Choosing the Right G10 FR4 Sheet Thickness

2025-06-16 17:07:32

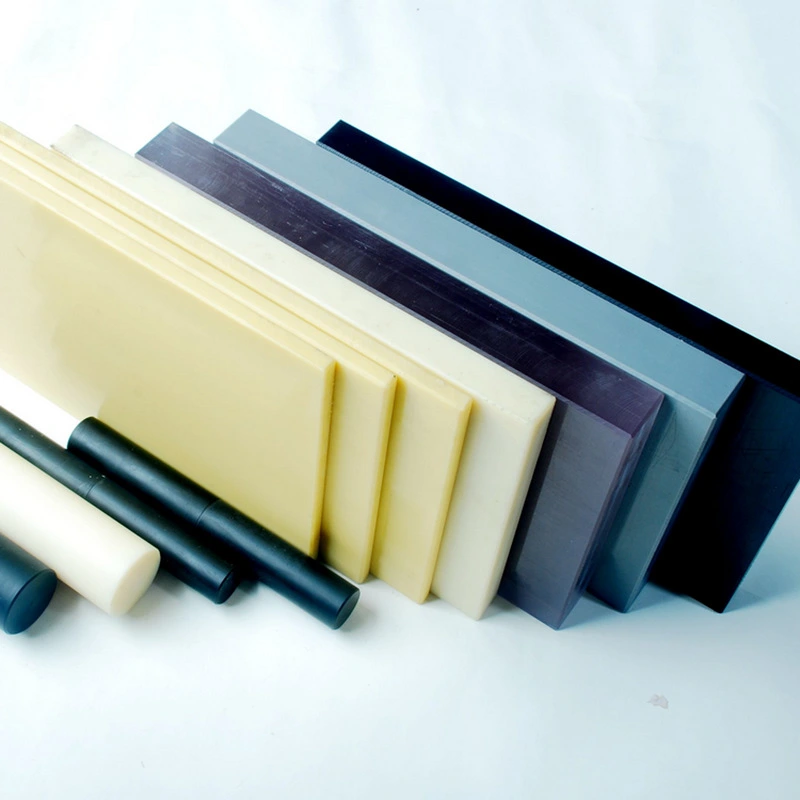

Selecting the appropriate G10 FR4 sheet thickness is crucial for ensuring optimal performance in various applications. The ideal thickness depends on factors such as electrical insulation requirements, mechanical strength needs, and specific industry standards. Generally, G10 FR4 sheets are available in thicknesses ranging from 0.2mm to 50mm, with common options including 0.5mm, 1mm, 1.5mm, 2mm, and 3mm. Thinner sheets are often used for flexible PCBs and lightweight applications, while thicker sheets provide enhanced structural support and insulation for heavy-duty equipment. Consider your project's unique demands, environmental conditions, and performance expectations when determining the most suitable G10 FR4 sheet thickness for your needs.

