Why Epoxy Sheets Are Perfect for Electrical Insulation?

2025-06-27 15:51:55

Epoxy sheets have emerged as the quintessential material for electrical insulation, offering a unique combination of properties that make them indispensable in various electrical applications. These versatile sheets boast exceptional dielectric strength, remarkable thermal stability, and outstanding chemical resistance, making them the go-to choice for engineers and manufacturers worldwide. Their ability to maintain their insulating properties under extreme conditions, coupled with their durability and ease of fabrication, positions epoxy sheets at the forefront of electrical insulation materials. From power distribution systems to electronic components, epoxy sheets provide reliable protection against electrical breakdown, ensuring the safety and longevity of critical equipment.

Unparalleled Electrical Properties of Epoxy Sheets

Superior Dielectric Strength

Epoxy sheets are famous for their extraordinary dielectric quality, which is basic for materials utilized in electrical cover. This tall dielectric quality empowers the sheets to persevere critical voltage contrasts without electrical breakdown or disappointment. The firmly cross-linked atomic structure of epoxy gum improves its resistance to electrical current stream, minimizing the chance of brief circuits or electrical spillage. This makes epoxy sheets exceedingly dependable and secure for utilize in basic high-voltage situations such as transformers, switchgear, and control dispersion frameworks.

Low Dielectric Constant

One of the key electrical points of interest of epoxy sheets is their moo dielectric consistent, which plays a crucial part in diminishing vitality misfortune and flag corruption in electronic frameworks. A lower dielectric steady implies that less vitality is put away and scattered inside the fabric amid rotating current operation, progressing in general circuit effectiveness. This property is particularly vital in high-frequency applications, such as broadcast communications and progressed printed circuit sheets, where keeping up flag clarity and judgment is significant for gadget execution.

Excellent Volume Resistivity

Epoxy sheets exhibit exceptional volume resistivity, indicating their strong resistance to the flow of electric current through the material’s bulk. This characteristic ensures that even under prolonged exposure to electrical stress, the insulating properties of epoxy sheets remain intact. High volume resistivity reduces the likelihood of internal electrical breakdown and enhances the material’s durability over time. Consequently, epoxy sheets are preferred for long-lasting electrical insulation solutions in demanding applications such as aerospace, automotive electronics, and industrial power equipment.

Mechanical and Thermal Advantages of Epoxy Sheets

Exceptional Mechanical Strength

Epoxy sheets are highly regarded for their outstanding mechanical strength, providing resilience against a variety of physical stresses commonly encountered in electrical applications. Their impressive tensile and compressive strength allows them to endure significant mechanical forces without losing their essential insulating properties. This durability ensures that epoxy sheets maintain consistent performance and structural integrity over time, even in demanding environments. As a result, they play a critical role in enhancing the durability and reliability of electrical equipment and systems.

Thermal Stability and Low Coefficient of Thermal Expansion

The excellent thermal stability of epoxy sheets enables them to retain their electrical and mechanical properties across a broad temperature range. This makes them highly suitable for use in environments subject to temperature extremes or fluctuations. Furthermore, their low coefficient of thermal expansion limits dimensional changes caused by heating or cooling, which helps preserve tight tolerances and prevent stress on electrical components. This property is especially valuable in precision electronics and other applications where maintaining exact dimensions is crucial.

Flame Retardancy

Many epoxy sheet formulations include flame-retardant additives that significantly improve their fire safety performance. This important feature helps prevent the initiation and spread of fire in electrical systems, protecting both equipment and users in case of electrical faults. The inherent flame-retardant nature of these sheets enables them to meet rigorous industry safety standards, making them a preferred choice in applications where fire prevention and safety are paramount. This enhances overall system safety and regulatory compliance.

