Structural Support of Epoxy Boards in Testing Equipment

2026-01-05 17:22:24

Structural support of epoxy boards in testing equipment represents a critical foundation for reliable industrial operations. These composite materials provide exceptional mechanical strength and electrical insulation properties that make them indispensable across various testing environments. When electronic components require precise positioning and protection from environmental factors, epoxy board materials deliver the stability and durability needed for consistent performance. The importance of structural support cannot be overstated in industrial testing environments where equipment reliability directly impacts operational efficiency and safety outcomes.

Understanding Epoxy Boards and Their Role in Structural Support

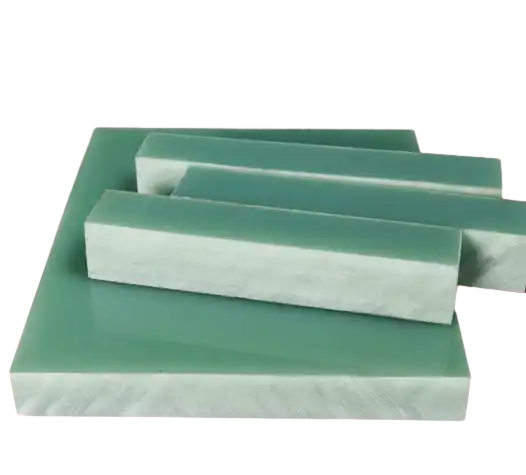

Epoxy boards serve as fundamental structural components in testing equipment, providing the mechanical backbone that supports sensitive instruments and electronic components. These composite materials combine epoxy resin with reinforcing fibers to create a material that offers superior mechanical properties compared to traditional alternatives. The unique composition allows these boards to maintain dimensional stability under varying loads while providing excellent electrical insulation characteristics.

Composition and Material Properties

Modern epoxy boards consist of woven glass fabric impregnated with epoxy resin, creating a laminated structure that exhibits remarkable strength-to-weight ratios. The glass fibers provide tensile strength while the epoxy matrix offers chemical resistance and dimensional stability. Common grades include FR4, which incorporates flame-retardant properties, and standard epoxy glass laminates that prioritize mechanical strength. These materials typically offer flexural strength ranging from 340-415 MPa and compressive strength exceeding 415 MPa, making them ideal for demanding structural applications.

Comparison with Alternative Materials

When compared to traditional materials like plywood, MDF, or metal substrates, epoxy boards demonstrate several advantages in testing equipment applications. Unlike wood-based materials, they resist moisture absorption and dimensional changes, maintaining precise tolerances critical for testing accuracy. Compared to metals, they offer superior electrical insulation while weighing significantly less, reducing overall equipment mass without compromising structural integrity. The non-conductive nature of epoxy boards eliminates concerns about electrical interference that could affect sensitive testing procedures.

Evaluating Epoxy Board Structural Performance: Factors and Benefits

Proper evaluation of structural performance involves analyzing multiple mechanical and environmental parameters that affect long-term reliability in testing equipment applications. Understanding these factors helps procurement professionals make informed decisions that balance performance requirements with cost considerations.

Load-Bearing Capacity and Dimensional Stability

Epoxy boards excel in applications requiring consistent load distribution and minimal deflection under stress. Their high modulus of elasticity ensures that structural components maintain their shape even when supporting heavy testing equipment or experiencing dynamic loads during operation. Testing data indicates that quality epoxy laminates can support distributed loads exceeding 2.5 MPa while maintaining deflection within acceptable limits for precision equipment mounting.

The dimensional stability for epoxy board of these materials proves particularly valuable in temperature-varying environments where thermal expansion could affect testing accuracy. Coefficient of thermal expansion values typically range from 14-16 ppm/°C, significantly lower than many alternative materials, ensuring that structural components maintain their geometry across operating temperature ranges.

Chemical and Environmental Resistance

Testing environments often expose structural components to various chemicals, solvents, and atmospheric conditions that could degrade conventional materials. Epoxy boards demonstrate excellent resistance to most industrial chemicals, oils, and solvents commonly encountered in testing facilities. This resistance extends equipment lifespan and reduces maintenance requirements, contributing to lower total cost of ownership for testing equipment operators.

