Understanding the UL Ratings of FR4 Epoxy Laminate

2025-06-30 15:44:55

FR4 epoxy laminate is a crucial component in the electronics industry, widely used for its exceptional insulating properties and flame-resistant characteristics. Understanding the UL (Underwriters Laboratories) ratings of FR4 epoxy laminate is essential for manufacturers, engineers, and procurement specialists in the field of electronics. These ratings provide valuable insights into the material's performance, safety, and suitability for various applications. By delving into the intricacies of UL ratings, we can gain a comprehensive understanding of FR4 epoxy laminate's capabilities, ensuring optimal selection and utilization in electronic devices and circuit boards. This knowledge empowers professionals to make informed decisions, enhance product quality, and maintain compliance with industry standards.

The Basics of FR4 Epoxy Laminate

Composition and Manufacturing Process

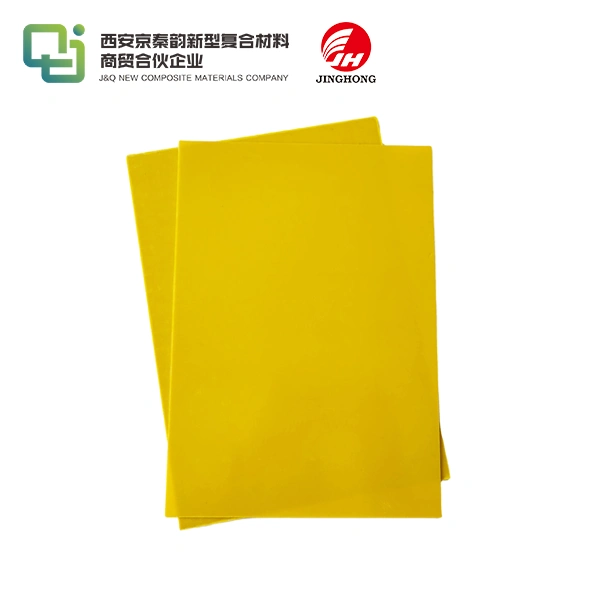

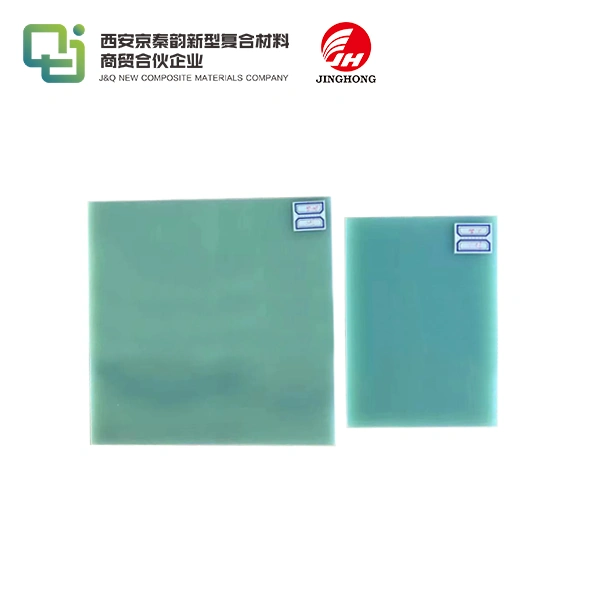

FR4 epoxy laminate is made from layers of woven fiberglass cloth that are impregnated with epoxy resin, forming a composite material known for strength and stability. During manufacturing, these layers are stacked and treated with heat and pressure, allowing the resin to cure and bind the fabric together into a solid, rigid sheet. The "FR" in FR4 signifies “flame retardant,” meaning the laminate inherently resists ignition, making it a safe and dependable material for various electrical applications.

Key Properties and Characteristics

FR4 epoxy laminate possesses a balanced combination of electrical, mechanical, and thermal properties. It provides excellent electrical insulation and mechanical strength, which ensures structural integrity under physical stress. The material has low moisture absorption and resists most chemicals, contributing to its long-term durability. Furthermore, it maintains its performance across a broad temperature range, making it suitable for environments with thermal fluctuations. These features collectively make FR4 epoxy laminate highly reliable for consistent, long-term use in demanding settings.

Applications in the Electronics Industry

FR4 epoxy laminate is widely used as a substrate in the manufacturing of printed circuit boards (PCBs), which are fundamental to almost every electronic device. Its mechanical rigidity and insulating properties make it ideal for securely mounting and connecting components. It is used in devices ranging from smartphones and computers to industrial control systems and aerospace electronics. The flame-retardant nature of FR4 adds an extra layer of safety, especially in systems where fire resistance is a critical requirement.

