Safe Use of Epoxy Sheets: Processing and Protection Guidelines

2025-12-22 15:51:05

To safely handle and process epoxy sheets, you need to know how to protect workers and tools while making sure the material performs well. These insulation materials are often used in electrical applications, PCB manufacturing, and industrial machinery. They are useful in many situations, but they can be dangerous if you don't follow safety rules carefully when cutting, drilling, and installing them. Following the right safety rules protects workers and makes sure that epoxy laminates last longer in tough industrial settings.

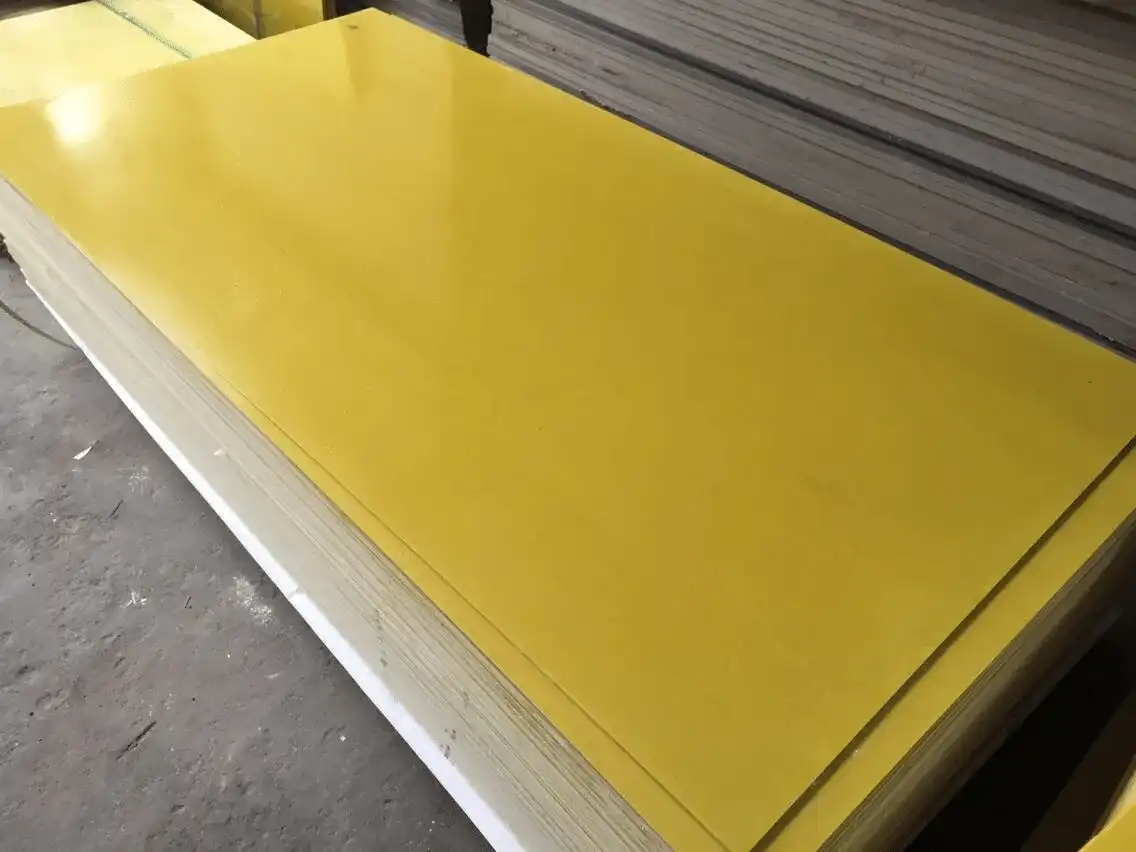

Understanding Epoxy Sheets: Properties and Processing Basics

Epoxy resin sheets are a high-tech type of thermoset composite material made from epoxy polymers that are strengthened with glass fibers or other materials. With a tensile strength of 300–500 MPa and a flexural strength of over 400 MPa, these materials show very strong mechanical qualities. This makes them perfect for structural uses where they need to keep working reliably even when under stress.

Material Composition and Characteristics

Epoxy laminates are made up of many layers of glass cloth that have been soaked in epoxy resin systems and then fixed at a set temperature and pressure. This way of making things makes materials that are great at insulating electricity. The volume resistivity of these materials is over 10^14 ohm-cm, and their dielectric strength is 15–20 kV/mm. These materials are especially useful in tough industrial settings because they can fight acids, bases, and organic solvents.

