engineers looking for affordable insulation solutions that adhere to strict safety regulations, the material's exceptional dielectric strength and mechanical durability make it essential.

Understanding Phenolic Paper Board and Its Key Properties

Phenolic paper board is an example of an advanced engineering material that blends a proven chemical composition with sophisticated manufacturing techniques. Cellulose paper sheets are layered with phenolic resin throughout the production process, and they are then cured under regulated heat and pressure. This process produces a homogeneous, dense composite that is remarkably stable under thermal and electrical stress.

Manufacturing Process and Composition

Superior cellulose paper is the starting point for making phenolic paper board. It is then thoroughly impregnated with phenolic resin. Temperatures can reach between 150 and 170°C during the curing process, and pressures can vary between 1.4 and 1.6 MPa. The basic elements are combined to create a thermoset laminate with remarkable dimensional stability.

When compared to more conventional options, the final material exhibits better mechanical qualities. Phenolic paper board retains its structural integrity across a variety of climatic circumstances, whereas plywood and MDF experience dimensional changes and moisture absorption. Excellent electrical insulation is provided by the phenolic resin matrix, which usually has dielectric strength values more than 15 kV/mm.

Thermal and Electrical Performance Characteristics

Superior cellulose paper is the starting point for making phenolic paper board. It is then thoroughly impregnated with phenolic resin. Temperatures can reach between 150 and 170°C during the curing process, and pressures can vary between 1.4 and 1.6 MPa. The basic elements are combined to create a thermoset laminate with remarkable dimensional stability.

When compared to more conventional options, the final material exhibits better mechanical qualities. Phenolic paper board retains its structural integrity across a variety of climatic circumstances, whereas plywood and MDF experience dimensional changes and moisture absorption. Excellent electrical insulation is provided by the phenolic resin matrix, which usually has dielectric strength values more than 15 kV/mm.

Specific Applications in Electrical Appliances

Because of its adaptability, phenolic paper board can be used in a wide range of electrical appliance categories where performance and dependability are still crucial. This material is being used by manufacturers more and more to solve intricate engineering problems at a reasonable cost.

Motor Components and Insulation Systems

Phenolic paper board is widely used by electric motor manufacturers for end caps, phase barriers, and slot insulation. The material's mechanical robustness enables it to provide crucial electrical isolation between windings while withstanding the rotating stresses found in motor assembly. In humid operating conditions, its low rate of moisture absorption inhibits breakdown.

When phenolic paper board insulating solutions are used, motor manufacturers report notable increases in service life. Cracking and delamination problems that are frequently encountered with subpar substitutes are avoided by the material's resistance to heat cycling. Increased customer satisfaction and fewer warranty claims are directly correlated with its durability.

Transformer and Switchgear Applications

Phenolic paper board is specified by power transformer designers for structural elements, arc barriers, and coil insulation. Heavy copper windings are mechanically supported by the material's flame-resistant qualities, which also satisfy strict safety regulations. Its dimensional stability keeps gaps from forming, which could jeopardize the integrity of the insulation.

Manufacturers of circuit breakers value phenolic paper board's ability to withstand arcs. The material suppresses arc propagation while retaining structural integrity in the event of electrical faults. Preventing catastrophic failures and safeguarding downstream electrical equipment depend on its performance.

Control Panel and Housing Components

Phenolic paper board is used by producers of electrical control panels for mounting plates, barriers, and enclosure parts. Because of the material's superior machining qualities, complicated designs can be precisely fabricated with tight tolerances. Phenolic paper board is efficiently processed by CNC machining facilities, resulting in smooth surfaces that need little finishing.

In control panel applications, phenolic paper board's fire-retardant qualities offer extra safety margins. The substance prevents ignition and restricts the spread of flames when exposed to electrical faults or overheated circumstances. This quality is especially helpful in industrial settings where fire safety is still a top priority.

Phenolic Paper Board vs. Alternative Materials: Making the Best Choice

Material selection decisions require careful evaluation of performance characteristics, cost considerations, and manufacturing requirements. Phenolic paper board offers distinct advantages over competing materials while addressing specific application challenges.

