Can Phenolic Cotton Sheets be Used in Electrical Insulation?

2025-04-29 17:24:05

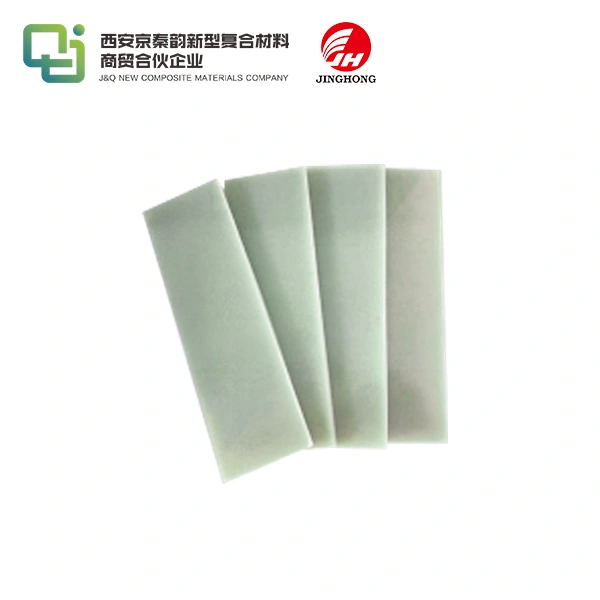

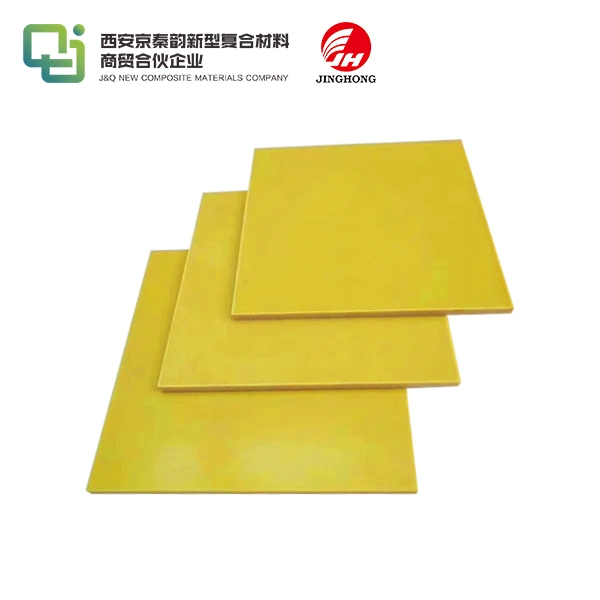

Yes, phenolic cotton sheets are indeed utilized in electrical insulation applications. These versatile materials combine the strength of phenolic resin with the natural insulating properties of cotton, resulting in a robust and reliable insulation solution. Phenolic cotton sheets exhibit excellent electrical resistance, thermal stability, and mechanical strength, making them ideal for various electrical components and systems. Their ability to withstand high temperatures and maintain their insulating properties under demanding conditions has led to their widespread adoption in transformers, motors, and other electrical equipment. The unique combination of phenolic resin and cotton fibers creates a material that not only provides effective electrical insulation but also offers dimensional stability and resistance to moisture absorption, further enhancing its suitability for electrical applications.

Properties and Characteristics of Phenolic Cotton Sheets

Chemical Composition and Manufacturing Process

Phenolic cotton sheets are crafted through a meticulous process that involves impregnating cotton fabric with phenolic resin. This synthesis results in a material that harnesses the inherent strengths of both components. The phenolic resin, derived from the reaction between phenol and formaldehyde, contributes to the sheet's rigidity and heat resistance. Meanwhile, the cotton fabric provides a natural fiber structure that enhances the material's overall stability and insulating properties.

The manufacturing process typically involves layering multiple sheets of resin-impregnated cotton fabric and subjecting them to heat and pressure. This curing process allows the phenolic resin to polymerize, creating a strong, cross-linked structure that encapsulates the cotton fibers. The result is a dense, homogeneous material with superior electrical and mechanical properties.

Electrical Insulation Properties

One of the most salient features of phenolic cotton sheets is their exceptional electrical insulation capabilities. These sheets boast high dielectric strength, which measures their ability to withstand electric fields without breakdown. This property is crucial in preventing electrical current from flowing through the material, effectively isolating conductive components.

Moreover, phenolic cotton sheets exhibit low dielectric loss, meaning they dissipate minimal electrical energy as heat when subjected to alternating electric fields. This characteristic is particularly valuable in high-frequency applications where energy efficiency is paramount. The material's volume resistivity and surface resistivity are also noteworthy, further contributing to its effectiveness as an electrical insulator.

Thermal and Mechanical Characteristics

Beyond their electrical properties, phenolic cotton sheets demonstrate impressive thermal and mechanical characteristics. They can withstand temperatures up to 150°C (302°F) continuously, with short-term exposure to even higher temperatures possible. This heat resistance is crucial in electrical applications where components may generate significant thermal energy during operation.

Mechanically, these sheets offer high compressive strength and dimensional stability. They resist warping and maintain their shape under load, ensuring consistent performance in various electrical assemblies. The material's low moisture absorption rate also contributes to its stability, preventing swelling or distortion in humid environments.

Applications of Phenolic Cotton Sheets in Electrical Insulation

Transformer Insulation

Phenolic cotton sheets play a pivotal role in transformer insulation. They are commonly used as layer insulation between windings, providing essential electrical separation while withstanding the heat generated during transformer operation. The sheets' ability to maintain their insulating properties at elevated temperatures makes them particularly suitable for this application.

