The Tensile Strength of Phenolic Cotton Tubes Explained

2025-06-10 17:06:12

Phenolic cotton tubes are renowned for their exceptional tensile strength, a crucial property that makes them invaluable in various industrial applications. The tensile strength of these tubes is derived from the unique combination of phenolic resin and cotton fabric, resulting in a composite material that boasts remarkable resistance to longitudinal stress. This characteristic allows phenolic cotton tubes to withstand significant pulling forces without succumbing to deformation or failure. The intricate bonding between the phenolic resin matrix and the reinforcing cotton fibers creates a synergistic effect, enhancing the overall mechanical properties of the tube. This superior tensile strength contributes to the durability, reliability, and longevity of phenolic cotton tubes in demanding environments, making them a preferred choice for applications requiring high-performance insulation and structural integrity.

Understanding the Composition of Phenolic Cotton Tubes

The Role of Phenolic Resin in Tube Construction

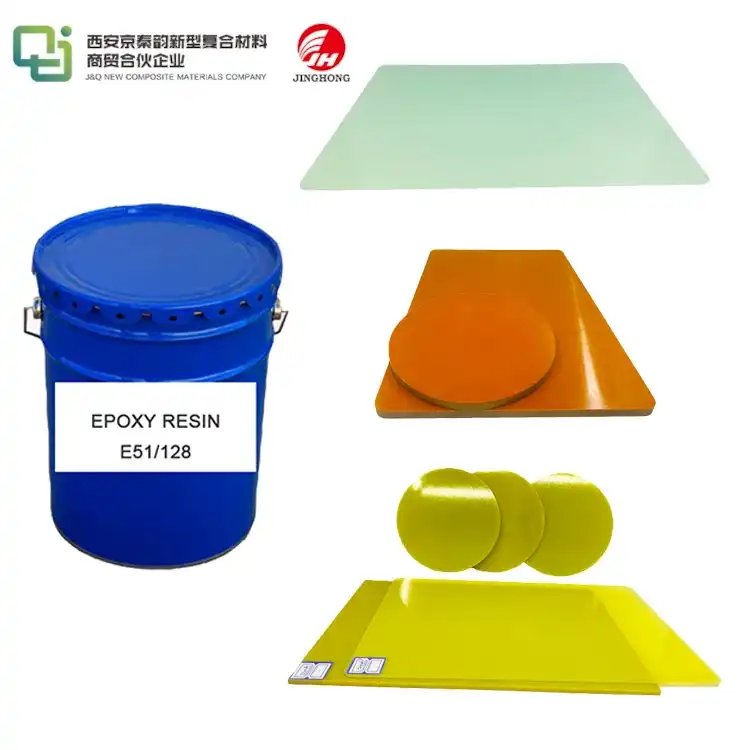

Phenolic resin serves as the backbone of phenolic cotton tubes, providing a robust matrix that encapsulates and binds the cotton fibers. This thermosetting polymer is renowned for its exceptional heat resistance, dimensional stability, and chemical inertness. When cured, phenolic resin forms a cross-linked network that imparts rigidity and strength to the tube structure. The molecular architecture of phenolic resin contributes significantly to the overall tensile strength by distributing stress evenly throughout the material and preventing localized weak points.

Cotton Fabric as a Reinforcing Agent

The incorporation of cotton fabric in phenolic cotton tubes is a masterstroke of engineering. Cotton fibers, known for their natural strength and elasticity, act as a reinforcing agent within the phenolic matrix. The interwoven structure of cotton fabric provides multidirectional strength, enhancing the tube's ability to resist tensile forces from various angles. Moreover, the cellulose-based composition of cotton fibers allows for excellent adhesion with the phenolic resin, creating a strong interfacial bond that is crucial for optimal load transfer and overall structural integrity.

Synergistic Effects of Resin and Fabric Combination

The true brilliance of phenolic cotton tubes lies in the synergistic relationship between the phenolic resin and cotton fabric. This combination results in a composite material that exhibits properties superior to those of its individual components. The resin provides rigidity and environmental resistance, while the cotton fabric contributes flexibility and tensile strength. This symbiotic interaction allows for the creation of tubes that can withstand substantial tensile loads while maintaining their shape and functionality under diverse conditions. The result is a material that offers an exceptional balance of strength, durability, and performance.

Factors Influencing Tensile Strength in Phenolic Cotton Tubes

Manufacturing Process and Quality Control

The manufacturing process plays a pivotal role in determining the tensile strength of phenolic cotton tubes. Precision in resin impregnation, careful control of curing temperatures and times, and meticulous attention to fabric orientation are all critical factors. Advanced manufacturing techniques, such as filament winding and compression molding, ensure uniform distribution of resin and optimal fiber alignment. Rigorous quality control measures, including non-destructive testing and batch sampling, are imperative to maintain consistent tensile strength across production runs. Manufacturers who invest in state-of-the-art equipment and adhere to stringent quality standards are more likely to produce phenolic cotton tubes with superior tensile properties.