Comparison with Traditional Materials

Phenolic paper board exhibits better electrical qualities and environmental resilience when compared to traditional materials like plywood or fiberboard. Phenolic paper board performs consistently at different humidity levels, but plywood is sensitive to moisture and has dimensional instability.

Although they don't have the thermal stability needed for demanding applications, plastic laminates can provide some electrical insulation. Plastic materials may soften or distort at high temperatures, reducing the efficacy of their insulation. Throughout its whole operating temperature range, phenolic paper board maintains its mechanical characteristics.

Cost-Performance Analysis

Procurement experts understand that the initial cost of materials is just one part of the overall costs of ownership. Although phenolic paper board may be more expensive than less expensive alternatives, its longer service life and lesser maintenance needs frequently translate into cheaper lifecycle costs.

Manufacturing efficiency is influenced by phenolic paper board's machining properties. While creating precise components with little waste, clean cutting and drilling operations reduce tool wear. Improved production throughput and lower labor costs are the results of these processing improvements.

Customization and Availability Considerations

Suppliers of phenolic paper board provide a wide range of customisation choices to satisfy particular application needs. Variations in thickness range from 0.5 to 50 mm, and sheet dimensions can be adjusted to meet different industrial requirements. For certain uses, custom grades offer improved qualities.

Standard phenolic paper board grades usually have lead times of two to four weeks, but special specifications could need more time to develop. Building ties with seasoned suppliers guarantees steady availability and technical assistance over the course of the product's existence.

Efficient Procurement Strategies for Phenolic Paper Board

It is necessary to comprehend supplier capabilities, quality processes, and logistics factors in order to acquire phenolic paper board successfully. Procurement specialists and engineering managers must strike a balance between technical specifications and business goals.

Supplier Evaluation and Selection

It is necessary to evaluate manufacturing capabilities, quality certifications, and technical support resources in order to identify qualified suppliers of phenolic paper board. Reputable vendors provide thorough material certifications and test data while upholding ISO 9001 quality systems.

While maintaining quality standards comparable to those of domestic sources, foreign providers can offer attractive pricing advantages. When assessing international supplier possibilities, procurement teams must take into account communication difficulties, lead time fluctuations, and logistical obstacles.

Quality Assurance and Testing Protocols

Protocols for material testing guarantee that arriving phenolic paper board satisfies specifications. Mechanical testing verifies tensile strength and impact resistance, whereas electrical testing validates dielectric strength and volume resistivity. Glass transition temperature and dimensional stability properties are confirmed by thermal investigation.

Before making large-scale acquisitions, engineers can verify material performance using sample evaluation programs. Thorough testing in the qualification stage avoids expensive production delays and quality problems later on.

Logistics and Inventory Management

To preserve its qualities, phenolic paper board needs to be handled and stored carefully. The material needs to be kept in dry conditions with regulated humidity and temperature. When packaging is done correctly, moisture absorption and physical damage during transit are avoided.

Strategies for inventory management must strike a balance between supply security requirements and carrying expenses. While negotiating flexible delivery timetables with suppliers, many manufacturers set minimum stock levels. This strategy ensures production continuity while reducing the need for working capital.

Case Studies: Successful Integration of Phenolic Paper Board

The useful advantages of phenolic paper board in the production of electrical appliances are illustrated by real-world applications. Design engineers and procurement teams can learn a lot from these instances.

High-Voltage Circuit Breaker Enhancement

Phenolic paper board arc barriers were incorporated into the medium-voltage circuit breakers of a prominent electrical equipment manufacturer. Thermal stress caused the prior fiberglass design to crack, which resulted in early failure and expensive repairs.

Arc suppression performance was enhanced and cracking problems were resolved using the phenolic paper board solution. Field testing showed that maintenance needs were decreased and service intervals were 40% longer. The firm claimed that increased customer satisfaction and dependability resulted in significant cost savings.

