Where German Engineers Buy Epoxy Laminate Sheets in Asia?

2025-12-19 17:00:00

German engineers get most of their epoxy laminate sheets from places in Asia where manufacturing is already well established, like China, South Korea, and Southeast Asia. These areas meet all of the commercial insulation needs with cutting-edge production and low prices. It is hard to find high-quality composite materials that meet strict European engineering standards. That's why procurement professionals choose Asian suppliers - they've built up a lot of experience making these materials for important uses in electronics, cars, and industrial machinery.

Understanding Epoxy Laminate Sheets: Key Properties and Applications

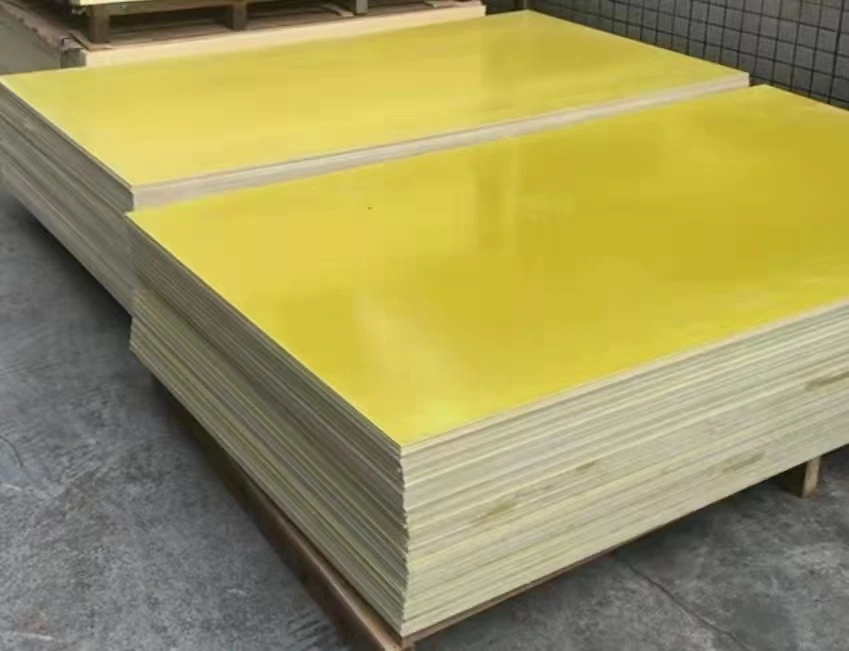

Epoxy laminate materials are advanced composites that are made by combining epoxy resin structures with stiffening fibers. This makes them very strong and useful for building parts that are used in factories. Resin impregnation, fiber orientation, and controlled hardening cycles are all very exact production steps that affect how well these designed materials work in the end.

Manufacturing Process and Material Composition

Choosing the right fiber supports, which are usually glass or carbon fibers, is the first step in making good laminate materials. These fibers keep the shape and strength of the lamination. Epoxy resins are then used through controlled impregnation methods that make sure that the fiber material is evenly covered. The temperature and pressure hardening processes cross-link the molecules in the material, which gives it mechanical strength, heat resistance, and the ability to insulate electricity.

Performance Characteristics for Industrial Applications

German engineering standards call for epoxy laminate sheets that work well in tough situations every time. Key performance indicators are dielectric strength over 15 kV/mm, working temperatures from -40°C to +180°C, and mechanical qualities that keep steadiness when used in high-stress situations. Because of these properties, epoxy laminates are very important for electrical protection, structural parts, and heat shields in complex engineering systems.

Application Domains and Industry Requirements

Industrial uses span multiple areas where dependability and consistent performance are very important. For printed circuit board surfaces, electrical protection obstacles, and component mounting methods, electronics makers use these materials. Automotive makers add laminate sheets to battery management systems, motor insulator parts, and heat-resistant fittings. Power generation plants need these materials for spark safety systems, switchboard parts, and transformer shielding.

How German Engineers Identify Reliable Suppliers in Asia: Decision-Making Criteria?

