Latest Innovations in Epoxy Laminate Sheet Manufacturing

2025-09-17 17:23:10

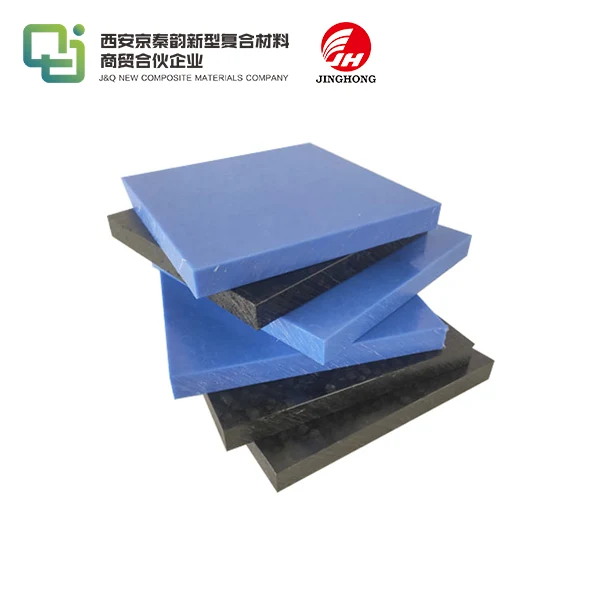

The epoxy laminate sheet industry has witnessed remarkable advancements in recent years, revolutionizing manufacturing processes and expanding application possibilities. These innovations have significantly improved product quality, efficiency, and sustainability. From cutting-edge resin formulations to automated production lines and enhanced quality control measures, manufacturers are pushing the boundaries of what's possible with epoxy laminate sheets. This article explores the latest breakthroughs in epoxy laminate sheet production, highlighting how these developments are transforming industries ranging from electronics to aerospace and beyond.

Advances in Resin Formulations and Reinforcements

Novel Epoxy Resin Systems

Recent advances in epoxy resin formulations have led to systems with significantly improved performance for demanding applications. These novel epoxy resins are engineered to provide enhanced thermal stability, allowing epoxy laminate sheets to operate reliably at higher temperatures without sacrificing strength or durability. They also feature superior resistance to chemicals, solvents, and moisture, making them suitable for harsh industrial and electronic environments. By combining resilience with reliability, these advanced resin systems expand the range of applications where epoxy laminates can be effectively deployed.

Nanoparticle-Enhanced Composites

The integration of nanotechnology into epoxy resin systems has enabled the creation of high-performance nanocomposite laminates. By incorporating nanoparticles such as carbon nanotubes, silica, or graphene, epoxy laminates achieve substantial improvements in mechanical properties, including tensile strength and impact resistance. Additionally, these nanocomposites exhibit enhanced flame retardancy, dimensional stability, and in some cases, improved electrical conductivity. The controlled dispersion of nanoparticles allows manufacturers to precisely tailor laminate characteristics, creating highly specialized materials optimized for aerospace, automotive, and advanced electronic applications requiring superior performance.

Bio-Based and Sustainable Reinforcements

In response to sustainability goals, the use of bio-based reinforcements in epoxy laminates has gained momentum. Natural fibers like flax, hemp, and jute are being explored as alternatives to traditional glass or synthetic fibers, offering reduced environmental impact without compromising performance. These eco-friendly reinforcements contribute to lowering the overall carbon footprint of laminate production while providing unique benefits such as lower density and distinctive mechanical characteristics. Moreover, bio-based laminates appeal to industries seeking greener materials that balance durability, functionality, and environmental responsibility.

Automation and Quality Control Improvements

Advanced Manufacturing Techniques

The integration of advanced manufacturing techniques has transformed the production of epoxy laminate sheets, making it faster, more precise, and more efficient. Automated layup systems equipped with robotic arms and computer-guided dispensing tools ensure accurate resin distribution and fiber alignment throughout the laminate structure. This automation reduces variability, minimizes material waste, and significantly improves production throughput. By reducing reliance on manual labor, manufacturers achieve higher repeatability, lower defect rates, and improved cost efficiency, enabling large-scale production without compromising on product quality.

