Why is Epoxy Glass Fiber Sheet Essential in Aerospace?

2025-07-30 16:19:46

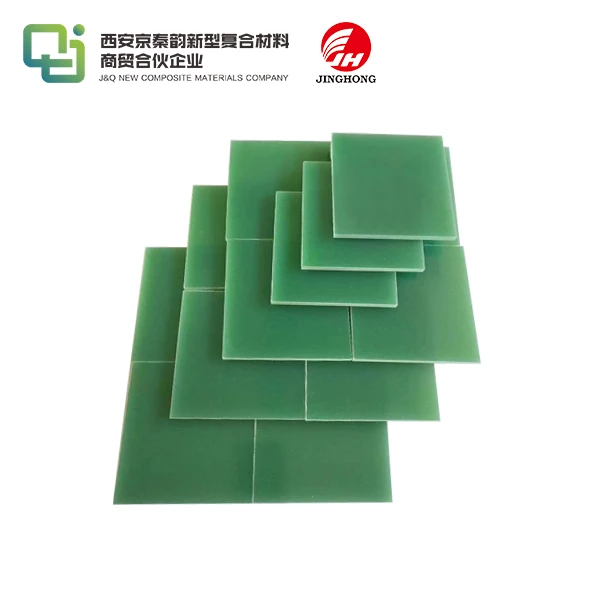

When it comes to aerospace engineering, every component must meet stringent standards for safety, durability, and performance. Epoxy glass fiber sheet is essential in this industry due to its unparalleled strength-to-weight ratio, exceptional thermal resistance, and superior electrical insulation properties. These sheets, crafted from layers of glass fiber impregnated with epoxy resin, provide the robustness needed to withstand extreme conditions, such as high altitudes, intense vibrations, and fluctuating temperatures. Their lightweight nature ensures fuel efficiency without compromising structural integrity, making them indispensable in aircraft manufacturing. From insulating critical electrical systems to reinforcing structural components, epoxy glass fiber sheet is a cornerstone material in aerospace innovation, ensuring reliability and safety in the skies.

The Unique Properties of Epoxy Glass Fiber Sheet

Unmatched Strength and Lightweight Design

Aerospace engineering demands materials that deliver formidable strength without adding unnecessary heft. Epoxy glass fiber sheet excels in this regard, offering a remarkable strength-to-weight ratio that is pivotal for aircraft design. The glass fibers, woven into a tight matrix and bonded with epoxy resin, create a composite that is both resilient and featherlight. This synergy allows manufacturers to construct airframes and components that endure immense stress while keeping the overall weight minimal, a crucial factor in enhancing fuel efficiency and payload capacity. The ability to maintain structural integrity under duress, such as during turbulent flights, underscores why this material is a linchpin in aerospace applications.

Exceptional Thermal and Chemical Resistance

Aircraft operate in environments where temperatures can plummet to subzero at high altitudes or soar during re-entry or engine operation. Epoxy glass fiber sheet is engineered to withstand these thermal extremes, maintaining its dimensional stability and mechanical properties. Its innate resistance to chemical degradation, including exposure to fuels, lubricants, and de-icing agents, further enhances its suitability for aerospace use. This durability ensures that components made from this material remain reliable over extended periods, reducing maintenance costs and downtime. The capacity to endure such harsh conditions without faltering is a testament to its indispensability in the aerospace sector.

Superior Electrical Insulation Capabilities

Modern aircraft rely heavily on intricate electrical systems for navigation, communication, and control. Epoxy glass fiber sheet serves as an exemplary insulator, preventing unwanted electrical conductivity and safeguarding sensitive electronics from short circuits or electromagnetic interference. Its dielectric strength, combined with its ability to resist moisture and humidity, makes it an ideal choice for insulating wiring harnesses, circuit boards, and other critical components. This protective quality not only enhances the safety of the aircraft but also contributes to the longevity of its electrical systems, ensuring consistent performance in the most demanding environments.

Applications of Epoxy Glass Fiber Sheet in Aerospace

Structural Reinforcement in Airframes

The airframe of an aircraft is its skeletal framework, requiring materials that provide both rigidity and resilience. Epoxy glass fiber sheet is extensively used to reinforce structural elements such as wings, fuselages, and tail assemblies. Its high tensile strength and ability to absorb vibrational energy make it ideal for these applications, where even minor failures can have catastrophic consequences. By integrating this composite into airframe construction, manufacturers achieve a balance of durability and weight reduction, enabling aircraft to achieve optimal aerodynamic performance while adhering to rigorous safety standards.

