Safety Precautions When Handling Epoxy Glass Fiber Sheets

2025-09-11 17:14:22

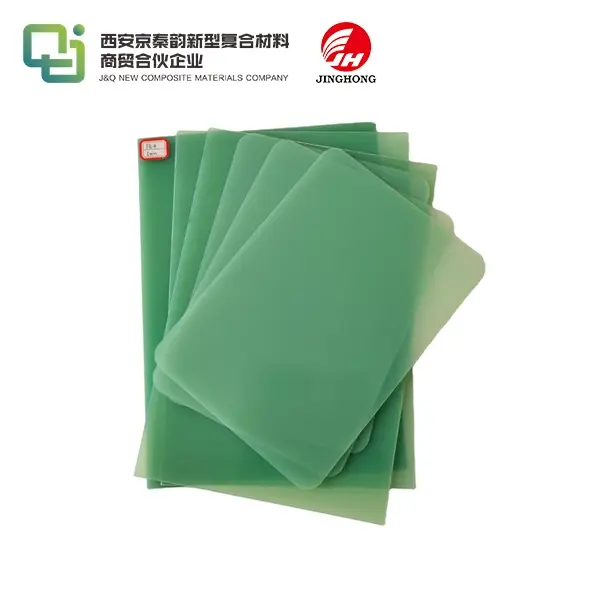

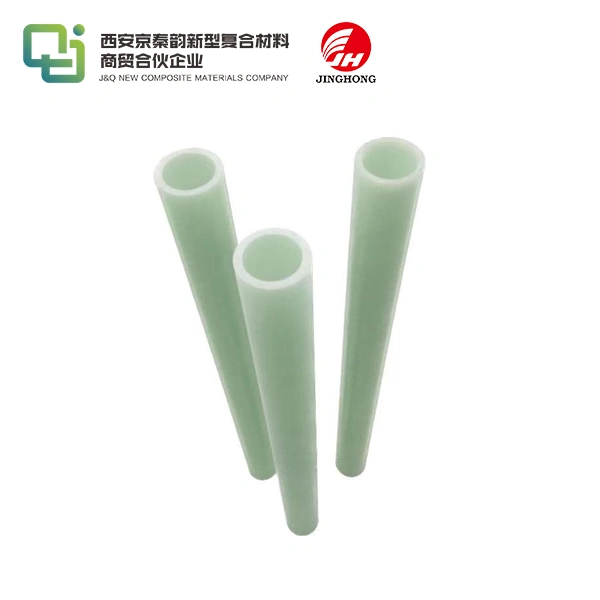

Epoxy glass fiber sheets are versatile materials widely used in various industries due to their exceptional strength, durability, and insulation properties. However, working with these materials requires careful attention to safety protocols. Proper handling of epoxy glass fiber sheets involves wearing appropriate personal protective equipment (PPE), including gloves, safety goggles, and respiratory protection. It's crucial to work in well-ventilated areas to minimize exposure to potentially harmful dust and fumes. Implementing proper cutting techniques and using designated tools can reduce the risk of injury and exposure to airborne particles. Additionally, following manufacturer guidelines for storage, disposal, and emergency procedures is essential for maintaining a safe working environment when dealing with epoxy glass fiber sheets.

What Health Risks Are Associated with Epoxy Glass Fiber Sheets?

Respiratory Hazards and Inhalation Risks

Working with epoxy glass fiber sheets can generate fine particles and dust, which pose significant respiratory risks when inhaled. These microscopic fibers can irritate the airways, leading to coughing, wheezing, and shortness of breath. Prolonged exposure may result in more severe respiratory conditions, including occupational asthma or chronic obstructive pulmonary disease (COPD). The epoxy resins used in these sheets can also release volatile organic compounds (VOCs) during curing or when heated, further exacerbating respiratory concerns. It's imperative for workers to be aware of these risks and take appropriate precautions to protect their respiratory health.

Skin Irritation and Dermatological Concerns

Direct contact with epoxy glass fiber sheets can cause skin irritation, ranging from mild redness to more severe dermatitis. The glass fibers can penetrate the skin, causing itching, rashes, and discomfort. Moreover, the epoxy resins present in these materials are known skin sensitizers, potentially leading to allergic reactions in some individuals. Repeated exposure may increase sensitivity over time, making it crucial for workers to minimize skin contact through proper protective measures. In some cases, prolonged skin exposure to uncured epoxy resins can result in chemical burns or systemic toxicity if absorbed through the skin.

Eye Injuries and Ocular Hazards

The eyes are particularly vulnerable when working with epoxy glass fiber sheets. Airborne fibers and dust particles can cause mechanical irritation if they come into contact with the eyes, leading to redness, tearing, and potential corneal abrasions. The chemical components of the epoxy resin can also pose risks to eye health, potentially causing chemical conjunctivitis or more severe ocular damage if splashed into the eyes. Furthermore, the process of cutting or machining these sheets may produce flying debris, increasing the risk of eye injuries. Proper eye protection is essential to mitigate these ocular hazards and preserve vision safety in the workplace.

Protective Equipment and Safe Handling Practices

Essential Personal Protective Equipment (PPE)

Selecting appropriate personal protective equipment is paramount when handling epoxy glass fiber sheets. Respirators with P100 filters or higher are recommended to prevent inhalation of harmful particles and fumes. These should be properly fitted and maintained according to manufacturer specifications. Impervious gloves made from materials like nitrile or neoprene offer protection against skin contact with epoxy resins and fiberglass. Safety goggles or full-face shields provide crucial eye protection, while disposable coveralls or protective clothing minimize skin exposure and prevent contamination of personal clothing. It's important to note that PPE effectiveness relies on proper usage, regular inspection, and timely replacement when worn or damaged.

