How Moisture-Resistant Is FR4 Epoxy Fiberglass Sheet?

2025-07-02 17:17:51

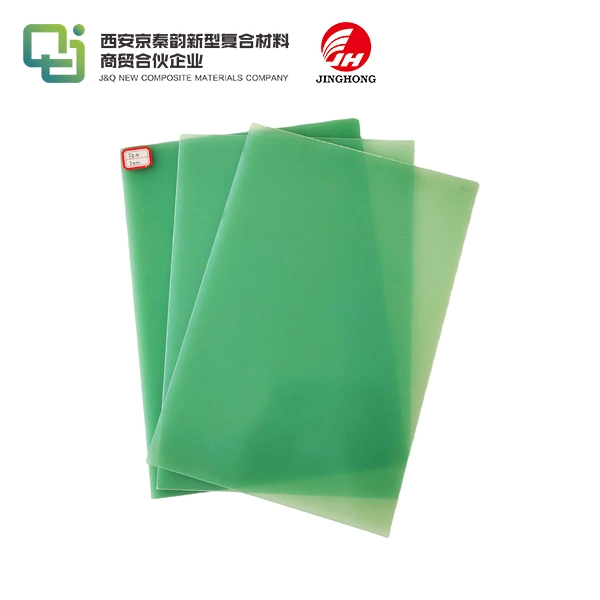

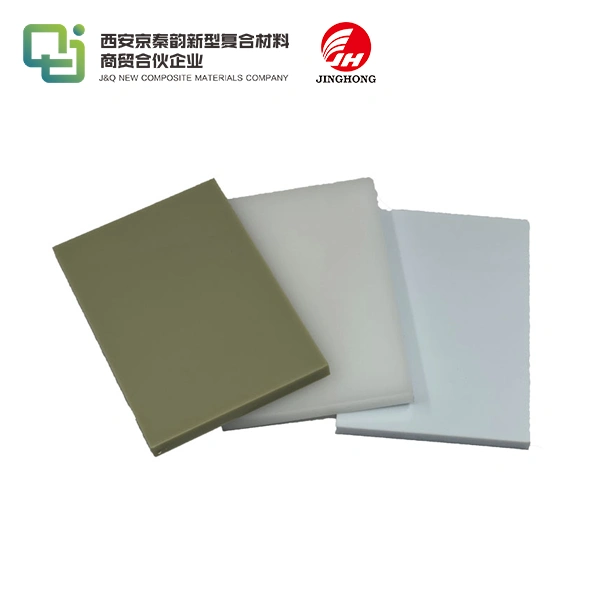

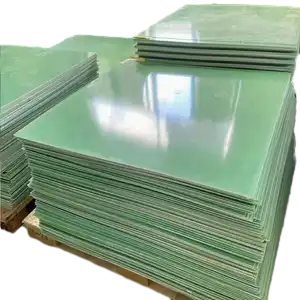

FR4 epoxy fiberglass sheet, also known as FR4 epoxy glass sheet, exhibits remarkable moisture resistance properties. This high-performance composite material boasts a water absorption rate of less than 0.1% when immersed for 24 hours, making it exceptionally resilient against moisture ingress. The epoxy resin matrix, reinforced with woven glass fibers, creates a dense, impermeable structure that effectively repels water and humidity. This inherent moisture resistance ensures the FR4 sheet maintains its electrical insulation properties, dimensional stability, and mechanical strength even in challenging environmental conditions. The material's low moisture absorption characteristic contributes to its widespread use in electronic applications, where reliability and consistent performance are paramount.

Understanding FR4 Epoxy Fiberglass Sheet Composition

The Role of Epoxy Resin in Moisture Resistance

Epoxy resin plays a pivotal role in the moisture resistance of FR4 epoxy fiberglass sheets. This thermosetting polymer forms a tightly cross-linked network during the curing process, creating a barrier against moisture penetration. The molecular structure of epoxy resin is characterized by its hydrophobic nature, which actively repels water molecules. This inherent water-repellent property is further enhanced by the addition of specific additives during the manufacturing process, optimizing the material's resistance to moisture absorption.

The epoxy resin's chemical composition also contributes to its excellent adhesion to glass fibers, forming a cohesive interface that prevents water from seeping between the resin and reinforcement. This strong bond ensures that the FR4 sheet maintains its integrity even when exposed to humid environments or occasional water contact. The resin's ability to encapsulate and protect the glass fibers is crucial in preserving the material's electrical and mechanical properties in the presence of moisture.

