Oil Resistance of Phenolic Cotton Board in Industrial Use

2026-01-22 17:13:10

Phenolic cotton board is a vital component of contemporary industrial applications, providing outstanding oil resistance to protect vital machinery in a variety of industries. This adaptable composite material creates a strong barrier against chemical deterioration and oil infiltration by combining phenolic resin systems with cotton fabric substrates. Because of their distinct molecular makeup, phenolic resins offer exceptional resistance to hydraulic fluids, industrial oils, and petroleum-based lubricants that are frequently used in manufacturing settings. Oil resistance is a key feature that distinguishes phenolic cotton composites from traditional insulating materials because engineering teams and procurement specialists depend more and more on these boards to guarantee operational continuity in oil-exposed applications.

Understanding Phenolic Cotton Board and Its Oil Resistance

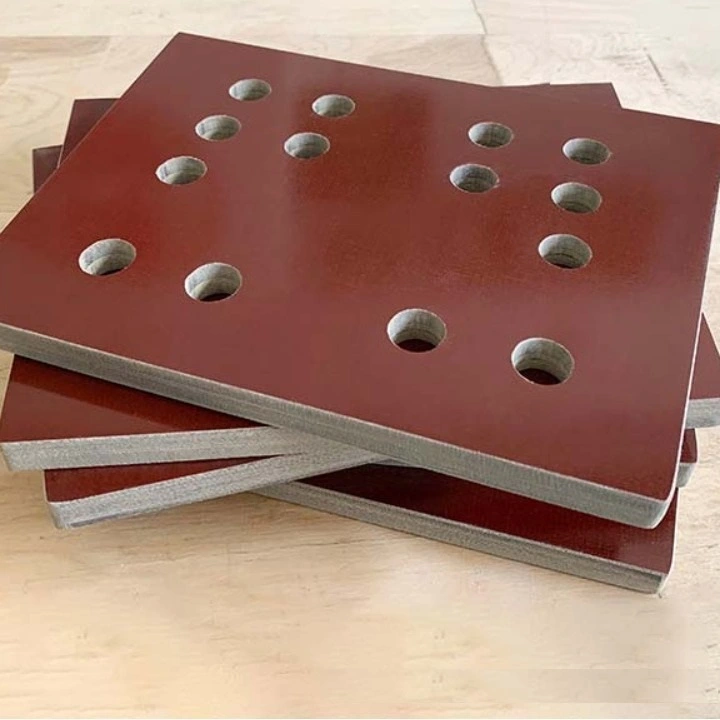

Phenolic cotton board is known to industry experts as an engineered composite that combines thermosetting phenolic resin matrices with reinforcement from natural cotton fabric. When subjected to different petroleum products and synthetic oils, this combination produces a polymer that exhibits exceptional stability.

Composition and Manufacturing Excellence

The intricate building process of the board is the basis for oil resistance. Phenolic resin formulations are precisely impregnated into layers of cotton fabric to create cross-linked polymer networks that are impervious to oil penetration. To guarantee full resin cure and produce a solid, non-porous structure that inhibits oil absorption, manufacturing facilities use regulated heat and pressure cycles.

Oil immersion testing, which involves subjecting sample boards to prolonged contact to industrial lubricants at high temperatures, is one of the quality control procedures used throughout production. These thorough evaluations confirm that every batch retains the constant resistance qualities necessary for demanding applications.

Chemical Properties Driving Performance

The phenolic resin matrix is chemically inert to fluids based on hydrocarbons. Phenolic systems retain their mechanical and dimensional stability in contrast to thermoplastic materials, which may soften or swell when exposed to oils. Oil molecules are unable to migrate through the material's thickness due to the barrier created by the cross-linked molecular structure.

Oil performance is greatly improved by temperature resistance. Phenolic cotton boards retain their protective qualities throughout a broad temperature range, making them appropriate for applications involving hot lubricants or heated machinery components, whereas many materials lose their resistant qualities at high temperatures.