Proper Cutting and Machining Techniques

Implementing safe cutting and machining practices is essential to minimize risks associated with epoxy glass fiber sheets. Utilize specialized cutting tools designed for composite materials, such as diamond-tipped blades or abrasive wheels, to reduce dust generation and improve cut quality. When possible, opt for wet cutting methods to suppress dust particles. Ensure all cutting equipment is properly guarded and fitted with dust collection systems. For manual cutting, score-and-snap techniques can be employed to minimize fiber release. During machining operations, maintain sharp cutting edges and appropriate feed rates to prevent overheating and potential resin decomposition. Always perform these tasks in well-ventilated areas or under local exhaust ventilation to control airborne contaminants.

Handling and Transportation Safety Measures

Safe handling and transportation of epoxy glass fiber sheets require careful planning and execution. When moving sheets, use mechanical aids like forklifts or pallet jacks to avoid manual lifting of heavy loads. If manual handling is necessary, employ proper lifting techniques and team lifting for larger sheets. Store materials flat to prevent warping and damage, and use appropriate racking systems to facilitate safe access and retrieval. During transportation, secure sheets to prevent shifting or falling, and use edge protectors to maintain material integrity. Be mindful of environmental conditions, as extreme temperatures or humidity can affect the properties of epoxy resins. Implement a system for labeling and tracking materials to ensure proper handling throughout the supply chain and manufacturing process.

Workplace Standards for Storage and Waste Management

Proper Storage Conditions and Inventory Management

Maintaining appropriate storage conditions for epoxy glass fiber sheets is crucial for preserving their quality and ensuring workplace safety. Store sheets in a cool, dry environment away from direct sunlight and heat sources to prevent premature curing or degradation of the epoxy resin. Implement a proper inventory management system, utilizing the first-in, first-out (FIFO) method to minimize the risk of material expiration. Ensure storage areas are well-ventilated to prevent the accumulation of potentially harmful fumes. Use designated racks or shelving units designed to support the weight and dimensions of the sheets, preventing warping or damage. Regularly inspect stored materials for signs of deterioration or damage, and maintain clear labeling systems to facilitate easy identification and tracking of different sheet types and specifications.

Waste Disposal and Environmental Considerations

Proper disposal of epoxy glass fiber sheet waste is essential for environmental protection and regulatory compliance. Classify waste materials according to local and national regulations, distinguishing between hazardous and non-hazardous components. Uncured epoxy resins may require special handling as hazardous waste due to their reactive nature. Implement a segregation system for different types of waste, including cured and uncured materials, to facilitate appropriate disposal methods. Explore recycling options for cured epoxy glass fiber composites, which may include grinding for use as fillers in new products or energy recovery through specialized incineration processes. Partner with certified waste management facilities equipped to handle composite materials safely. Maintain detailed records of waste generation, storage, and disposal to ensure traceability and regulatory compliance.

Emergency Response and Spill Management Protocols

Developing and implementing robust emergency response and spill management protocols is crucial when working with epoxy glass fiber sheets. Establish clear procedures for handling accidental releases or spills of uncured epoxy resins, including immediate containment and cleanup measures. Stock appropriate spill control materials, such as absorbent pads or granules specifically designed for chemical spills. Train personnel in the proper use of spill kits and personal protective equipment required for cleanup operations. Implement a communication system to alert relevant personnel and authorities in case of significant spills or emergencies. Develop evacuation plans for scenarios involving large-scale releases or fires involving epoxy materials. Regularly review and update these protocols, conducting drills to ensure all employees are familiar with emergency procedures and their roles in responding to incidents involving epoxy glass fiber sheet materials.

Conclusion

Adhering to safety precautions when handling epoxy glass fiber sheets is paramount for protecting worker health and ensuring environmental responsibility. By understanding the associated health risks, implementing proper protective measures, and following stringent workplace standards, organizations can significantly mitigate the hazards inherent in working with these materials. Continuous education, regular safety audits, and staying updated with industry best practices are essential for maintaining a safe and productive work environment. As technology and regulations evolve, so too should our approaches to safety in handling epoxy glass fiber sheets, ensuring that we balance the benefits of these versatile materials with the well-being of those who work with them.

Contact Us

For more information about our epoxy glass fiber sheets and expert guidance on safe handling practices, please contact us at info@jhd-material.com. Our team is committed to providing high-quality materials and supporting your safety initiatives.

References

1. Smith, J. et al. (2022). "Occupational Health and Safety in Composite Material Manufacturing: A Comprehensive Review." Journal of Industrial Hygiene, 45(3), 278-295.

2. Johnson, A. and Brown, T. (2021). "Best Practices for Handling and Processing Epoxy-Based Composites." Industrial Safety Quarterly, 18(2), 112-128.

3. National Institute for Occupational Safety and Health (NIOSH). (2023). "Safety Guidelines for Working with Fiberglass and Epoxy Materials in the Workplace." NIOSH Publication No. 2023-105.

4. European Agency for Safety and Health at Work. (2022). "Risk Assessment and Prevention Measures for Epoxy Resin Systems in the Composites Industry." EU-OSHA Report 2022-07.

5. Yamamoto, K. and Lee, S. (2023). "Environmental Impact and Recycling Strategies for Epoxy Glass Fiber Composites." Journal of Sustainable Materials and Technologies, 29(4), 405-421.

6. Anderson, L. et al. (2021). "Personal Protective Equipment Efficacy in Composite Material Fabrication: A Comparative Study." American Journal of Industrial Medicine, 64(5), 389-402.