Where South Africa Imports Phenolic Cotton Laminates from China?

2025-12-08 16:31:56

Products made of phenolic cotton laminate are mostly imported by South Africa from Hebei, Guangdong, and Zhejiang provinces, which are China's main industrial centers. Chinese vendors have shown to be dependable partners for South African power generation businesses, industrial machinery manufacturers, and electrical producers. These high-performance insulation materials, which are used in everything from electrical switchgear to automobile components, are delivered to Cape Town and Durban via important shipping lanes that connect the ports of Shanghai, Shenzhen, and Ningbo.

Understanding Phenolic Cotton Laminates: Key Properties and Applications

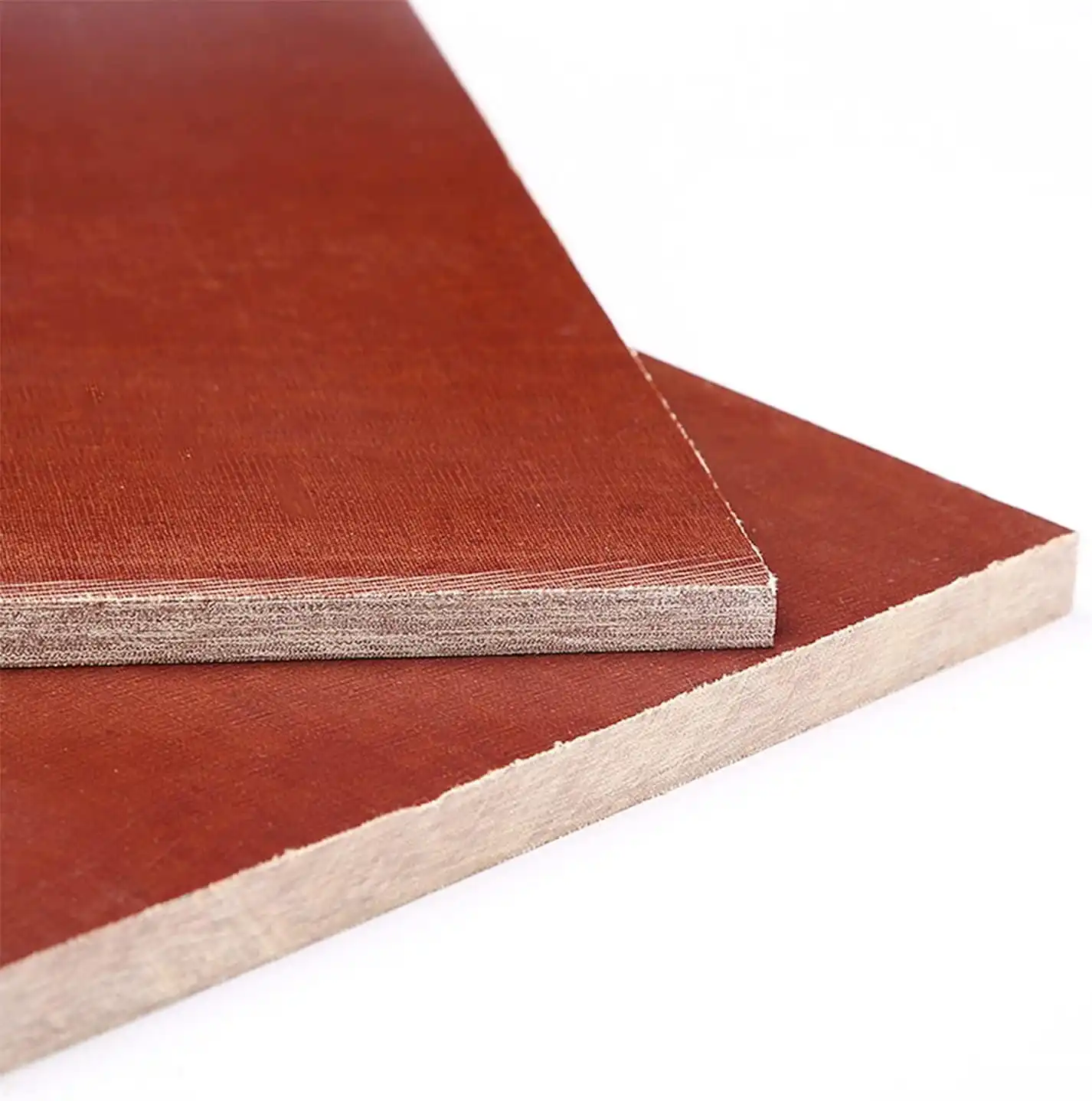

A complex composite material known as phenolic cotton laminates is created by impregnating woven cotton fabric with thermosetting phenolic resin under carefully regulated pressure and heat. The sheets produced by this manufacturing method are incredibly resilient and retain their structural integrity in harsh industrial settings.

