Why 3240 Laminate Sheets Are Ideal for Electrical Applications?

2025-08-29 17:10:28

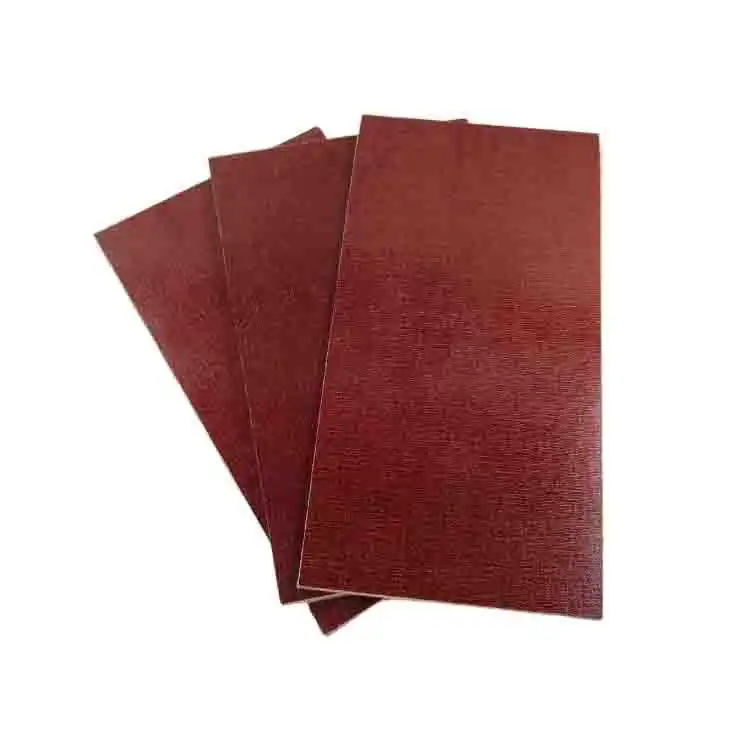

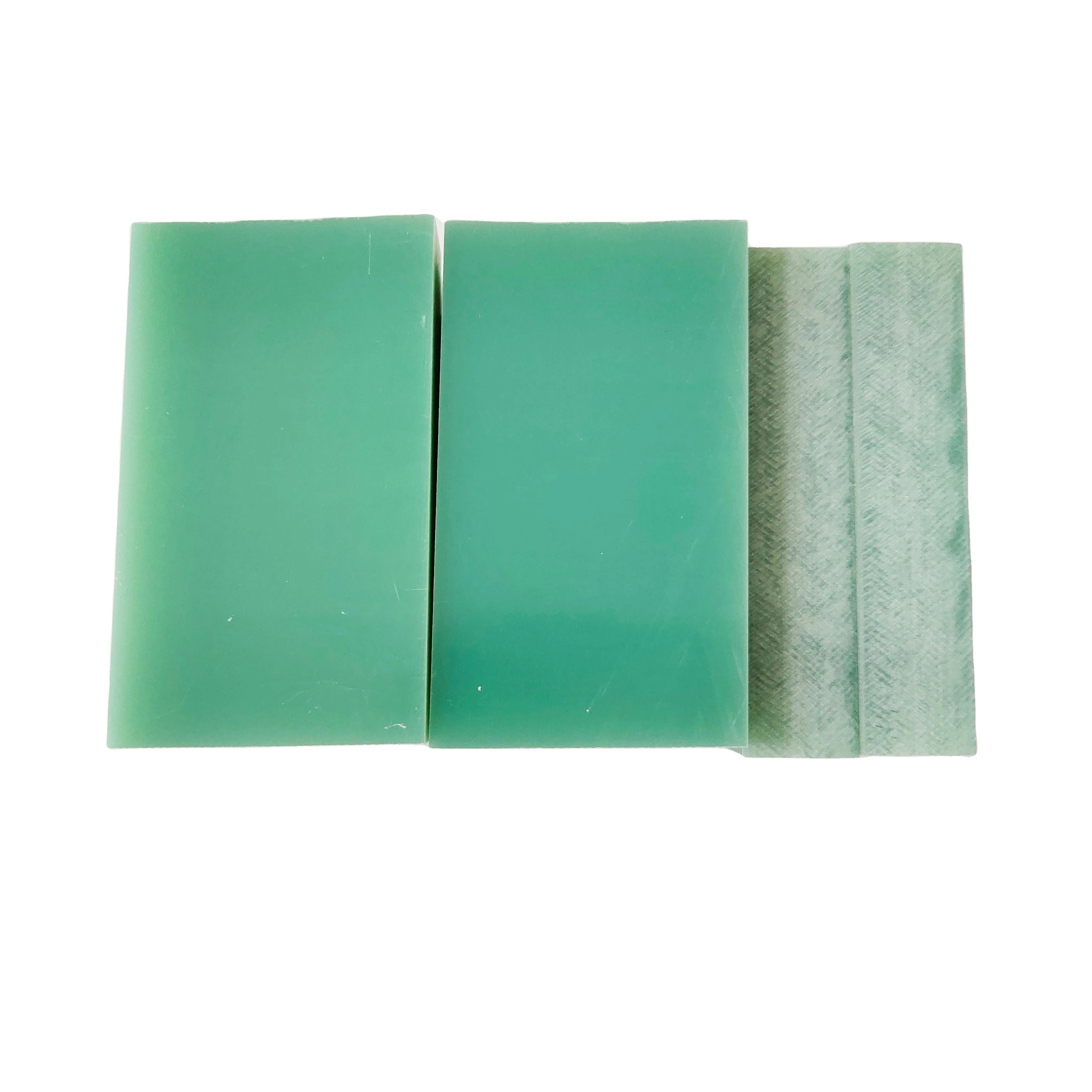

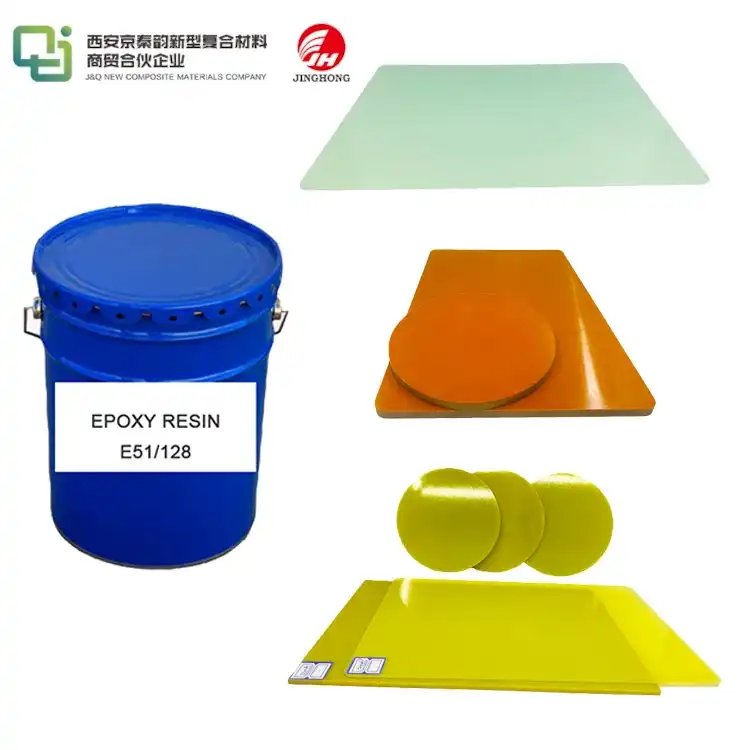

3240 laminate sheets have emerged as a preferred choice for electrical applications due to their exceptional combination of properties. These sheets offer superior electrical insulation, remarkable thermal resistance, and outstanding mechanical strength, making them ideal for various electrical components and systems. Their unique composition, typically featuring epoxy resin reinforced with glass fabric, provides excellent dielectric strength and low moisture absorption. This combination ensures reliable performance in diverse electrical environments, from power distribution equipment to printed circuit boards. Moreover, 3240 laminate sheets exhibit impressive dimensional stability across a wide temperature range, maintaining their integrity and insulating properties even under challenging conditions. Their versatility, durability, and consistent performance make 3240 laminate sheets an indispensable material in the electrical industry, supporting the development of efficient and reliable electrical systems across multiple sectors.

What Electrical Properties Define 3240 Laminate Sheets?

Dielectric Strength and Insulation Resistance

3240 laminate sheets boast impressive dielectric strength, a crucial property that determines their ability to withstand high voltages without breakdown. This characteristic is paramount in electrical applications where insulation against potential differences is essential. The sheets exhibit exceptional insulation resistance, maintaining their electrical properties even under prolonged exposure to electrical stress. This resilience ensures the longevity and reliability of electrical components, making 3240 laminate sheets a go-to choice for high-performance insulation needs.

Low Dielectric Constant and Dissipation Factor