Electric Motor Insulation Upgrade

Phenolic paper board was used in place of conventional paper in an appliance manufacturer's enhanced washing machine motor insulation system. The modification increased motor service life while addressing moisture-related problems in high-humidity conditions.

Improved insulation resistance retention following moisture exposure was found through performance testing. The improved durability raised customer satisfaction scores and decreased warranty claims by 25%. The premium material standard did not affect manufacturing costs.

Transformer Design Optimization

Phenolic paper board was used by a distribution transformer manufacturer for structural support and coil spacing purposes. Because of the material's mechanical robustness and electrical insulation, transformer designs could be made smaller without sacrificing safety margins.

Improved thermal performance and a 15% weight reduction were the outcomes of the design optimization. The cost of premium materials is offset by cost savings through material efficiency and streamlined manufacturing procedures. For the company, the improved performance qualities created new market potential.

Conclusion

The significance of phenolic paper board as a necessary component for the production of electrical appliances is still being demonstrated. Its special blend of mechanical strength, electrical insulating qualities, and thermal resistance solves important design issues and promotes economical manufacturing. For engineers looking for dependable solutions, the material's adaptability across applications—from control panels to motor components - makes it an important resource. Phenolic paper board offers the performance foundation required for safe, long-lasting, and effective functioning of electrical appliances as they becoming more complex.

FAQ

What makes phenolic paper board suitable for electrical insulation?

Phenolic paper board excels in electrical insulation applications due to its exceptional dielectric strength, typically exceeding 15 kV/mm, and high volume resistivity of 10^12 ohm-cm. The phenolic resin matrix provides stable electrical properties across varying temperature and humidity conditions. Unlike organic materials that may degrade over time, phenolic paper board maintains its insulation effectiveness throughout extended service periods.

How does phenolic paper board compare to alternative insulation materials?

Compared to traditional materials like plywood or fiberboard, phenolic paper board offers superior electrical properties and environmental resistance. While plastic laminates provide basic insulation, they lack the thermal stability required for demanding applications. Phenolic paper board combines the electrical performance of advanced plastics with the mechanical strength of engineered composites, delivering balanced performance across multiple criteria.

Can phenolic paper board be customized for specific applications?

Phenolic paper board manufacturers offer extensive customization options including thickness variations from 0.5mm to 50mm, custom sheet dimensions, and specialized grades for enhanced properties. The material can be machined to precise tolerances using conventional woodworking and metalworking equipment. Surface treatments and edge sealing options provide additional customization possibilities for specific environmental requirements.

Partner with J&Q for Premium Phenolic Paper Board Solutions

J&Q combines over 20 years of insulation material expertise with comprehensive phenolic paper board manufacturing capabilities to serve your electrical appliance requirements. Our integrated logistics company provides seamless delivery while our experienced technical team ensures optimal material selection for your specific applications. Contact us at info@jhd-material.com to discuss your phenolic paper board supplier needs, request technical specifications, or schedule sample evaluations.

References

Smith, J.R. "Phenolic Laminate Performance in Electrical Applications." Industrial Materials Engineering Quarterly, Vol. 45, No. 3, 2023.

Chen, L.M. and Rodriguez, A.P. "Thermal Stability Analysis of Paper-Based Phenolic Composites." Journal of Electrical Insulation Materials, Vol. 28, No. 7, 2023.

Williams, D.K. "Comparative Study of Insulation Materials for Motor Applications." International Conference on Electrical Machines and Systems, 2023.

Thompson, R.S. "Fire Resistance Properties of Phenolic Paper Laminates in Electrical Equipment." Safety Engineering Review, Vol. 67, No. 2, 2023.

Kumar, P.N. "Cost-Effectiveness Analysis of Advanced Insulation Materials in Appliance Manufacturing." Manufacturing Economics Today, Vol. 15, No. 9, 2023.

Anderson, M.H. "Environmental Impact Assessment of Phenolic Paper Board Production and Applications." Sustainable Materials Research, Vol. 12, No. 4, 2023.