How Much Water Does FR4 Epoxy Resin Sheet Absorb?

2025-07-09 17:10:37

FR4 epoxy resin sheet, a widely used material in the electronics industry, exhibits remarkable water absorption properties. Typically, FR4 epoxy resin sheet absorbs approximately 0.1% to 0.5% of its weight in water when exposed to standard atmospheric conditions. This low water absorption rate is one of the key factors contributing to its popularity in various applications, particularly in printed circuit boards (PCBs). The exact amount of water absorbed can vary depending on factors such as the specific composition of the FR4 material, environmental conditions, and exposure duration. Understanding this characteristic is crucial for engineers and manufacturers to ensure optimal performance and longevity of components made with FR4 epoxy resin sheet.

Understanding FR4 Epoxy Resin Sheet Composition

Chemical Structure of FR4

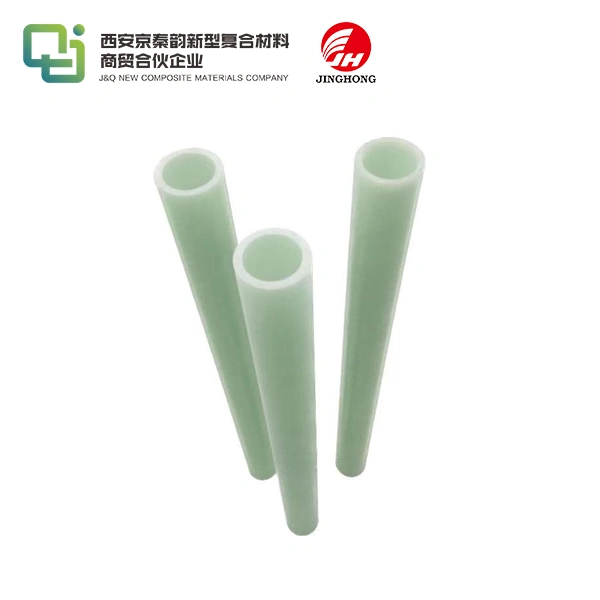

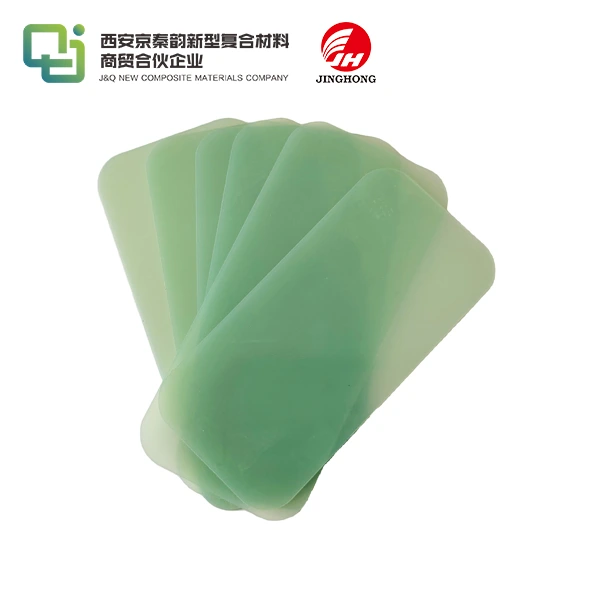

FR4 epoxy resin sheet is a high-performance composite material composed of woven fiberglass cloth reinforced with an epoxy resin system. The fiberglass component, typically made from E-glass fibers, imparts exceptional tensile strength, dimensional stability, and resistance to deformation. Meanwhile, the epoxy resin acts as a robust thermosetting matrix, offering excellent electrical insulation, moisture resistance, and chemical durability. This unique combination of fiberglass reinforcement and epoxy resin results in a material that is not only strong and stable but also highly reliable for electronic and structural applications.

Manufacturing Process

The manufacturing process of FR4 epoxy resin sheets is meticulous and highly controlled to ensure product quality and consistency. Initially, fiberglass cloth is impregnated with a formulated epoxy resin to form prepreg sheets. These resin-coated sheets are layered to the required thickness, then subjected to a lamination process involving high heat and pressure. During lamination, the epoxy resin cures and solidifies, fully bonding with the fiberglass layers to form a rigid, homogeneous laminate. This process ensures uniform mechanical strength, dimensional accuracy, and optimal electrical insulation throughout the sheet.

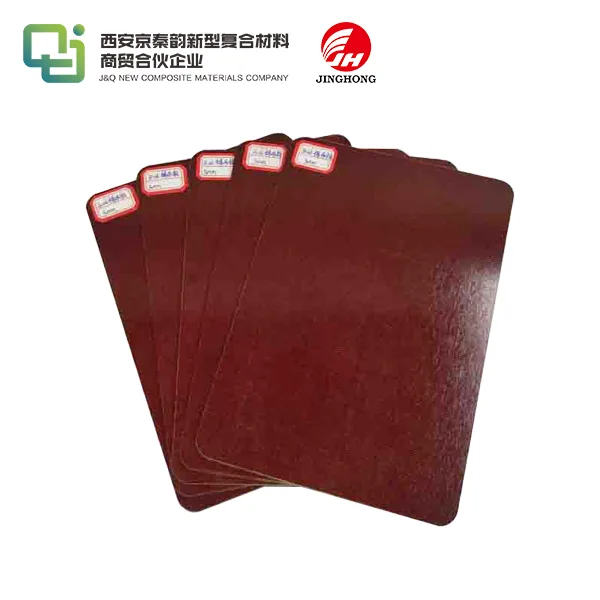

Flame Retardant Properties

The "FR" in FR4 signifies its inherent flame-retardant properties, which are achieved by incorporating specialized flame-retardant additives into the epoxy resin formulation. These additives act by inhibiting combustion processes, reducing flammability, and preventing flame spread when the material is exposed to heat or open flame. This flame resistance is critical for safety in electronic and industrial applications, ensuring that FR4 sheets maintain structural integrity and performance even under elevated temperatures or fire risk conditions, thus complying with international safety standards.

