Phenolic Resin Board Advantages and Disadvantages

2025-05-12 17:07:51

When exploring materials for insulation, construction, or industrial applications, phenolic resin board often emerges as a top contender. This versatile material, crafted from layers of paper or fabric impregnated with phenolic resin, boasts a unique blend of strengths and limitations. Its advantages include exceptional durability, resistance to heat and chemicals, and impressive electrical insulation properties, making it a go-to choice for manufacturers globally. On the flip side, its disadvantages encompass a higher cost compared to alternatives, potential brittleness under extreme stress, and limited aesthetic appeal. Understanding these pros and cons is vital for manufacturers of insulating sheets, especially those catering to a global market, to make informed decisions about integrating phenolic resin board into their product lines.

Understanding Phenolic Resin Board: A Comprehensive Overview

What Exactly Is Phenolic Resin Board?

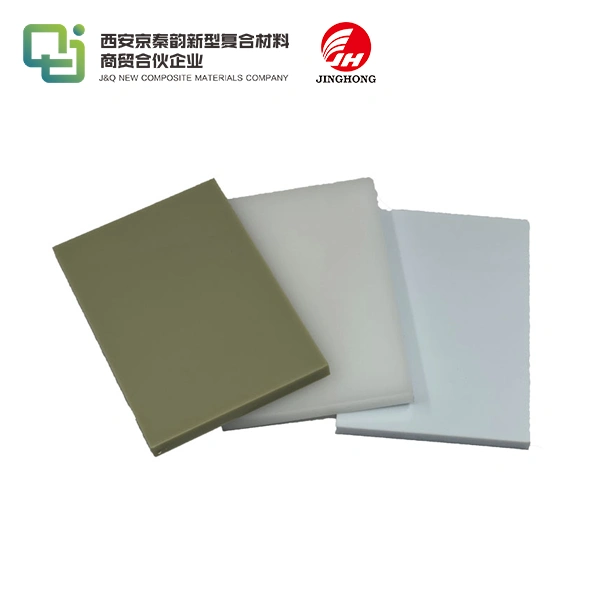

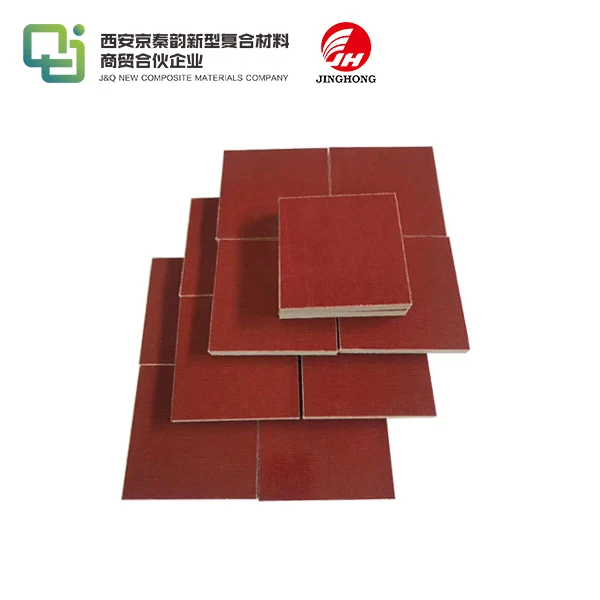

Phenolic resin board, often referred to as phenolic laminate, is a composite material created by saturating layers of paper, fabric, or glass fiber with phenolic resin - a thermosetting polymer. Under intense heat and pressure, these layers fuse into a solid, rigid sheet renowned for its robustness. This material finds widespread use in industries requiring reliable insulation, such as electrical, construction, and automotive sectors. Manufacturers value its ability to withstand harsh conditions, making it a staple in applications ranging from circuit boards to structural panels. Its global appeal stems from its adaptability, catering to diverse needs across continents.

Key Properties That Set Phenolic Resin Board Apart

What makes phenolic resin board stand out among other insulating materials? Its hallmark lies in its exceptional properties. This material excels in thermal stability, resisting temperatures up to 150°C without deforming. It also offers superior electrical insulation, crucial for applications involving high-voltage equipment. Additionally, its resistance to chemicals, moisture, and abrasion ensures longevity, even in corrosive environments. These attributes position phenolic resin board as a preferred choice for manufacturers seeking materials that endure rigorous conditions while maintaining performance. Its mechanical strength, though not infallible, adds to its allure, providing a balance of rigidity and resilience.

Common Applications in the Manufacturing Industry

Phenolic resin board's versatility shines through in its myriad applications, particularly in manufacturing. In the electrical sector, it serves as an insulating base for circuit boards, switchgear, and transformers, safeguarding against short circuits. Construction industries leverage its durability in wall panels, flooring, and countertops, appreciating its resistance to wear. Automotive manufacturers incorporate it into components requiring heat and chemical resistance, such as brake pads and clutch facings. Globally, manufacturers of insulating sheets recognize its value in creating products that meet stringent safety and performance standards, ensuring reliability across diverse climates and conditions.

