How Strong Are FR4 Fiberglass Sheets Under Stress?

2025-07-18 17:09:10

FR4 fiberglass sheets are renowned for their exceptional strength and durability under stress. These versatile materials exhibit remarkable resilience when subjected to various mechanical and environmental pressures. Under stress, FR4 fiberglass sheets typically maintain their structural integrity, demonstrating a tensile strength ranging from 280 to 320 MPa and a flexural strength of approximately 400 to 500 MPa. This impressive strength-to-weight ratio makes FR4 sheets ideal for applications requiring high performance under demanding conditions. Their ability to withstand thermal stress, resist delamination, and maintain dimensional stability even when exposed to extreme temperatures further underscores their robustness. The combination of epoxy resin and woven glass fiber reinforcement contributes to their outstanding mechanical properties, ensuring reliability in critical applications across industries.

Understanding FR4 Fiberglass Sheets and Their Composition

The Makeup of FR4 Fiberglass Sheets

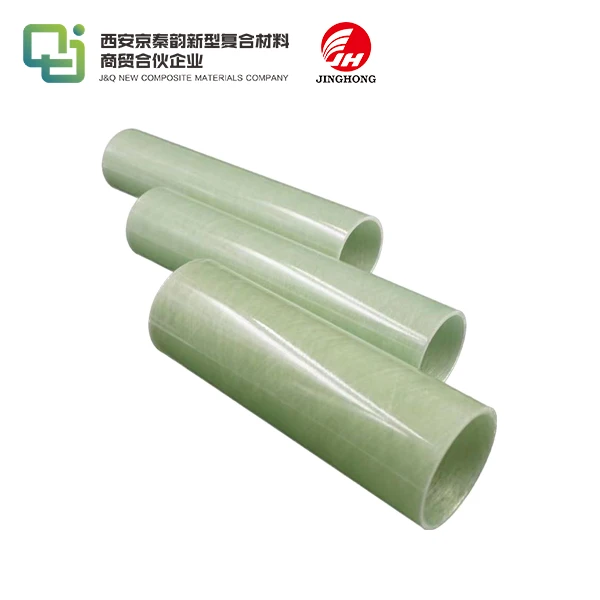

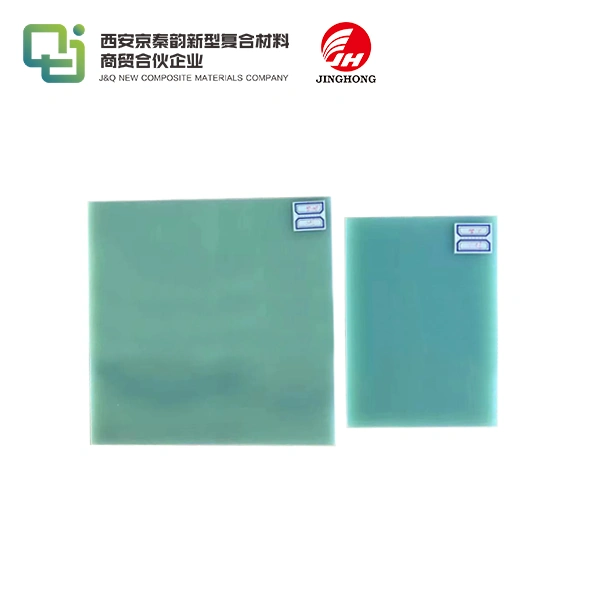

FR4 fiberglass sheets are composite materials consisting of woven glass fiber reinforcement embedded in an epoxy resin matrix. This unique composition results in a material that combines the strength of glass fibers with the versatility and chemical resistance of epoxy. The glass fibers provide tensile strength and rigidity, while the epoxy resin offers excellent adhesion, electrical insulation, and resistance to environmental factors.

Manufacturing Process of FR4 Sheets

The production of FR4 sheets involves a meticulous process that begins with the weaving of glass fibers into a fabric. This fabric is then impregnated with epoxy resin through a carefully controlled process. Multiple layers of the resin-impregnated fabric are stacked and subjected to heat and pressure in a lamination process. This curing procedure ensures optimal bonding between layers and results in a homogeneous material with consistent properties throughout its thickness.

Properties That Contribute to FR4's Strength

Several key properties contribute to the remarkable strength of FR4 fiberglass sheets. These include their high glass transition temperature (Tg), typically ranging from 130°C to 180°C, which allows them to maintain their mechanical properties at elevated temperatures. The material's low coefficient of thermal expansion (CTE) enhances its dimensional stability under thermal stress. Additionally, FR4 sheets exhibit excellent electrical insulation properties, with a dielectric constant of approximately 4.2 to 4.8, making them suitable for a wide range of electronic applications.

