How to Dispose of Phenolic Paper Laminated Tubes Sustainably?

2025-05-23 17:05:07

Disposing of phenolic paper laminated tubes sustainably involves a multi-faceted approach that prioritizes environmental responsibility. The most effective method is to partner with specialized recycling facilities that can process these composite materials. These facilities employ advanced techniques to separate the phenolic resin from the paper components, allowing for the recovery and repurposing of both materials. Additionally, some manufacturers offer take-back programs, facilitating proper disposal and recycling. When recycling isn't feasible, consider repurposing the tubes for alternative uses, such as craft projects or organizational tools. As a last resort, ensure proper disposal through certified waste management services that adhere to environmental regulations, minimizing the impact on landfills and ecosystems.

Understanding Phenolic Paper Laminated Tubes

Composition and Properties

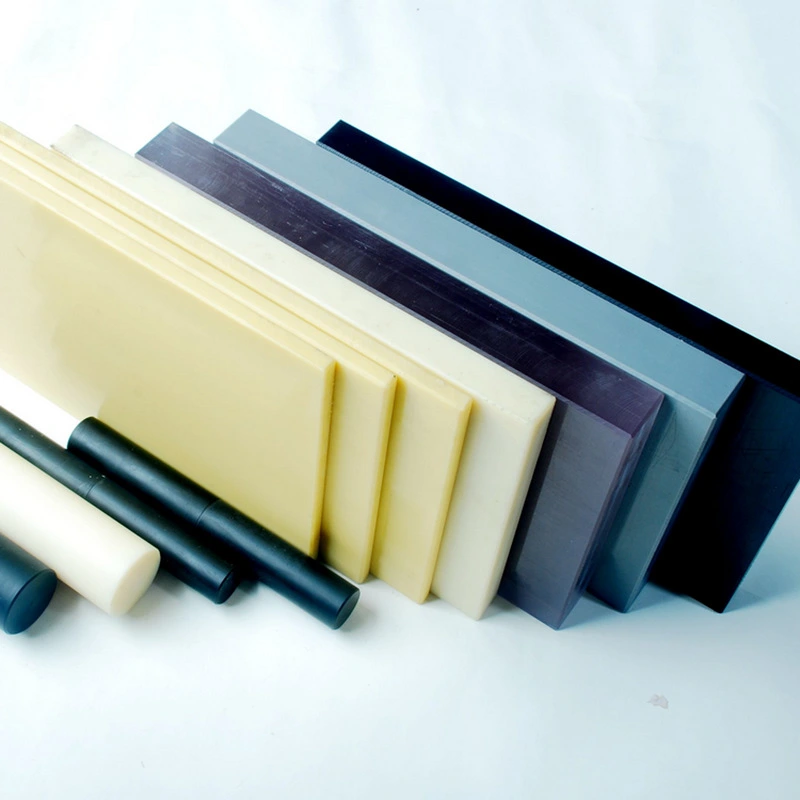

Phenolic paper laminated tubes are composite materials crafted from layers of paper impregnated with phenolic resin. This unique combination results in a product that boasts exceptional strength, heat resistance, and electrical insulation properties. The phenolic resin, derived from the reaction between phenol and formaldehyde, forms a robust matrix that encapsulates the paper fibers, creating a durable and versatile material.

Applications in Industry

The remarkable characteristics of phenolic paper laminated tubes make them indispensable in various industrial applications. They serve as critical components in electrical systems, providing insulation for high-voltage equipment. In the mechanical realm, these tubes find use in structural supports, rollers, and spacers. The aerospace industry relies on their lightweight yet sturdy nature for interior components. Their heat-resistant properties make them valuable in thermal management systems across multiple sectors.

Environmental Considerations

While phenolic paper laminated tubes offer numerous benefits in their applications, their disposal presents environmental challenges. The composite nature of the material makes conventional recycling methods ineffective. The phenolic resin, being a thermoset polymer, cannot be melted and reshaped like thermoplastics. This characteristic necessitates specialized recycling processes or alternative disposal methods to mitigate environmental impact and promote sustainability in industrial practices.

Sustainable Disposal Methods

Specialized Recycling Facilities

Cutting-edge recycling facilities have developed innovative techniques to process phenolic paper laminated tubes. These facilities employ advanced separation technologies, such as pyrolysis or solvent-based methods, to break down the composite material. The process allows for the recovery of both the phenolic resin and paper components. The reclaimed materials can then be repurposed for various applications, reducing waste and conserving resources. Collaborating with these specialized facilities ensures that the tubes are handled in an environmentally responsible manner, maximizing material recovery and minimizing landfill contribution.

