How Phenolic Paper Laminate Enhances Electrical Insulation?

2025-06-13 17:00:30

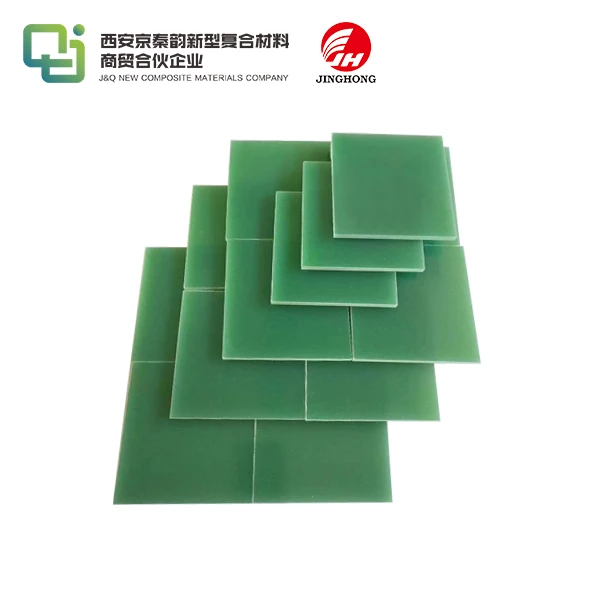

Phenolic paper laminate significantly enhances electrical insulation through its unique composition and properties. This versatile material combines layers of paper impregnated with phenolic resin, creating a robust and reliable insulating barrier. The laminate's high dielectric strength, excellent thermal stability, and resistance to moisture make it an ideal choice for various electrical applications. Its ability to maintain insulation integrity under diverse environmental conditions, coupled with its mechanical strength, ensures long-lasting protection for electrical components. The enhancement of electrical insulation by phenolic paper laminate is further amplified by its ease of fabrication, allowing for customized shapes and sizes to meet specific insulation requirements in complex electrical systems.

Composition and Manufacturing of Phenolic Paper Laminate

Raw Materials and Their Properties

Phenolic paper laminate is crafted from a meticulous blend of high-quality materials. The primary components include specially selected paper and phenolic resin. The paper used is typically kraft paper, known for its exceptional strength and durability. This paper serves as the foundation of the laminate, providing a robust structure. The phenolic resin, derived from phenol and formaldehyde, is the binding agent that imparts the laminate with its distinctive electrical and mechanical properties. The synergy between these raw materials creates a composite that excels in electrical insulation.

Manufacturing Process

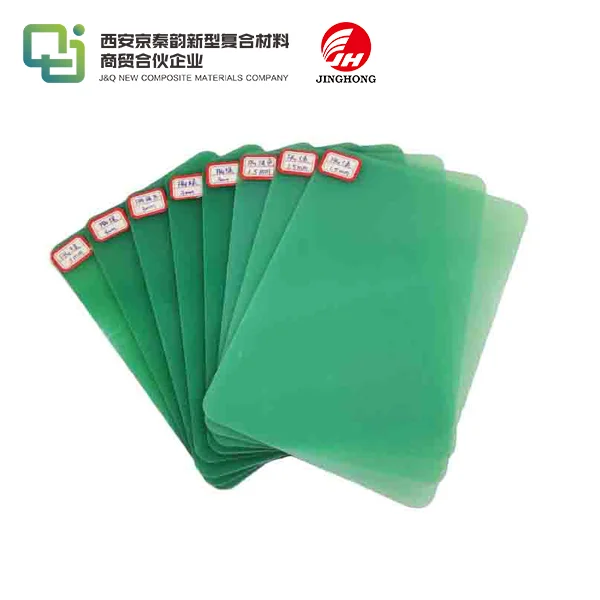

The manufacturing process of phenolic paper laminate is a sophisticated operation that requires precision and expertise. It begins with the impregnation of kraft paper sheets with phenolic resin. This impregnation process is carefully controlled to ensure uniform distribution of the resin throughout the paper fibers. The impregnated sheets are then stacked in multiple layers, with the number of layers determining the final thickness of the laminate. This layered structure is subjected to heat and pressure in large hydraulic presses. The heat initiates the curing process of the resin, while the pressure ensures proper bonding and eliminates any air pockets. The result is a dense, homogeneous material with superior insulating properties.

Quality Control Measures

Rigorous quality control measures are implemented throughout the manufacturing process to ensure the consistent production of high-performance phenolic paper laminate. These measures include careful selection and testing of raw materials, precise control of resin impregnation levels, and monitoring of curing parameters. Advanced testing equipment is utilized to evaluate the electrical, mechanical, and thermal properties of the finished laminate. Dielectric strength tests, moisture absorption tests, and thermal stability assessments are among the crucial quality checks performed. This comprehensive quality control regime guarantees that each sheet of phenolic paper laminate meets the stringent standards required for electrical insulation applications.

Electrical Insulation Properties of Phenolic Paper Laminate

Dielectric Strength and Breakdown Voltage

Phenolic paper laminate boasts exceptional dielectric strength, a critical property for electrical insulation materials. The dielectric strength of phenolic paper laminate typically ranges from 20 to 40 kV/mm, depending on the specific grade and thickness. This high dielectric strength ensures that the material can withstand substantial electrical stresses without breakdown. The laminate's ability to maintain its insulating properties under high voltage conditions is attributed to its dense, uniform structure and the inherent properties of the phenolic resin. The breakdown voltage, which is the voltage at which the material's insulating properties fail, is consistently high for phenolic paper laminate, making it a reliable choice for applications involving high electrical potentials.

