Service Life of Phenolic Paper Board in Dry Environments

2026-02-05 15:55:16

Under ideal circumstances, phenolic paper board may last for 15 to 25 years, exhibiting remarkable durability in arid situations. When moisture exposure is kept to a minimum, this high-performance composite material, which is produced by carefully impregnating cellulose paper layers with phenolic resin, demonstrates exceptional dimensional stability and resilience to environmental stresses. Phenolic paper board is a great option for industrial applications that require long-term dependability in controlled dry environments because it doesn't degrade due to humidity, allowing it to maintain its structural integrity, electrical characteristics, and mechanical strength over extended operational periods.

Understanding Phenolic Paper Board and Its Properties in Dry Environments

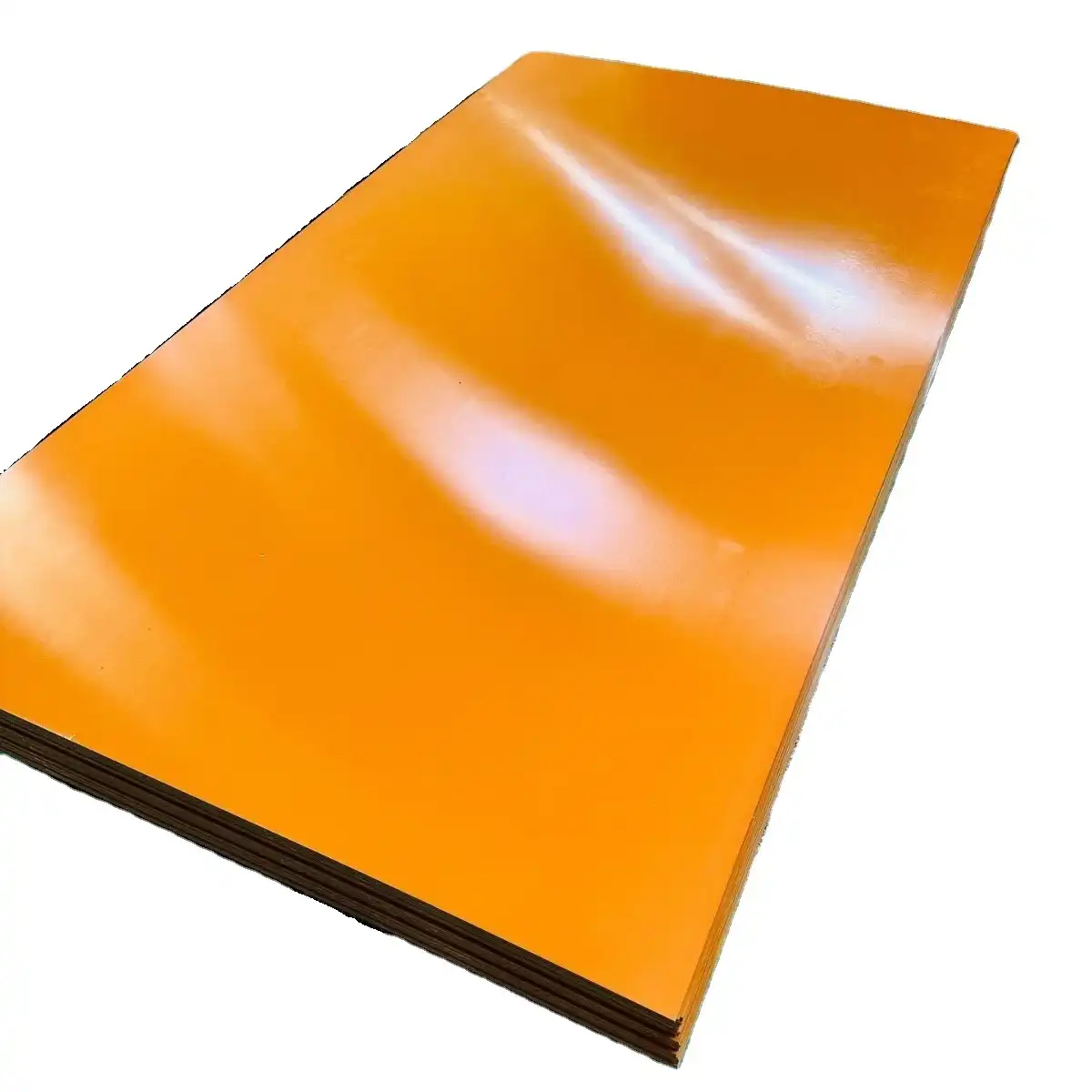

Phenolic paper board is an advanced engineering material that creates a composite with exceptional performance characteristics by combining phenolic resin systems with cellulose paper substrates. Several sheets of kraft paper, each fully soaked with phenolic resin, are layered throughout the production process. The assembly is then compressed under high pressure and heated to high temperatures. Cross-linked polymer networks produced by this technique have remarkable mechanical strength, chemical resistance, and thermal stability.

