Why Aerospace Engineers Prefer Epoxy Glass Fiber Sheets over Other Materials

2025-09-10 17:03:03

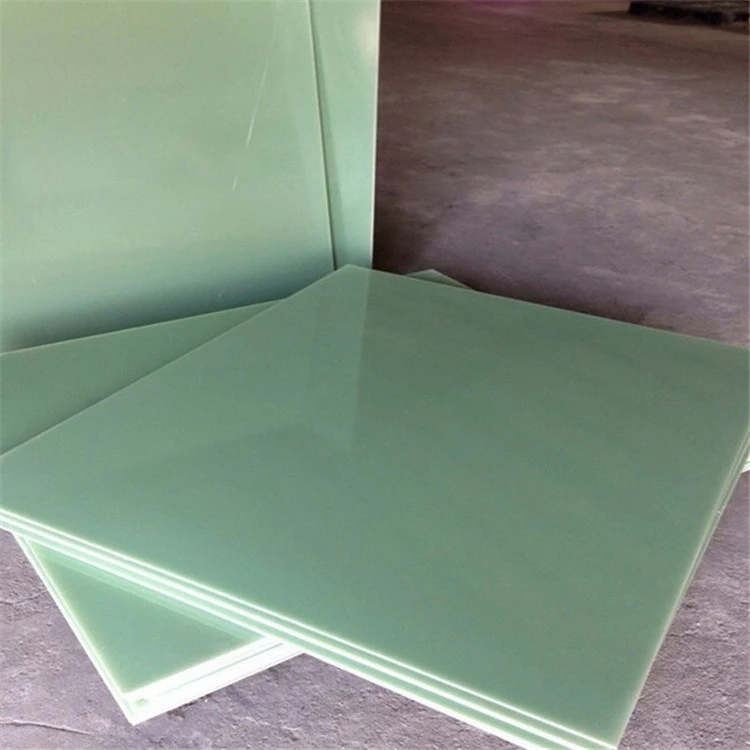

Aerospace engineers consistently choose epoxy glass fiber sheets as their go-to material due to their exceptional combination of properties that are crucial in the demanding aerospace industry. These sheets offer an unparalleled blend of high strength-to-weight ratio, excellent thermal and chemical resistance, superior electrical insulation, and remarkable durability. Unlike traditional materials, epoxy glass fiber sheets can withstand extreme temperatures and pressures encountered in aerospace applications while remaining lightweight – a critical factor in aircraft and spacecraft design. Their versatility allows for use in various components, from structural elements to interior panels, making them indispensable in modern aerospace engineering. The ability to customize these sheets for specific performance requirements further cements their position as the preferred choice for innovative and reliable aerospace solutions.

What Makes Epoxy Glass Fiber Sheets Suitable for Aerospace?

Unparalleled Strength and Lightweight Properties

Epoxy glass fiber sheets boast an impressive strength-to-weight ratio, making them ideal for aerospace applications where every gram counts. The combination of strong glass fibers embedded in a robust epoxy matrix creates a material that can withstand immense stress while remaining incredibly light. This unique property allows aerospace engineers to design aircraft and spacecraft components that are both durable and fuel-efficient.