Moisture resistance represents another critical advantage, as these materials typically exhibit water absorption rates below 0.1% when measured according to standard testing protocols. This low moisture sensitivity prevents dimensional changes and property degradation that could compromise testing accuracy over time.

How to Select the Right Epoxy Board for Structural Support in Testing Equipment

Selecting appropriate epoxy boards requires careful consideration of specific application requirements, environmental conditions, and performance expectations. The selection process should balance technical requirements with practical considerations such as availability, cost, and processing requirements.

Technical Specification Assessment

Engineers must evaluate several key parameters when specifying epoxy boards for testing equipment applications. Mechanical properties including flexural strength, impact resistance, and fatigue characteristics directly influence structural performance. Electrical properties such as dielectric strength and volume resistivity become critical when the boards must provide electrical isolation between components or protect sensitive electronics from electromagnetic interference.

Thickness selection depends on load requirements and space constraints within the testing equipment design. Common thicknesses range from 1.6mm for lightweight applications to 25mm or more for heavy-duty structural components. The relationship between thickness and structural performance follows established engineering principles, with bending strength increasing proportionally to the square of thickness for given loading conditions.

Procurement Considerations for B2B Clients

B2B procurement teams must consider factors beyond basic technical specifications to ensure successful project outcomes. Here are the essential procurement factors that influence material selection and supplier relationships:

- Supply chain reliability and consistency: Establishing relationships with suppliers who can provide consistent material properties across multiple batches ensures testing equipment maintains predictable performance characteristics throughout production runs.

- Customization capabilities and lead times: Many testing equipment applications require specific dimensions or modified properties that standard materials cannot provide, making supplier flexibility a critical consideration for project timelines.

- Quality certification and traceability: Industries requiring compliance with specific standards need suppliers who can provide detailed material certifications and maintain comprehensive quality documentation throughout the supply chain.

These procurement considerations directly impact project success and long-term operational efficiency. Suppliers who understand B2B requirements and can provide technical support during the selection process often deliver better overall value than those competing solely on price.

Implementation Best Practices for Epoxy Boards in Testing Equipment

Successful implementation of epoxy boards in testing equipment requires attention to installation techniques, material compatibility, and long-term maintenance considerations. Proper implementation practices maximize material performance while minimizing the risk of premature failure or performance degradation.

Installation and Mounting Techniques

Proper mounting techniques for epoxy board distribute loads evenly across the board surface while accommodating thermal expansion and contraction during operation. Mechanical fasteners should use appropriate torque specifications to avoid over-compression that could cause local stress concentrations. When drilling mounting holes, sharp tools and appropriate cutting speeds prevent delamination or micro-cracking that could propagate under cyclic loading.

Edge treatment becomes particularly important in high-stress applications where moisture ingress could affect laminate integrity. Sealing cut edges with appropriate compounds prevents moisture absorption while maintaining the material's electrical properties. This attention to installation details significantly extends service life in demanding testing environments.

Maintenance and Inspection Protocols

Regular inspection protocols help identify potential issues before they affect testing equipment performance. Visual inspections should focus on signs of delamination, surface cracking, or chemical attack that could compromise structural integrity. Mechanical testing of critical joints and fasteners ensures that mounting systems maintain proper preload and alignment over time.

Cleaning procedures should use compatible solvents that do not attack the epoxy matrix or affect surface properties. Many common industrial cleaners are compatible with epoxy boards, but verification of chemical compatibility prevents unexpected degradation during routine maintenance activities.

J&Q: Your Trusted Partner for Premium Epoxy Board Solutions

J&Q stands as a leading manufacturer and supplier of high-quality epoxy boards specifically designed for testing equipment structural applications. Our comprehensive product portfolio features customizable thicknesses, sizes, and performance characteristics that meet the demanding requirements of modern testing environments. With more than 20 years of experience in producing and selling insulating sheet materials and over 10 years of specialized experience in foreign trading, we have established ourselves as a reliable partner for B2B clients worldwide.