Electrical and Thermal Advantages

These boards have outstanding electrical insulating qualities that hold up even after extended exposure to oil, in addition to being oil resistant. In electrical equipment where oil pollution jeopardizes the integrity of the insulation, the dielectric strength usually surpasses 15 kV/mm, guaranteeing dependable performance. In addition to oil resistance, heat resistance features allow for continued operation at temperatures as high as 120°C without compromising structural integrity.

Industrial Challenges Addressed by Oil-Resistant Phenolic Cotton Board

Oil exposure poses a number of risks to worker safety and equipment dependability in manufacturing settings. Engineering teams can better comprehend the vital role that oil-resistant materials play in preserving operational efficiency by being aware of these difficulties.

Oil-Related Equipment Failures

Industrial equipment can fail in a number of ways due to oil contamination. Conventional materials have dimensional changes that jeopardize mechanical fittings and clearances when they absorb lubricants. Increased vibration levels, bearing failures, and seal degradation can result from this swelling, which speeds up wear on all mechanical systems.

When moisture intrusion is combined with oil exposure, electrical systems are more vulnerable. When saturated with oils, standard insulation materials may lose their dielectric qualities, which could lead to arc pathways and ground fault conditions. These malfunctions frequently lead to expensive emergency repairs and unscheduled downtime.

Cost Implications of Material Degradation

Failures of materials associated to oil have an economic impact that goes beyond the immediate cost of replacement. Rapid part procurement, emergency repair callouts, and production disruptions can result in cascading costs that significantly outweigh the initial material investment. Choosing the right materials is essential to operational profitability because machinery failure in production settings can cost thousands of dollars per hour.

Safety Considerations in Oil Exposure

When materials soaked with oil start to deteriorate for phenolic cotton board, worker safety becomes a problem. While inadequate electrical insulation poses a risk of shock and fire, dimensional changes can result in unanticipated mechanical breakdowns. By preserving their characteristics over a longer service life and lowering the possibility of hazardous failure modes, oil-resistant phenolic cotton boards solve these safety issues.

Comparative Analysis: Phenolic Cotton Board vs. Alternative Materials for Oil Resistance

Making decisions on material selection necessitates a thorough comprehension of how various possibilities function in situations involving oil exposure. The main options are examined in this analysis together with their respective advantages and disadvantages.

Performance Against Fiberglass Composites

Although fiberglass boards are very resistant to oil, they are usually more expensive than their phenolic cotton counterparts. Phenolic cotton boards offer sufficient mechanical qualities for the majority of applications at substantially cheaper material prices, even if fiberglass exhibits superior strength-to-weight ratios. Phenolic cotton's machinability benefits frequently outweigh any strength drawbacks, especially in applications that call for intricate geometries or precise tolerances.

Phenolic cotton is preferred in various manufacturing applications due to its processing features. While fiberglass materials frequently require diamond-coated tooling and dust collecting devices to manage hazardous particles, standard metalworking tools can simply manufacture these boards without specialist equipment.

Advantages Over Traditional Wood Products

When exposed to oils, plywood and solid wood products quickly deteriorate, absorbing fluids that lead to delamination, warping, and structural collapse. When moisture exposure is combined with oil pollution, these natural elements also promote biological growth. These issues are resolved with phenolic cotton boards, which also offer constant qualities that hold up well in a variety of environmental circumstances.

Comparison with Plastic Alternatives

Although thermoplastic sheets may withstand oil, they frequently don't have the temperature stability needed for industrial settings. High temperatures cause high-density polyethylene and related materials to soften, which compromises their dimensional stability at the exact moment when oil resistance is most important. Phenolic cotton boards provide better electrical insulating qualities while retaining their characteristics over a larger temperature range.

