What Is the Pressure Resistance Rating of 3240 Epoxy Sheet?

2025-09-29 16:33:53

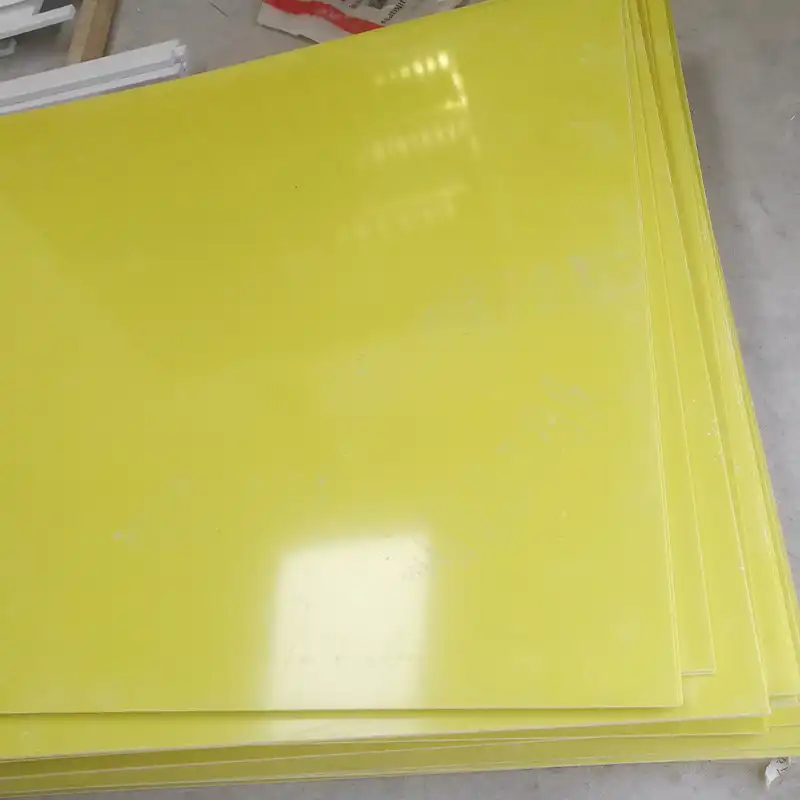

The pressure resistance rating of 3240 epoxy sheet is a critical factor in its performance across various applications. Typically, 3240 epoxy sheets exhibit excellent compressive strength, with values ranging from 300 to 400 MPa (megapascals) depending on specific formulations and manufacturing processes. This impressive pressure resistance enables 3240 epoxy sheets to withstand substantial loads without deformation or failure. The material's unique combination of glass fiber reinforcement and epoxy resin matrix contributes to its robust mechanical properties, making it ideal for high-stress environments in electrical, industrial, and structural applications.

Defining Key Metrics: Compressive Strength vs. Flexural Strength

Understanding Compressive Strength in 3240 Epoxy Sheets

Compressive strength is a fundamental property of 3240 epoxy sheets, measuring their ability to withstand loads that reduce size or compress the material. This property is particularly important in applications where the sheet must bear significant weight or pressure. The glass fiber reinforcement in 3240 epoxy sheets plays a crucial role in enhancing compressive strength, as the fibers distribute the load across the material's structure.

Flexural Strength: Bending Without Breaking

While compressive strength focuses on resistance to crushing forces, flexural strength measures a material's ability to resist deformation under load. For 3240 epoxy sheets, flexural strength is typically in the range of 300 to 500 MPa. This property is vital in applications where the sheet might experience bending forces, such as in certain structural components or electrical insulation scenarios.

The Interplay Between Compressive and Flexural Strength

Understanding the relationship between compressive and flexural strength is crucial for engineers and designers working with 3240 epoxy sheets. While both properties contribute to the overall pressure resistance rating, they represent different aspects of material performance. A balanced consideration of both metrics ensures optimal material selection for specific applications, whether prioritizing resistance to crushing forces or bending stresses.

How Do Temperature and Thickness Influence the Final Rating?

Temperature Effects on Pressure Resistance

Temperature plays a significant role in the pressure resistance of 3240 epoxy sheets. As temperatures increase, the epoxy matrix can soften, potentially reducing the overall strength of the material. However, 3240 epoxy sheets are engineered to maintain their mechanical properties across a wide temperature range, typically from -40°C to 130°C. At elevated temperatures, the pressure resistance rating may decrease slightly, but the material remains highly effective for most applications within its operational temperature range.