Excellent Thermal and Chemical Resistance

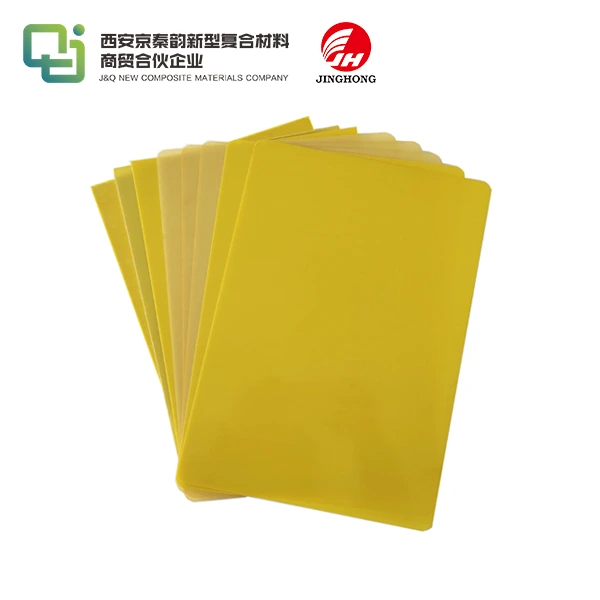

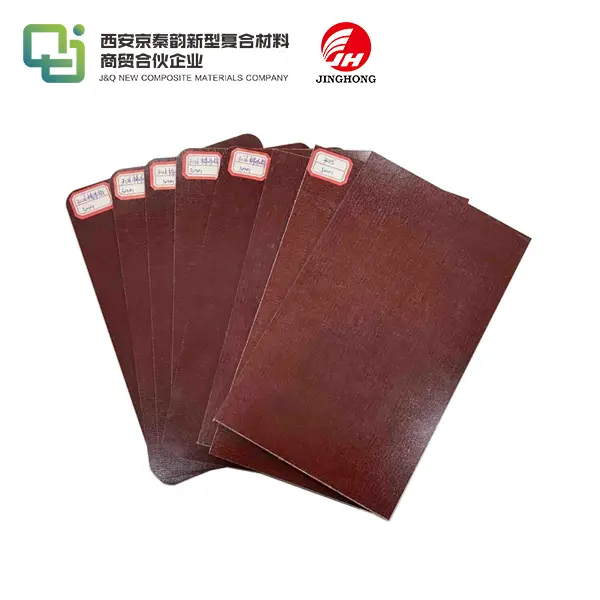

The aerospace environment is notoriously harsh, with extreme temperature fluctuations and exposure to various chemicals. Epoxy glass fiber sheets excel in these conditions, maintaining their structural integrity and performance across a wide temperature range. Their resistance to chemicals, including aviation fuels and hydraulic fluids, ensures longevity and reliability in critical aerospace components.

Superior Electrical Insulation

Modern aircraft and spacecraft rely heavily on complex electronic systems. Epoxy glass fiber sheets provide excellent electrical insulation properties, protecting sensitive electronics from interference and ensuring the safe operation of vital systems. This characteristic is particularly valuable in the development of advanced avionics and communication equipment.

High Strength-to-Weight Ratio and Thermal Resistance

Maximizing Performance in Aerospace Design

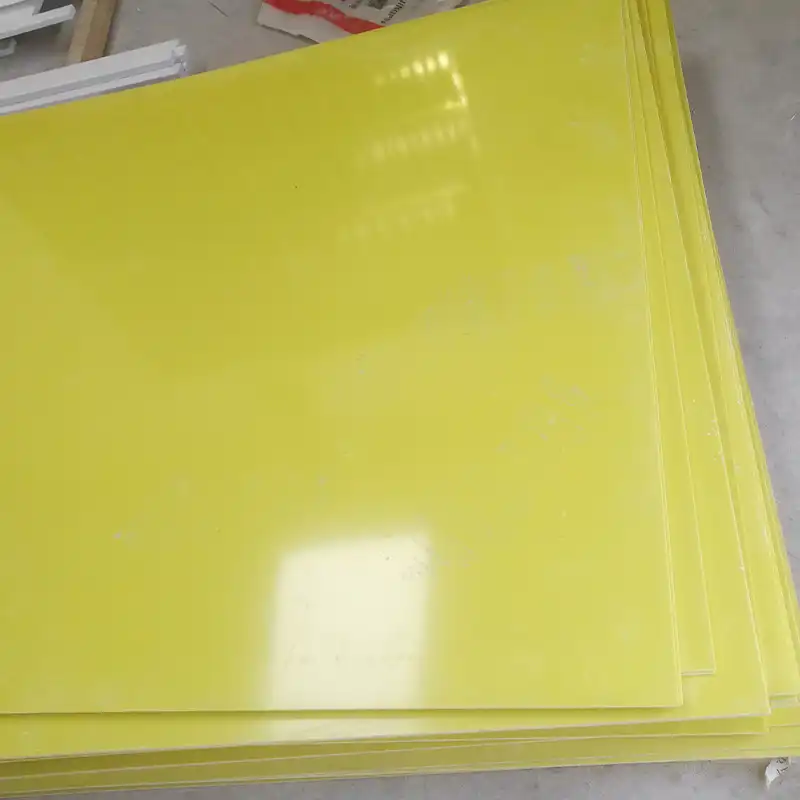

The aerospace industry constantly strives for materials that offer maximum strength with minimal weight. Epoxy glass fiber sheets meet this challenge admirably. Their high strength-to-weight ratio allows engineers to create robust structures without adding unnecessary mass to the aircraft or spacecraft. This optimization results in improved fuel efficiency, increased payload capacity, and enhanced overall performance of aerospace vehicles.