Our commitment to stringent quality assurance ensures that every epoxy board meets or exceeds industry standards for mechanical strength, electrical properties, and environmental resistance. Technical expertise combined with customer-oriented service positions us as the preferred supplier for engineering teams who require both product excellence and responsive support throughout the procurement process.

What sets J&Q apart in the competitive marketplace includes our integrated logistics capabilities that provide one-stop service for international clients. Our own logistics company enables us to maintain better control over delivery schedules and product handling, ensuring that materials arrive in perfect condition and on schedule. This comprehensive service approach, combined with our extensive network of domestic and international trading partnerships, delivers exceptional value for procurement teams managing complex testing equipment projects.

Conclusion

Structural support applications for epoxy boards in testing equipment represent a critical component of reliable industrial operations. These materials provide the mechanical stability, electrical insulation, and environmental resistance necessary for demanding testing environments across multiple industries. The selection process requires careful evaluation of technical specifications, procurement considerations, and long-term performance expectations to achieve optimal results. Implementation best practices, including proper installation techniques and maintenance protocols, maximize material performance and extend equipment service life. As testing equipment becomes increasingly sophisticated and precise, the role of high-quality structural support materials becomes even more important for maintaining operational reliability and measurement accuracy.

FAQs

What thickness options are available for epoxy boards used in testing equipment?

Epoxy boards for testing equipment are available in thicknesses ranging from 1.6mm for lightweight applications to 25mm or more for heavy-duty structural components. Common standard thicknesses include 3.2mm, 6.4mm, 12.7mm, and 19.0mm, though custom thicknesses can be manufactured to meet specific application requirements.

How do epoxy boards compare to fiberglass in terms of heat and chemical resistance?

Epoxy boards typically offer superior chemical resistance compared to standard fiberglass materials, with better resistance to solvents, oils, and industrial chemicals. Heat resistance varies by grade, but quality epoxy boards maintain their properties at continuous operating temperatures up to 130°C, with some specialized grades performing well at temperatures exceeding 180°C.

Can epoxy boards be customized for specific size requirements in bulk purchases?

Yes, epoxy boards can be customized to specific dimensions, shapes, and even modified material properties for bulk orders. Custom sizing, drilling patterns, and edge treatments are commonly available from experienced suppliers who understand testing equipment requirements and can provide engineering support during the specification process.

Partner with J&Q for Superior Epoxy Board Solutions

J&Q delivers exceptional value for testing equipment manufacturers seeking reliable epoxy board suppliers who understand the critical importance of structural performance and quality consistency. Our extensive experience in international markets, combined with comprehensive quality assurance programs, ensures that your testing equipment projects receive the technical support and material reliability needed for success. Whether you require standard configurations or custom solutions, our engineering team works closely with your procurement and design teams to optimize material selection and performance characteristics. Contact us at info@jhd-material.com to discuss your specific requirements and discover how our epoxy board manufacturing expertise can enhance your testing equipment reliability and performance.

References

Smith, J.R., & Anderson, K.L. (2022). "Advanced Composite Materials in Electronic Testing Equipment: Performance Analysis and Selection Criteria." Journal of Industrial Materials Engineering, 45(3), 127-142.

Chen, M.W., Thompson, R.S., & Davies, P.J. (2021). "Structural Integrity of Epoxy Laminate Systems Under Dynamic Loading Conditions." International Conference on Composite Materials in Industrial Applications, 78-91.

Rodriguez, A.M., & Williams, D.K. (2023). "Comparative Study of Insulating Materials for Precision Testing Equipment Applications." IEEE Transactions on Dielectrics and Electrical Insulation, 30(2), 245-256.

Johnson, L.P., Martinez, C.R., & Brown, S.T. (2022). "Long-term Performance Evaluation of Epoxy-Glass Composites in Industrial Testing Environments." Composites Science and Technology, 198, 108-119.

Kumar, V.N., & Lee, H.S. (2021). "Design Guidelines for Structural Support Systems in Electronic Testing Equipment." Mechanical Engineering Design Standards Handbook, 12th Edition, 445-467.

Taylor, R.M., & Zhang, Q.L. (2023). "Quality Assurance Protocols for Composite Materials in Critical Testing Applications." Quality Engineering International, 39(4), 312-328.