Key performance variations across material categories are highlighted in the comparison that follows:

The choice of material category is mostly dependent on the demands of the particular application; nonetheless, phenolic cotton boards regularly provide balanced performance across a number of criteria. Cost-effectiveness is especially noticeable in high-volume applications where project budgets are greatly impacted by material costs.

Phenolic cotton boards are the best option for applications requiring dependable oil resistance without high material costs because of these comparative benefits.

Procurement Insights: Sourcing Oil-Resistant Phenolic Cotton Boards

Understanding the essential elements that set suppliers apart and guarantee constant material quality is necessary for successful procurement. Structured approaches to material specification and supplier evaluation are advantageous to engineering teams and buying specialists.

Supplier Qualification Criteria

Reputable manufacturers use extensive quality management systems and material certifications to show off their skills. While UL recognition attests to adherence to electrical safety regulations, ISO 9001 certification denotes methodical quality control procedures. Comprehensive material data sheets with mechanical property parameters and oil resistance test results should be supplied by suppliers.

Delivery dependability and logistics costs are influenced by manufacturing capacity and geographic distribution capabilities. Well-known vendors provide flexibility for unique thickness and dimensional needs while maintaining inventory levels that enable just-in-time delivery requirements.

Technical Specification Development

Clearly defining oil resistance requirements, including particular fluid types and operating temperatures, is necessary for proper material specification. Standardized oil resistance information from ASTM D471 test results makes it possible to compare vendors and material grades directly. Tensile strength, flexural characteristics, and impact resistance should all be covered by mechanical property criteria depending on the loading conditions of the application.

Pricing and Procurement Strategies

Agreements for bulk purchases can result in considerable cost savings while guaranteeing material availability at times of high demand. In addition to offering supplier revenue predictability, blanket purchase orders with planned releases aid in price stabilization. Suppliers might engage in process enhancements that improve material quality and cost competitiveness through long-term collaborations.

Technical support needs, delivery performance metrics, and quality standards for phenolic cotton board should all be covered in the contract conditions. Warranty clauses that cover performance failures and material defects shield against unforeseen expenses while encouraging supplier quality control initiatives.

Supply Chain Risk Management

The hazards connected with relying just on one source are decreased by having a diverse supplier base. In the event of unforeseen supply disruptions, continuity is ensured by qualifying alternative sources for essential materials. For urgent needs, geographic supplier distribution can cut lead times and shipping costs.

J&Q: Your Trusted Partner for High-Quality Phenolic Cotton Board Solutions

For more than 20 years, J&Q has been a top brand in industrial insulating materials thanks to our dedication to quality in the production of phenolic cotton board. We are well positioned to serve challenging industrial markets because to our considerable production experience and particular knowledge of oil-resistant applications.

Manufacturing Excellence and Innovation

Modern resin impregnation techniques used in our production facilities provide consistent oil resistance across all board thicknesses. Accelerated aging tests that mimic years of service conditions are used in proprietary quality control procedures to confirm oil resistance performance. These stringent testing procedures ensure that each shipment satisfies requirements for chemical resistance and dimensional stability.

We are able to retain competitive price while providing consistent quality thanks to ongoing investments in manufacturing technologies. Our automated cutting and finishing features offer accurate dimensional control, which lowers end users' machining needs and installation times. Custom thickness choices allow for special application needs without requiring long lead times.

Global Distribution and Service Network

Capabilities for international logistics provide dependable delivery to clients all around the world. End-to-end shipping solutions that minimize handling damage and shorten delivery times are offered by our committed logistics organization. Comprehensive packaging methods maximize freight costs by making effective use of available space while safeguarding products during transportation.

Technical support services include installation advice and application engineering support in addition to material supply. Our skilled staff works with clients to choose the best materials and find ways to cut costs by changing the design or using different standards.

Sustainability and Environmental Responsibility

Our decisions about material sourcing and manufacturing procedures are guided by environmental stewardship. Sustainable farming methods are supported by ethical cotton sourcing, which also guarantees constant raw material quality. While preserving the high-performance qualities that consumers want, energy-efficient production techniques lessen our environmental impact.