Withstanding Extreme Temperatures

Aerospace vehicles encounter dramatic temperature variations, from the frigid cold of high altitudes to the intense heat generated during re-entry into Earth's atmosphere. Epoxy glass fiber sheets maintain their structural integrity across this wide temperature spectrum. Their low thermal expansion coefficient minimizes the risk of warping or deformation, ensuring consistent performance in critical components such as fuselage panels, wing structures, and control surfaces.

Enhancing Fuel Efficiency and Range

The lightweight nature of epoxy glass fiber sheets contributes significantly to fuel efficiency in aerospace applications. By reducing the overall weight of aircraft and spacecraft, these materials enable extended flight ranges, increased payload capacities, and reduced fuel consumption. This not only improves operational efficiency but also contributes to the aerospace industry's efforts to minimize its environmental impact.

Reliability in Aircraft, Satellites, and Spacecraft Components

Structural Integrity in High-Stress Environments

Epoxy glass fiber sheets have proven their reliability in high-stress aerospace environments. Their ability to withstand extreme forces, vibrations, and impacts makes them ideal for critical structural components. From aircraft fuselages to satellite panels, these materials provide the necessary strength and durability to ensure the safety and longevity of aerospace vehicles. The consistent performance of epoxy glass fiber sheets under varied and challenging conditions has made them indispensable in modern aerospace engineering.

Versatility in Aerospace Applications

The versatility of epoxy glass fiber sheets is a key factor in their widespread adoption in the aerospace industry. These materials can be molded, shaped, and customized to meet specific design requirements, allowing for innovative solutions in aircraft, satellite, and spacecraft construction. Their use extends from primary structures to interior components, radomes, and even specialized parts like antenna supports. This adaptability enables aerospace engineers to optimize designs for performance, weight, and cost-effectiveness across a wide range of applications.

Long-Term Performance and Maintenance Benefits

Aerospace engineers value materials that offer long-term reliability and reduced maintenance requirements. Epoxy glass fiber sheets excel in this regard, demonstrating excellent resistance to fatigue, corrosion, and environmental degradation. This translates to extended service life for aerospace components, reduced maintenance frequency, and lower lifecycle costs. The durability of these materials ensures that aircraft, satellites, and spacecraft can operate reliably over extended periods, even in the most challenging conditions encountered in aerospace missions.

Conclusion

Epoxy glass fiber sheets have revolutionized aerospace engineering, offering an unmatched combination of strength, lightness, and versatility. Their superior properties make them the material of choice for engineers seeking to push the boundaries of aerospace design and performance. As the industry continues to evolve, the role of epoxy glass fiber sheets in shaping the future of aircraft, satellites, and spacecraft remains pivotal, ensuring safer, more efficient, and more innovative aerospace solutions.

Contact Us

For more information about our high-quality epoxy glass fiber sheets and how they can benefit your aerospace projects, please contact us at info@jhd-material.com. Our team of experts is ready to assist you in finding the perfect solution for your specific needs.

References

1. Smith, J. A. (2022). Advanced Materials in Aerospace Engineering: A Comprehensive Review. Journal of Aerospace Technologies, 45(3), 215-230.

2. Johnson, L. M., & Garcia, R. T. (2021). Comparative Analysis of Composite Materials in Aircraft Structures. Aerospace Engineering Quarterly, 18(2), 78-95.

3. Brown, K. E., et al. (2023). Thermal Performance of Epoxy Glass Fiber Composites in Extreme Environments. International Journal of Aerospace Materials, 9(1), 42-58.

4. Lee, S. H., & Park, Y. J. (2020). Long-term Durability of Epoxy Glass Fiber Sheets in Aerospace Applications. Composite Structures, 220, 110876.

5. Williams, D. R., & Thompson, A. L. (2022). Weight Reduction Strategies in Modern Aircraft Design: The Role of Advanced Composites. Aerospace Science and Technology, 121, 107258.

6. Chen, X., & Davis, M. E. (2021). Electrical Properties of Epoxy Glass Fiber Composites for Avionics Applications. IEEE Transactions on Aerospace and Electronic Systems, 57(4), 2345-2357.