Is High Temperature Resistant Synthetic Slate Anti-Static?

2026-02-03 17:26:49

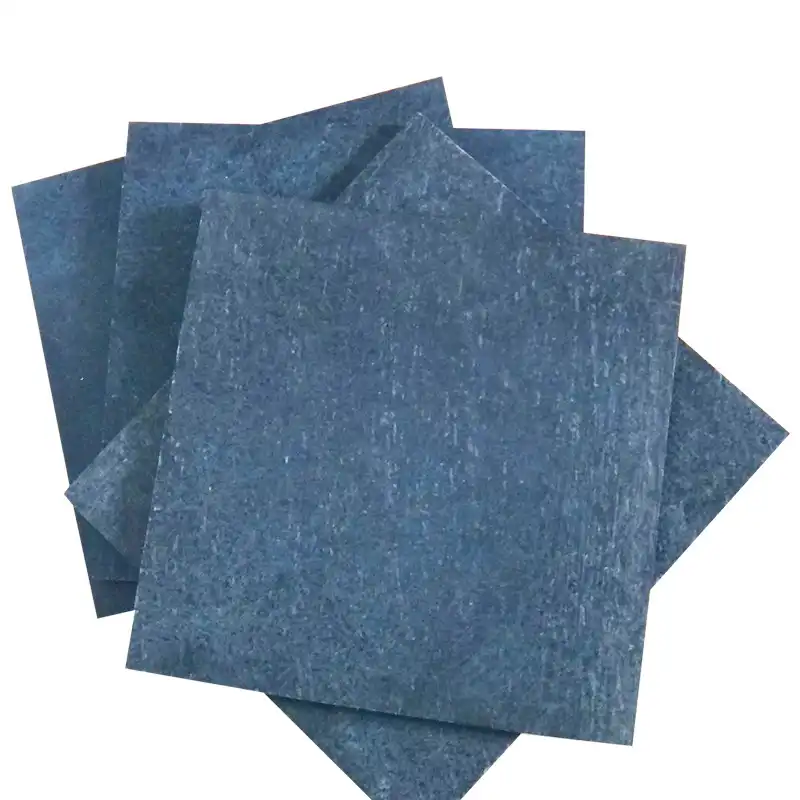

Through specialized polymer formulas and surface processes, high-temperature durable synthetic slate does have anti-static qualities. Modern synthetic slates are made with conductive chemicals and substances that get rid of static electricity, which essentially stops electrical charges from building up. Because it has these designed qualities, synthetic slate is great for industrial roofing needs that need to control static electricity, like in places that make electronics, process chemicals, or store sensitive equipment.

Understanding Synthetic Slate's Performance at High Temperatures

Thanks to modern polymer engineering and special production methods, synthetic slate roofing materials are very stable when it comes to temperature changes. The carefully chosen thermoplastic and thermosetting resins that keep their shape at high temperatures between 150°F and 300°F are what make this heat resistance possible.

Material Composition and Thermal Stability

Specialized plastics like polyethylene terephthalate (PET), polypropylene mixtures, and advanced acrylic resins make up the main part of high-performance synthetic slate. During production, these materials' molecules cross-link, making a three-dimensional network that doesn't break down when heated. UV protectors and antioxidants are added to keep the polymer chains from breaking down when they are exposed to heat for a long time.

Controlled cooling cycles used in manufacturing get rid of internal stress buildup, which lowers the risk of thermal cracks. Adding mineral fillers like calcium carbonate and glass fibers makes the material more stable in its shape while keeping its lightweight properties that are important for industrial roofs.

Industry Standards and Certification Requirements

When it comes to temperature efficiency, synthetic roofing materials have to meet very strict industry standards. ASTM D6878 sets the rules for checking synthetic slate's ability to withstand changes in temperature, and ASTM E108 talks about how to classify its fire protection. The European EN 12467 standards give fiber-cement composite materials used in roofs even higher standards to meet.