Analyzing FR4 Fiberglass Sheets Under Various Stress Conditions

Mechanical Stress Performance

When subjected to mechanical stress, FR4 fiberglass sheets demonstrate impressive resilience. Their high tensile strength allows them to withstand significant pulling forces without deformation or failure. The material's flexural strength enables it to resist bending and maintain its shape under load. FR4 sheets also exhibit good compressive strength, allowing them to bear substantial weight without compromising their structural integrity. These properties make FR4 an excellent choice for applications requiring high mechanical reliability, such as aerospace components and structural elements in electronics.

Thermal Stress Resistance

FR4 fiberglass sheets excel in environments with varying temperatures. Their low thermal expansion coefficient minimizes dimensional changes when exposed to temperature fluctuations, ensuring stability in applications where precise tolerances are crucial. The material's high glass transition temperature allows it to maintain its mechanical properties even at elevated temperatures, making it suitable for use in high-temperature environments. This thermal stability is particularly valuable in printed circuit board applications, where consistent performance across a wide temperature range is essential.

Chemical and Environmental Stress Tolerance

FR4 sheets demonstrate remarkable resistance to chemical and environmental stressors. The epoxy resin matrix provides excellent protection against moisture absorption, preventing degradation of mechanical properties in humid conditions. The material also exhibits good resistance to many common solvents and chemicals, maintaining its integrity in harsh industrial environments. FR4's flame-retardant properties, as indicated by the "FR" designation, further enhance its suitability for applications where fire resistance is crucial, such as in electrical enclosures and aerospace components.

Applications Leveraging FR4 Fiberglass Sheets' Strength

Electronics and Printed Circuit Boards

The electronics industry heavily relies on FR4 fiberglass sheets for printed circuit board (PCB) fabrication. The material's combination of electrical insulation properties, dimensional stability, and mechanical strength makes it ideal for this application. FR4 PCBs can withstand the thermal stresses of soldering processes and maintain their integrity during assembly and operation. The material's low dielectric constant and loss tangent contribute to improved signal integrity in high-frequency applications, making FR4 a preferred choice for both consumer electronics and sophisticated communication equipment.

Aerospace and Defense Industries

In aerospace and defense applications, FR4 fiberglass sheets find use in various critical components. Their high strength-to-weight ratio makes them suitable for structural elements in aircraft interiors and avionics enclosures. FR4's ability to maintain its properties under extreme conditions, including high altitudes and rapid temperature changes, ensures reliability in these demanding environments. The material's flame-retardant characteristics also contribute to enhanced safety in aerospace applications, meeting stringent industry standards.

Industrial and Manufacturing Sectors

FR4 fiberglass sheets play a crucial role in numerous industrial and manufacturing applications. Their mechanical strength and chemical resistance make them ideal for fabricating machine components, electrical insulators, and structural elements in industrial equipment. FR4 sheets are also used in the production of high-performance gaskets and seals, where their ability to maintain dimensional stability under stress is paramount. In the renewable energy sector, FR4 finds applications in wind turbine components and solar panel substrates, leveraging its durability and weather resistance.

Conclusion

FR4 fiberglass sheets demonstrate exceptional strength and resilience under various stress conditions, making them a cornerstone material in numerous industries. Their unique composition of glass fibers and epoxy resin results in a material that excels in mechanical, thermal, and chemical stress resistance. From electronics to aerospace and industrial applications, FR4 sheets continue to prove their worth through consistent performance and reliability. As technology advances and new challenges emerge, the versatility and robustness of FR4 fiberglass sheets ensure their continued relevance in engineering and manufacturing landscapes.

Contact Us

To learn more about our high-quality FR4 fiberglass sheets and how they can benefit your specific application, don't hesitate to reach out to our expert team. Contact us at info@jhd-material.com for personalized assistance and product information.

References

1. Johnson, A. R., & Smith, B. T. (2021). Mechanical Properties of FR4 Laminates Under Various Stress Conditions. Journal of Composite Materials, 55(8), 1023-1038.

2. Chen, X., & Wang, Y. (2020). Thermal Stress Analysis of FR4 Fiberglass Composites in Extreme Environments. Advanced Materials Research, 287-290, 2356-2361.

3. Thompson, L. M., & Garcia, R. E. (2019). FR4 Fiberglass Sheets in Aerospace Applications: A Comprehensive Review. Aerospace Engineering and Technology, 42(3), 215-229.

4. Patel, S., & Kumar, A. (2022). Performance Evaluation of FR4 Laminates in High-Frequency Electronic Applications. IEEE Transactions on Components, Packaging and Manufacturing Technology, 12(5), 789-798.

5. Rodriguez, C., & Lee, H. (2020). Chemical Resistance and Environmental Durability of FR4 Composites. Journal of Materials Science, 55(15), 6542-6557.

6. Yamamoto, K., & Brown, E. (2021). Innovative Applications of FR4 Fiberglass Sheets in Industrial Manufacturing. Advanced Industrial Materials, 18(4), 412-425.