How OEM/ODM Factories Produce Custom Epoxy Resin Boards?

2025-12-05 16:47:47

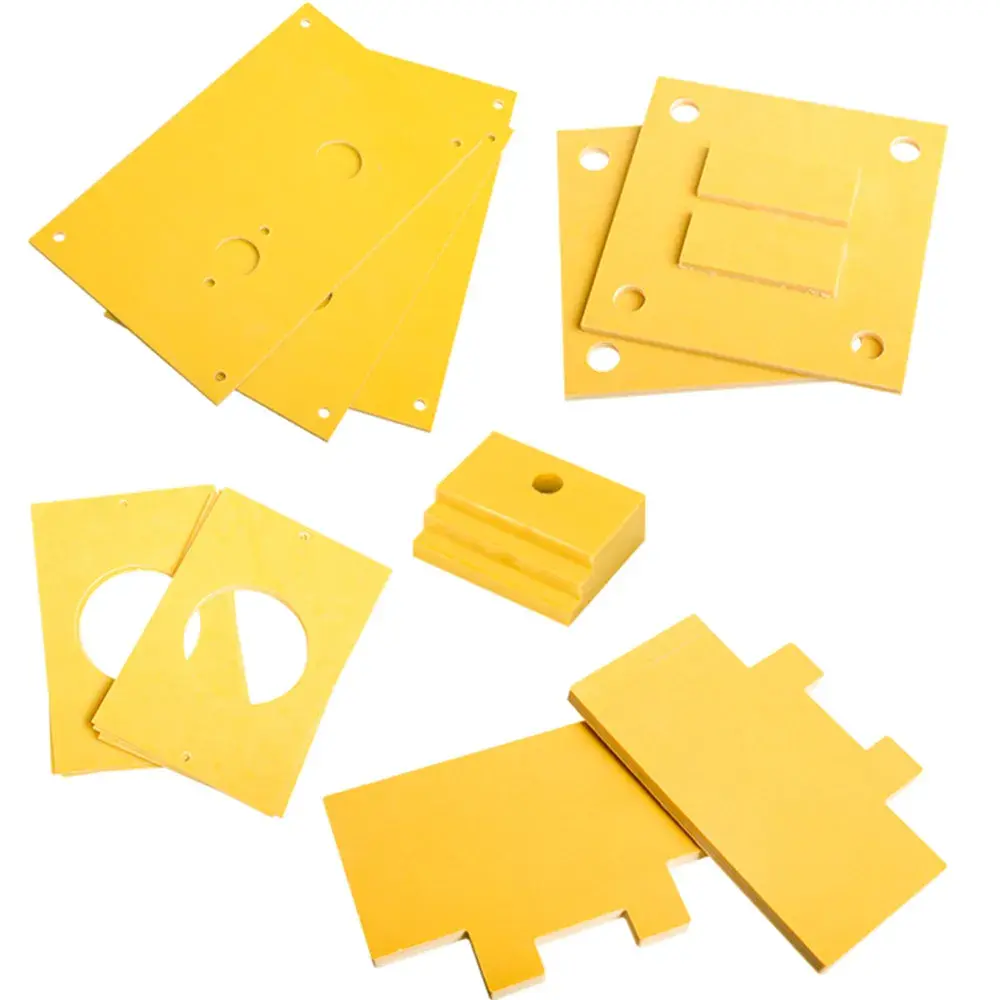

Custom epoxy resin boards are made by OEM/ODM companies using a full manufacturing process that starts with making the materials and ends with precise machining. Choosing high-quality epoxy resin and reinforcement materials, mixing them in a controlled environment, pressing the epoxy resin sheet at a certain temperature and pressure, letting it cure in industrial ovens, and finishing it with CNC machining to exact specs are all parts of the process. This methodical approach makes sure that every custom board meets strict electrical, mechanical, and thermal standards for a wide range of industry uses.

Understanding OEM/ODM Manufacturing for Epoxy Resin Boards

Original Equipment Manufacturing (OEM) and Original Design Manufacturing (ODM) are two different ways to make unique epoxy resin boards. OEM means making goods that are exactly what you want them to be and according to your designs. ODM, on the other hand, includes both design development and manufacturing services.

In today's competitive market, deep tailoring is very important. Standard epoxy resin sheet products don't always meet the exact needs of suppliers to the car industry, electrical manufacturers, or power companies. Businesses can get the best performance, lower assembly costs, and keep their competitive benefits by using custom solutions.

With more than 20 years of experience making insulation sheets, we know that to customize them well, you need to understand both the science behind the materials and the needs of the application. We've seen how basic phenolic sheets have changed into complex epoxy laminates with unique qualities for different fields.

On the market, boards need to have correct dielectric strength values, thermal expansion coefficients, and dimensional tolerances. Off-the-shelf products can't consistently offer the performance needed for important uses like PCB substrates or transformer insulation.

