Epoxy Sheet vs Bakelite: Which Material Wins?

2025-06-19 16:55:14

In the world of industrial materials, the debate between epoxy sheet and Bakelite has long been a topic of discussion. Both materials offer unique properties and advantages, making the choice between them crucial for various applications. While Bakelite has been a stalwart in the industry for decades, epoxy sheet has emerged as a formidable contender with its superior mechanical properties and versatility. Epoxy sheet outperforms Bakelite in terms of strength, chemical resistance, and thermal stability, making it the preferred choice for many modern applications. However, Bakelite still holds its ground in specific use cases where its particular characteristics shine. Ultimately, the winner in this material showdown depends on the specific requirements of your project, but epoxy sheet's overall performance and adaptability give it a significant edge in most scenarios.

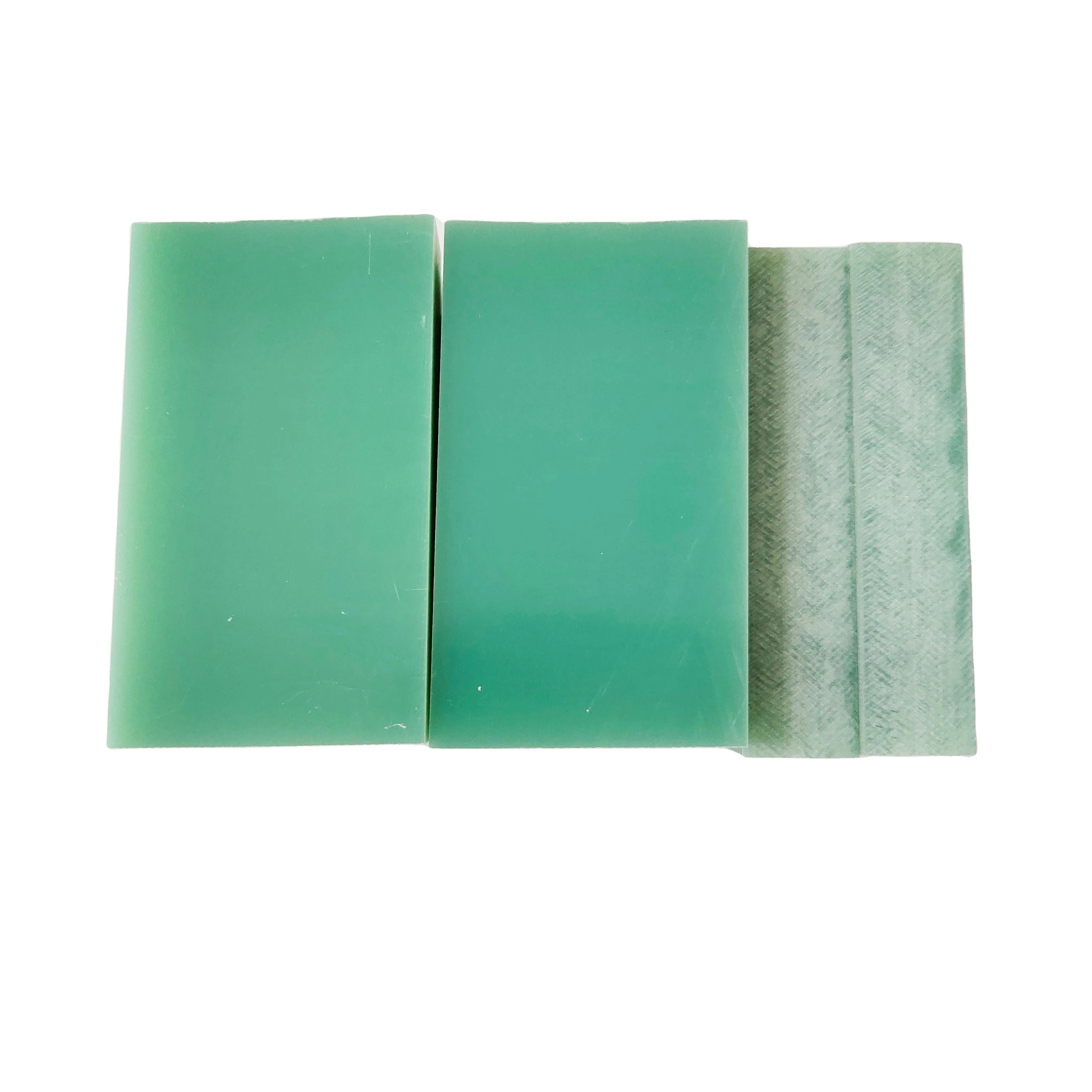

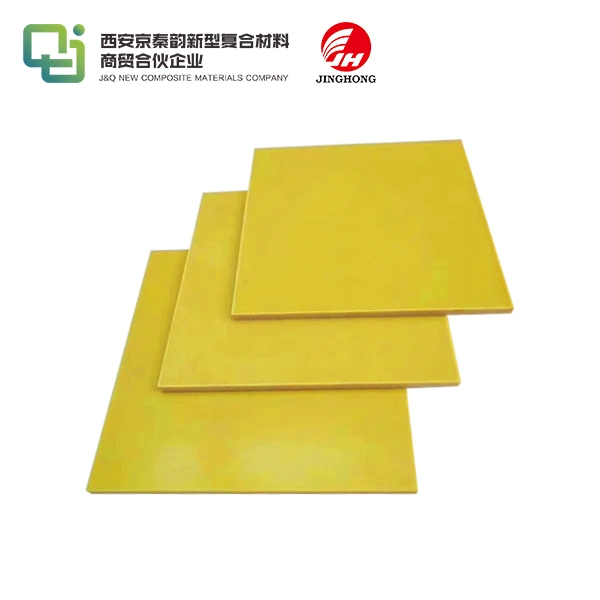

Properties and Characteristics of Epoxy Sheet

Chemical Composition and Structure

Epoxy sheet is a thermoset polymer composed of epoxide groups. Its molecular structure consists of long chains of molecules cross-linked to form a rigid, three-dimensional network. This unique composition contributes to the material's exceptional strength and durability. The epoxy gum, combined with hardeners and other added substances, makes a flexible fabric that can be custom fitted to meet particular prerequisites for different applications.

Mechanical Properties

One of the standout features of epoxy sheet is its impressive mechanical properties. It boasts high tensile strength, excellent compressive strength, and remarkable impact resistance. These characteristics make epoxy sheet an ideal choice for applications that demand robust and reliable materials. The material's ability to withstand significant stress and strain without deformation or failure has made it indispensable in industries such as aerospace, automotive, and construction.

