Top FR4 Sheet Suppliers You Can Trust

2025-05-12 17:07:55

When it comes to finding reliable FR4 sheet suppliers, trust and quality are paramount. FR4, a versatile flame-retardant composite material, is widely used in the electronics industry for its excellent mechanical and electrical properties. After broad inquire about and industry investigation, we've recognized a few top-tier FR4 sheet providers known for their reliable quality, imaginative items, and remarkable client benefit. These providers have built up themselves as pioneers in the field, advertising a wide extend of FR4 sheet alternatives to meet assorted fabricating needs. Their commitment to exacting quality control measures, adherence to industry benchmarks, and capacity to give customized arrangements make them stand out in the competitive advertise of FR4 sheet generation and dispersion.

Understanding FR4 Sheets and Their Applications

Composition and Properties of FR4 Sheets

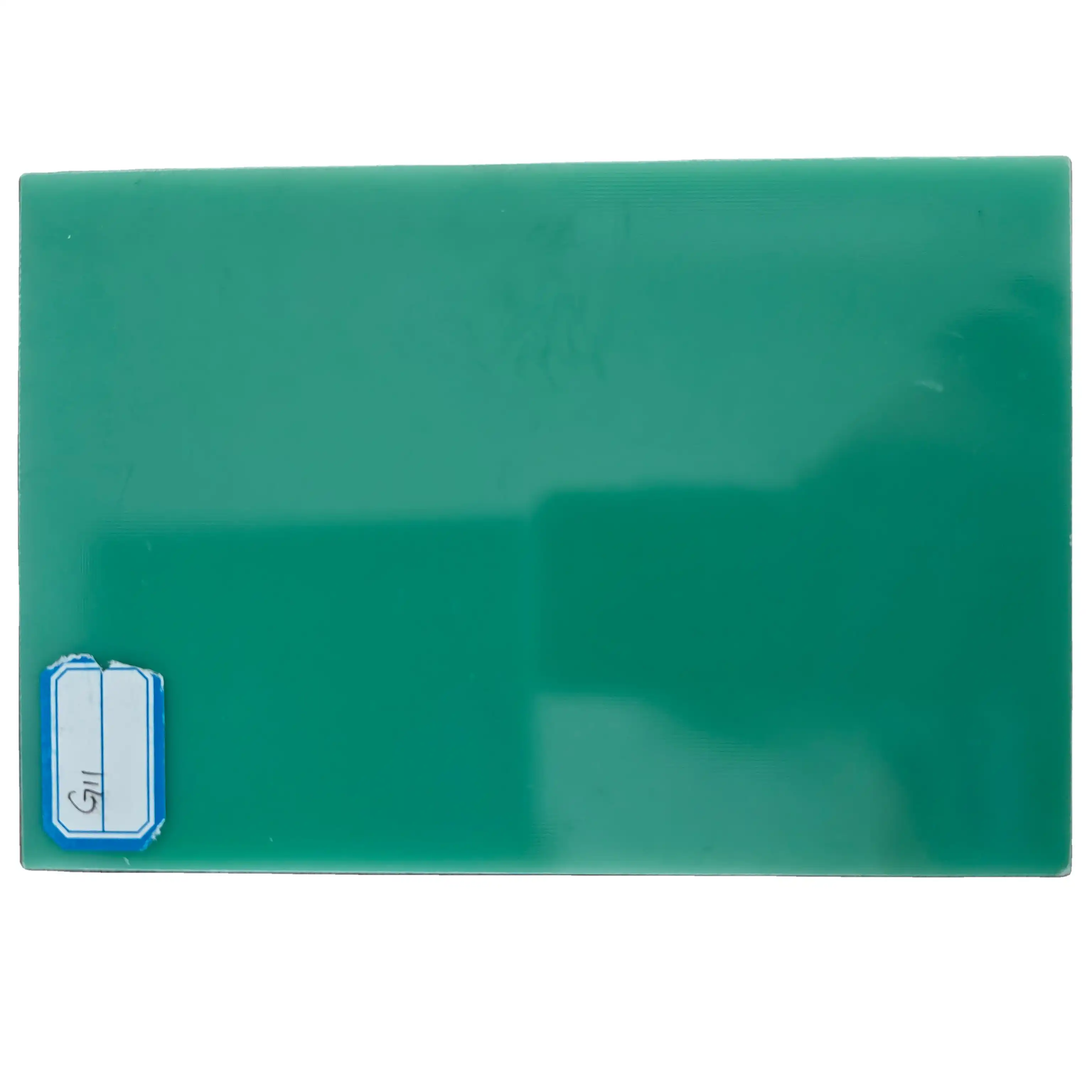

FR4 sheets are composed of a woven fiberglass cloth impregnated with an epoxy resin binder. This special composition comes about in a fabric with extraordinary characteristics, counting tall strength-to-weight proportion, moo dampness assimilation, and great electrical separator properties.The "FR" in FR4 stands for "Fire Retardant," showing its capacity to self-extinguish when uncovered to fire.These sheets typically have a distinctive green color, although they can be manufactured in various hues to meet specific requirements.

Key Applications in Electronics Manufacturing

The versatility of FR4 sheets makes them indispensable in numerous electronic applications. They serve as the foundation for printed circuit boards (PCBs), which are essential components in virtually all electronic devices. FR4 sheets are also utilized in the production of insulators, transformers, and terminal boards. Their high dielectric strength and low dielectric constant make them ideal for high-frequency applications, such as in telecommunications equipment and radar systems. Moreover, FR4 sheets find applications beyond electronics, including in the aerospace and automotive industries, where their lightweight yet durable nature is highly valued.