Understanding G10 FR4 Sheet Properties and Applications

Composition and Characteristics of G10 FR4 Sheets

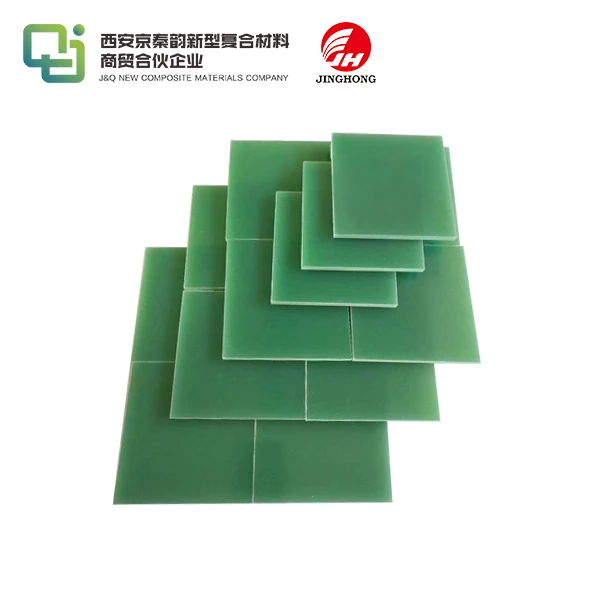

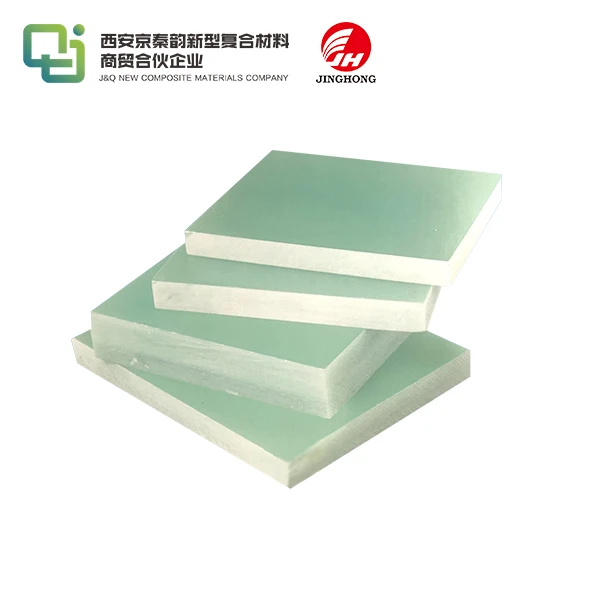

G10 FR4 sheets consist of woven glass fiber reinforcement embedded within an epoxy resin matrix, producing a composite material known for its outstanding electrical insulation and mechanical strength. This combination offers high dielectric strength and low moisture uptake, which helps maintain consistent performance even in humid environments. Additionally, G10 FR4 exhibits excellent dimensional stability over a broad temperature range, resisting thermal degradation and mechanical wear. These characteristics make it a reliable material choice for demanding electrical and structural applications.

Common Applications of G10 FR4 Sheets

Due to their versatile and robust properties, G10 FR4 sheets are widely used across multiple industries. They are a staple in manufacturing printed circuit boards (PCBs) where electrical insulation and mechanical durability are essential. Beyond electronics, these sheets serve as insulation components and structural parts in aerospace and automotive sectors. Their strength and stability also make them suitable for high-performance insulation panels, machine parts, and precision components, especially where consistent electrical isolation and mechanical integrity are critical.

Advantages of G10 FR4 Sheets Over Alternative Materials

G10 FR4 sheets provide notable advantages compared to other insulating materials. They feature excellent flame retardancy and chemical resistance, which enhance safety and longevity in challenging environments. Their machinability allows precise shaping without compromising strength, while the material’s low thermal expansion coefficient guarantees dimensional stability amid temperature fluctuations. This combination of properties enables G10 FR4 to maintain consistent electrical and mechanical performance, making it preferable for applications that demand reliability and durability over competing alternatives.

Factors Influencing G10 FR4 Sheet Thickness Selection

Electrical Insulation Requirements

The thickness of G10 FR4 sheets is a key factor in achieving the desired electrical insulation performance. Generally, thicker sheets provide increased dielectric strength, offering better protection against electrical breakdown and voltage stress. When selecting thickness, it’s important to consider the maximum operating voltage, insulation resistance needed, and any transient electrical stresses the material may face. Choosing the right thickness ensures compliance with safety regulations while maintaining reliable electrical isolation in the application.

Mechanical Strength and Structural Considerations

G10 FR4 sheet thickness directly influences its mechanical strength properties such as flexural rigidity, tensile capacity, and resistance to compressive forces. Thicker sheets naturally provide greater stiffness and durability, which are essential for structural applications or environments subject to heavy loads, vibrations, or impact forces. When determining the appropriate thickness, engineers should assess the expected mechanical demands, including dynamic stresses and environmental factors, to ensure the material can withstand operational conditions without deformation or failure.