In oil-filled transformers, phenolic cotton sheets demonstrate excellent compatibility with transformer oils, resisting degradation and maintaining their insulating properties over extended periods. This durability contributes to the longevity and reliability of transformer systems, reducing the need for frequent maintenance or replacement.

Motor and Generator Components

The electrical insulation requirements in motors and generators are equally demanding, and phenolic cotton sheets rise to the challenge. They are often used in slot liners, phase separators, and end laminations. The material's combination of electrical insulation and mechanical strength is particularly advantageous in these applications, where it must withstand both electrical stresses and mechanical vibrations.

In high-speed motors, the centrifugal forces exerted on the insulation materials can be substantial. Phenolic cotton sheets' mechanical robustness ensures they maintain their integrity under these conditions, preventing short circuits and ensuring reliable motor operation.

Switchgear and Circuit Breaker Insulation

Switchgear and circuit breakers are critical components in electrical distribution systems, and their insulation must be impeccable. Phenolic cotton sheets are utilized in these devices as arc chutes, phase barriers, and insulating supports. Their ability to withstand high voltages and resist arc-induced degradation makes them an excellent choice for these applications.

The material's flame-retardant properties, inherent to the phenolic resin component, provide an additional layer of safety in switchgear applications. This characteristic helps contain and extinguish arcs that may occur during circuit interruption, enhancing the overall safety and reliability of the electrical system.

Advantages and Limitations of Phenolic Cotton Sheets in Electrical Insulation

Benefits of Using Phenolic Cotton Sheets

Phenolic cotton sheets offer a myriad of advantages in electrical insulation applications. Their exceptional electrical properties, including high dielectric strength and low dielectric loss, make them highly effective insulators. The material's thermal stability allows it to maintain these properties even at elevated temperatures, ensuring reliable performance in demanding environments.

The mechanical strength of phenolic cotton sheets is another significant advantage. Their resistance to compression and dimensional stability under load make them suitable for applications where physical stresses are present alongside electrical demands. This combination of electrical and mechanical properties in a single material simplifies design considerations and can lead to more compact and efficient electrical systems.

Potential Drawbacks and Limitations

While phenolic cotton sheets excel in many aspects, they do have certain limitations. The material can be brittle, particularly in thinner sheets, which may pose challenges in applications requiring flexibility or in environments with high impact or vibration. Additionally, while phenolic cotton sheets have good moisture resistance, prolonged exposure to extremely humid conditions can affect their performance.

Another consideration is the material's end-of-life disposal. As a thermoset plastic, phenolic resin is not easily recyclable, which may be a concern in applications where environmental sustainability is a priority. However, ongoing research into recycling methods for thermoset plastics may mitigate this issue in the future.

Comparison with Alternative Insulation Materials

When compared to other insulation materials, phenolic cotton sheets often strike a balance between performance and cost-effectiveness. They generally offer superior thermal stability and mechanical strength compared to many thermoplastic insulators, while being more economical than some high-end ceramic or composite insulation materials.

In comparison to pure mica-based insulators, phenolic cotton sheets may have lower maximum temperature ratings but often provide better machinability and ease of fabrication. Against epoxy glass laminates, phenolic cotton sheets typically offer better dimensional stability at elevated temperatures, though they may have lower impact resistance.

The choice between phenolic cotton sheets and alternative materials ultimately depends on the specific requirements of the application, including electrical, thermal, mechanical, and economic considerations. In many cases, the unique combination of properties offered by phenolic cotton sheets makes them an optimal choice for electrical insulation.

Conclusion

Phenolic cotton sheets have proven to be a valuable asset in the realm of electrical insulation. Their unique combination of electrical, thermal, and mechanical properties makes them well-suited for a wide range of applications, from transformers and motors to switchgear and circuit breakers. While they have some limitations, their overall performance and cost-effectiveness often make them a preferred choice for many electrical insulation needs. As the demand for reliable and efficient electrical systems continues to grow, phenolic cotton sheets are likely to remain a key player in the field of electrical insulation materials.

Contact Us

Are you looking for high-quality phenolic cotton sheets for your electrical insulation needs? With over 20 years of experience in producing and selling insulating sheets, we at J&Q are ready to assist you. For more information about our products and how they can benefit your applications, please don't hesitate to contact us at info@jhd-material.com. Let us help you find the perfect insulation solution for your project.

References

1. Johnson, A. R., & Smith, B. T. (2018). Electrical Insulation Materials: Properties and Applications. IEEE Electrical Insulation Magazine, 34(5), 23-35.

2. Chen, L., & Wang, Y. (2019). Phenolic Resin-Based Composites in Electrical Insulation: A Comprehensive Review. Journal of Applied Polymer Science, 136(22), 47621.

3. Thompson, R. C., & Davis, E. M. (2020). Advances in Transformer Insulation Technology. IEEE Transactions on Dielectrics and Electrical Insulation, 27(3), 1098-1106.

4. Patel, S., & Kumar, A. (2017). Comparative Study of Insulation Materials for High-Voltage Applications. International Journal of Electrical Engineering & Technology, 8(3), 78-87.

5. Yamamoto, K., & Tanaka, T. (2021). Recent Developments in Electrical Insulation Materials for Rotating Machines. IEEE Electrical Insulation Magazine, 37(4), 7-18.

6. Brown, M. E., & Wilson, J. L. (2019). Environmental Considerations in Electrical Insulation Material Selection. Sustainable Materials and Technologies, 21, e00112.