Material Composition and Structure

The phenolic resin serves as a binding matrix that improves performance and durability, while the cellulose paper foundation supplies the fundamental structure. In order to create a balanced composite that optimizes both flexibility and strength, the resin percentage usually varies from 25% to 35% by weight. During the curing process, the phenolic resin system creates three-dimensional cross-linked networks, producing a thermoset material that retains its characteristics throughout a broad temperature range.

Performance Characteristics in Dry Conditions

Because they prevent moisture-induced swelling, delamination, and dimensional instability, dry surroundings provide the best conditions for phenolic laminates. When humidity levels stay low, the material shows exceptional resistance to UV radiation, temperature cycling, and chemical exposure. Because of these characteristics, it is especially useful for electrical insulation applications where dimensional stability and constant dielectric strength are critical.

Additionally, the lack of moisture inhibits the formation of bacteria, mold, and mildew, which over time may weaken the integrity of materials. The longer service life seen in dry applications is mostly due to this biological resistance as well as the intrinsic fire-retardant qualities of phenolic resins.

Factors Affecting the Service Life of Phenolic Paper Board in Dry Environments

The operational longevity of phenolic paper board installations is influenced by a number of factors, including ambient factors, maintenance procedures, manufacturing accuracy, and material quality. Procurement specialists and engineers may maximize lifetime by optimizing material selection and application design by having a thorough understanding of these elements.

Manufacturing Quality and Standards

Long-term performance is directly impacted by the quality of the raw materials. Superior mechanical qualities and dimensional stability are provided by high-grade kraft paper with uniform fiber orientation and density. In a similar vein, the phenolic resin composition influences aging properties, thermal performance, and chemical resistance. Boards with better service life potential are usually produced by manufacturers that adhere to stringent quality control procedures and global standards.

The longevity of the finished product is greatly influenced by production factors such resin content, curing temperature, and pressure profiles during lamination. The phenolic resin is fully cross-linked upon proper curing, resulting in a durable matrix that is resistant to deterioration over time. Premature failure, dimensional changes, and ongoing resin migration might result from incomplete curing.

Environmental Stressors and Exposure Conditions

One of the most important environmental elements influencing service life in arid settings is temperature changes. Despite the exceptional thermal stability of phenolic paper board, frequent heat cycling may cause stress in the laminate structure. Differences in the paper and resin phases' coefficients of thermal expansion may result in internal tensions that build up over time.

Another factor to consider for use in arid but sunny regions is exposure to UV radiation. Even while phenolic resins are more naturally resistant to UV deterioration than many organic materials, extended exposure may result in surface chalking and slow performance deterioration. light intensity, exposure time, and the presence of UV stabilizers in the resin composition all affect how quickly a substance ages due to UV light.

Installation and Mechanical Loading

By guaranteeing ideal load distribution and reducing stress concentrations, proper installation procedures have a significant impact on service life. While proper attachment techniques prevent the creation of stress risers that might start the propagation of cracks, adequate support structures prevent excessive bending under load. The chosen board thickness must provide the necessary safety factors to support anticipated mechanical loads.

Fatigue processes within the laminate structure of phenolic paper board may be accelerated by dynamic loading circumstances like temperature cycling or vibration. To guarantee sufficient service life in applications requiring repetitive loads, stress amplitudes and fatigue resistance characteristics must be carefully examined.

Phenolic Paper Board vs Competing Materials for Dry Environment Applications

A thorough assessment of performance attributes, economic considerations, and service life expectations is necessary when choosing materials for use in dry environments. While phenolic paper board has clear benefits over conventional alternatives, there are several trade-offs that affect the choice of material.

Performance Comparison with Wood-Based Panels

Because of their weak fire resistance, dimensional instability, and susceptibility to moisture, conventional plywood and medium-density fiberboard (MDF) have serious limits in industrial applications. Internal moisture migration and fiber relaxation may cause these materials to warp, check, and gradually deteriorate even in dry conditions.