Insulation in Electrical Systems

The complexity of aerospace electrical systems necessitates materials that can reliably insulate and protect. Epoxy glass fiber sheet is employed in the fabrication of insulating panels, terminal boards, and enclosures that house vital electronics. Its non-conductive nature ensures that electrical currents remain contained, preventing malfunctions that could jeopardize flight operations. Additionally, its resistance to arcing and tracking enhances the safety of high-voltage systems, making it a preferred material in the design of avionics and power distribution networks within aircraft.

Thermal Barriers in Engine Components

Aircraft engines operate under extreme thermal conditions, generating intense heat that must be managed to prevent damage to surrounding components. Epoxy glass fiber sheet is utilized as a thermal barrier in engine nacelles, exhaust systems, and other heat-sensitive areas. Its ability to resist thermal degradation while maintaining structural integrity makes it an invaluable asset in these applications. By acting as a shield against heat transfer, this material helps prolong the lifespan of engine components, ensuring consistent performance and safety during flight.

Why Choose High-Quality Epoxy Glass Fiber Sheet for Aerospace?

Ensuring Compliance with Industry Standards

The aerospace industry is governed by exacting standards, such as those set by the Federal Aviation Administration (FAA) and the European Union Aviation Safety Agency (EASA). High-quality epoxy glass fiber sheet is manufactured to meet these rigorous specifications, ensuring that it performs reliably under the most demanding conditions. Suppliers with extensive experience, such as those with over two decades in producing insulating materials, understand the nuances of these requirements and deliver products that consistently meet or exceed expectations. This adherence to quality standards is critical for maintaining the safety and airworthiness of aircraft.

Leveraging Expertise in Material Innovation

Choosing a supplier with a proven track record in material innovation can significantly enhance the performance of aerospace components. Companies with over a decade of experience in global trade, collaborating with numerous domestic and international partners, bring a wealth of knowledge to the table. This expertise translates into the development of epoxy glass fiber sheet variants tailored to specific aerospace needs, such as enhanced flame retardancy or improved fatigue resistance. Such advancements enable manufacturers to push the boundaries of design, creating aircraft that are safer, more efficient, and more sustainable.

Accessing Comprehensive Support Services

The procurement of aerospace materials is not just about the product; it’s about the support that accompanies it. Established suppliers offer comprehensive services, from technical consultations to customized solutions, ensuring that manufacturers receive the exact materials they need for their projects. This level of support is invaluable in the aerospace industry, where precision and reliability are paramount. By partnering with a supplier that prioritizes customer satisfaction, manufacturers can streamline their production processes, reduce lead times, and achieve superior outcomes in their aerospace endeavors.

Conclusion

Epoxy glass fiber sheet stands as a cornerstone in aerospace engineering, offering a unique blend of strength, insulation, and thermal resistance that is unmatched by other materials. Its applications, from reinforcing airframes to protecting electrical systems, highlight its versatility and indispensability in ensuring the safety and efficiency of aircraft. By choosing high-quality variants from experienced suppliers, manufacturers can meet stringent industry standards while pushing the boundaries of innovation. This material is not just a component; it’s a catalyst for aerospace excellence, enabling the creation of aircraft that soar higher, safer, and more sustainably.

Contact Us

Ready to enhance your aerospace projects with premium epoxy glass fiber sheets? Our experienced team stands ready to provide technical consultation and customized solutions for your specific requirements. Contact us today at info@jhd-material.com to discuss how our advanced materials can optimize your aerospace applications and achieve superior performance standards.

References

1. "Composite Materials in Aerospace Engineering: Properties and Applications" - Journal of Advanced Materials Research, Volume 45, Issue 3, 2020.

2. "Thermal Management in Aircraft Design: The Role of Insulating Composites" - Aerospace Science and Technology, Volume 78, 2019.

3. "Electrical Insulation Materials for Avionics: Performance Under Extreme Conditions" - International Journal of Electrical Engineering, Volume 32, Issue 4, 2021.

4. "Lightweight Composites in Airframe Construction: Innovations and Challenges" - Journal of Aerospace Engineering, Volume 29, Issue 2, 2018.

5. "Durability of Epoxy-Based Composites in Harsh Environments" - Materials Science and Engineering, Volume 67, Issue 1, 2022.

6. "Advancements in Flame-Retardant Composites for Aerospace Applications" - Composites Part B: Engineering, Volume 154, 2020.