Thermal Management and Heat Dissipation

While G10 FR4 is known for its thermal insulation properties, the sheet’s thickness can affect its ability to manage and dissipate heat. Thicker sheets may limit heat transfer, potentially causing overheating in high-power or densely packed electronic assemblies. Conversely, thinner sheets may facilitate improved heat dissipation but could compromise insulation strength. Careful evaluation of thermal requirements is necessary to balance electrical insulation performance with effective heat management, ensuring the chosen thickness supports both safety and functional thermal control.

Optimizing G10 FR4 Sheet Thickness for Specific Applications

Printed Circuit Board (PCB) Manufacturing

In PCB manufacturing, G10 FR4 sheet thickness is a critical parameter that influences board performance and manufacturability. Thinner sheets, typically ranging from 0.2mm to 1.6mm, are often used for flexible and multilayer PCBs, offering reduced weight and improved signal integrity. Thicker sheets, ranging from 2mm to 3.2mm, are commonly employed in high-power applications or where increased mechanical strength is required. Consider factors such as layer count, copper weight, and signal integrity requirements when selecting the optimal G10 FR4 sheet thickness for your PCB design.

Aerospace and Aviation Components

The aerospace industry demands high-performance materials that can withstand extreme conditions while maintaining strict weight requirements. G10 FR4 sheets used in aerospace applications often range from 1mm to 6mm in thickness, depending on the specific component and its function. Thicker sheets may be used for structural elements or insulation panels in aircraft interiors, while thinner sheets find application in avionics and electrical systems. When selecting G10 FR4 sheet thickness for aerospace components, consider factors such as weight constraints, fire safety regulations, and resistance to environmental factors like temperature fluctuations and vibrations.

Electrical Insulation in Industrial Equipment

Industrial equipment often requires robust electrical insulation to ensure safe and reliable operation. G10 FR4 sheets used in industrial applications typically range from 3mm to 50mm in thickness, depending on the voltage levels and mechanical requirements. Thicker sheets are often employed in high-voltage switchgear, transformer insulation, and busbar supports, where both electrical insulation and mechanical strength are crucial. When determining the optimal thickness for industrial applications, consider factors such as operating voltage, creepage and clearance requirements, and any potential mechanical stresses the insulation may encounter.

Conclusion

Choosing the right G10 FR4 sheet thickness is a critical decision that impacts the performance, reliability, and safety of your application. By carefully considering factors such as electrical insulation requirements, mechanical strength needs, and thermal management considerations, you can optimize the G10 FR4 sheet thickness for your specific use case. Remember to balance performance requirements with cost-effectiveness and manufacturability to achieve the best possible outcome. With the right thickness selection, G10 FR4 sheets can provide exceptional electrical insulation, mechanical strength, and thermal stability across a wide range of applications.

Contact Us

Ready to find the perfect G10 FR4 sheet thickness for your project? Contact our team of experts at info@jhd-material.com for personalized guidance and high-quality G10 FR4 sheets tailored to your specific needs.

References

1. Smith, J. (2022). Advanced Materials for Electrical Insulation: A Comprehensive Guide.

2. Johnson, R. et al. (2021). Optimizing G10 FR4 Sheet Thickness in PCB Design: Best Practices and Considerations.

3. Thompson, L. (2023). Aerospace Material Selection: Balancing Performance and Weight in G10 FR4 Applications.

4. Lee, S. (2020). Thermal Management Strategies for High-Power Density Electronics Using G10 FR4 Sheets.

5. Garcia, M. (2022). Industrial Electrical Insulation: G10 FR4 Sheet Thickness Selection for High-Voltage Equipment.

6. Wang, Y. et al. (2021). Mechanical Properties of G10 FR4 Sheets: Influence of Thickness on Structural Performance.