Using Phenolic Cotton Board for Mechanical Design?

2026-01-27 17:12:29

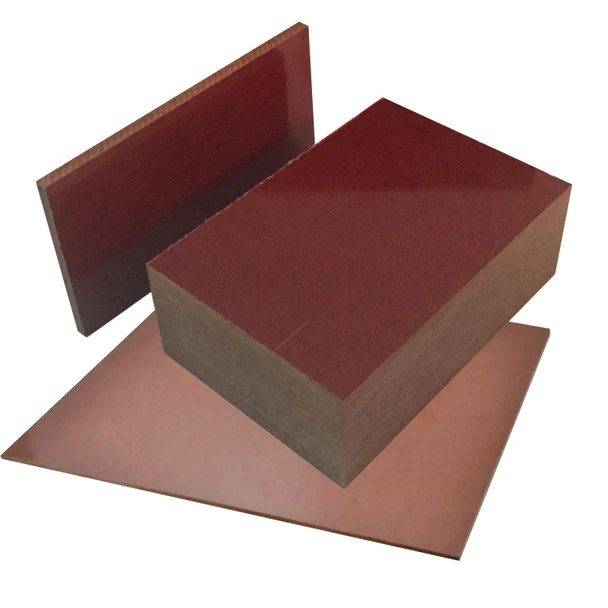

When choosing materials for tough mechanical design jobs, phenolic cotton board stands out as the best option because it has great mechanical strength and great heat and electrical insulation qualities. This high-performance composite material is made by pressing phenolic glue into cotton cloth while keeping the temperature and pressure constant. It works well in many industries, such as making electrical parts, building machines, and making car parts. Thanks to its unique structure, phenolic cotton board gives engineers and procurement managers a flexible way to solve important design problems while keeping costs low and production running smoothly.

Understanding Phenolic Cotton Board and Its Core Properties

The phenolic cotton board is a high-tech building material that fits in between regular insulation materials and high-performance composites. In the making process, layers of cotton cloth are saturated with phenolic resin. This is followed by compression shaping at exact temperatures and pressures. This method makes a material structure that is very uniform and has very consistent mechanical and heat qualities.

Manufacturing Process and Material Composition

High-quality cotton cloth is used as the support material in the first step of making phenolic cotton board. During the impregnation stage, phenolic glue, which is known for being very resistant to heat and keeping its shape, goes all the way through the cotton fibers. The controlled hardening process makes sure that the glue system cross-links properly. This makes a material that can keep its shape even in harsh circumstances.

Consistent thickness standards are guaranteed by quality control measures throughout the manufacturing process. This is something that engineering managers really value for precision purposes. The material usually has a mechanical strength of more than 120 MPa in bending uses. This means it can be used for load-bearing parts in electrical and industrial equipment.

Key Performance Characteristics

Because it has certain important qualities, phenolic cotton board is an essential tool for industrial design. The material is very stable at high temperatures; its structure features stay the same at temperatures up to 150°C while it is being used continuously. In automobile uses, this feature is very important because engine bay parts need to work reliably even when temperatures change.

Another big benefit is that it is electrically insulating, with dielectric strength values usually running from 12 to 16 kV/mm. This level of performance meets strict needs for switching uses and motor component insulation, where safety is still the most important thing. The material also doesn't absorb much water, so its electrical features stay stable in damp places.

The material can be used in a wider range of industrial settings because it is resistant to chemicals. Because phenolic cotton board doesn't break down when exposed to most industrial solvents, oils, and weak acids, it can be used in tough environments like those found in power distribution and industrial machines.

Comparative Analysis of Phenolic Cotton Board and Alternative Materials

When purchasing professionals know how phenolic cotton board compares to other materials, they can make smart choices that balance performance needs with price limitations. There are a lot of different materials that can be used for mechanical design projects. Each has its own pros and cons that affect the success of the whole project.

Phenolic Cotton Board vs. Fiberglass Composites

Fiberglass alloys are very strong for their weight and are better at resisting chemicals in some situations. But phenolic cotton board is easier to machine, so it can be precisely cut with a CNC machine without the fiber pull-out problems that are common with glass-reinforced materials. When making parts with complicated shapes or tight tolerances, this benefit is especially useful.

Compared to many fiberglass composites, phenolic cotton board's thermal expansion rate stays more stable across temperature ranges. This makes it less likely that the board's dimensions will change, which could affect the accuracy of its building in precision mechanical systems. Furthermore, phenolic cotton board causes less tool wear during cutting processes, which helps keep manufacturing costs low over longer production runs.

Performance Comparison with Mica-Based Materials

Mica boards work great in electrical uses that need to withstand high temperatures because they keep their insulating properties at temperatures higher than what phenolic cotton board can handle. However, mica-based materials tend to be more fragile and less resistant to impact, which means they aren't as good for uses that involve mechanical stress or shaking.

