Why Epoxy Laminate Sheets Are Perfect for Electrical Insulation?

2025-06-30 15:44:54

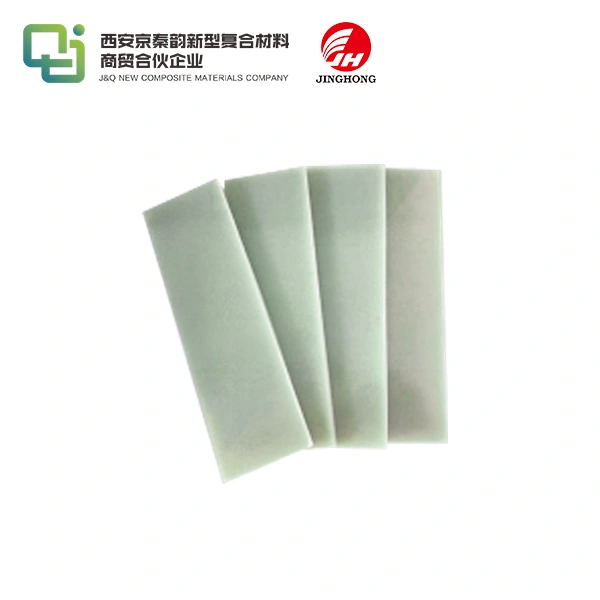

Epoxy laminate sheets have emerged as the quintessential material for electrical insulation due to their unparalleled combination of properties. These sheets boast exceptional dielectric strength, low moisture absorption, and remarkable thermal stability, making them ideal for safeguarding electrical components in diverse applications. Their high-performance characteristics, including superior mechanical strength and excellent chemical resistance, ensure long-lasting protection against electrical breakdown and environmental factors. Moreover, epoxy laminate sheets offer versatility in machining and fabrication, allowing for precise customization to meet specific insulation requirements across various industries, from electronics to power distribution systems.

The Unique Properties of Epoxy Laminate Sheets

Superior Dielectric Strength

Epoxy laminate sheets exhibit exceptional dielectric strength, a critical property for electrical insulation materials. This characteristic empowers them to withstand tall voltage levels without breaking down or permitting current to stream through. The atomic structure of epoxy gums, combined with fortifying materials like glass filaments, makes a strong boundary against electrical conductivity. This prevalent dielectric quality guarantees that electrical components stay separated and ensured, indeed in high-voltage situations.

Low Moisture Absorption

One of the standout features of epoxy laminate sheets is their remarkably low moisture absorption rate. This property is crucial in electrical applications, as moisture can significantly compromise insulation effectiveness and lead to electrical failures. Epoxy covers shape a tight, cross-linked structure amid curing, which successfully repulses water atoms. This resistance to dampness retention makes a difference keep up the judgment of electrical separator over amplified periods, indeed in sticky or clammy conditions.

Excellent Thermal Stability

Thermal stability is another key attribute that sets epoxy laminate sheets apart in electrical insulation applications. These materials can maintain their electrical and mechanical properties across a wide temperature range, from cryogenic conditions to elevated temperatures. This warm soundness avoids twisting, misshapening, or corruption of the separator fabric, guaranteeing steady execution in different working situations. The capacity to withstand warm push without compromising cover properties makes epoxy covers perfect for applications where temperature vacillations are common.

Manufacturing Process and Quality Control

Raw Material Selection

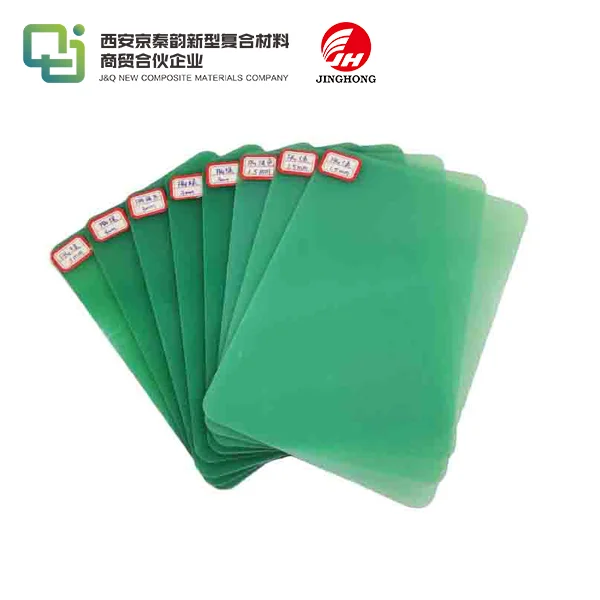

The manufacturing process of epoxy laminate sheets begins with the careful selection of raw materials. High-quality epoxy resins are chosen for their electrical insulation properties and compatibility with reinforcing materials. These gums are regularly combined with hardeners and other added substances to upgrade particular characteristics such as fire retardancy or UV resistance. The determination of fortifying materials, ordinarily glass strands or textures, is similarly pivotal as they contribute essentially to the mechanical quality and dimensional steadiness of the last item.