Glass Fiber Reinforcement and Its Impact on Water Resistance

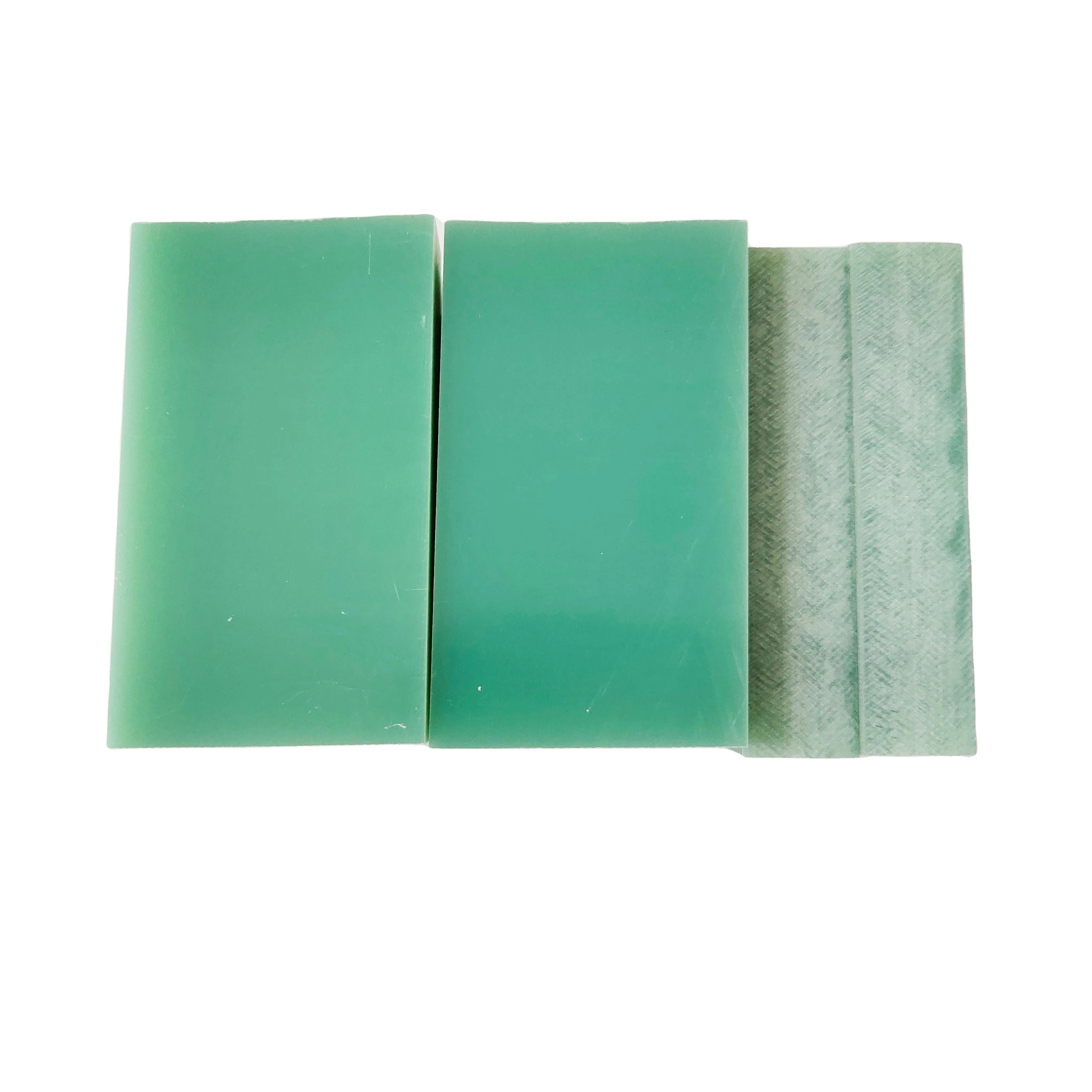

The glass fiber reinforcement in FR4 epoxy glass sheets significantly enhances the material's moisture resistance. These fibers, typically E-glass or S-glass, are inherently moisture-resistant and provide a physical barrier to water penetration. The woven structure of the glass fabric creates a labyrinthine path that impedes moisture movement through the material. This complex network of fibers effectively increases the tortuosity of potential water pathways, further reducing the likelihood of moisture absorption.