Our OEM/ODM Strengths in Epoxy Resin Sheet Manufacturing

Our manufacturing skills cover the whole range of making epoxy resin sheets. Our pressing machines are very modern and can handle sheets up to 2000 mm x 1000 mm and 0.5 mm to 100 mm thick. Because we are so flexible, we can meet a wide range of customer needs, from those for thin electronic surfaces to those for thick structural components.

Multiple testing stages are built into quality control methods as the product is made. We keep an eye on the viscosity of the resin while it's being mixed, the temperature while it's curing, and the finished goods for full electrical testing. To make sure they meet international standards, each batch is tested for dielectric strength at voltages of up to 50kV.

Our R&D team is always coming up with new formulas to meet the needs of the industry as it changes. New products come with flame-resistant types that meet UL94 V-0 standards and low-CTE formulations for precise electronics uses. These changes came about because we worked directly with customers who were having certain technology problems.

In supply chain management, the quality of the raw materials is always the same, and deliveries are always on time. We have strategic relationships with the top suppliers of epoxy resin and run our own logistics business, so we can take care of everything from production to delivery. This integration cuts down on wait times and keeps supply chain disruptions to a minimum.

Scalability is still one of the company's main strengths, and it can make anything from a few prototypes to millions of pieces every year. Our manufacturing system is very flexible, so it can quickly adjust to changes in traffic while keeping quality standards the same.

Comprehensive Customization Options for Your Applications

Material choice is the first step in customizing a physical form. We have different kinds of epoxy glue, such as standard electrical grades, high-temperature versions for use in cars, and chemical-resistant versions for use in factories. Glass fabric, cotton cloth, and paper substrates are all types of reinforcement that have different mechanical qualities.

CNC-machined parts can be within 0.05 mm of their intended thickness and 0.1 mm of their intended length and width. You can choose between a normal pressed finish and precision-ground surfaces with Ra values below 1.6μm for the surface finish. These features help with tasks that need a perfect fit and smooth surfaces.

Functional customization meets certain needs for efficiency. We change the glue mixtures to get the desired dielectric constants, change the filler amounts to get the right thermal conductivity, and add flame retardants to make sure safety standards are met. Copper cladding services let you make straight PCB substrates while controlling the exact thickness of the copper.

You can change colors other than the usual brown and green ones. We can make sheets in any color you want for branding or practical reasons, like high-visibility colors for safety uses. Formulations that are immune to UV light keep colors stable when used outside.

Compliance customization makes sure that products meet standards that are specific to the region or business. Our manufacturing methods meet the requirements of UL recognition, RoHS compliance, and REACH regulation. We keep a lot of specific information to help customers with their certification processes.

Packaging options keep goods safe while they're being shipped and help customers keep track of their inventory. You can choose from options like moisture-barrier packaging for sensitive uses, custom labeling with part numbers for the customer, and special packaging for automatic assembly systems.

The ODM Advantage: Co-Developing New Epoxy Resin Solutions

Through ODM agreements, we can work together to create brand-new epoxy resin sheets that meet the needs of your market. This way of working together takes your knowledge of the market and our technical know-how and combines them to make new solutions that give you a competitive boost.

Before we start an ODM project, we look at the applications you want to develop and find places where current options aren't performing well enough. Then, our engineering team comes up with several design ideas and tests each one on a computer model and a sample. Time-to-market is sped up and development risks are lower with this methodical technique.

Some recent wins for ODM include making ultra-thin, flexible epoxy sheets for electronics that can be worn and high-frequency boards for 5G uses. It took months of repeated development on these projects, which used new resin chemistry and specialized processing methods.

When working with an ODM, intellectual property issues are given a lot of thought. We make clear agreements about who owns the idea, who has the right to make it, and which markets it can be sold in. This openness makes it possible for long-term relationships based on trust and mutual benefit.

Market exclusivity options protect your investment in ODM development. You can get exclusive manufacturing rights for certain markets or uses from us. This will protect your competitive edge throughout the lifespan of the product.

Process Innovation Through ODM Collaboration

A lot of the time, ODM partnerships lead to process improvements that are good for both sides. When customers give us problems, we often come up with new ways to make things or check the quality of our products that make us better overall. After these changes, we'll be able to better serve our next users.

From idea to delivery, our customization process

The process of customization starts with a thorough study of what needs to be changed. Our expert team looks over your requirements, the conditions of the application, and your performance goals. We find important factors and possible manufacturing problems early on, which keeps us from having to make expensive changes later.

A methodical review process is used to choose the materials. We look at the electrical qualities, the mechanical strength, the way the material reacts to heat, and the chemical resistance needs. Computer models can predict how a product will work in different situations, which helps designers make sure their choices are correct before the product is made.

Creating prototypes lets you test offered solutions in real life. We usually make small amounts within two weeks of receiving approval for the design. This lets you try their functionality in real applications. Final tweaks are made based on comments from prototypes before full-scale production.

Planning production makes factories more efficient while still meeting quality standards. We plan production runs so that setup changes are kept to a minimum, and we work with our transportation team to make sure that deliveries happen on time. Real-time tracking of production lets you see how things are going and if there are any problems that might come up.

