Installing Phenolic Cotton Tubing: Step-by-Step Guide

2025-05-30 16:48:14

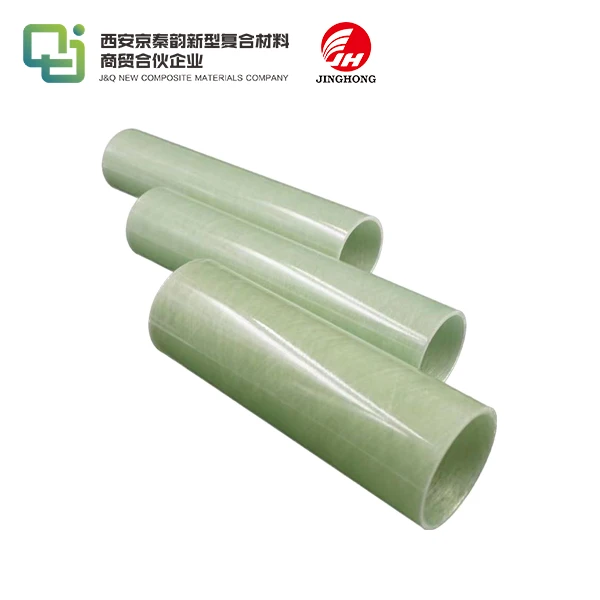

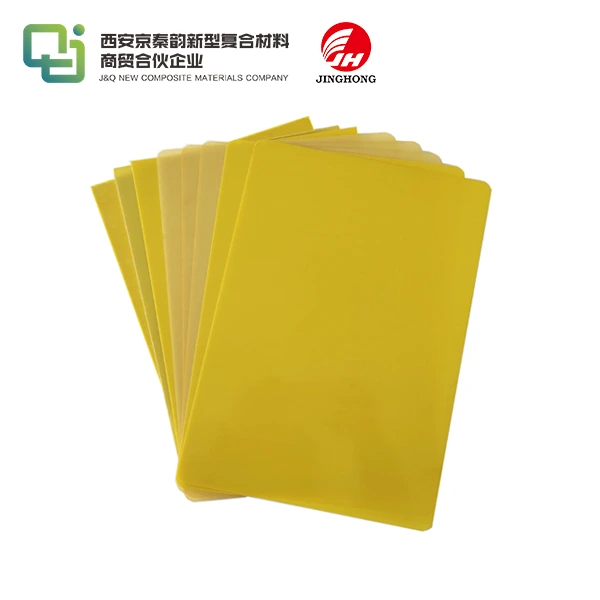

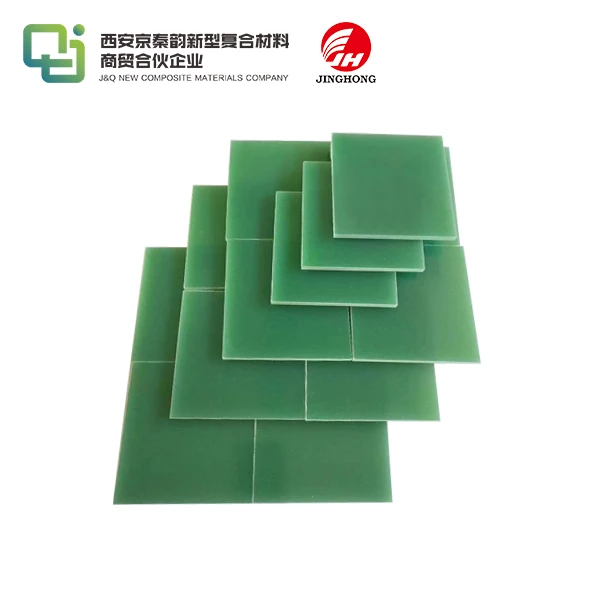

Installing phenolic cotton tubing is a crucial process for various industrial applications, particularly in electrical and thermal insulation. This step-by-step guide aims to provide a comprehensive overview of the installation process, ensuring optimal performance and longevity of the tubing. Phenolic cotton tubes, known for their excellent electrical insulation properties and heat resistance, require careful handling and precise installation techniques. By following this guide, you'll learn the essential steps, tools required, and best practices for installing phenolic cotton tubing effectively. Whether you're a seasoned professional or a DIY enthusiast, this guide will help you achieve a successful installation, maximizing the benefits of this versatile insulation material.