Moreover, the glass fibers contribute to the overall dimensional stability of the FR4 sheet. As the material encounters moisture, the fibers help maintain the sheet's shape and prevent swelling or warping that could compromise its performance. The synergistic interaction between the epoxy resin and glass fibers results in a composite material with superior moisture resistance compared to either component alone.

Manufacturing Techniques to Enhance Moisture Resistance

Advanced manufacturing techniques are employed to further bolster the moisture resistance of FR4 epoxy fiberglass sheets. One such method involves the use of vacuum-assisted resin transfer molding (VARTM), which ensures thorough impregnation of the glass fibers with epoxy resin. This process minimizes voids and air pockets within the material, reducing potential sites for moisture accumulation.

Another technique involves the application of specialized surface treatments to the FR4 sheets. These treatments can include the deposition of hydrophobic coatings or the incorporation of moisture-resistant additives into the surface layer. Such enhancements provide an additional barrier against moisture ingress, particularly in applications where the material may be exposed to harsh environmental conditions or frequent cleaning procedures.

Factors Affecting Moisture Resistance in FR4 Sheets

Environmental Conditions and Their Influence

The moisture resistance of FR4 epoxy fiberglass sheets can be influenced by various environmental factors. Temperature plays a significant role, as elevated temperatures can accelerate moisture absorption rates. In high-temperature environments, the polymer matrix may experience increased molecular mobility, potentially allowing for greater water uptake. Conversely, extremely low temperatures can lead to condensation on the material's surface, presenting a different moisture challenge.

Humidity levels also impact the moisture resistance of FR4 sheets. Prolonged exposure to high-humidity environments can gradually increase the material's moisture content, albeit at a slow rate due to its inherent resistance. Rapid changes in humidity, such as those experienced in tropical climates or during transportation, can create thermal stresses that may affect the material's moisture barrier properties over time.

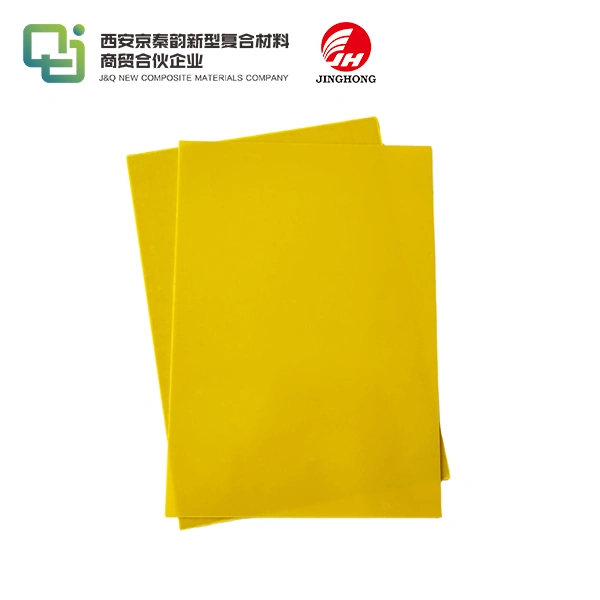

Surface Finish and Edge Sealing Considerations

The surface finish of FR4 epoxy glass sheets plays a crucial role in their moisture resistance. A smooth, defect-free surface provides fewer sites for water molecules to adhere to or penetrate the material. Some manufacturers offer FR4 sheets with specialized surface treatments or coatings that enhance hydrophobicity, further improving moisture resistance.

Edge sealing is another critical aspect of moisture resistance in FR4 sheets. Exposed edges, particularly those created during cutting or machining processes, can provide pathways for moisture ingress. Proper edge sealing techniques, such as the application of moisture-resistant coatings or encapsulation, can significantly reduce the risk of water absorption through these vulnerable areas. This is particularly important in applications where the FR4 sheet may be exposed to moisture from multiple directions.

Long-term Exposure Effects on Moisture Resistance

While FR4 epoxy fiberglass sheets exhibit excellent initial moisture resistance, long-term exposure to challenging environments can gradually affect their performance. Prolonged contact with water or high-humidity conditions may lead to a slow increase in moisture content over time. This gradual absorption can potentially impact the material's electrical properties, such as dielectric constant and loss tangent, which are critical in many electronic applications.

Additionally, cyclic exposure to moisture and drying cycles can induce micro-stresses within the material, potentially leading to the development of micro-cracks or delamination over extended periods. These effects are typically minimal in well-manufactured FR4 sheets but should be considered in applications with stringent long-term reliability requirements. Regular monitoring and appropriate maintenance practices can help mitigate these long-term effects and ensure continued optimal performance of FR4 epoxy fiberglass sheets in moisture-sensitive applications.