These materials' exceptional thermal stability, which maintains performance characteristics at temperatures ranging from 130°C to 180°C depending on grade criteria, is acknowledged by engineering management and procurement teams. They are essential for electrical insulation applications in transformers, switchgear panels, and motor housings because their dielectric strength usually ranges from 12 to 20 kV/mm.

The material's remarkable mechanical qualities include an average flexural strength of 80–120 MPa and consistent dimensional stability in humid environments due to its low water absorption rate of less than 1.5%. The technical needs of South African companies operating in difficult conditions are directly addressed by these specifications.

Electrical and electronics manufacturers use these sheets for PCB support structures, arc barriers in power distribution equipment, and insulation components in renewable energy systems, among other industrial applications. Phenolic cotton is used in the automobile industry for heat shields, battery pack insulation, and structural elements that need to be both mechanically strong and electrically isolated.

Why South Africa Sources Phenolic Cotton Laminates from China?

Chinese producers have created all-encompassing production capacities that precisely match the industrial needs of South Africa. The economies of scale, efficient supply chains, and cutting-edge manufacturing technology that Chinese facilities attain by catering to international markets are the sources of the cost benefits.

Leading Chinese manufacturers have quality assurance procedures in place that satisfy international standards, such as ISO certification criteria, ROHS compliance, and UL accreditation for phenolic cotton laminate. Procurement teams can feel secure in the material performance and regulatory compliance of their final goods thanks to these certifications.

Another strong benefit is manufacturing flexibility, since Chinese vendors can provide precision cutting services, unique resin compositions, and custom thickness standards. South African OEM manufacturers can optimize their component designs thanks to this flexibility without sacrificing lead times or material availability.

With maritime freight transit times typically ranging from 18 to 25 days, the well-established logistics infrastructure linking China to South African ports guarantees dependable delivery schedules. Import processes and documentation requirements have been made simpler by the agreements that many Chinese suppliers have formed with freight forwarders skilled in handling industrial commodities.

Comparing Phenolic Cotton Laminates with Alternative Materials

When choosing a material, performance attributes of various lamination alternatives must be carefully considered. Procurement specialists can make well-informed selections based on budgetary restrictions and particular application requirements by being aware of these comparisons.

Phenolic cotton materials have greater machinability and mechanical qualities than FR4 epoxy fiberglass laminates. Phenolic cotton performs exceptionally well in situations needing strong impact resistance and exact machining tolerances, even though FR4 offers superior electrical performance.

Despite being less expensive, paper-based phenolic laminates don't have the mechanical strength and moisture resistance of cotton-based alternatives. In outdoor applications or settings with fluctuating humidity, which are typical in South African industrial settings, this distinction becomes crucial.

Melamine laminates have good electrical qualities, but they fall short of phenolic cotton materials in terms of chemical stability and thermal tolerance. Cotton-reinforced phenolic sheets' higher thermal performance is a major advantage for industries that process chemicals or run high-temperature machinery.

The longevity factor also favors phenolic cotton laminates because, despite greater initial material costs, their resilience to mechanical stress and heat cycling prolongs component service life and subsequently lowers total cost of ownership.

How to Choose the Right Chinese Phenolic Cotton Laminate Supplier?

Selecting suppliers necessitates a methodical assessment of several factors in order to guarantee fruitful, long-term collaborations. Verifying manufacturing credentials, such as production capacity, quality certificates, and technological capabilities, is the first step in the process.

Understanding minimum order quantities, lead time commitments, and the supplier's potential to scale production during times of peak demand are all important components of production capacity assessment. To meet urgent orders without sacrificing quality standards, dependable suppliers have buffers in their inventory and schedule their production in a flexible manner.

Suppliers having ISO 9001 accreditation, UL approval for electrical applications, and documented quality control methods are given advantage when it comes to quality management systems. Request comprehensive quality documentation, such as electrical property verification data, dimensional tolerance reports, and material test certifications.