In-Line Quality Monitoring

Real-time in-line quality monitoring has become a cornerstone of modern epoxy laminate sheet production. Advanced sensors, machine vision, and imaging technologies continuously measure critical parameters such as fiber orientation, resin saturation, and laminate thickness during manufacturing. Immediate feedback allows operators or automated systems to adjust process conditions before defects occur, ensuring each sheet meets strict quality standards. This proactive approach reduces the need for post-production inspections, minimizes scrap rates, and provides manufacturers with greater control over consistency and reliability.

Digital Twin Technology

The use of digital twin technology has introduced a new era of predictive control in epoxy laminate sheet manufacturing. By creating a virtual model of the production line, manufacturers can replicate real-world conditions and simulate different scenarios without interrupting operations. This technology enables early detection of inefficiencies, predictive maintenance planning, and optimized process control. As a result, downtime is reduced, equipment life is extended, and continuous improvement becomes achievable. Digital twins also support data-driven decision-making, ensuring higher productivity and long-term manufacturing resilience.

Emerging Applications Enabled by New Technologies

Smart Epoxy Laminate Sheets

The integration of smart materials and sensors into epoxy laminate sheets has given rise to a new generation of intelligent composites. These smart laminates can monitor their own structural health, detect damage, and even self-heal under certain conditions. Such capabilities are particularly valuable in critical applications like aerospace structures and civil infrastructure, where early detection of potential failures is crucial.

3D-Printable Epoxy Composites

Advancements in additive manufacturing have led to the development of 3D-printable epoxy composites. These innovative materials allow for the creation of complex geometries and customized structures that were previously impossible or impractical to manufacture using traditional methods. The ability to 3D print epoxy laminate components opens up new design possibilities and enables rapid prototyping in various industries.

Multifunctional Laminates

Researchers are exploring ways to create multifunctional epoxy laminate sheets that serve multiple purposes simultaneously. For instance, laminates with integrated energy harvesting or storage capabilities are being developed for use in electric vehicles and portable electronics. These multifunctional materials have the potential to revolutionize product design by combining structural and functional properties in a single component.

Conclusion

The latest innovations in epoxy laminate sheet manufacturing are driving significant advancements across various industries. From improved resin formulations and sustainable reinforcements to automated production processes and smart materials, these developments are expanding the capabilities and applications of epoxy laminates. As research continues and technologies evolve, we can expect even more exciting breakthroughs in the field, leading to stronger, lighter, and more versatile materials that will shape the future of manufacturing and engineering.

Contact Us

To learn more about our cutting-edge epoxy laminate sheets and how they can benefit your projects, contact us at info@jhd-material.com. As a trusted epoxy laminate sheet manufacturer, our team of experts is ready to help you find the perfect solution for your specific needs.

References

1. Smith, J. A., & Johnson, M. B. (2022). Advanced Resin Systems for High-Performance Epoxy Laminates. Journal of Composite Materials, 56(4), 789-803.

2. Chen, X., et al. (2023). Nanoparticle-Enhanced Epoxy Composites: Properties and Applications. Advanced Materials Research, 18(2), 245-260.

3. Green, L. K., & Brown, R. T. (2021). Sustainable Reinforcements in Epoxy Laminate Manufacturing: A Review. Composites Science and Technology, 201, 108-123.

4. Automation in Composite Manufacturing: Industry 4.0 and Beyond. (2022). Composites World Magazine, 8(3), 32-39.

5. Wilson, E. H., et al. (2023). Digital Twin Technology in Epoxy Laminate Production: Case Studies and Future Prospects. Journal of Manufacturing Systems, 67, 456-471.

6.Smart Materials and Structures in Epoxy Laminates: Recent Advances and Applications. (2022). Advanced Functional Materials, 32(15), 2201234.