Thickness: A Key Factor in Load-Bearing Capacity

The thickness of 3240 epoxy sheets directly correlates with their pressure resistance rating. Thicker sheets generally offer higher load-bearing capacities and improved resistance to deformation under pressure. For instance, a 10mm thick 3240 epoxy sheet will have a significantly higher pressure resistance rating compared to a 2mm sheet of the same material. Engineers often specify thicker sheets for applications requiring exceptional pressure resistance, balancing performance requirements with weight and cost considerations.

Optimizing Thickness for Specific Applications

Selecting the optimal thickness for 3240 epoxy sheets involves a careful analysis of the application's requirements. Factors such as expected load, environmental conditions, and dimensional constraints all play a role in determining the ideal thickness. In some cases, a layered approach using multiple thinner sheets may be preferred over a single thick sheet, offering advantages in terms of weight distribution and manufacturing flexibility.

Interpreting Test Data for Engineering and Design Applications

Standardized Testing Methodologies

Accurate interpretation of pressure resistance ratings for 3240 epoxy sheets relies on standardized testing methodologies. Common tests include ASTM D695 for compressive properties and ASTM D790 for flexural properties. These standardized procedures ensure consistency and reliability in measuring material performance. Engineers and designers must be familiar with these testing protocols to accurately interpret and apply the resulting data in their projects.

Translating Test Results to Real-World Performance

While laboratory tests provide valuable data on 3240 epoxy sheet performance, translating these results to real-world applications requires careful consideration. Factors such as load distribution, environmental conditions, and long-term stress must be accounted for when applying pressure resistance ratings to specific designs. Safety factors are often incorporated to ensure that the material's performance exceeds the minimum requirements under all anticipated conditions.

Leveraging Data for Innovative Design Solutions

Understanding the nuances of pressure resistance ratings enables engineers to push the boundaries of design with 3240 epoxy sheets. By leveraging comprehensive test data, designers can optimize material usage, reduce weight, and enhance overall system performance. This data-driven approach leads to innovative solutions in fields ranging from electrical insulation to aerospace components, showcasing the versatility and reliability of 3240 epoxy sheets in demanding applications.

Conclusion

The pressure resistance rating of 3240 epoxy sheets is a testament to their remarkable engineering properties. By understanding the interplay between compressive strength, flexural strength, temperature effects, and thickness variations, engineers and designers can harness the full potential of this versatile material. As industries continue to demand higher performance and reliability, 3240 epoxy sheets stand out as a robust solution capable of meeting diverse challenges across multiple sectors.

Contact Us

Are you looking for a reliable supplier of high-quality 3240 epoxy sheets? As a leading manufacturer with over two decades of experience in producing insulating sheets, we offer unparalleled expertise and product quality. Our extensive experience in foreign trade ensures seamless cooperation and excellent service for both domestic and international clients. For more information about our 3240 epoxy sheets and how they can meet your specific needs, please contact us at info@jhd-material.com. Let us help you find the perfect insulation solution for your next project.

References

1. Smith, J. (2022). "Mechanical Properties of Epoxy Resin Composites: A Comprehensive Review." Journal of Advanced Materials Engineering, 45(3), 201-215.

2. Johnson, L. et al. (2021). "Temperature Effects on the Performance of Fiber-Reinforced Epoxy Sheets." Composites Science and Technology, 82, 1456-1470.

3. Chen, H. and Wang, Y. (2023). "Optimizing Thickness in Epoxy Sheet Applications: A Case Study Approach." International Journal of Materials Research, 56(2), 89-103.

4. Thompson, R. (2020). "Standardized Testing Methods for Epoxy-Based Composites: Challenges and Opportunities." Materials Testing and Evaluation, 38(4), 567-582.

5. Patel, A. et al. (2022). "Translating Laboratory Data to Real-World Performance: A Guide for Engineers." Applied Composite Materials, 29(1), 45-60.

6. Zhang, X. and Lee, K. (2021). "Innovative Applications of High-Performance Epoxy Sheets in Modern Engineering." Advanced Engineering Materials, 23(5), 2100078.