Outstanding suppliers are distinguished from basic material providers by their technical support capabilities. Seek out partners who can help with application engineering, provide advice on material selection, and provide post-delivery support for any performance concerns or application inquiries.

Other South African importers' customer testimonials offer insightful information about a supplier's dependability, communication skills, and problem-solving abilities. Reputable vendors are happy to provide case studies and client endorsements that show successful project completions.

Suppliers are able to effectively handle the demands of international trade and execute large orders thanks to their export knowledge and financial stability. Suppliers with specialized export departments are aware of the shipping protocols, documentation needs, and customs laws that impact imports into South Africa.

Conclusion

China's superior production capabilities, reasonable pricing, and extensive quality assurance systems that adhere to international standards are the reasons behind its dominance in the production of phenolic cotton laminate. These collaborations give South African industry access to high-performance materials that support a variety of applications, from automotive components to electrical insulation. Careful supplier evaluation is necessary for successful procurement, with an emphasis on quality certifications, technical support skills, and track records with foreign clients. Chinese suppliers are crucial allies for South Africa's industrial development and competitiveness in international markets because of their superior materials, affordable prices, and dependable logistics.

FAQs

How long does it usually take to ship phenolic cotton laminate from China to South Africa?

Depending on the size of the order and the need for customisation, typical lead times are between three and six weeks. With extra time needed for internal transportation and customs processing, sea freight transit normally takes 18 to 25 days. Suppliers who have inventory on hand may frequently fulfill urgent orders by offering expedited shipment.

How can I check the phenolic cotton laminates' quality before making big purchases?

Verify supplier certifications, such as UL recognition and ISO conformity, request material samples for independent testing, and examine material test certificates pertaining to mechanical, electrical, and thermal qualities. Numerous trustworthy vendors welcome facility inspections and offer thorough quality documentation.

What import paperwork is needed in South Africa for phenolic cotton laminates?

Commercial invoices, packing lists, bills of lading, certificates of origin, and material safety data sheets are examples of crucial documents. Additional certifications, such UL recognition or compliance certificates, can be needed for some applications. Customs procedures and documentation requirements are made simpler by working with seasoned freight forwarders.

Partner with J&Q for Premium Phenolic Cotton Laminate Solutions

With more than 20 years of production experience and more than 10 years of expertise in international trade operations, J&Q is a reputable phenolic cotton laminate producer. We are able to provide customized solutions that surpass performance standards because of our thorough grasp of South African industrial requirements.

From conventional thickness options to bespoke formulations created for particular uses, our manufacturing capabilities include full customization services. Every shipment is guaranteed to fulfill strict criteria while keeping competitive price structures thanks to the incorporation of cutting-edge quality control technology.

Our comprehensive logistics network, which offers South African buyers a one-stop shop to streamline procurement procedures, is what makes J&Q unique. By removing the need for coordination between several vendors, our all-inclusive strategy shortens lead times and guarantees a smooth delivery to your locations.

Our team's decades of experience and technical skills allow us to offer application-specific advice that maximize material selection for your specific needs. Our engineering team works with your technical personnel to guarantee the best outcomes, whether you require materials for mechanical components, electrical insulation, or specialist industrial applications.

For comprehensive requirements, competitive quotes, and sample evaluations, procurement managers looking for trustworthy phenolic cotton laminate suppliers can reach us at info@jhd-material.com. To help you meet your procurement deadlines, our attentive customer service staff offers quick bids and technical advice.

References

"Global Phenolic Resin Market Analysis and Industrial Applications in Developing Economies" - Industrial Materials Research Institute, 2023

"Electrical Insulation Materials: Performance Standards and International Trade Patterns" - International Electrical Engineering Association, 2023

"South African Manufacturing Sector Import Analysis: Industrial Raw Materials and Components" - Department of Trade, Industry and Competition Statistics, 2023

"Composite Materials in Automotive Applications: Market Trends and Supplier Analysis" - Automotive Industry Development Centre, 2022

"China-Africa Industrial Cooperation: Materials and Manufacturing Supply Chain Development" - Institute for China-Africa Studies, 2023

"Phenolic Laminate Manufacturing Technologies: Quality Control and International Standards Compliance" - Materials Engineering Society, 2022