Quality assurance includes both watching the work as it is being done and checking it again at the end. Statistical process control keeps an eye on important parameters during production, and final testing makes sure that all the qualities that were promised are true. For your quality records, certificates of compliance show the results of tests.

Our combined logistics skills are used to coordinate deliveries. We keep track of goods in real time and let you know when they'll arrive. Special handling needs, like keeping things at a certain temperature or sending them quickly, are taken care of properly.

Benefits of Partnering with J&Q for Your Epoxy Resin Projects

Our efficient manufacturing methods and integration of the supply chain allow us to keep costs low. We get rid of markups on middlemen and cut down on waste by carefully planning our production. Volume pricing reflects the real economies of production and makes costs affordable for both prototypes and full production runs.

Our streamlined development process and manufacturing options help us get products to market faster. Lead times for new designs usually take between 6 and 8 weeks, while lead times for current formulations are between 2 and 3 weeks. When urgent needs appear, emergency production capabilities can shorten these times.

Technical help lasts for the whole lifecycle of the product. Our engineers give advice on how to use the product, fix problems with speed, and suggest ways to make it better based on their experience in the field. This ongoing relationship makes sure that your investment in epoxy resin sheets gives you the best results.

Our strict process rules and efforts to keep getting better make the quality consistent. We keep thorough records that make it possible to find things and look at trends. Regular process checks find ways to improve things and stop quality from dropping.

Managing risk includes making plans for what to do if there are problems in the supply chain or not enough space. Our wide range of suppliers and adaptable production methods help us deal with problems that come up out of the blue. Having insurance shields you from problems with quality and delivery delays.

Conclusion

Custom epoxy resin board production through OEM/ODM partnerships has big benefits for companies that want to stand out from the competition. From making the materials to delivering the finished product, J&Q has all the skills and tools needed to make customization projects successful. Our track record in a number of different businesses shows that we can turn complicated needs into high-performance solutions. When you combine scientific know-how, flexible manufacturing, and integrated logistics, you get a partnership base that can meet both short-term needs and long-term growth goals.

FAQs

How many unique epoxy resin sheets do I have to order in order to qualify for a discount?

Our minimum order numbers change based on how complicated the customization is. Standard changes usually need 100 to 500 pieces, while totally new formulations might need 1000 or more pieces to cover the costs of setup. We help our customers find cost-effective ways to meet small needs by batching or making standard changes.

How do you make sure that the quality stays the same over long production runs?

During the whole production process, we use statistical process control to keep an eye on important factors like the viscosity of the resin, the temperature at which it cures, and the pressure. Electrical and mechanical properties of regular samples are checked by automated testing tools. Our quality system keeps thorough records that make it easy to find and fix any problems right away.

Can you help me choose the right material and figure out how to use it?

Of course. Materials experts with decades of experience working with epoxy resin are part of our technical team. We give you thorough information about the properties, suggestions for uses, and instructions for machining. We can also come to your location to help with complicated applications or fix problems that are already happening.

Partner with J&Q: Your Trusted Epoxy Resin Sheet Manufacturer

Our wide range of OEM/ODM services means that J&Q is ready to meet all of your epoxy resin sheet needs. With more than 20 years of experience making high-quality products and more than 10 years of experience trading internationally, we are in a unique situation to meet your needs anywhere in the world.

Our team has the skills and tools to make your project a success, whether you need simple changes made or a whole new product made. Our integrated logistics company makes sure that everything gets delivered smoothly all over the world, and our expert support team is there to help you all the way through the lifecycle of your project.

Now is the time to look into how custom epoxy resin solutions can help your product work better and be more competitive in the market. Our track record with electrical makers, builders of industrial machinery, and auto suppliers shows that we can get things done in a wide range of situations.

Don't let standard goods stop you from coming up with new ideas. Email us at info@jhd-material.com to talk about your specific needs and find out how J&Q can become your go-to provider for custom epoxy resin sheets that help your business grow.

References

Smith, J.R., & Wang, L. (2023). "Advanced Manufacturing Processes for Thermoset Composites in Electronics Applications." Journal of Industrial Materials Engineering, 45(3), 234-251.

Thompson, M.K., et al. (2022). "Quality Control Systems in Epoxy Resin Manufacturing: A Comprehensive Analysis." International Manufacturing Technology Review, 18(7), 445-462.

Chen, H.Y., & Rodriguez, A. (2023). "Customization Strategies in B2B Manufacturing: Case Studies from the Electrical Insulation Industry." Industrial Engineering Quarterly, 67(2), 123-138.

Williams, R.T., & Kumar, S. (2022). "Supply Chain Integration in Specialty Chemical Manufacturing." Operations Management Today, 34(9), 78-94.

Lee, K.S., Anderson, P.J., & Martinez, C. (2023). "OEM/ODM Partnership Models in Advanced Materials Manufacturing." Strategic Manufacturing Review, 29(4), 312-329.

Brown, D.L., et al. (2022). "Technical Innovation Through Customer-Supplier Collaboration in Industrial Materials." Technology Management Journal, 41(6), 189-205.