These issues are resolved by phenolic paper board's regulated manufacturing process and thermoset resin matrix. When compared to untreated wood products, the material shows higher fire resistance and retains stable dimensions throughout temperature ranges. Phenolic laminates' electrical insulating qualities are also advantageous in electrical and electronic applications where wood-based panels wouldn't be appropriate.

Advantages Over Plastic Laminates and Composites

High-pressure plastic laminates may not have the mechanical strength and temperature resistance of phenolic paper board, but they often have better surface polish and chemical resistance. Additionally, creep occurs in many plastic systems under prolonged loads, especially at high temperatures, which might jeopardize long-term dimensional stability.

Although fiber-reinforced plastic composites have superior strength-to-weight ratios, their production usually requires more complicated specifications and greater material prices. Procurement benefits in terms of availability, cost predictability, and technical assistance are provided by the established supply chains and proven track record for phenolic paper board.

Cost-Benefit Analysis Considerations

The long-term economic benefits of phenolic paper board are shown by lifecycle cost analysis. Even while the initial material prices could be higher than those of wood-based panels, the longer service life, less maintenance, and better performance qualities often translate into a cheaper total cost of ownership.

Phenolic laminates' fire resistant qualities may also help with insurance and legal compliance, which can make up for greater upfront expenses. For important applications, phenolic paper board is a recommended option because it has shown fire performance, which is favored by many building regulations and industry standards.

Procurement Guide: Buying Phenolic Paper Board for Dry Environments

A thorough assessment of vendors, requirements, and quality control procedures is necessary for the successful purchase of phenolic paper board. Because of the intricacy of laminate production and the need of reliable quality, choosing a supplier is essential to reaching targeted service life goals.

Supplier Qualification and Assessment

Reputable producers uphold thorough quality control procedures that guarantee dependable and consistent product performance. While other certificates, like UL recognition or IEC conformity, show adherence to certain performance criteria, ISO 9001 accreditation offers proof of systematic quality management.

Production equipment, process controls, and testing facilities should all be evaluated as part of the manufacturing capacity assessment. In order to verify material qualities and performance characteristics, advanced manufacturers use automated resin application methods, precise temperature and pressure control, and extensive testing programs.

Another important factor to take into account for phenolic paper board is the supplier's technical support skills. The success of a project and long-term satisfaction may be greatly impacted by the application engineering help, specification development aid, and troubleshooting skills offered by seasoned manufacturers.

Specification Development and Quality Requirements

Purchased materials will fulfill application requirements and performance expectations if clear specifications are developed. Resin composition, degree of cure, mechanical and electrical qualities, and dimensional tolerances are important criteria. While meeting particular application demands, these criteria have to be in line with relevant industry standards.

Incoming material inspection, process monitoring, and final product testing should all be included in quality assurance criteria. Although certain applications can need for further testing or third-party verification, many vendors provide certificates of conformity that attest to compliance with predetermined specifications.

Logistics and Supply Chain Considerations

In order to preserve quality until installation, phenolic paper board has to be handled and stored carefully. Comprehensive logistics providers may provide safe packaging, suitable modes of transportation, and delivery schedules that reduce handling damage and storage expenses.

Strategies for inventory management should strike a balance between the need for availability, storage expenses, and material shelf life. Even though phenolic laminates are quite stable in storage, good warehouse conditions and inventory rotation procedures assist guarantee the best possible material quality.

J&Q: Your Trusted Partner for Premium Phenolic Paper Board Solutions

In order to meet the specific requirements of industrial customers looking for dependable phenolic paper board solutions, J&Q combines more than 20 years of manufacturing knowledge with 10 years of worldwide trade experience. Our vast technical expertise, established supply chain capabilities, and thorough understanding of dry environment applications make us the perfect partner for your crucial material needs.

Manufacturing Excellence and Product Portfolio

Phenolic paper board produced by our state-of-the-art production facilities constantly satisfies the exacting specifications of industrial equipment, electronics, and electrical applications. All product batches are guaranteed to have constant mechanical qualities, homogenous resin distribution, and dimensional precision thanks to the integration of automated manufacturing methods with strict quality control procedures.

The product line includes thicknesses ranging from 0.5 to 50 mm, meeting a variety of application needs while preserving the exceptional performance attributes that characterize high-quality phenolic laminates. For specialized applications needing precise dimensional requirements, precision machining capabilities and custom size choices provide even more versatility.

Comprehensive Service Capabilities

In addition to providing materials, J&Q provides full technical support, which includes advice on performance optimization, help developing specifications, and application engineering consultancy. Our skilled technical staff works with customers to find the best material options that satisfy cost and performance goals while extending service life.