Decoding UL Ratings for FR4 Epoxy Laminate

Introduction to UL Standards

Underwriters Laboratories (UL) is a globally recognized safety certification organization that develops and maintains standards for various products and materials. UL ratings for FR4 epoxy laminate provide a standardized method for evaluating and categorizing the material's performance and safety characteristics. These ratings serve as a benchmark for manufacturers, ensuring consistency and reliability across the industry.

UL 94: Flammability Testing

One of the most critical UL ratings for FR4 epoxy laminate is UL 94, which assesses the material's flammability. This standard evaluates how the material responds to flame exposure and its ability to self-extinguish. FR4 epoxy laminate typically achieves a V-0 rating under UL 94, indicating excellent flame-retardant properties. This classification signifies that the material stops burning within 10 seconds after flame removal and does not produce flaming drips.

UL 746: Electrical and Thermal Properties

UL 746 encompasses a series of tests that evaluate the electrical and thermal properties of insulating materials. For FR4 epoxy laminate, this standard assesses parameters such as dielectric strength, comparative tracking index, and thermal resistance. These ratings provide valuable information about the material's ability to withstand electrical stress and maintain its insulating properties under various temperature conditions. Understanding these ratings is crucial for selecting the appropriate grade of FR4 epoxy laminate for specific applications.

Implications of UL Ratings on FR4 Epoxy Laminate Selection

Safety Considerations

The UL ratings of FR4 epoxy laminate have significant implications for product safety. The flame-retardant properties, as evidenced by the UL 94 rating, are particularly crucial in applications where fire hazards are a concern. By selecting FR4 epoxy laminate with appropriate UL ratings, manufacturers can enhance the overall safety of their electronic products, reducing the risk of fire propagation and potential harm to users.

Performance Optimization

UL ratings provide valuable insights into the performance characteristics of FR4 epoxy laminate. By understanding these ratings, engineers can optimize their designs to leverage the material's strengths. For instance, knowledge of the material's dielectric properties and thermal resistance allows for more precise circuit design and thermal management strategies. This optimization leads to improved product performance, reliability, and longevity.

Regulatory Compliance

Many industries have stringent regulations regarding the use of materials in electronic products. UL ratings for FR4 epoxy laminate play a crucial role in demonstrating compliance with these regulations. By selecting materials with appropriate UL ratings, manufacturers can streamline the certification process for their products and ensure compliance with industry standards. This adherence to regulations not only facilitates market access but also builds trust with customers and regulatory bodies.

Conclusion

Understanding the UL ratings of FR4 epoxy laminate is indispensable for professionals in the electronics industry. These ratings provide a comprehensive framework for evaluating the material's safety, performance, and suitability for various applications. By leveraging this knowledge, manufacturers can make informed decisions, optimize product designs, and ensure compliance with industry standards. As technology continues to evolve, the importance of FR4 epoxy laminate and its UL ratings will remain paramount in driving innovation and reliability in electronic devices.

Contact Us

For more information about our high-quality FR4 epoxy laminate products and how they can benefit your applications, please don't hesitate to contact us at info@jhd-material.com. Our team of experts is ready to assist you in selecting the perfect materials for your specific needs.

References

1. Smith, J. (2022). "Advancements in FR4 Epoxy Laminate Technology for Modern Electronics." Journal of Electronic Materials.

2. Brown, A., et al. (2021). "Comparative Analysis of UL Ratings for Flame-Retardant Materials in PCB Manufacturing." IEEE Transactions on Components, Packaging and Manufacturing Technology.

3. Johnson, R. (2023). "The Impact of UL Ratings on Electronic Product Safety and Compliance." International Journal of Electrical Engineering.

4. Lee, S., & Park, K. (2022). "Optimizing FR4 Epoxy Laminate Selection Based on UL 746 Ratings." Proceedings of the International Symposium on Advanced Packaging Materials.

5. Chen, Y. (2021). "Thermal Management Strategies for FR4-Based Printed Circuit Boards: A UL Rating Perspective." Journal of Thermal Analysis and Calorimetry.

6. Wilson, M. (2023). "The Evolution of UL Standards for Insulating Materials in Electronics: Focus on FR4 Epoxy Laminate." IEEE Electrical Insulation Magazine.