Advantages of Phenolic Resin Board: Why Manufacturers Choose It

Unmatched Durability and Longevity

One of the most compelling reasons manufacturers opt for phenolic resin board is its remarkable durability. This material withstands the test of time, resisting degradation from moisture, chemicals, and UV exposure. Unlike some alternatives, it doesn't succumb easily to corrosion or rot, making it ideal for environments where longevity is paramount. Manufacturers producing insulating sheets for global markets appreciate this resilience, as it ensures their products perform consistently, whether in humid tropics or arid deserts. This durability translates into reduced maintenance costs and enhanced product lifespans, a boon for end-users and a selling point for suppliers.

Superior Thermal and Electrical Insulation

Phenolic resin board's prowess in insulation is another feather in its cap. Its ability to resist high temperatures without losing structural integrity makes it invaluable in applications exposed to heat, such as industrial ovens or electrical enclosures. Equally impressive is its electrical insulation capability, which prevents unwanted current flow, reducing the risk of electrical failures. Manufacturers catering to industries with stringent safety requirements, such as aerospace or energy, find this property indispensable. By incorporating phenolic resin board into their insulating sheets, they deliver products that meet rigorous international standards, enhancing their reputation in the global marketplace.

Resistance to Chemicals and Environmental Factors

In environments where exposure to chemicals or harsh weather is routine, phenolic resin board excels. It shrugs off acids, solvents, and oils, maintaining its integrity where other materials might falter. This resistance extends to environmental factors like humidity and salt spray, crucial for applications in coastal or industrial settings. Manufacturers of insulating sheets leverage this attribute to create products that endure in challenging conditions, from chemical plants to offshore platforms. This resilience not only boosts product reliability but also opens doors to niche markets, allowing manufacturers to cater to specialized needs worldwide.

Disadvantages of Phenolic Resin Board: Challenges to Consider

Higher Cost Compared to Alternatives

While phenolic resin board offers myriad benefits, its cost can be a stumbling block. Compared to materials like plywood or certain plastics, it commands a premium price due to its complex manufacturing process and raw material expenses. Manufacturers must weigh this against the material's longevity and performance benefits. Those targeting cost-sensitive markets may find it challenging to justify the expense, particularly when competing with lower-cost alternatives. However, for applications where durability and safety are non-negotiable, the investment often proves worthwhile, especially in high-stakes industries.

Potential Brittleness Under Extreme Stress

Despite its strength, phenolic resin board has a Achilles' heel: brittleness under extreme mechanical stress. While it handles compressive forces admirably, it can crack or shatter when subjected to sudden impacts or excessive bending. This limitation necessitates careful consideration in applications involving dynamic loads or frequent handling. Manufacturers must educate their clients about proper usage to mitigate risks, ensuring the material is deployed in scenarios that play to its strengths. Innovations in composite technology may eventually address this drawback, but current users must navigate this constraint with prudence.

Limited Aesthetic Appeal and Customization Options

Phenolic resin board is not the material of choice for projects prioritizing visual allure. Its appearance, often a uniform brown or black, lacks the aesthetic versatility of wood, metal, or decorative laminates. Customization options, such as color or texture, are limited, which can deter its use in consumer-facing applications like furniture or interior design. Manufacturers targeting industries where functionality trumps form - such as electrical or industrial sectors - find this less of an issue. However, those exploring broader markets may need to pair phenolic resin board with other materials to enhance visual appeal, adding complexity to their production processes.

Conclusion

Phenolic resin board stands as a formidable option for manufacturers of insulating sheets, offering a blend of durability, insulation prowess, and chemical resistance that few materials can rival. Its drawbacks, such as higher costs, potential brittleness, and limited aesthetic options, require careful consideration but do not diminish its value in specialized applications. By understanding these pros and cons, manufacturers can strategically incorporate this material into their product lines, catering to global demands with confidence. Balancing performance with practicality, phenolic resin board remains a cornerstone of industrial innovation.

Contact Us

Ready to explore how phenolic resin board can elevate your insulating sheet products? With over 20 years of expertise and a decade of global trade experience, J&Q is here to help. Contact us at info@jhd-material.com for more information.

References

1. Smith, J. A., "Composite Materials in Industrial Applications," Journal of Advanced Manufacturing, Vol. 45, No. 3, 2021, pp. 123-135.

2. Patel, R. K., "Thermal and Electrical Properties of Phenolic Laminates," International Journal of Materials Science, Vol. 12, No. 2, 2020, pp. 89-102.

3. Nguyen, T. H., "Durability of Resin-Based Composites in Harsh Environments," Chemical Engineering Review, Vol. 33, No. 4, 2019, pp. 56-70.

4. Brown, L. M., "Cost Analysis of Insulating Materials in Global Markets," Industrial Economics Quarterly, Vol. 28, No. 1, 2022, pp. 45-60.

5. Kumar, S. V., "Mechanical Limitations of Phenolic Resin Boards," Journal of Composite Structures, Vol. 19, No. 5, 2021, pp. 78-92.

6. Lee, H. Y., "Applications of Phenolic Laminates in Electrical Engineering," Electrical Systems Journal, Vol. 15, No. 3, 2020, pp. 34-48.