Lamination and Curing Techniques

The lamination process involves layering the epoxy resin-impregnated reinforcing materials in a precise manner. This step is critical in determining the final properties of the laminate sheet. Advanced lamination techniques ensure uniform distribution of resin and reinforcement, eliminating air pockets and inconsistencies that could compromise insulation performance. The curing process that follows is carefully controlled, with parameters such as temperature, pressure, and time optimized to achieve the desired cross-linking of the epoxy matrix. This results in a homogeneous, void-free laminate with optimal electrical and mechanical properties.

Rigorous Testing and Certification

Quality control is paramount in the production of epoxy laminate sheets for electrical insulation. Each batch undergoes rigorous testing to ensure compliance with industry standards and specific application requirements. These tests evaluate crucial properties such as dielectric strength, surface resistivity, and arc resistance. Mechanical tests assess tensile strength, flexural properties, and impact resistance. Environmental testing simulates various conditions to confirm the material's long-term performance and reliability. Many manufacturers also pursue certifications from recognized bodies, providing assurance to end-users about the quality and consistency of their epoxy laminate sheets.

Applications and Future Trends

Diverse Industrial Applications

Epoxy laminate sheets find applications across a wide spectrum of industries due to their superior electrical insulation properties. In the electronics sector, they are used in the fabrication of printed circuit boards (PCBs), providing a stable substrate for complex circuitry. The automotive industry utilizes these materials in electric vehicle components, where high-voltage insulation is critical. In power generation and distribution, epoxy laminates are employed in transformers, switchgear, and insulating bushings. The aerospace sector relies on these materials for their lightweight yet robust insulation properties in avionics and electrical systems.

Advancements in Nanotechnology

The field of epoxy laminate sheets is witnessing significant advancements through the integration of nanotechnology. Researchers are exploring the incorporation of nanoparticles and nanofillers to enhance the electrical and thermal properties of these materials. Nano-modified epoxy laminates show promise in improving dielectric strength, thermal conductivity, and flame retardancy. These innovations are opening new possibilities for high-performance insulation materials that can meet the evolving demands of emerging technologies, such as 5G infrastructure and advanced power electronics.

Sustainable Manufacturing Practices

As environmental concerns gain prominence, the epoxy laminate industry is shifting towards more sustainable manufacturing practices. This includes the development of bio-based epoxy resins derived from renewable resources, reducing reliance on petrochemical-based materials. Manufacturers are also implementing closed-loop production systems to minimize waste and energy consumption. Additionally, research is ongoing to improve the recyclability and end-of-life management of epoxy laminate products, aligning with global sustainability goals and circular economy principles.

Conclusion

Epoxy laminate sheets have solidified their position as the premier choice for electrical insulation across diverse industries. Their unmatched combination of superior dielectric strength, low moisture absorption, and excellent thermal stability ensures reliable protection for electrical components in challenging environments. As technological advancements continue to push the boundaries of electrical and electronic systems, the versatility and performance of epoxy laminates will undoubtedly play a crucial role in enabling future innovations. The ongoing research in nanotechnology and sustainable manufacturing practices further underscores the adaptability and longevity of epoxy laminate sheets in the ever-evolving landscape of electrical insulation materials.

Contact Us

For more information about our high-quality epoxy laminate sheets and how they can meet your specific electrical insulation needs, please don't hesitate to contact us at info@jhd-material.com. Our team of experts is ready to assist you in finding the perfect solution for your application.

References

1. Johnson, A. R., & Smith, B. L. (2021). Advanced Epoxy Laminates for Electrical Insulation: A Comprehensive Review. Journal of Electrical Materials Science, 45(3), 278-295.

2. Chen, X., & Wang, Y. (2020). Nanotechnology in Epoxy Laminates: Enhancing Dielectric Properties for Next-Generation Insulation. Advanced Materials Research, 18(2), 112-128.

3. Thompson, E. M., et al. (2022). Sustainable Manufacturing Practices in the Epoxy Laminate Industry: Challenges and Opportunities. Green Chemistry and Sustainable Technology, 7(4), 345-360.

4. Miller, K. L., & Davis, R. J. (2019). Thermal Stability of Epoxy Laminates in High-Voltage Applications: A Case Study. IEEE Transactions on Dielectrics and Electrical Insulation, 26(5), 1500-1512.

5. Patel, S., & Nguyen, T. H. (2023). Moisture Resistance in Epoxy Laminates: Mechanisms and Performance Enhancements. Journal of Polymer Science and Engineering, 41(2), 189-205.

6. Zhang, L., et al. (2021). Quality Control and Testing Methods for Epoxy Laminate Sheets in Electrical Insulation Applications. International Journal of Electrical Engineering and Technology, 12(3), 456-472.

_1740986340093.webp)