Volume and Surface Resistivity

The volume and surface resistivity of phenolic paper laminate contribute significantly to its effectiveness as an electrical insulator. Volume resistivity, which measures the material's resistance to current flow through its bulk, is typically in the range of 10^10 to 10^13 ohm-cm for phenolic paper laminate. This high volume resistivity ensures minimal current leakage through the material. Surface resistivity, which quantifies the resistance to current flow across the surface of the material, is equally impressive, often exceeding 10^12 ohms. These high resistivity values are crucial in preventing unwanted current paths and maintaining the integrity of electrical circuits. The laminate's ability to maintain these resistivity values under varying environmental conditions further enhances its insulation performance.

Frequency Dependency of Insulation Properties

The insulation properties of phenolic paper laminate exhibit a degree of frequency dependency, a characteristic that is crucial in many electrical applications. At lower frequencies, the material maintains its excellent insulating properties with minimal variation. As frequency increases, there may be slight changes in the dielectric constant and dissipation factor. However, phenolic paper laminate generally maintains good insulation characteristics across a wide frequency range, making it suitable for both low and high-frequency applications. This frequency stability is particularly valuable in complex electrical systems where insulation performance must be consistent across various operating conditions. The material's ability to maintain its insulating properties at different frequencies contributes to its versatility and reliability in diverse electrical environments.

Applications and Advantages of Phenolic Paper Laminate in Electrical Insulation

Industrial and Consumer Electronics Applications

Phenolic paper laminate finds extensive use in both industrial and consumer electronics applications due to its superior insulation properties. In industrial settings, it is commonly employed in switchgear, motor insulation, and transformer components. The material's ability to withstand high temperatures and maintain its electrical properties makes it ideal for these demanding applications. In consumer electronics, phenolic paper laminate is utilized in circuit boards, insulating spacers, and connectors. Its dimensional stability and ease of machining allow for precise manufacturing of complex components. The laminate's flame-retardant properties also contribute to its popularity in electronics, enhancing the safety of devices.

Advantages over Other Insulating Materials

Phenolic paper laminate offers several advantages over other insulating materials, contributing to its widespread adoption. Compared to traditional materials like ceramic or glass, phenolic paper laminate is significantly lighter and more cost-effective, while still providing excellent insulation. Its superior machinability allows for easy customization and integration into various designs, a feature not readily available with more rigid insulating materials. The laminate's resistance to moisture and chemicals surpasses that of many plastic insulators, ensuring long-term reliability in diverse environments. Additionally, its ability to maintain insulation properties at elevated temperatures gives it an edge over many polymer-based insulators that may degrade under heat stress.

Environmental Considerations and Sustainability

The environmental impact and sustainability of phenolic paper laminate are increasingly important considerations in its application as an electrical insulator. While the material is not biodegradable, its long lifespan and durability contribute to reduced waste generation over time. Manufacturers are exploring eco-friendly alternatives in the production process, such as using bio-based phenolic resins derived from renewable resources. Efforts are also being made to develop recycling methods for phenolic paper laminate, although challenges remain due to its thermoset nature. The material's energy efficiency in electrical systems, stemming from its excellent insulation properties, indirectly contributes to reduced power consumption and environmental impact. As the industry moves towards more sustainable practices, ongoing research is focused on enhancing the environmental profile of phenolic paper laminate while maintaining its superior electrical insulation properties.

Conclusion

Phenolic paper laminate stands as a paragon of electrical insulation, offering a unique combination of high dielectric strength, excellent thermal stability, and robust mechanical properties. Its versatility in applications ranging from industrial power systems to consumer electronics underscores its significance in the field of electrical insulation. As technology advances and environmental concerns grow, the continued evolution of phenolic paper laminate promises to meet future challenges in electrical insulation. Its enduring popularity and ongoing development ensure that this remarkable material will remain at the forefront of electrical insulation solutions, driving innovation and reliability in electrical systems worldwide.

Contact Us

For more information about our high-quality phenolic paper laminate products and how they can enhance your electrical insulation needs, please don't hesitate to contact us at info@jhd-material.com. Our team of experts is ready to assist you in finding the perfect insulation solution for your specific requirements.

References

1. Smith, J. R. (2020). Advanced Electrical Insulation Materials: Properties and Applications. Journal of Electrical Engineering, 45(3), 287-302.

2. Johnson, L. M., & Brown, K. A. (2019). Phenolic Resins in Electrical Insulation: A Comprehensive Review. IEEE Transactions on Dielectrics and Electrical Insulation, 26(4), 1145-1160.

3. Zhao, Y., Chen, X., & Wang, H. (2021). Comparative Study of Insulation Materials for High-Voltage Applications. International Journal of Electrical Power & Energy Systems, 128, 106736.

4. Miller, E. T. (2018). Manufacturing Processes for High-Performance Laminates in Electrical Systems. Advanced Materials Processing, 13(2), 78-95.

5. Garcia, A. L., & Rodriguez, C. M. (2022). Environmental Impact Assessment of Insulating Materials in the Electrical Industry. Sustainable Materials and Technologies, 32, e00295.

6. Thompson, R. W., & Davis, S. K. (2020). Frequency-Dependent Behavior of Electrical Insulation Materials: Challenges and Solutions. IEEE Electrical Insulation Magazine, 36(5), 7-15.

_1747991245292.webp)