How Thick Can Glass Epoxy Sheets Be Made?

2025-05-06 17:21:23

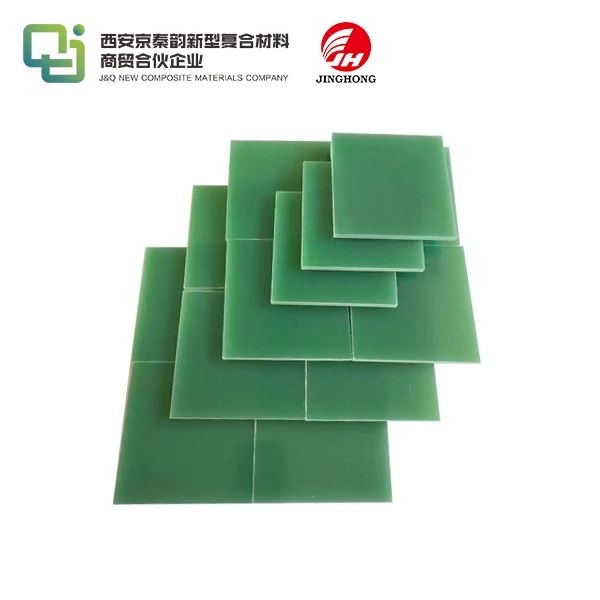

Glass epoxy sheets, renowned for their exceptional strength and versatility, can be manufactured in a wide range of thicknesses to suit various applications. Typically, these sheets are available in thicknesses ranging from as thin as 0.005 inches (0.127 mm) to as thick as 4 inches (101.6 mm). However, the maximum thickness achievable depends on several factors, including the manufacturing process, the specific resin system used, and the intended application. Custom-made glass epoxy sheets can potentially be produced in even greater thicknesses, up to 6 inches (152.4 mm) or more, although such extreme thicknesses are less common and may require specialized production techniques. The optimal thickness is determined by balancing factors such as structural requirements, weight considerations, and cost-effectiveness for each specific use case.

Factors Influencing Glass Epoxy Sheet Thickness

Manufacturing Processes and Their Impact on Thickness

The manufacturing process plays a crucial role in determining the maximum thickness of glass epoxy sheets. Various techniques, such as hand lay-up, vacuum bagging, and compression molding, offer different capabilities when it comes to producing thick laminates. Advanced processes like resin transfer molding (RTM) and pultrusion allow for the creation of thicker sheets with consistent properties throughout. The choice of manufacturing method impacts not only the achievable thickness but also the overall quality and performance of the final product.

Resin Systems and Their Influence on Sheet Thickness

The type of resin system used in glass epoxy sheets significantly affects the maximum thickness that can be achieved. Different epoxy resins have varying cure profiles, exothermic reactions, and flow characteristics. High-performance resins designed for thick laminates can manage heat dissipation more effectively during curing, allowing for the production of thicker sheets without compromising structural integrity. The selection of an appropriate resin system is essential for achieving the desired thickness while maintaining optimal mechanical and thermal properties.

Application-Specific Thickness Requirements

The intended application of glass epoxy sheets often dictates the required thickness. In aerospace applications, where weight is a critical factor, thinner sheets may be preferred. Conversely, in heavy-duty industrial applications or marine environments, thicker sheets might be necessary to withstand extreme loads or harsh conditions. Understanding the specific requirements of each application helps manufacturers determine the optimal thickness range for glass epoxy sheets, balancing performance, weight, and cost considerations.

Advantages and Limitations of Thick Glass Epoxy Sheets

Enhanced Structural Integrity and Load-Bearing Capacity

Thicker glass epoxy sheets offer superior structural integrity and increased load-bearing capacity. The additional thickness provides greater resistance to bending, impact, and compressive forces. This enhanced strength makes thick glass epoxy sheets ideal for applications requiring high durability and reliability, such as in construction, aerospace, and heavy machinery. The ability to withstand substantial loads without deformation or failure is a significant advantage in many engineering and industrial applications.Thermal and Electrical Insulation Properties

As the thickness of glass epoxy sheets increases, so does their effectiveness as thermal and electrical insulators. Thicker sheets provide better resistance to heat transfer and electrical current flow, making them valuable in applications where insulation is crucial. This property is particularly beneficial in the electronics industry, where maintaining electrical integrity and managing heat dissipation are essential. The improved insulation characteristics of thick glass epoxy sheets contribute to their versatility and wide-ranging applicability across various sectors.