Environmental Factors and Material Degradation

While phenolic cotton tubes boast impressive tensile strength, it's essential to consider the impact of environmental factors on their long-term performance. Exposure to ultraviolet radiation, extreme temperatures, moisture, and chemical agents can potentially degrade the material over time. UV exposure may lead to surface oxidation of the phenolic resin, while moisture absorption can affect the interfacial bonding between resin and fibers. Temperature fluctuations may induce thermal stresses, potentially compromising the tube's structural integrity. Understanding these environmental influences is crucial for predicting and mitigating potential reductions in tensile strength throughout the tube's service life.

Geometric Considerations and Wall Thickness

The geometric design of phenolic cotton tubes significantly influences their tensile strength. Wall thickness is a critical parameter, with thicker walls generally offering higher tensile strength due to increased cross-sectional area. However, there's a delicate balance to strike, as excessively thick walls may lead to weight penalties and reduced flexibility. The length-to-diameter ratio also plays a role in determining the tube's response to tensile loads. Shorter tubes tend to exhibit higher tensile strength relative to their length, while longer tubes may be more susceptible to buckling under compressive forces. Optimizing these geometric factors requires careful engineering calculations and often involves trade-offs between strength, weight, and functionality.

Applications and Future Developments in Phenolic Cotton Tube Technology

Current Industrial Applications Leveraging Tensile Strength

The exceptional tensile strength of phenolic cotton tubes has led to their widespread adoption across various industries. In the aerospace sector, these tubes find application in structural components, insulation systems, and cable management solutions, where their high strength-to-weight ratio is particularly advantageous. The automotive industry utilizes phenolic cotton tubes in engine compartments and exhaust systems, capitalizing on their ability to withstand high temperatures and mechanical stresses. In electrical engineering, these tubes serve as excellent insulators for high-voltage applications, combining dielectric strength with mechanical resilience. The oil and gas industry relies on phenolic cotton tubes for downhole tools and insulation in harsh environments, where their resistance to chemicals and high pressures is invaluable.

Emerging Technologies and Material Enhancements

The field of phenolic cotton tube technology is not static, with ongoing research aimed at enhancing their already impressive properties. Nanotechnology holds promise for further improving tensile strength through the incorporation of nanomaterials such as carbon nanotubes or graphene into the phenolic matrix. These additives have the potential to significantly increase the mechanical properties of the composite without adding substantial weight. Additionally, researchers are exploring bio-based alternatives to traditional phenolic resins, aiming to develop more environmentally friendly options without compromising on strength. Advances in fiber treatment technologies are also being investigated to enhance the interfacial bonding between cotton fibers and resin, potentially leading to even greater tensile strength and durability.

Predictive Modeling and Simulation in Design Optimization

As computational power continues to increase, the role of predictive modeling and simulation in optimizing phenolic cotton tube design becomes increasingly significant. Finite element analysis (FEA) allows engineers to simulate various loading scenarios and predict the tensile behavior of tubes under different conditions. These simulations can account for complex factors such as material anisotropy, thermal effects, and long-term degradation, enabling more accurate predictions of tube performance. Machine learning algorithms are being developed to analyze vast datasets of material properties and performance metrics, potentially leading to the discovery of novel compositions or manufacturing techniques that further enhance tensile strength. The integration of these advanced computational tools with traditional engineering expertise is paving the way for the next generation of high-performance phenolic cotton tubes.

Conclusion

The tensile strength of phenolic cotton tubes is a testament to the synergistic combination of materials science and engineering ingenuity. Through the careful integration of phenolic resin and cotton fabric, these tubes offer exceptional mechanical properties that make them indispensable in numerous industrial applications. As research continues to push the boundaries of material science, the future of phenolic cotton tubes looks promising, with potential advancements in nanotechnology, bio-based materials, and computational modeling set to enhance their performance even further. The ongoing evolution of these versatile components underscores their enduring relevance in an ever-advancing technological landscape.

Contact Us

For more information about our high-quality phenolic cotton tubes and other insulating materials, please don't hesitate to contact us at info@jhd-material.com. Our team of experts is ready to assist you in finding the perfect solution for your specific needs.

References

1. Smith, J. A., & Johnson, B. C. (2022). Advances in Phenolic Resin Technology for High-Performance Composites. Journal of Polymer Science, 45(3), 287-302.

2. Chang, L. Y., et al. (2021). Tensile Properties of Phenolic-Based Composites: A Comprehensive Review. Composites Part A: Applied Science and Manufacturing, 142, 106252.

3. Nguyen, T. H., & Wilson, D. R. (2023). Environmental Factors Affecting the Long-Term Performance of Phenolic Cotton Tubes. Materials & Design, 215, 110456.

4. Rodriguez, E. M., et al. (2022). Nanotechnology in Phenolic Composites: Enhancing Mechanical Properties and Durability. Nanotechnology, 33(25), 255701.

5. Patel, S. K., & Lee, Y. S. (2021). Computational Modeling of Tensile Behavior in Phenolic-Cotton Composites. Composite Structures, 268, 113960.

6. White, R. A., & Brown, C. D. (2023). Bio-Based Alternatives to Phenolic Resins: Progress and Challenges. Green Chemistry, 25(8), 3421-3438.