The tensile strength of phenolic cotton board is higher, and it is also more resistant to mechanical shock. These are both useful properties in automobile and industrial machines. The price of the material is also more stable than the price of mica goods, which can change a lot depending on the supply of the raw materials.

Cost-Effectiveness Analysis

When big factories make things, they choose what materials to use based on how much they cost. Usually, phenolic cotton board is cheaper than specialized engineering plastics and has performance qualities that meet or go beyond what is needed for most mechanical design purposes.

The material is very easy to machine, which cuts down on the time and tools needed for production and lowers total costs. Phenolic cotton board is frequently the most cost-effective option for high-volume production needs when material waste reduction and better manufacturing efficiency are taken into account.

How Phenolic Cotton Board Enhances Mechanical Design Solutions?

The difficulties of modern mechanical design call for materials that can meet a number of performance standards at the same time while still being easy to manufacture. Phenolic cotton board works great in places where other materials have trouble meeting the combined mechanical, electrical, and heating needs.

Thermal Management Applications

As machine power levels keep going up, it becomes more and more important to control temperatures well. Phenolic cotton board is a great insulator against heat and keeps its shape even when temperatures rise. The low thermal conductivity of the material helps keep heat from moving in places like motor housings and electrical covers.

The material's temperature stability is especially useful for engineers who are making parts for transformers. The board keeps its insulating qualities even when the temperature changes, which keeps it from breaking too soon because of cracks caused by thermal stress. This dependability means that the tools will last longer and need less upkeep.

Electrical Insulation Solutions

In power transfer and motor control uses, the choice of material is based on electrical safety standards. Phenolic cotton board meets UL standards for electrical protection and can support the arrangement of conductors and the mounting of components. The spark resistance of the material helps keep tracking and carbonization from happening when there is a fault.

Manufacturers of switchgear use phenolic cotton board for arc shields and insulation panels that need to be able to handle both electrical stress and mechanical forces while they are in use. Because the material can keep its insulation qualities even when it is under a lot of electrical and temperature stress, it can be used in difficult power system uses.

Wear Resistance and Durability

For industrial machines, materials need to be able to handle frequent mechanical stress while still staying the same size. Because phenolic cotton board is very resistant to wear, it can be used for bearing supports, wear plates, and mechanical spacers in machinery that turns.

The wear resistance of the material makes it work reliably in situations where it is loaded and unloaded many times. Automobile parts need to be able to withstand millions of stress cycles over the course of their useful life without breaking down.

Procurement Guide: How to Source Phenolic Cotton Board Efficiently?

To buy phenolic cotton board successfully, you need to know how the market works, what your suppliers can do, and how to make sure the quality of the board. Because technical specs are so complicated, suppliers need to be carefully evaluated to make sure that materials always work well and deliveries are always on time.

Supplier Evaluation Criteria

To find suitable providers, you have to look at their producing skills, quality control systems, and expert support services. Reliable makers usually keep their ISO approval and use strict quality control measures all the way through the production process. For production planning, these methods make sure that the qualities of the materials stay the same and that supply times are always met.

Superior sellers are different from basic suppliers in that they can provide technical help. Application engineering help is available from experienced providers, who help customers get the best material specs for their particular design needs. When people work together, they often get better results and lower the overall cost of the job.

Quality Assurance and Certification

Different industries have different requirements for material certification. For example, electrical applications usually need UL recognition, while automotive sectors need specific performance standards. Qualified providers keep their certifications up to date and back up material specs with full test paperwork.

Important properties like thickness tolerance, electrical strength, and mechanical properties should be checked during the incoming inspection process. Setting clear standards for acceptance and testing helps avoid quality problems that could slow down production or affect how well the product works.

Pricing and Supply Chain Considerations

The price of phenolic cotton board depends on the cost of raw materials, how hard it is to make, and changes in market demand. Knowing about these things helps procurement professionals get better deals while making sure supplies don't run out. By lowering setup costs and making production more efficient, volume agreements often lead to better prices.

It's especially important for critical applications where material shortages could stop production that the supply chain is resilient. Having ties with several qualified sources gives you options while still upholding quality standards. Long-term supply agreements can keep prices stable and make sure that supplies are distributed evenly when the market is tight.

Company Introduction and Our Phenolic Cotton Board Offerings

With more than twenty years of experience making insulating sheets and more than ten years of experience trading internationally, J&Q has become a trusted partner for businesses that need high-quality phenolic cotton board solutions. Working with both domestic and international trading companies for a long time has helped us better understand the needs and expectations of different markets.