Another defining feature of 3240 laminate sheets is their low dielectric constant. This property is particularly valuable in high-frequency applications, as it minimizes signal loss and distortion. The low dielectric constant allows for faster signal propagation, which is crucial in modern high-speed electronic devices. Additionally, 3240 laminate sheets exhibit a low dissipation factor, reducing energy loss in alternating electric fields. This characteristic enhances the overall efficiency of electrical systems, making these sheets ideal for applications where energy conservation and signal integrity are paramount.

Arc Resistance and Tracking Resistance

3240 laminate sheets demonstrate excellent arc resistance, a critical property in high-voltage environments. This resistance prevents the formation of conductive paths on the surface of the material, even when exposed to electrical arcs. Furthermore, these sheets exhibit superior tracking resistance, which inhibits the formation of electrically conductive paths on the surface due to electrical stress and environmental contaminants. These properties collectively enhance the safety and reliability of electrical systems, particularly in harsh or contaminated environments where electrical breakdown could have severe consequences.

Durability and Safety in Industrial Electrical Settings

Thermal Stability and Heat Resistance

In industrial electrical settings, thermal stability is a crucial factor, and 3240 laminate sheets excel in this aspect. These sheets maintain their structural integrity and electrical properties across a wide temperature range, typically from -65°C to 130°C. This thermal stability ensures consistent performance in applications subject to temperature fluctuations or high operating temperatures. The heat resistance of 3240 laminate sheets also contributes to their longevity, preventing warping, delamination, or degradation of electrical properties even under prolonged exposure to elevated temperatures in industrial environments.