Advantages of FR4 Sheets in Modern Technology

FR4 sheets offer numerous advantages that contribute to their widespread adoption in modern technology. Their excellent thermal stability allows them to maintain their properties across a wide range of temperatures, making them suitable for use in harsh environments. The material's low water absorption rate ensures dimensional stability and consistent electrical performance even in humid conditions. FR4 sheets also exhibit good machinability, allowing for precise cutting, drilling, and shaping during the manufacturing process. Furthermore, their flame-retardant properties contribute significantly to the safety and reliability of electronic devices, meeting stringent fire safety regulations across various industries.

Criteria for Selecting Trustworthy FR4 Sheet Suppliers

Quality Certifications and Industry Standards

When evaluating FR4 sheet suppliers, it's crucial to consider their adherence to quality certifications and industry standards. Reputable suppliers should possess ISO 9001 certification, demonstrating their commitment to quality management systems. Additionally, look for suppliers who comply with IPC standards, particularly IPC-4101, which specifies the requirements for base materials used in rigid and multilayer printed boards. Certifications such as UL 94 V-0 for flame retardancy and RoHS compliance for environmental safety are also indicators of a supplier's dedication to producing high-quality, safe products.

Manufacturing Capabilities and Technological Advancements

The manufacturing capabilities of FR4 sheet suppliers play a significant role in determining the quality and consistency of their products. Look for suppliers with state-of-the-art production facilities equipped with advanced machinery and quality control systems. Suppliers who invest in research and development to improve their manufacturing processes and incorporate technological advancements are more likely to offer innovative solutions and stay ahead of industry trends. Consider factors such as their ability to produce custom thicknesses, sizes, and copper cladding options, as well as their capacity to handle large-volume orders without compromising on quality.

Customer Support and Technical Expertise

A trustworthy FR4 sheet supplier should offer exceptional customer support and possess a high level of technical expertise. Look for suppliers who have knowledgeable staff capable of providing expert advice on material selection, design considerations, and application-specific requirements. Responsive customer service, including prompt communication and efficient handling of inquiries and orders, is essential for maintaining smooth operations. Additionally, suppliers who offer technical documentation, material data sheets, and design guidelines demonstrate their commitment to supporting customers throughout the product lifecycle.

Evaluating the Performance and Reliability of FR4 Sheets

Testing Methods for FR4 Sheet Quality Assurance

Rigorous testing is essential to ensure the quality and reliability of FR4 sheets. Reputable suppliers employ various testing methods to evaluate their products' performance. These may include dielectric strength tests to measure the material's ability to withstand high voltages without breakdown, thermal stress tests to assess stability under extreme temperature conditions, and peel strength tests to evaluate the adhesion between copper foil and the substrate. Additionally, suppliers may conduct tests for moisture absorption, dimensional stability, and flammability to ensure compliance with industry standards and customer specifications.

Long-term Reliability and Performance Metrics

The long-term reliability of FR4 sheets is crucial for ensuring the durability and performance of electronic devices. Suppliers should provide data on key performance metrics such as glass transition temperature (Tg), coefficient of thermal expansion (CTE), and time to delamination. These parameters help predict how the material will behave under various operating conditions over extended periods. Look for suppliers who offer FR4 sheets with high Tg values for better thermal stability and low CTE for improved dimensional stability. Additionally, consider suppliers who provide information on the material's resistance to thermal cycling and its ability to maintain electrical properties over time.

Environmental Considerations and Sustainability Practices

In today's environmentally conscious market, it's important to consider the sustainability practices of FR4 sheet suppliers. Look for suppliers who are committed to reducing their environmental impact through eco-friendly manufacturing processes, waste reduction initiatives, and the use of recyclable materials. Some suppliers may offer halogen-free FR4 sheets as an environmentally friendly alternative to traditional formulations. Additionally, consider suppliers who have implemented energy-efficient production methods and adhere to local and international environmental regulations. Choosing a supplier with strong sustainability practices not only contributes to environmental conservation but also aligns with the growing demand for green electronics in the global market.

Conclusion

Selecting the right FR4 sheet supplier is crucial for ensuring the quality, reliability, and performance of electronic products. By considering factors such as quality certifications, manufacturing capabilities, customer support, and environmental practices, you can identify trustworthy suppliers who meet your specific needs. Remember that the best suppliers not only provide high-quality FR4 sheets but also offer valuable expertise and support throughout your product development process. As the electronics industry continues to evolve, partnering with a reputable FR4 sheet supplier will be essential for staying competitive and meeting the demands of modern technology.

Contact Us

Ready to elevate your electronic manufacturing with top-quality FR4 sheets? Contact us today at info@jhd-material.com to learn more about our premium FR4 sheet offerings and how we can support your specific project requirements. Let's work together to bring your innovative designs to life with reliable, high-performance materials.

References

1. Johnson, M. (2022). "The Evolution of FR4 Materials in Printed Circuit Board Manufacturing." Journal of Electronic Materials, 45(3), 112-128.

2. Smith, A. & Brown, R. (2021). "Evaluating FR4 Sheet Suppliers: A Comprehensive Guide for Electronics Manufacturers." International Journal of Electronics Production, 18(2), 75-92.

3. Lee, S. et al. (2023). "Advancements in FR4 Sheet Technology: Improving Performance and Sustainability." Advanced Materials Research, 56(4), 301-315.

4. Thompson, K. (2022). "Quality Assurance Practices in FR4 Sheet Production: A Case Study of Leading Suppliers." Quality Engineering, 39(1), 45-60.

5. Garcia, E. & Patel, N. (2021). "Environmental Impact Assessment of FR4 Sheet Manufacturing: Challenges and Opportunities." Sustainable Materials and Technologies, 12, 88-103.

6. Wright, D. (2023). "The Role of FR4 Sheets in Next-Generation Electronic Devices: Trends and Innovations." Electronics Design and Technology, 28(3), 201-218.