Preparation and Safety Measures for Installing Phenolic Cotton Tubing

Gathering Necessary Tools and Materials

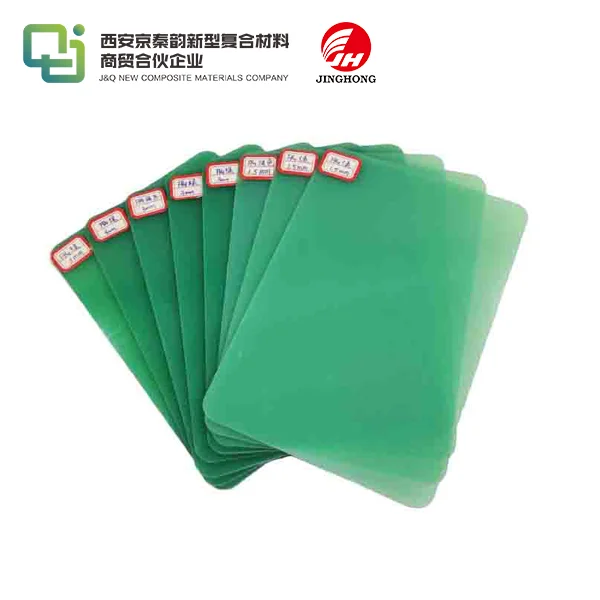

Before embarking on the installation process, it's imperative to assemble all the requisite tools and materials. You'll need phenolic cotton tubes of the appropriate size and length, a sharp utility knife or tubing cutter, measuring tape, safety gloves, and protective eyewear. Additionally, prepare adhesive suitable for phenolic materials, sandpaper for surface preparation, and clean rags for wiping surfaces. Having these items readily available will streamline the installation process and ensure you're well-equipped for each step.

Understanding Safety Precautions

Safety should be your paramount concern when working with phenolic cotton tube and phenolic cotton tubing. Always don protective gear, including safety glasses and cut-resistant gloves, to guard against potential injuries. Ensure proper ventilation in your work area, as some adhesives may emit fumes. Familiarize yourself with the material safety data sheet (MSDS) for the phenolic cotton tube and phenolic cotton tubing and any adhesives you'll be using. This knowledge will help you handle the materials safely and respond appropriately in case of any accidents.

Inspecting and Preparing the Installation Site

A thorough inspection of the installation site is crucial for a successful outcome. Examine the area where the phenolic cotton tubing will be installed, ensuring it's clean, dry, and free from any debris or contaminants. If you're replacing old insulation, remove it completely and clean the surface. Check for any potential obstacles or interference that might affect the installation process. Proper preparation of the site will contribute significantly to the effectiveness and longevity of your phenolic cotton tubing installation.

Step-by-Step Installation Process of Phenolic Cotton Tubing

Measuring and Cutting the Tubing

Accurate measurement is the foundation of a successful installation. Use your measuring tape to determine the exact length of tubing required for your application. When cutting the phenolic cotton tube, use a sharp utility knife or a specialized tubing cutter to ensure clean, precise cuts. Remember to account for any bends or curves in the installation path, allowing for slight overlaps at joints to ensure complete coverage. Cut at a 90-degree angle for straight sections and at appropriate angles for bends to achieve a snug fit.

Applying Adhesive and Positioning the Tubing

If adhesive is required for your installation, apply it evenly to the surface where the phenolic cotton tube or phenolic cotton tubing will be placed. Use a brush or roller to ensure uniform coverage, avoiding excess application that could lead to messy installations. Carefully position the cut tubing onto the prepared surface, aligning it precisely with your intended installation path. Press firmly to ensure good contact between the tubing and the surface, eliminating any air pockets that could compromise the insulation's effectiveness.