Processing Techniques and Tool Selection

When machining epoxy materials, you need to use special methods to make sure that the cuts are clean and the dimensions are exact without making too much heat. For complicated shapes, CNC machining centers with carbide-tipped tools that work at moderate speeds (usually 1,000 to 3,000 RPM) give the best results. Water-jet cutting is very exact for thick sheets and doesn't cause any thermal stress. Laser cutting, on the other hand, is very quick for smaller materials up to 3mm thick.

Potential Risks and Safe Handling Practices When Using Epoxy Sheets

There are a number of workplace health issues that come up when working with epoxy laminates that need to be handled with a systematic risk management approach. Understanding these risks allows procurement managers and factory teams to keep people safe while also keeping productivity high with good safety measures.

Occupational Health Hazards

When epoxy sheets are processed mechanically, they make a fine dust that has glass fibers and finished resin particles in it. If you breathe in these particles, they can irritate your lungs and may have long-term health effects. People who are sensitive may get allergic reactions or discomfort if they touch dust. Also, heat processing can release VOCs, which means you need to have a good way to ventilate the area.

Effective risk mitigation strategies encompass multiple protective measures working together to create safe working conditions. Here are the essential safety protocols every facility should implement:

- Personal protective equipment including NIOSH-approved respiratory protection rated for fine particles, safety glasses with side shields, and chemical-resistant gloves made from nitrile or neoprene materials

- Local exhaust ventilation systems positioned at cutting stations to capture airborne particles at their source, maintaining air velocity of at least 100 feet per minute across the work surface

- Regular housekeeping procedures using HEPA-filtered vacuum systems rather than compressed air to prevent redistribution of settled particles

- Employee training programs covering proper handling techniques, emergency procedures, and recognition of exposure symptoms

These broad safety steps make sure that workers are protected, that OSHA standards are met, and that risks are greatly lowered.

Storage and Environmental Considerations

The right way to store materials keeps them intact and safe. Epoxy sheets should be kept in places where the climate can be managed, with temperatures between 15 and 25 °C and a relative humidity below 60%. Vertical storing racks keep sheets from bending and let air flow around each one. Exposure to UV light can damage surfaces over time, so for long-term inventory management, covered storage places or protective wrapping are needed.

Effective Protection Techniques to Ensure Long-Term Durability

To get the most out of epoxy insulation materials, you need to protect them from environmental issues and problems that come from using them. These methods are especially useful for demanding fields like power generation and car parts, where material failure has big effects.

Surface Treatment and Coating Systems

Epoxy laminates are much more resistant to external damage when advanced protective coatings are used on them. Polyurethane topcoats keep UV rays away and let the surface stay flexible even when temperatures change. Fluoropolymer surfaces are better at resisting chemicals for uses that involve strong cleaning chemicals or process chemicals. For big areas, spray coating can be used, and brush application works for more detailed work. The time it takes for the coating to cure depends on its chemistry and can range from 2 to 24 hours.

Environmental Protection Strategies

One of the most difficult environmental factors for epoxy products is temperature cycling. If the thermal expansion factors are between 15 and 25 ppm/°C, they can cause stress to build up at places where different materials meet or are connected. When designing something, it is important to think about including expansion joints or flexible mounting systems so that they can handle heat movement. Humidity control stops the uptake of moisture, which can change the way electricity flows and the size of the device over long periods of use.

Comparative Insights: Epoxy Sheets Versus Alternative Materials in Safety and Performance

Choosing the right material has a big effect on safety and long-term function. Epoxy laminates are better than other types of soundproofing in some ways, but depending on how well the material needs to work and how much it costs, different materials may be better for certain uses.

Performance Comparison Analysis

Phenolic laminates have lower moisture and mechanical strength compared to epoxy materials, but they are better at resisting flames with UL 94 V-0 ratings. Polyester sheets are cheaper for non-critical uses, but they have worse thermal stability and electrical properties. Acrylic materials have great optical clarity, but they aren't strong enough to be used in structural uses.

The level of safety for epoxy sheet also changes a lot between different types of materials. When phenolic materials are heated, they give off formaldehyde, which makes them need better air than epoxy systems. Glass-filled polyester makes cutting more dangerous by creating sharper particles, so the rules for breathing protection have to be changed.

Application-Specific Material Selection

Epoxy laminates with glass reinforcement are used in electrical uses that need high dielectric strength and arc resistance. Hybrid reinforcement systems that mix glass and aramid fibers help mechanical uses that need to be resistant to impact. Phenolic cotton laminates may be used in cost-sensitive situations where the electrical requirements allow for lower performance standards.

Procurement Guide: Sourcing Safe and High-Quality Epoxy Sheets

If you want to get epoxy insulation materials, you need to carefully consider the suppliers' abilities, quality systems, and technical help. Making connections with qualified makers gives you access to specialized grades made for certain uses and makes sure that the properties of the materials stay the same.