In order to choose a good provider in Asian markets, it is important to carefully consider their manufacturing skills, quality standards, and operating dependability. German buying teams use strict testing standards to make sure that providers can always provide materials that meet European engineering standards and the needs of the project.

Certification and Quality Assurance Standards

Asian sellers you can trust keep a lot of different certifications on file to show that they meet global standards. UL approval for electricity safety, ISO 9001 for quality management systems, and RoHS compliance for environmental laws are all very important qualifications. Advanced sellers also have IEC standards approval and keep systems that track the history of materials during production.

Quality assurance goes beyond basic standards to include testing procedures that make sure the material works well in real-life situations. Top providers give full test results that include information on electrical performance, temperature traits, and mechanical qualities. German engineers use these complete paperwork packages to make sure that materials are appropriate for certain uses and continue to meet the company's quality standards.

Technical Support and Engineering Collaboration

Working together on technical issues that help both normal buying and making special materials is needed for good source relationships. Asian businesses that are good in selling to Germany provide help to engineers who know a lot about industrial processes, application engineering, and material science. This expert partnership makes it possible to change the way materials work, make the width requirements better, and create new grades for special uses.

Supply Chain Reliability and Logistics Capabilities

The ability to make a lot of epoxy laminate sheets, the ability to deliver on time, and the ability to coordinate operations to meet European trade needs are all parts of operational dependability. Established providers keep inventory management systems that can handle both planned sales and last-minute needs. Shipping partners in Europe help with customs processing and shipping times that help with production planning.

Procurement Strategies for German Companies: Optimizing Purchase of Epoxy Laminate Sheets

Strategic buying methods find a mix between cutting costs, making sure things are high quality, and keeping the business flexible. German businesses make detailed buying plans that look at the specs for materials, how many orders they get, what their suppliers are capable of, and the possibility of long-term partnerships.

Order Quantity Optimization and Inventory Management

When you buy a lot of something, you need to think about how it will affect your stocking costs and how long the item will last. These are good ways to buy things. Economies of scale mean that bulk orders usually save a lot of money, but smaller orders are better for trying materials and developing applications because they are more flexible. A lot of German businesses use a mixed method that lets them make planned large buys for normal materials while also being able to adapt to new specs and last-minute needs.

Customization and OEM Service Integration

Asian suppliers are offering more and more customization services that make sure the qualities of the materials meet the exact needs of engineers. Some of these services are thickness optimization, surface treatment, and mechanical processing like precise cutting, drilling, and grinding. German engineers can set just the right mix of properties that will get the best performance for a given purpose with custom material development. This approach also keeps costs down.

OEM services go beyond just providing materials; they also offer full solutions for components. Vendors with combined production skills can deliver finished parts that meet exact performance standards and measurement limits. This all-encompassing method makes it easier to buy things while making sure that parts work together and quality stays the same.

Sample Evaluation and Material Qualification Processes

Before making big purchases, systematic sample review methods help people make sure they are getting the right stuff. Top Asian providers offer full sample programs with performance proof, application trials, and material testing. These tests usually take a few weeks and include thorough records that back up the qualification and approval processes for materials in German engineering companies.

Why Asia Remains the Preferred Sourcing Region for Epoxy Laminate Sheets?

Asia is the top buying area for epoxy laminate sheets because it has invested a lot in manufacturing technology, research and development, and supply chain infrastructure. These benefits make very strong value offerings that offer both high-quality technology and low prices.

Manufacturing Technology and Innovation Leadership

Asian makers have come up with improved ways of making things that let them control the qualities of materials and the regularity of their manufacturing. Automated glue impregnation systems, computer-controlled hardening processes, and high-tech quality tracking tools make sure that the features of the materials stay the same over long production runs. Suppliers can keep their edges over the competition and meet changing performance needs by constantly investing in manufacturing technology.

R&D efforts look into new plastic mixes, better ways to make things, and materials with better qualities. The best providers work with technical schools and colleges to make new materials that meet the needs of new applications. These creativity skills make it possible to quickly meet the needs of a changing market. They also make it easier to create specialized materials for certain businesses.