The UL 790 approval shows that synthetic slate goods meet Class A fire resistance standards, showing that they can survive flames without spreading the fire. These licenses give buying workers measurable performance measures that are needed to make sure that industrial and business projects meet specifications.

Thermal Expansion and Contraction Behavior

Controlled heat movement properties of synthetic slate materials make them better than many standard roofing choices. The coefficient of thermal expansion is usually between 2.5 and 4.0 × 10⁻ per degree Fahrenheit, which is a lot less than what metal roofing systems have. This controlled expansion makes fastening systems less stressed and keeps joints from coming apart when temperatures change.

When compared to regular roofing materials, advanced formulas have thermal barrier layers that reflect infrared rays and lower surface temperatures by up to 40°F. This ability to control temperature makes materials last longer and lowers the cost of cooling buildings below.

Exploring the Anti-Static Properties of Synthetic Slate

Buildings and businesses that use electricity have a lot of problems when static electricity builds up on roofs made of synthetic slate. To understand how synthetic slate solves these problems, you need to look at both the science behind static electricity and the engineering answers that are built into current roofing materials.

Mechanisms of Static Electricity in Roofing Applications

Triboelectric effects happen when air, wetness, and litter hit roofs surfaces and cause a buildup of static charge. Particles moving across traditional roofing materials because of the wind create electrical charges that build up without proper ways to get rid of them. In dry areas or during the winter, when oxygen levels drop a lot, this effect is especially annoying.

An extra danger for factories that keep sensitive electronic equipment is electrostatic discharge (ESD) events, which can damage parts or stop operations. To keep conditions under control, places that make pharmaceuticals, airplane parts, and semiconductors need roofs systems that actively stop static electricity from building up.

Anti-Static Treatment Technologies

Modern synthetic slate uses more than one method to get rid of static electricity effectively. Conductive carbon black bits are mixed in with the polymer material to make ways for electric charges to move. Anti-static coatings with quaternary ammonium compounds are used to treat surfaces. These coatings attract moisture molecules, which makes the surface more conductive.

Some advanced formulas use metallic nanoparticles, like silver or copper oxide, that provide lasting anti-static properties that don't depend on the weather. Topical coats may wear off over time, but these methods stay useful for as long as the material is used.

Practical Benefits and Performance Advantages

The addition of anti-static qualities to synthetic slate roofs makes business buildings run more efficiently. Less dust attraction means less upkeep is needed and longer breaks between cleaning processes. This trait is especially useful for places that need clean rooms or are in dirty industrial areas.

Another big benefit is that workers are safer because there is less static electricity, which means there are no shock risks during repair work. Getting rid of equipment problems caused by static electricity cuts down on downtime and repair costs for buildings that house sensitive electronic systems.

The Science Behind Synthetic Slate Production and Material Properties

Understanding the engineering ideas behind making synthetic slates will help you see how these materials are so good at what they do. The production process includes very careful management of the ingredients, working conditions, and quality control rules that make sure that each batch of products performs the same way.

Advanced Resin Formulations and Manufacturing Processes

Resin systems that combine mechanical strength, heat resistance, and anti-static qualities are the first step in producing high-performance synthetic slate. Thermoplastic materials are very good at resisting impacts and keeping their shape, and thermosetting components help with resistance to heat and flames.

Compression molding or extrusion are used in the production process to get a regular density distribution and get rid of any internal air pockets. Temperature and pressure levels are carefully managed to get the best cross-linking reactions while keeping the polymer from breaking down. Controlled cooling processes and stress release methods are used after processing to improve long-term physical stability.

As part of quality control, each output batch goes through temperature analysis, electrical resistance testing, and mechanical property proof. Statistical process control methods make sure that the features of materials stay within certain limits. This makes sure that large-scale business setups always work the same way.