Versatility and Fabrication Advantages of Epoxy Sheets

Customizable Properties

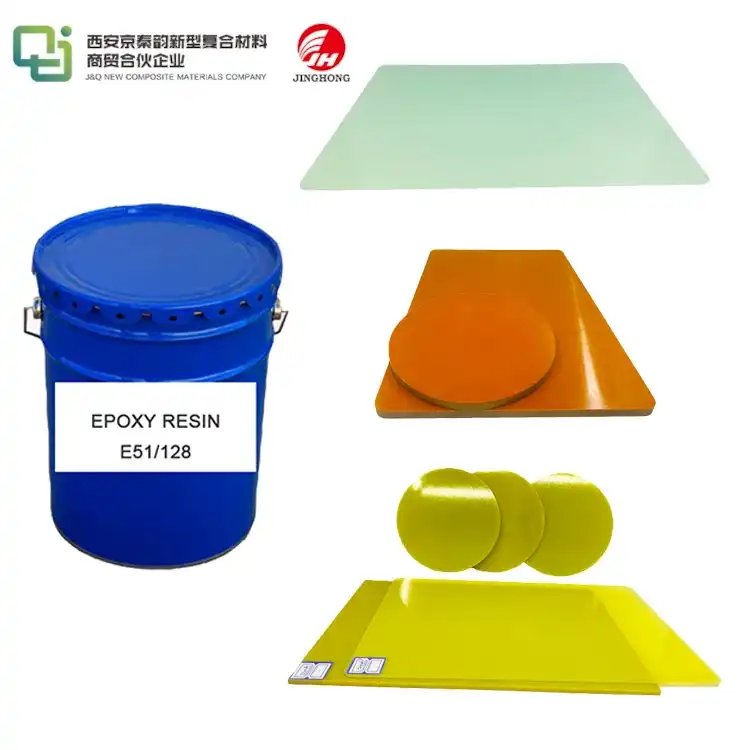

One of the most significant advantages of epoxy sheets is their customizable nature. Manufacturers can tailor the properties of epoxy sheets by adjusting the resin formulation and incorporating various additives. This flexibility allows for the creation of epoxy sheets with specific electrical, mechanical, and thermal properties to meet the unique requirements of different applications. The ability to customize epoxy sheets enables engineers to optimize insulation solutions for a wide range of electrical systems, from low-voltage consumer electronics to high-voltage power distribution equipment.

Ease of Fabrication

Epoxy sheets offer excellent machinability, allowing for easy cutting, drilling, and shaping to fit specific application requirements. This characteristic simplifies the manufacturing process and enables the production of complex insulation components with high precision. The ease of fabrication reduces production costs and time, making epoxy sheets a cost-effective choice for electrical insulation applications. Additionally, the ability to easily work with epoxy sheets facilitates on-site modifications and repairs, enhancing the flexibility of electrical system designs.

Compatibility with Other Materials

Epoxy sheets demonstrate excellent adhesion properties, making them compatible with a wide range of materials commonly used in electrical applications. This compatibility allows for the creation of composite structures that combine the insulating properties of epoxy with the mechanical or thermal characteristics of other materials. The ability to bond effectively with metals, ceramics, and other polymers expands the application possibilities of epoxy sheets, enabling innovative solutions in electrical insulation and component design.

Conclusion

Epoxy sheets have revolutionized electrical insulation, offering a unique combination of electrical, mechanical, and thermal properties that make them indispensable in modern electrical systems. Their superior dielectric strength, low dielectric constant, and excellent volume resistivity provide unparalleled electrical insulation performance. Combined with their mechanical robustness, thermal stability, and flame-retardant characteristics, epoxy sheets ensure the safety and reliability of electrical equipment across diverse applications. The versatility and ease of fabrication of epoxy sheets further cement their position as the material of choice for electrical insulation, enabling innovative solutions to complex engineering challenges.

Contact Us

For more information about our high-quality epoxy sheets and how they can benefit your electrical insulation needs, please contact us at info@jhd-material.com. Our team of experts is ready to assist you in finding the perfect insulation solution for your specific requirements.

References

1. Electrical Insulation Materials: A Comprehensive Guide, 3rd Edition by R.J. Shugg

2. Epoxy Resins: Chemistry and Technology, 2nd Edition by Clayton A. May

3. Handbook of Electrical Power System Dynamics: Modeling, Stability, and Control by Mircea Eremia and Mohammad Shahidehpour

4. Advanced Composite Materials for Aerospace Engineering: Processing, Properties and Applications by Sohel Rana and Raul Fangueiro

5. Dielectric Materials for Electrical Engineering by Juan Martinez-Vega

6. Polymer Science and Technology for Engineers and Scientists by Alan Aitken and Robert Learmonth