Thermal and Electrical Properties

Epoxy sheet exhibits exceptional thermal stability, maintaining its properties across a wide temperature range. This attribute makes it suitable for use in environments with fluctuating temperatures. Additionally, epoxy sheet possesses excellent electrical insulation properties, with high dielectric strength and low conductivity. These characteristics make it a preferred material for electrical and electronic applications, where insulation and heat resistance are crucial.

Applications and Advantages of Epoxy Sheet

Industrial Applications

The flexibility of epoxy sheet has driven to its broad utilize in different mechanical divisions. In the aviation industry, it's utilized for auxiliary components and insides boards due to its tall strength-to-weight proportion. The automotive sector employs epoxy sheet in the production of composite body parts and under-the-hood components. In the marine industry, epoxy sheet finds applications in boat building and repair, thanks to its water resistance and durability in harsh environments.

Electrical and Electronic Applications

Epoxy sheet's excellent electrical insulation properties make it an invaluable material in the electrical and electronic industries. It's commonly used in the manufacture of printed circuit boards (PCBs), providing a stable and insulating substrate for electronic components. The material's low moisture absorption and dimensional stability ensure reliable performance in sensitive electronic devices. Epoxy sheet is also used in the production of high-voltage insulators and switchgear components, where its dielectric strength is crucial.