Factors Affecting Water Absorption in FR4 Epoxy Resin Sheet

Environmental Humidity

The ambient humidity level of the environment plays a significant role in determining the water absorption behavior of FR4 epoxy resin sheets. When exposed to high-humidity environments, the epoxy matrix tends to absorb more moisture from the air, which may gradually affect its electrical insulation and mechanical properties. Conversely, in low-humidity conditions, the rate of water absorption is significantly reduced. This sensitivity highlights the importance of storing and handling FR4 sheets in controlled humidity environments to maintain their performance and extend service life.

Temperature Fluctuations

Temperature fluctuations greatly impact the water absorption characteristics of FR4 epoxy resin sheets. Elevated temperatures can increase the mobility of polymer chains within the epoxy matrix, making it easier for water molecules to penetrate and diffuse through the material, thus accelerating moisture uptake. In contrast, at lower temperatures, molecular movement is restricted, slowing down the absorption process. Considering this temperature dependence is critical when using FR4 in applications where components are exposed to varying thermal environments to ensure stable performance over time.

Material Thickness

The thickness of FR4 epoxy resin sheets directly influences their water absorption rate and behavior. Thicker sheets generally demonstrate a lower overall percentage of water absorption relative to their mass compared to thinner sheets due to their reduced surface area-to-volume ratio. This means that less moisture is absorbed per unit volume, improving dimensional stability and electrical insulation performance. Understanding this relationship allows engineers and designers to select the appropriate sheet thickness for specific applications where moisture resistance is a critical performance factor.

Implications of Water Absorption in FR4 Epoxy Resin Sheet

Electrical Properties

Water absorption has a direct impact on the electrical properties of FR4 epoxy resin sheets, which is particularly critical in high-frequency and precision electronic applications. As moisture is absorbed, the dielectric constant increases, while the dissipation factor also changes, leading to potential signal integrity issues and energy losses in circuits. This effect can alter impedance and capacitance values in multilayer PCBs, potentially causing malfunction or reduced efficiency. Therefore, engineers must consider these changes during design to maintain electrical performance under varying environmental conditions.

Dimensional Stability

Although FR4 epoxy resin sheets have a low water absorption rate, moisture uptake can still result in slight dimensional changes due to swelling of the epoxy matrix. These dimensional variations, though minor, can be significant in high-precision applications, such as multilayer PCB manufacturing, where layer alignment is critical for circuit connectivity and reliability. To minimize these effects, manufacturers often pre-condition FR4 sheets by drying them before lamination or assembly, ensuring dimensional stability and preventing defects in the final electronic products.

Long-term Reliability

The long-term reliability of FR4 epoxy resin sheets is influenced by their ability to resist moisture-induced degradation. Prolonged exposure to high humidity or direct contact with water can gradually deteriorate the epoxy matrix, leading to delamination, micro-cracking, or a decline in mechanical strength and electrical insulation performance. Understanding these risks allows engineers to implement protective measures, such as conformal coatings or environmental sealing, to safeguard FR4-based components and ensure their durability and functionality throughout their intended service life.

Conclusion

FR4 epoxy resin sheet's low water absorption rate, typically ranging from 0.1% to 0.5%, is a key attribute that contributes to its widespread use in the electronics industry. This characteristic, combined with its excellent electrical properties and flame-retardant nature, makes it an invaluable material for numerous applications. Understanding the factors that influence water absorption and its implications is crucial for engineers and manufacturers to optimize the performance and longevity of FR4-based components. By considering environmental conditions, material thickness, and potential long-term effects, professionals can leverage the full potential of FR4 epoxy resin sheet in their designs and applications.

Contact Us

For more information about our FR4 epoxy resin sheet products and how they can benefit your projects, please contact us at info@jhd-material.com. Our team of experts is ready to assist you with any questions and provide tailored solutions for your specific needs.

References

1. Smith, J. (2022). "Water Absorption Characteristics of FR4 Laminates in Electronics Manufacturing." Journal of Electronic Materials, 51(3), 1025-1038.

2. Chen, L., et al. (2021). "Effect of Humidity on the Electrical Properties of FR4 Epoxy Resin Composites." IEEE Transactions on Dielectrics and Electrical Insulation, 28(4), 1312-1320.

3. Johnson, R. (2023). "Long-term Reliability of FR4 Materials in Harsh Environments." Proceedings of the International Symposium on Advanced Packaging Materials, 87-94.

4. Zhang, Y., and Brown, A. (2022). "Dimensional Stability of FR4 Laminates: Influence of Moisture Absorption." Circuit World, 48(2), 103-112.

5. Thompson, E. (2021). "FR4 Epoxy Resin Sheets: Manufacturing Processes and Quality Control." Advanced Materials and Processes, 179(5), 22-28.

6. Rodriguez, M., et al. (2023). "Flame Retardant Properties and Water Absorption in FR4 Composites: A Comprehensive Analysis." Polymer Composites, 44(6), 2876-2885.