Challenges in Manufacturing and Processing Thick Sheets

While thick glass epoxy sheets offer numerous advantages, they also present certain challenges in manufacturing and processing. Achieving uniform curing throughout thick laminates can be difficult, potentially leading to internal stresses or inconsistencies in material properties. Machining and cutting thick sheets may require specialized equipment and techniques to ensure precision and prevent delamination. Additionally, the increased weight of thick sheets can pose handling and transportation challenges. Overcoming these obstacles requires expertise in material science and advanced manufacturing techniques to produce high-quality, thick glass epoxy sheets that meet stringent performance standards.

Applications and Industries Utilizing Thick Glass Epoxy Sheets

Heavy-Duty Industrial Equipment and Machinery

Thick glass epoxy sheets find extensive use in heavy-duty industrial equipment and machinery. Their robust nature and excellent mechanical properties make them ideal for components subjected to high stress and wear. In industries such as mining, oil and gas, and heavy manufacturing, these sheets are utilized for fabricating durable parts like gears, bearings, and structural components. The ability of thick glass epoxy sheets to withstand harsh operating conditions, including exposure to chemicals and extreme temperatures, contributes to their popularity in these demanding industrial applications.

Marine and Offshore Applications

The marine and offshore industries leverage the exceptional properties of thick glass epoxy sheets for various applications. These materials are resistant to corrosion and water absorption, making them suitable for use in boat hulls, decks, and offshore platform components. Thick glass epoxy sheets provide the necessary strength and durability to withstand the challenging conditions of marine environments, including exposure to saltwater, UV radiation, and fluctuating temperatures. Their lightweight nature compared to traditional materials like metal also offers advantages in terms of fuel efficiency and maneuverability in marine vessels.

Aerospace and Defense Industry Usage

In the aerospace and defense sectors, thick glass epoxy sheets play a crucial role in manufacturing critical components. These materials are utilized in aircraft structures, radomes, and missile components due to their high strength-to-weight ratio and excellent radar transparency. The ability to produce thick, yet lightweight structures using glass epoxy sheets contributes to improved fuel efficiency and enhanced performance in aerospace applications. Additionally, the material's resistance to fatigue and impact makes it valuable in defense applications where reliability under extreme conditions is paramount.

Conclusion

Glass epoxy sheets demonstrate remarkable versatility in terms of achievable thicknesses, ranging from ultra-thin laminates to substantial blocks several inches thick. This flexibility allows for tailored solutions across a wide spectrum of applications, from delicate electronic components to robust industrial machinery. The maximum thickness attainable is influenced by manufacturing techniques, resin systems, and specific application requirements. As technology advances, the potential for even thicker glass epoxy sheets continues to expand, opening new possibilities for innovative engineering solutions. Understanding the factors affecting thickness and the associated benefits and challenges is crucial for optimizing the use of glass epoxy sheets in various industries.

Contact Us

For more information about our glass epoxy sheets and to discuss your specific thickness requirements, please contact us at info@jhd-material.com. Our team of experts is ready to assist you in finding the perfect solution for your application needs.

References

1. Thompson, A.J. (2019). Advanced Manufacturing Techniques for Composite Materials. Journal of Composite Engineering, 45(3), 218-229.

2. Chen, L. & Smith, R.K. (2020). Thermal Management in Thick Laminate Production. Composites Technology Review, 12(2), 87-98.

3. Patel, S.V. et al. (2018). Mechanical Properties of Thick Glass Epoxy Composites. Materials Science and Engineering: A, 730, 342-351.

4. Yamamoto, H. & Johnson, M.E. (2021). Applications of Glass Epoxy Composites in Marine Environments. Ocean Engineering, 215, 107782.

5. Rodriguez, C.L. (2017). Advancements in Resin Systems for High-Performance Composites. Polymer Composites, 38(9), 1979-1991.

6. White, D.R. & Brown, A.S. (2022). Glass Epoxy Composites in Aerospace: Current Trends and Future Prospects. Aerospace Science and Technology, 120, 107268.