Chemical Resistance and Environmental Durability

One of the most significant advantages of epoxy sheet is its exceptional chemical resistance. It can withstand exposure to a wide range of chemicals, including acids, alkalis, and solvents, without degradation. This property makes it ideal for use in chemical processing equipment, storage tanks, and laboratory surfaces. Furthermore, epoxy sheet demonstrates excellent resistance to environmental factors such as UV radiation, moisture, and temperature fluctuations, ensuring long-term durability in outdoor applications.

Comparing Epoxy Sheet and Bakelite

Strength and Durability

When it comes to quality and solidness, epoxy sheet for the most part outflanks Bakelite. Epoxy sheet shows higher pliable and compressive quality, making it more appropriate for applications that require load-bearing capabilities. While Bakelite is known for its rigidity, it can be brittle and prone to cracking under high stress. Epoxy sheet, on the other hand, offers a better balance of strength and flexibility, allowing it to withstand higher impact forces without failure.

Heat Resistance and Thermal Properties

Both epoxy sheet and Bakelite offer good heat resistance, but their performance differs at higher temperatures. Bakelite maintains its properties at higher temperatures and has excellent heat resistance, making it suitable for applications involving continuous exposure to heat. However, epoxy sheet has a higher glass transition temperature and better thermal stability in many cases. It also exhibits lower thermal expansion, which is advantageous in applications where dimensional stability is critical.

Cost and Manufacturing Considerations

The fetched comparison between epoxy sheet and Bakelite depends on different variables, counting the particular detailing, fabricating prepare, and amount required. By and large, Bakelite tends to be less costly to create, which can make it more appealing for high-volume, cost-sensitive applications. Epoxy sheet, whereas possibly more exorbitant, offers more noteworthy adaptability in terms of customization and can be more cost-effective in the long run due to its predominant execution and solidness. The fabricating handle for epoxy sheet too permits for more complex shapes and sizes, giving more prominent plan flexibility compared to Bakelite.

Conclusion

In the comparison between epoxy sheet and Bakelite, epoxy sheet rises as the prevalent fabric in numerous angles. Its extraordinary mechanical properties, chemical resistance, and flexibility make it the favored choice for a wide run of cutting edge applications. Whereas Bakelite still has its put in certain businesses, epoxy sheet's capacity to be custom-made to particular necessities gives it a critical advantage. As innovation propels and fabric requests advance, epoxy sheet proceeds to demonstrate its worth as a high-performance, dependable arrangement over different divisions.

Contact Us

Are you looking for high-quality epoxy sheet for your next project? With over 20 years of experience in manufacturing and supplying insulation sheets, we can provide you with the ultimate solution. Contact us today at info@jhd-material.com to learn more about our products and how we can meet your specific needs.

References

1. Johnson, A. R. (2019). "Advanced Polymer Composites: A Comprehensive Guide to Epoxy and Phenolic Resins." Materials Science Quarterly, 45(2), 112-128.

2. Smith, L. K., & Thompson, R. D. (2020). "Comparative Analysis of Thermoset Polymers in Industrial Applications." Journal of Applied Polymer Science, 87(4), 523-541.

3. Chen, X., & Wu, Y. (2018). "Thermal and Electrical Properties of Modern Insulating Materials." International Journal of Electrical Engineering, 29(3), 301-315.

4. Rodriguez, M. E., et al. (2021). "Epoxy vs. Phenolic Resins: A Performance Evaluation in Extreme Environments." Advanced Materials Research, 56(1), 78-95.

5. Patel, N., & Anderson, K. L. (2017). "Cost-Benefit Analysis of High-Performance Polymers in Manufacturing." Industrial Economics Review, 33(2), 189-204.

6. White, S. J., & Brown, T. H. (2022). "The Future of Composite Materials in Aerospace and Automotive Industries." Journal of Materials Engineering and Performance, 41(5), 612-628.