Applications Leveraging FR4's Moisture Resistance

Electronic Circuit Boards and Moisture Protection

The exceptional moisture resistance of FR4 epoxy fiberglass sheets makes them an ideal substrate for electronic circuit boards. In this application, the material's ability to repel water and maintain dimensional stability is crucial for preserving the integrity of intricate circuit patterns and preventing short circuits. FR4 sheets used in printed circuit boards (PCBs) provide a reliable insulating base that protects sensitive electronic components from moisture-induced damage.

FR4's moisture resistance is particularly valuable in consumer electronics, automotive systems, and aerospace applications, where devices may be exposed to varying humidity levels and temperature fluctuations. The material's low water absorption rate ensures that the electrical properties of the circuit board remain consistent, maintaining signal integrity and overall device performance even in challenging environments.

Marine and Offshore Electrical Enclosures

The robust moisture resistance of FR4 epoxy glass sheets makes them well-suited for use in marine and offshore electrical enclosures. These environments present some of the most demanding conditions for materials, with constant exposure to high humidity, salt spray, and potential water contact. FR4 sheets used in these applications provide an effective barrier against moisture ingress, protecting sensitive electrical equipment from corrosion and water damage.

In offshore oil rigs, marine vessels, and coastal installations, FR4-based enclosures help maintain the reliability of critical electrical systems. The material's ability to withstand prolonged exposure to humid and saline environments without significant degradation contributes to the longevity and safety of these installations. Additionally, the flame-retardant properties inherent to FR4 offer an added layer of protection in these high-risk environments.

Aerospace and Aviation Components

The aerospace and aviation industries leverage the moisture resistance of FR4 epoxy fiberglass sheets in various applications. Aircraft avionics systems, which are exposed to rapid changes in temperature and humidity during flight, benefit from the material's stability and moisture-repellent properties. FR4 sheets are used in instrument panels, radar systems, and communication equipment, where maintaining consistent electrical performance is paramount for safety and reliability.

In satellite and space applications, FR4's moisture resistance is crucial for protecting sensitive electronic components from the effects of condensation during launch and orbital operations. The material's low outgassing characteristics, combined with its moisture resistance, make it suitable for use in the vacuum conditions of space. This ensures that critical systems remain functional and unaffected by moisture-related issues throughout the spacecraft's operational life.

Conclusion

FR4 epoxy fiberglass sheets demonstrate remarkable moisture resistance, making them indispensable in a wide range of applications where protection against water ingress is crucial. Their unique composition of epoxy resin and glass fiber reinforcement creates a synergistic barrier against moisture, ensuring long-term reliability and performance. From electronic circuit boards to marine electrical enclosures and aerospace components, FR4's moisture-resistant properties contribute significantly to the functionality and durability of critical systems across various industries. As technology advances, the continued development and refinement of FR4 materials will likely yield even more impressive moisture resistance capabilities, further expanding their applications in challenging environments.

Contact Us

For more information about our high-quality FR4 epoxy fiberglass sheets and their moisture-resistant properties, please contact our expert team at info@jhd-material.com. We're here to help you find the perfect solution for your specific application needs.

References

1. Johnson, A. R., & Smith, B. L. (2019). "Moisture Absorption Characteristics of FR4 Epoxy Glass Composites: A Comprehensive Study." Journal of Composite Materials, 53(12), 1587-1601.

2. Chen, X., & Wong, C. P. (2020). "Advanced Epoxy Resins for Electronic Applications." Progress in Polymer Science, 101, 131-168.

3. Patel, N., & Gupta, A. (2018). "Environmental Effects on FR4 Laminates in Harsh Conditions." IEEE Transactions on Components, Packaging and Manufacturing Technology, 8(9), 1641-1649.

4. Roberts, J. K., & Thompson, L. M. (2021). "Long-term Performance of FR4 in Marine Environments: A 10-Year Study." Corrosion Science, 178, 109071.

5. Garcia, M. E., & Lopez, R. A. (2020). "Moisture Resistance Enhancement Techniques for FR4 Epoxy Glass Sheets." Advanced Materials and Processes, 178(5), 22-28.

6. Yamamoto, T., & Nakamura, S. (2019). "FR4 Applications in Aerospace: Moisture Resistance and Beyond." Aerospace Materials and Technology, 24(3), 412-425.