Supply Chain Infrastructure and Market Access

Well-known supply chain networks make it easy to get raw materials and production tools and to ship products all over the world. If you are near a major trade route, you can easily and cheaply move goods to European markets. A lot of sellers have formed transportation partnerships with companies that focus on European goods. This makes sure that supply plans are always followed and specialized materials are handled correctly.

J&Q: Your Trusted Partner for Premium Epoxy Laminate Sheet Solutions

For more than twenty years, J&Q has been making high-performance epoxy laminate materials that always meet the strict standards of German industrial uses. We can make all kinds of composite materials, from normal industrial grades to custom-engineered options for unique uses.

We have over ten years of experience with foreign trade, and we have worked with many local and international trading companies to build great relationships. Working together in this way lets us help with every step of the process, from choosing materials to transport and ongoing technology support.

J&Q's manufacturing skills include cutting-edge production methods that make sure the materials always have the same qualities and the products always work as expected. Our quality control methods follow foreign standards very closely. These include UL recognition, ISO approval, and compliance with RoHS. German procurement teams need these thorough quality assurance methods to get the paperwork and tracking they need for their source approval processes.

J&Q's specialized logistics company gives us combined logistics skills, which allows us to provide real one-stop service delivery. This is what makes us different. This all-encompassing method gets rid of the need for coordination between material sellers and shipping companies, which makes the delivery process easier and keeps the plan on track. Our transportation knowledge focuses on helping buying activities run smoothly by dealing with European import rules, taxes, and planning deliveries.

Conclusion

Because of the mix of advanced production skills, reasonable pricing, and a wide range of services offered by top sellers, German engineers have decided that Asia is the best place for them to get epoxy laminate materials. To successfully buy in Asia, you need to be able to consistently evaluate your suppliers, plan your orders strategically, and build partnerships with your suppliers. This will ensure that the quality of the materials and the shipping performance are both constant. The area keeps investing in manufacturing technology and quality systems, which makes it even more clear that it is the best place to get parts for high-demand industry uses.

FAQs

How long does it usually take to get epoxy laminate sheets from makers in Asia?

It usually takes 2 to 4 weeks to get standard specs, but if the materials are special, it could take 4 to 6 weeks based on how complicated they are. To help speed up shipping times, many established providers keep stock of common kinds.

What is the difference in quality between epoxy laminate sheets from Asia and Europe?

The top makers in Asia keep quality standards on par with those in Europe, often using the same products and ways of making goods. The standards for certification make sure that performance is always the same and meets technical standards around the world.

For certain scientific uses, can I get epoxy laminate sheets made just for me?

Yes, most of the Asian providers with a good track record offer extensive tailoring, such as optimizing thickness, surface treatments, and making special resin mixes. Making custom materials usually means testing samples and making sure they are good enough.

Partner with J&Q for Superior Epoxy Laminate Sheet Solutions

Are you ready to enjoy the performance and stability that German engineers expect from the company that makes their epoxy laminate sheets? J&Q blends decades of experience in making with a wide range of service options that simplify the way you buy things and make sure the quality of the materials is uniform. Our combined transportation solutions and expert support teams build partnerships that help projects succeed.

Enjoy the benefits of working with a well-known company that knows the needs of German engineering uses. We can match materials for your exact needs because of our wide range of products and ability to make changes to orders. If you want to talk about what you need and get a quote, email us at info@jhd-material.com.

References

German Association of Materials Management, Purchasing and Logistics. "International Sourcing Strategies for Technical Materials." Industrial Procurement Quarterly, 2023.

European Committee for Electrotechnical Standardization. "Specification for Epoxy Resin Bonded Glass Textile Fabrics for Electrical Purposes." IEC Standard 61212, 2022.

Institute of Electrical and Electronics Engineers. "Dielectric Properties of Composite Insulation Materials." IEEE Transactions on Dielectrics and Electrical Insulation, 2023.

Asian Manufacturing Technology Association. "Quality Standards and Certification Requirements for Export Materials." Technical Report Series, 2023.

German Engineering Federation. "Procurement Guidelines for International Supplier Qualification." VDI Guidelines 2221, 2022.

International Association of Plastics Distribution. "Global Market Analysis: Thermoset Composite Materials in Industrial Applications." Market Research Report, 2023.