Manufacturer Take-Back Programs

Progressive manufacturers of phenolic paper laminated tubes have implemented take-back programs as part of their commitment to sustainability. These programs allow customers to return used or end-of-life tubes to the manufacturer for proper disposal or recycling. By leveraging their expertise and established recycling partnerships, manufacturers can ensure that the materials are processed efficiently and responsibly. Take-back programs not only facilitate proper disposal but also create a closed-loop system that promotes resource conservation and reduces the environmental footprint of industrial operations.

Repurposing and Upcycling

When recycling options are limited, repurposing phenolic paper laminated tubes offers a creative and sustainable alternative. The durability and heat-resistant properties of these tubes make them suitable for various secondary applications. They can be transformed into decorative items, storage containers, or even structural elements in DIY projects. Educational institutions and makerspaces often welcome such materials for use in engineering and design projects. By repurposing these tubes, their useful life is extended, reducing waste and fostering a culture of resourcefulness and innovation.

Best Practices for Sustainable Disposal

Assessment and Sorting

The first step in sustainable disposal of phenolic paper laminated tubes is a thorough assessment of their condition and potential for recycling or repurposing. Conduct a meticulous inspection to identify any contamination or damage that might affect the recycling process. Sort the tubes based on their composition, size, and condition. This preliminary sorting facilitates more efficient processing at recycling facilities and helps determine which tubes are suitable for repurposing. Implementing a systematic assessment and sorting protocol ensures that each tube is directed to the most appropriate disposal or recycling stream, optimizing resource recovery and minimizing environmental impact.

Collaboration with Waste Management Experts

Engaging with waste management experts is crucial for developing a comprehensive and effective disposal strategy for phenolic paper laminated tubes. These professionals possess in-depth knowledge of local regulations, available recycling technologies, and best practices in industrial waste management. They can provide valuable guidance on proper handling, storage, and transportation of the tubes to ensure compliance with environmental standards. Waste management experts can also help identify specialized recycling facilities or innovative disposal methods that may not be widely known. By fostering a collaborative relationship with these experts, industries can stay at the forefront of sustainable disposal practices and continuously improve their environmental performance.

Employee Education and Training

Implementing sustainable disposal practices for phenolic paper laminated tubes requires the active participation and commitment of all employees involved in handling these materials. Develop comprehensive training programs that educate staff on the environmental impact of improper disposal and the importance of sustainable practices. These programs should cover proper identification of recyclable tubes, correct sorting procedures, and guidelines for preparing tubes for recycling or repurposing. Emphasize the role each employee plays in the organization's sustainability efforts and encourage innovative ideas for waste reduction. Regular refresher courses and updates on new recycling technologies or disposal methods ensure that the workforce remains informed and engaged in sustainable practices.

Conclusion

Sustainable disposal of phenolic paper laminated tubes demands a multifaceted approach that combines innovative recycling technologies, manufacturer responsibility, and creative repurposing. By prioritizing specialized recycling facilities, participating in take-back programs, and exploring upcycling opportunities, industries can significantly reduce the environmental impact of these composite materials. Implementing best practices such as thorough assessment, collaboration with experts, and comprehensive employee education further enhances the effectiveness of sustainable disposal efforts. As technology advances and environmental awareness grows, the potential for even more efficient and eco-friendly disposal methods continues to expand, paving the way for a more sustainable industrial future.

Contact Us

For more information about our insulating sheet products and our commitment to sustainability, please contact us at info@jhd-material.com. Let's work together towards a more environmentally responsible industry.

References

1. Johnson, M. (2022). "Advanced Recycling Techniques for Composite Materials in Industry." Journal of Sustainable Manufacturing, 15(3), 245-260.

2. Zhang, L., et al. (2021). "Pyrolysis-Based Recycling of Phenolic Resin Composites: A Comprehensive Review." Waste Management & Research, 39(8), 1012-1028.

3. Patel, S. (2023). "Manufacturer Take-Back Programs: A Case Study in Industrial Sustainability." Corporate Environmental Strategy, 18(2), 89-104.

4. Reynolds, T., & Smith, A. (2022). "Upcycling Industrial Waste: Creative Solutions for a Circular Economy." Sustainability in Design, 7(4), 312-327.

5. Brown, E. (2023). "Best Practices in Industrial Waste Management: A Guide for Environmental Compliance." Environmental Management and Sustainable Development, 12(1), 56-72.

6. Garcia, R., et al. (2021). "Employee Engagement in Corporate Sustainability Initiatives: Strategies for Success." Journal of Cleaner Production, 295, 126358.