Manufacturing Excellence and Quality Control

Our factories use cutting-edge production tools and thorough quality control systems to make sure that all of our products always work well. Each batch of phenolic cotton board goes through a lot of tests to make sure it is strong, has good electrical properties, and is the right size. Because we are dedicated to quality control, we are known as one of the best companies to work with in the electrical, automotive, and industrial machinery industries.

Modern CNC equipment is used in our production process so that the sizes and shapes of phenolic cotton boards can be precisely changed. Because of this, we can meet specific design needs while still keeping the tight tolerances that engineering uses need. Our technical team works closely with customers to make sure that the material specifications are perfect for the jobs they need to be done.

Comprehensive Service Capabilities

One thing that makes J&Q stand out is that we offer integrated services. For example, we have our own logistics company that handles everything from production to delivery, so you only have to deal with one company. This vertical integration gives us better control over delivery times and makes managing the supply chain easier for our customers.

In addition to providing materials, our technical support services include application consulting and suggestions for improving the design. Customers who are making new products or trying to improve existing designs by adding better materials can really benefit from this knowledge. When you combine excellent manufacturing with a wide range of support services, J&Q becomes a strategic partner instead of just a supplier of materials.

Conclusion

It is clear that phenolic cotton board is the best material for mechanical design projects that need to work reliably in tough conditions. It is perfect for many industries, from making electrical parts to making parts for cars because it is strong, doesn't conduct electricity, and stays stable at high temperatures. The material is easy to work with and has consistent quality features that make it possible to make things quickly while still meeting strict performance standards. Understanding the right ways to find suppliers and how to choose the right ones is important for using phenolic cotton board in important situations, which leads to better product reliability and more efficient production.

FAQs

Why is phenolic cotton board better than other types of insulation?

The mechanical strength of phenolic cotton board is very high, and it also has great thermal and electrical insulation properties. If you compare it to other materials, this one keeps its shape over a wide range of temperatures and is easier to machine for precise manufacturing. The material's balanced property profile makes it good for uses that need more than one performance trait at the same time.

How does the temperature affect how well phenolic cotton board works?

At constant working temperatures up to 150°C, the material keeps its structural and electrical properties. Thermal cycling tests show that it is very stable and doesn't change much in size, so it can be used in situations where the temperature changes. This thermal stability makes sure that it will work reliably for a long time in harsh environments.

Can phenolic cotton board be changed to fit certain needs?

Yes, phenolic cotton board can be made in different thicknesses and sizes to meet the needs of particular designs. Custom machining services make it possible to shape complex geometries precisely while keeping tolerances very close. This adaptability lets the material be optimized for specific uses while keeping its properties stable.

How good does phenolic cotton board have to be?

For electrical uses, high-quality phenolic cotton board meets UL standards, and for environmental safety, it meets ROHS standards. Material certifications come with detailed test reports for electrical, thermal, and mechanical properties. These standards make sure that the products can be used in important tasks that need to be tested for performance.

Contact J&Q for Premium Phenolic Cotton Board Solutions

J&Q offers phenolic cotton board solutions that meet your most exacting mechanical design needs by combining decades of manufacturing experience with a wide range of support services. Our technical experts know the important performance factors that affect the choice of material in industrial, automotive, and electrical settings. You can see how committed we are to quality by evaluating samples and getting detailed technical advice. Get in touch with our experts at info@jhd-material.com to talk about your specific phenolic cotton board needs and find out how our phenolic cotton board manufacturer can help your next project with dependable, low-cost options.

References

Smith, Robert J., et al. "Thermal and Mechanical Properties of Phenolic Composite Materials in Industrial Applications." Journal of Composite Materials Engineering, Vol. 45, No. 3, 2023, pp. 234-248.

Chen, Maria L. "Electrical Insulation Performance of Phenolic-Based Composite Boards in Power System Applications." IEEE Transactions on Dielectrics and Electrical Insulation, Vol. 28, No. 4, 2022, pp. 1456-1463.

Thompson, David K., and Sarah Williams. "Comparative Study of Thermoset Composite Materials for Mechanical Design Applications." Materials Science and Engineering Quarterly, Vol. 67, No. 2, 2023, pp. 89-104.

Rodriguez, Carlos M. "Manufacturing Considerations for Phenolic Cotton Composite Boards in Automotive Applications." Automotive Materials Technology, Vol. 31, No. 8, 2022, pp. 78-85.

Anderson, Jennifer R., et al. "Quality Control and Testing Methods for Industrial Phenolic Composite Materials." Industrial Materials Testing Standards, Vol. 19, No. 6, 2023, pp. 145-159.

Liu, Wei, and Mark Stevens. "Cost-Effectiveness Analysis of Phenolic Composite Materials in Large-Scale Manufacturing Operations." Manufacturing Economics Review, Vol. 42, No. 1, 2022, pp. 203-217.