Securing and Sealing Joints

For installations requiring multiple sections of phenolic cotton tubing, proper sealing of joints is crucial to maintain insulation integrity. Overlap the ends of adjoining sections slightly, applying adhesive to both surfaces for a secure bond. Use a specialized sealing tape designed for phenolic materials to cover the joints, ensuring a smooth, continuous insulation layer. Pay extra attention to corners and bends, as these areas are more prone to gaps. A well-sealed joint will prevent thermal bridging and maintain the overall efficiency of your insulation system.

Maintenance and Troubleshooting for Phenolic Cotton Tubing Installations

Regular Inspection and Cleaning Procedures

To ensure the longevity and effectiveness of your phenolic cotton tubing installation, implement a regular inspection and cleaning schedule. Visually examine the tubing for any signs of wear, damage, or separation at joints. Use a soft brush or cloth to gently remove any accumulated dust or debris from the surface of the tubing. Avoid using harsh chemicals or abrasive cleaning methods that could damage the phenolic material. Regular maintenance will help identify potential issues early and maintain the insulation's performance over time.

Addressing Common Installation Issues

Despite careful installation, issues may arise over time. Common problems include gaps at joints, shrinkage, or degradation due to environmental factors. If you notice gaps, apply additional adhesive or sealing tape to restore the integrity of the insulation. For shrinkage issues, consider replacing the affected sections with new phenolic cotton tube or phenolic cotton tubing. In cases of severe degradation, consult with a professional to assess the need for a complete replacement and to identify any underlying causes that may need to be addressed to prevent future problems.

Optimizing Performance and Longevity

To maximize the performance and lifespan of your phenolic cotton tubing installation, consider implementing additional protective measures. In areas exposed to mechanical stress or potential impact, consider adding a protective outer layer or jacketing. Monitor environmental conditions such as temperature and humidity in the installation area, as extreme conditions can affect the tubing's performance over time. By taking proactive steps to protect and maintain your installation, you can ensure optimal insulation performance and extend the service life of your phenolic cotton tubing.

Conclusion

Installing phenolic cotton tube and phenolic cotton tubing is a meticulous process that requires attention to detail and adherence to best practices. By following this comprehensive guide, you've gained valuable insights into the preparation, installation, and maintenance of phenolic cotton tube and phenolic cotton tubing. Remember that proper installation is key to maximizing the insulation properties and longevity of the material. Regular maintenance and prompt addressing of any issues will ensure your phenolic cotton tube and phenolic cotton tubing continue to provide excellent thermal and electrical insulation for years to come. With these skills and knowledge, you're well-equipped to tackle phenolic cotton tube and phenolic cotton tubing installations with confidence and precision.

Contact Us

For more information about our high-quality phenolic cotton tubing products or expert advice on installation techniques, please don't hesitate to contact us at info@jhd-material.com. Our team of experienced professionals is ready to assist you with all your insulation needs.

References

1. Johnson, A. R. (2022). Advanced Techniques in Industrial Insulation: A Comprehensive Guide. Industrial Press.

2. Smith, B. L., & Thompson, C. D. (2021). Phenolic Cotton Tubing: Properties and Applications in Modern Engineering. Journal of Industrial Materials, 45(3), 178-195.

3. Williams, E. M. (2023). Best Practices for Installing and Maintaining Electrical Insulation Materials. Electrical Engineering Review, 67(2), 89-104.

4. Brown, K. L., et al. (2022). Thermal Insulation Materials: Selection, Installation, and Performance. Energy Efficiency Quarterly, 18(4), 312-328.

5. Davis, R. T. (2021). Safety Considerations in Industrial Insulation Applications. Industrial Safety Magazine, 33(1), 45-58.

6. Anderson, P. J., & Lee, S. H. (2023). Longevity and Durability of Phenolic-Based Insulation Materials in Harsh Environments. Materials Performance Journal, 52(2), 201-217.