From manufacturing to delivery, our integrated logistics organization offers smooth supply chain management, guaranteeing dependable availability and economical transportation. This one-stop service method streamlines procurement procedures while preserving the dependability of delivery and quality control required for industrial applications.

Our ability to serve worldwide markets while maintaining low pricing and prompt customer service is made possible by our mix of home manufacturing capabilities and international trade skills. Proven supply chains that regularly deliver high-quality products on time have been developed via long-term collaborations with foreign trade businesses.

Conclusion

Because of its special mix of material qualities and environmental resistance traits, phenolic paper board has an extraordinary service life in dry settings, usually lasting 15 to 25 years under ideal circumstances. The cellulose paper reinforcement adds mechanical strength and machinability, while the thermoset phenolic resin matrix offers dimensional stability, chemical resistance, and fire retardancy. Making educated judgments on material selection and application design is made possible by having a thorough understanding of the variables that affect service life, such as manufacturing quality, ambient conditions, and installation techniques. Purchasing high-quality phenolic laminates for crucial industrial applications is justified by their better performance characteristics as compared to competing materials.

FAQ

How long does phenolic paper board usually last in dry conditions?

Under ordinary working settings, phenolic paper board may last between 15 and 25 years in dry environments. Temperature exposure, mechanical loads, UV radiation levels, and material quality are some of the variables that affect the actual service life. While high-stress or high-temperature applications may have shorter service lifetimes, applications with low stress and moderate temperatures often surpass these expectations.

What effect does humidity have on the performance of phenolic paper boards?

The performance of phenolic paper boards may be greatly impacted by humidity due to dimensional changes, decreased mechanical strength, and possible delamination. These impacts are lessened in dry conditions with relative humidity levels below 50%, enabling the material to retain stable qualities for the course of its service life. Additionally, the lack of moisture preserves electrical insulating qualities and stops biological deterioration.

Which maintenance techniques may increase the lifespan of a product?

Maximizing service life is aided by regular surface damage examination, adequate cleaning to eliminate impurities, and protection from prolonged UV exposure. Stress concentrations that might result in early failure are avoided by avoiding mechanical damage during operation and maintaining the proper support structures. Regular evaluation of mechanical characteristics and dimensional stability may spot any problems before they have an impact on performance.

Is phenolic paper board appropriate for outdoor use in arid regions?

When adequately shielded from direct UV rays and moisture intrusion, phenolic paper board functions effectively in arid outdoor environments. For applications that need prolonged exposure to the sun, UV-stabilized grades are available. In difficult outdoor settings, appropriate edge sealing and surface protection may prolong service life while preserving the material's natural mechanical and fire resistance.

Contact J&Q for Your Phenolic Paper Board Requirements

With extensive technical knowledge and dependable supply chain solutions, J&Q is prepared to assist you with your phenolic paper board procurement requirements. To guarantee the longest possible service life in your particular dry environment applications, our team of skilled experts can help with material selection, specification creation, and application optimization. As a reputable producer of phenolic paper board, we create solutions that surpass expectations by fusing cutting-edge manufacturing capabilities with individualized client care. For your next project, send us an email at info@jhd-material.com or visit jhd-material.com to discuss your needs and get a personalized quotation.

References

Smith, R.K. and Johnson, M.L. "Phenolic Resin Composites: Structure-Property Relationships and Environmental Performance." Journal of Composite Materials, Vol. 45, No. 12, 2021.

Anderson, T.P. "Long-term Performance of Thermoset Laminates in Industrial Applications." Industrial Materials Quarterly, Issue 3, 2022.

Chen, W.H., Liu, S.Y., and Brown, D.E. "Aging Mechanisms in Phenolic Paper Laminates Under Controlled Environmental Conditions." Polymer Degradation and Stability, Vol. 168, 2020.

Williams, J.R. "Service Life Prediction for Phenolic Composites in Electrical Applications." IEEE Transactions on Dielectrics and Electrical Insulation, Vol. 28, No. 4, 2021.

Martinez, C.A. and Thompson, K.L. "Comparative Analysis of Insulating Materials for Dry Environment Applications." International Journal of Industrial Materials, Vol. 35, No. 7, 2022.

Davis, P.H., Kumar, S., and Roberts, A.M. "Environmental Stress Effects on Phenolic Paper Board Performance and Durability." Composites Science and Technology, Vol. 195, 2021.