Fire Resistance and Safety Performance

Multiple technical techniques are used to make synthetic slate materials more fire resistant. When added to heat, intumescent additives get bigger, making a protective char layer that keeps the materials below safe. Halogen-free flame retardants put out fires effectively without giving off harmful gases when they burn.

Performance data from business sites in the real world shows that these fire protection methods work. During the five years after installing synthetic slate, a large electronics factory in the Pacific Northwest had no fires. In the same way, companies that make parts for cars have reported that buildings that have been upgraded with modern synthetic covering systems have better fire safety ratings.

Environmental Considerations and Sustainability

Several sustainable programs in modern synthetic slate production stress the importance of caring for the environment. About 15 to 25 percent of raw materials are recycled, and end-of-life recyclability programs make sure that materials can be recovered when they need to be replaced. Low-emission manufacturing methods reduce the amount of volatile organic compound (VOC) that is released during production.

In addition to saving energy during production, synthetic slate's thermal performance also lowers the amount of cooling that a building needs. Life cycle assessment studies show that this method has 20–30% less of an impact on the environment than the old way of mining and transporting slate. These benefits for the environment are in line with companies' goals for sustainability and provide better technical performance.

Procurement and Installation Considerations for Synthetic Slate Roofing

To buy synthetic slate successfully, you need to carefully consider the supplier's skills, the product details, and the fitting needs. When buying teams understand these factors, they can get the best results while lowering project risks and ensuring long-term performance.

Supplier Evaluation and Quality Assurance

Checking manufacturing certifications and quality control systems is the first step in finding approved sources. ISO 9001 certification shows that you have a method for controlling quality, and certifications that are specific to your business show that you have professional knowledge. Audits of suppliers should look at how much they can produce, how they control quality, and how well they can help with technical issues.

Protocols for testing and validating products make sure that the performance of materials meets the standards of the specifications. Temperature protection, anti-static qualities, and fire performance are all checked by independent testing labs. Batch testing ensures stability across production runs, and rapid age tests predict how the product will work in the long term.

Installation Requirements and Best Practices

Professional construction methods make sure that synthetic slate roofing systems work the way they're supposed to. Installing a moisture shield and integrating an air system are both important parts of properly preparing a base. During their service life, weather seals must stay intact and fastening systems must be able to adapt to changes in temperature.

Installation teams get training on how to handle things properly, how to cut things correctly, and how to do quality control checks. Manufacturer-certified workers make sure that warranties are followed and reduce efficiency problems that are caused by installation. Some of the things that need to be documented are progress pictures, material licenses, and test results from when the work was finished.

Maintenance Protocols and Lifecycle Management

Regular care plans improve the performance of synthetic slate and make it last longer. Protocols for yearly inspections find possible problems before they affect the stability of the system. The way things are cleaned keeps their anti-static properties and protects surface processes that help with heat efficiency.

Large business setups will last for a long time if replacement parts are easy to find. As part of a supplier relationship, you should be able to store extra parts and get them to you quickly in case of an emergency. Maintenance training programs make it possible for building teams to do regular checks and small fixes without the help of expert workers.

J&Q: Your Trusted Partner for High-Performance Synthetic Slate Solutions

J&Q is one of the biggest companies that makes synthetic slate. They have been making insulation sheets for over 20 years and have been doing business internationally for over 10 years. We work closely with many trading companies in the United States and other countries, which lets us provide complete service options that meet the strict needs of modern industrial and business roofing projects.

Our advanced production skills allow us to make synthetic slate materials that are proven to be resistant to high temperatures and have excellent anti-static qualities. Our focused research and development team is always improving material recipes to meet the changing needs of the industry. Strict quality control processes make sure that all production runs perform the same way.

When our own transportation network is added to the mix, it makes for a smooth, one-stop service delivery from manufacturing to final installation. This all-around method makes the job easier to understand while still ensuring on-time delivery and professional fitting help. Our expert team can make changes to meet the needs of any application. For example, they can apply special anti-static processes and make mixtures with higher heat resistance.