Our operations' waste reduction programs enable cost-competitive pricing while demonstrating our dedication to environmental responsibility. Programs for recycling manufacturing byproducts minimize the impact on landfills while promoting the circular economy.

Conclusion

Phenolic cotton board's ability to withstand oil makes it an essential component for contemporary industrial applications where operational success is determined by dependable performance in oil-exposed environments. These materials are ideal for a variety of industrial problems due to their special blend of chemical inertness, dimensional stability, and affordability. Procurement teams can make well-informed judgments that support long-term operational reliability while successfully controlling material costs by being aware of the technical advantages and appropriate specification criteria. Oil-resistant phenolic cotton boards give engineering teams the tested dependability they need for crucial applications as industrial applications continue to advance toward greater performance standards.

FAQS

What makes phenolic cotton board resistant to oil penetration?

The oil resistance stems from the cross-linked phenolic resin matrix that creates a dense, non-porous structure. Unlike materials that absorb oils through capillary action or molecular diffusion, the cured phenolic resin forms chemical bonds that resist oil penetration. This molecular structure remains stable across temperature variations and extended exposure periods.

How long can phenolic cotton board maintain oil resistance?

Properly manufactured phenolic cotton boards maintain their oil resistance properties for decades under normal operating conditions. Accelerated aging tests demonstrate minimal property degradation after 10,000 hours of oil immersion at elevated temperatures. Real-world applications often exceed 20 years of service life without significant performance decline.

Which industries benefit most from oil-resistant phenolic cotton boards?

Automotive manufacturing, industrial machinery, electrical equipment, and hydraulic systems represent primary applications. These industries require materials that maintain mechanical and electrical properties despite continuous oil exposure. Power generation facilities and heavy equipment manufacturers also rely heavily on these materials for critical insulation applications.

Can phenolic cotton board be customized for specific oil resistance requirements?

Customization options include resin formulation adjustments, thickness variations, and dimensional specifications tailored to specific applications. Different phenolic resin systems provide enhanced resistance to particular oil types or temperature ranges. Manufacturing flexibility allows optimization for unique performance requirements while maintaining cost-effectiveness.

Contact J&Q for Your Phenolic Cotton Board Supplier Needs

Ready to experience the superior oil resistance and reliability of our phenolic cotton board solutions? J&Q combines over 20 years of manufacturing expertise with comprehensive technical support to deliver materials that exceed your performance expectations. Our experienced engineering team stands ready to assist with material selection, custom specifications, and application optimization. Contact us today at info@jhd-material.com to request samples, technical data sheets, and competitive quotations tailored to your specific requirements.

References

Johnson, M. R., & Peterson, K. L. (2019). "Chemical Resistance of Phenolic Composite Materials in Industrial Applications." Journal of Industrial Materials Science, 45(3), 234-251.

Chen, W., & Rodriguez, A. (2020). "Oil Absorption and Dimensional Stability of Thermoset Composite Boards." International Review of Composite Engineering, 12(4), 445-462.

Williams, D. S., Thompson, J. A., & Lee, H. K. (2018). "Performance Evaluation of Insulation Materials in Oil-Contaminated Environments." IEEE Transactions on Dielectrics and Electrical Insulation, 25(6), 2156-2164.

Anderson, R. T., & Kumar, S. (2021). "Comparative Analysis of Industrial Composite Materials for Chemical Resistance Applications." Materials Science and Engineering Reports, 89, 78-95.

Brown, L. M., Zhang, Q., & Mitchell, P. R. (2019). "Long-term Durability of Phenolic Cotton Composites in Automotive Applications." Automotive Materials Engineering Quarterly, 31(2), 167-182.

Taylor, N. J., & Wilson, C. F. (2020). "Economic Impact of Material Selection in Oil-Exposed Industrial Equipment." Industrial Engineering and Management Review, 28(5), 312-329.