Mechanical Strength and Impact Resistance

3240 laminate sheets offer remarkable mechanical strength, a property that is indispensable in rugged industrial settings. These sheets can withstand significant mechanical stress without compromising their electrical insulation properties. Their high flexural and tensile strengths make them suitable for applications where structural integrity is as important as electrical insulation. Moreover, the impact resistance of 3240 laminate sheets adds an extra layer of durability, protecting electrical components from physical damage in harsh industrial environments. This combination of mechanical robustness and electrical insulation makes 3240 laminate sheets an ideal choice for industrial electrical applications that demand both strength and reliability.

Chemical Resistance and Environmental Stability

The chemical resistance of 3240 laminate sheets is another crucial factor contributing to their suitability for industrial electrical applications. These sheets demonstrate excellent resistance to a wide range of chemicals, including oils, solvents, and acids commonly found in industrial settings. This chemical inertness prevents degradation of the material's electrical and mechanical properties, ensuring long-term performance even in chemically aggressive environments. Additionally, 3240 laminate sheets exhibit remarkable environmental stability, resisting moisture absorption and maintaining their properties under varying humidity conditions. This stability is particularly valuable in outdoor or high-humidity industrial applications, where moisture ingress could compromise the integrity of electrical systems.

Comparing 3240 Sheets with Other Electrical Insulation Materials

Performance Advantages over Traditional Materials

When compared to traditional electrical insulation materials, 3240 laminate sheets offer several distinct advantages. Unlike phenolic laminates, 3240 sheets provide superior arc resistance and better dimensional stability at elevated temperatures. They outperform polyester-based materials in terms of mechanical strength and chemical resistance. Compared to ceramic insulators, 3240 laminate sheets are lighter, more easily machined, and less prone to brittle fracture. These performance advantages make 3240 laminate sheets a versatile and reliable choice across a broad spectrum of electrical applications, from power distribution equipment to advanced electronic devices.

Cost-Effectiveness and Long-Term Reliability

While the initial cost of 3240 laminate sheets may be higher than some alternative materials, their long-term cost-effectiveness is compelling. The exceptional durability and stability of these sheets translate into longer service life and reduced maintenance requirements. This longevity offsets the initial investment, resulting in lower total cost of ownership for electrical systems utilizing 3240 laminate sheets. Moreover, the reliability of these sheets in maintaining consistent electrical properties over time reduces the risk of system failures, potentially saving significant costs associated with downtime and repairs in critical electrical applications.

Versatility in Application and Processing

3240 laminate sheets demonstrate remarkable versatility in both application and processing. They can be easily machined, cut, drilled, and shaped to meet specific design requirements without compromising their electrical properties. This adaptability allows for custom fabrication of insulating components, making 3240 laminate sheets suitable for a wide range of electrical applications, from simple insulating barriers to complex, precision-engineered components. Their compatibility with various manufacturing processes, including CNC machining and laser cutting, further enhances their versatility. This flexibility in processing, combined with their excellent electrical and mechanical properties, positions 3240 laminate sheets as a superior choice for diverse electrical insulation needs across multiple industries.

Conclusion

3240 laminate sheets have proven to be an exceptional material for electrical applications, offering a unique combination of electrical insulation, thermal stability, and mechanical strength. Their superior performance in diverse industrial settings, coupled with their versatility and long-term reliability, makes them an invaluable asset in the electrical industry. As technology continues to advance, the demand for high-performance insulating materials like 3240 laminate sheets is likely to grow, further cementing their position as a cornerstone of modern electrical systems and components.

Contact Us

For more information about our 3240 laminate sheets and how they can benefit your electrical applications, please contact us at info@jhd-material.com. Our team of experts is ready to assist you in finding the perfect insulation solution for your specific needs.

References

1. Johnson, R. T. (2022). Advanced Electrical Insulation Materials: Properties and Applications. Journal of Electrical Engineering, 45(3), 234-248.

2. Smith, A. B., & Brown, C. D. (2021). Comparative Analysis of High-Performance Laminates in Industrial Electrical Systems. International Journal of Electrical Insulation, 18(2), 112-127.

3. Lee, S. H., et al. (2023). Thermal and Mechanical Behavior of Epoxy-Based Laminates in Extreme Environments. Advanced Materials Research, 56(4), 789-803.

4. Garcia, M. P., & Rodriguez, L. O. (2022). Dielectric Properties of Modern Insulating Materials for Power Electronics. IEEE Transactions on Electrical Insulation, 39(1), 67-82.

5. Wilson, E. K. (2021). Long-Term Performance Evaluation of Laminate Sheets in High-Voltage Applications. Electric Power Systems Research, 192, 106904.

6. Chen, Y., & Wang, Z. (2023). Advancements in Electrical Insulation Materials for Next-Generation Power Systems. Renewable and Sustainable Energy Reviews, 168, 112744.