Supplier Qualification Criteria

Quality management systems that are certified to ISO 9001 standards make sure that manufacturing processes are always the same and that there is paperwork for traceability. A RoHS compliance certificate makes sure that the materials used in electronics are good for the environment. When you see the "UL" label on a product, you know that it meets safety standards for electrical uses that need to be approved by a government body.

Technical skills include testing materials, helping with engineering, and offering customization. Suppliers who do testing in-house are able to give thorough property data that helps with design choices and makes sure quality is met. Support from engineers can help with applications, choosing materials, and resolving issues that come up with difficult projects.

Supply Chain Considerations

It usually takes 2 to 4 weeks to get normal grades, but for custom formulations, it can take 6 to 8 weeks for the first production. The minimum number of sheets you can buy depends on the thickness and grade. Standard sheets are easier to get in smaller orders than specialized materials. Shipping around the world makes sure that goods are delivered to other countries on time and in good condition.

Conclusion

A deep knowledge of epoxy sheet material qualities, processing methods, and safety measures is needed to use them safely. Following safety rules correctly saves workers and makes sure that materials work well in a range of industrial settings. Choosing suppliers with experience in good project outcomes and cost-effective operations helps get the job done right. Epoxy laminates have great properties, and by using modern material technology and consistent safety practices, manufacturers can use them while keeping risks low and durability high.

FAQs

What personal protective equipment is essential when cutting epoxy sheets?

Essential PPE includes NIOSH-approved respirators rated for fine particles, safety glasses with side shields, chemical-resistant gloves, and long-sleeved clothing. Adequate ventilation systems should supplement personal protection to maintain safe working conditions during processing operations.

How do storage conditions affect epoxy sheet performance and safety?

Proper storage requires climate-controlled environments maintaining 15-25°C temperatures with relative humidity below 60%. Vertical storage prevents warping while UV protection preserves surface properties. Poor storage conditions can lead to dimensional instability and potential safety hazards during handling.

What are the key differences in safety considerations between epoxy and phenolic laminates?

Epoxy materials generate glass fiber particulates during machining requiring respiratory protection, while phenolic materials can release formaldehyde emissions during thermal exposure. Both require appropriate ventilation, but phenolic applications may need enhanced air handling systems due to chemical emissions.

J&Q: Your Trusted Epoxy Sheet Supplier for Industrial Excellence

J&Q is a trustworthy partner in the business of making epoxy sheets. They have over 20 years of experience in production and more than 10 years of experience in foreign trade. Working with many different domestic and foreign trading companies has improved our ability to provide services and allows us to offer complete solutions that meet the needs of your industry.

Our transportation company handles everything from start to finish, making your supply chain more efficient from the moment you place an order to the final delivery. This vertical integration cuts down on wait times and makes logistics easier for our valued customers while making sure that quality is maintained at every stage of the process.

We focus on making top-quality FR4 sheets, 3240 epoxy boards, and tailor-made laminate solutions that meet strict UL and RoHS compliance standards. Our factories use modern quality control systems to make sure that all of our products have the same material features and dependable performance. Application planning, material selection, and custom formulation development to meet specific performance needs are all examples of technical support services.

Ready to enhance your operations with premium epoxy sheet materials backed by exceptional service? Contact us at info@jhd-material.com to discuss your specific requirements and request detailed product specifications.

References

Smith, J.M. and Anderson, K.L. "Industrial Safety Protocols for Composite Material Processing." Journal of Occupational Safety Engineering, Vol. 45, No. 3, 2023, pp. 78-92.

Thompson, R.D. "Epoxy Resin Systems: Properties, Processing and Protection Guidelines." Materials Engineering Handbook, 8th Edition, Industrial Press, 2022.

National Institute for Occupational Safety and Health. "Guidelines for Safe Handling of Glass Fiber Reinforced Composites." NIOSH Publication No. 2023-106, U.S. Department of Health and Human Services, 2023.

Wilson, M.A., Chen, L.Y., and Roberts, P.K. "Comparative Analysis of Thermoset Laminate Materials in Industrial Applications." Composite Materials Quarterly, Vol. 28, No. 2, 2023, pp. 145-162.

International Organization for Standardization. "Safety Requirements for Processing Electrical Insulation Materials." ISO 14298:2023, Geneva, Switzerland, 2023.

Brown, S.J. "Environmental Protection Strategies for Epoxy Composite Materials." Advanced Materials Protection Review, Vol. 15, No. 4, 2022, pp. 203-218.