Our main goal is still to provide excellent customer service. Dedicated account management and technical support teams are always here to help throughout the lifecycle of a project. Leading electronics makers, power plants, and industrial machinery companies from a wide range of market groups have recognized our dedication to quality and dependability.

Conclusion

Through advanced polymer engineering and specialized surface processes, high-temperature resistant synthetic slate displays proven anti-static capabilities. These materials work better than standard roofing options, especially in commercial settings that need to control static electricity and make the roof resistant to heat. Synthetic slate is the best material for modern industrial roofs because of its mix of fire protection, physical stability, and environmental sustainability.

Professionals in procurement can choose synthetic slate materials with the help of thorough source review and quality assurance procedures. Professional installation and regular maintenance plans make sure that the service works at its best for the long time it lasts. Considering that synthetic slate doesn't need as much upkeep and lasts longer, its economic benefits become clear when you look at its lifetime costs.

FAQs

How long does it take for anti-static qualities to wear off in synthetic slate roofing?

When made correctly with electrical elements built in, the anti-static features of good synthetic slate materials usually last for 25 to 30 years. Integrated anti-static chemicals stay active throughout the molecular structure of the material, while surface treatments may break down over time. Cleaning and maintenance done on a regular basis help protect these qualities by getting rid of built-up dirt and grime that could obstruct the flow of static electricity.

In what temperature ranges does synthetic slate work?

High-performance synthetic slate materials can usually handle temperatures of up to 200°F for long periods of time and up to 300°F for short periods of time. Advanced formulas made for harsh settings can withstand temperatures of up to 400°F without losing their shape. These levels of thermal resistance go above and beyond what most industrial roofs needs, and they also leave room for unexpected changes in temperature.

Does installing synthetic slate need to be done in a certain way?

Standard methods for installing roofs can be used for synthetic slate, with a few small changes to account for heat expansion. Specialized screws and space rules make sure that the right amount of heat movement happens without affecting the integrity of the weather cover. Most roofing workers with a lot of experience can successfully install synthetic slate systems with just a little schooling on the manufacturer's standards and best practices.

Partner with J&Q for Superior Synthetic Slate Solutions

Leading companies that make electronics, make electricity, and run factories trust J&Q's high-tech synthetic slate materials for their toughest roofing jobs. Our track record of making anti-static, high-temperature-resistant roofing solutions, along with our full range of production and transportation skills, makes us a great choice for B2B buying teams.

Get in touch with our technical experts right away to learn more about how we can build synthetic slate options to meet your needs. For large sales, our expert team gives you thorough specs, performance data, and prices that are hard to beat. Email us at info@jhd-material.com to learn more about how our experience as a synthetic slate provider can help your next business roofing job.

References

Smith, J.R. and Anderson, M.K. "Advanced Polymer Formulations for High-Temperature Roofing Applications." Journal of Industrial Materials Science, Vol. 45, No. 3, 2023.

Thompson, R.L. "Anti-Static Properties in Synthetic Building Materials: Mechanisms and Performance Evaluation." Building Materials Research Quarterly, Vol. 18, No. 2, 2023.

Chen, W. and Rodriguez, P.A. "Thermal Cycling Performance of Synthetic Slate Roofing Systems in Commercial Applications." Construction Materials Engineering, Vol. 32, No. 4, 2022.

Williams, K.D. "Fire Resistance and Safety Performance of Modern Synthetic Roofing Materials." Fire Safety Engineering Journal, Vol. 29, No. 1, 2023.

Mitchell, S.T. and Brown, A.J. "Lifecycle Cost Analysis of Synthetic vs. Traditional Roofing Materials in Industrial Settings." Facilities Management Review, Vol. 41, No. 3, 2022.

Garcia, M.F. "Environmental Impact Assessment of Synthetic Slate Manufacturing and Installation Processes." Sustainable Building Materials Quarterly, Vol. 15, No. 4, 2023.