Epoxy Glass Fiber Sheet: The Future of Electrical Insulation

2025-07-31 17:17:47

In a time when electrical systems are becoming increasingly compact and subjected to higher voltages, the reliability of insulation materials is paramount. Epoxy glass fiber sheet meets these demands with excellent moisture resistance, dimensional stability, and long-term performance across diverse environmental conditions. Industries from aerospace to renewable energy harness its prowess to safeguard components, minimizing failures and extending lifespans. As innovations push boundaries, epoxy glass fiber sheet not only meets current needs but anticipates future challenges, evolving through advanced formulations that enhance flame retardancy and environmental sustainability. This positions it as the cornerstone of tomorrow's electrical insulation landscape, where safety and efficiency converge seamlessly.

What Makes Epoxy Glass Fiber Sheet Stand Out?

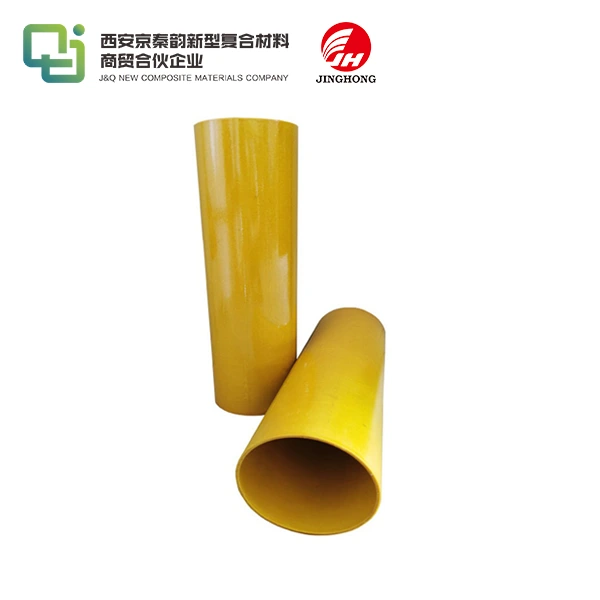

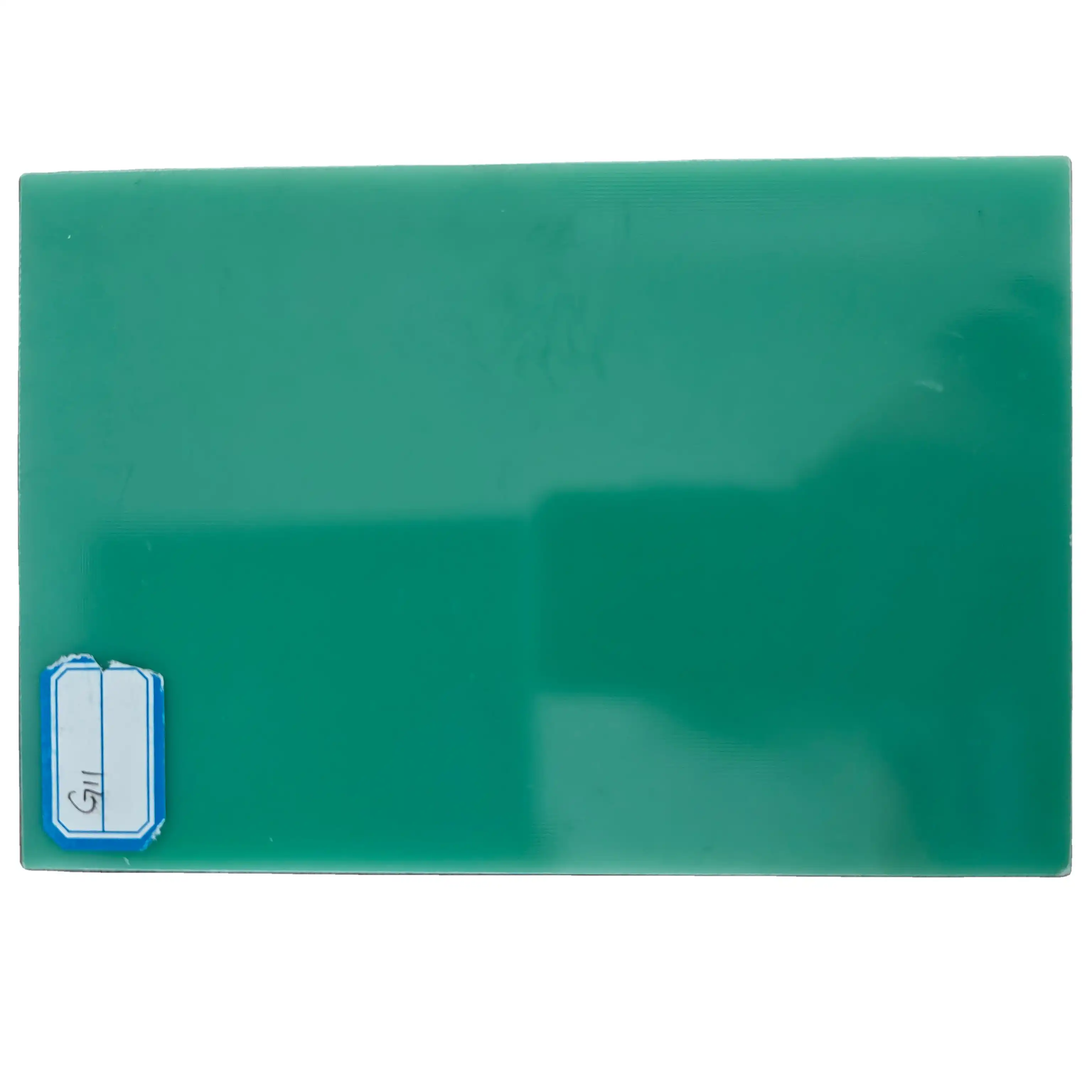

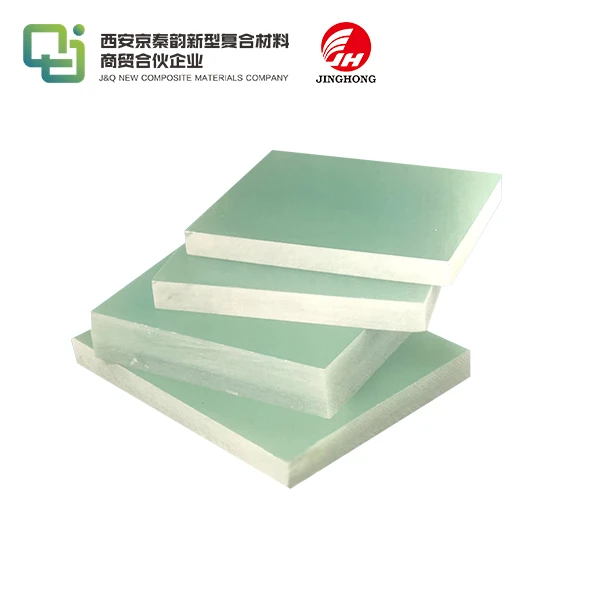

Epoxy glass fiber sheet captivates with its unique amalgamation of properties, setting it apart in the realm of insulating materials. This composite, often designated as G10 or FR4 in technical circles, integrates high-tensile glass fibers with thermosetting epoxy, yielding a product that excels in demanding environments.

Unrivaled Dielectric Properties

At the core of its appeal lies exceptional dielectric strength, which prevents electrical breakdown even under intense voltages. This attribute stems from the epoxy's ability to form a non-conductive matrix around glass strands, creating a barrier that thwarts current leakage. Engineers value this for applications in circuit boards and transformers, where precision insulation averts short circuits and enhances system longevity. Moreover, its low dissipation factor ensures minimal energy loss, making it ideal for high-frequency operations in telecommunications gear.

Mechanical Resilience and Durability

Beyond electrical merits, epoxy glass fiber sheet boasts impressive mechanical tenacity. It withstands compressive forces and impacts without fracturing, thanks to the interwoven glass reinforcement that distributes stress evenly. This durability proves invaluable in harsh settings, such as automotive underhood components exposed to vibrations and thermal cycling. The material's resistance to warping under load further bolsters its reliability, allowing for intricate machining into custom shapes without compromising integrity.

Thermal and Chemical Resistance

Heat poses no formidable foe to this sheet, as it endures temperatures up to 150°C or higher in specialized grades, maintaining structural coherence. This thermal fortitude arises from the epoxy's cross-linked polymer structure, which resists degradation. Chemically, it repels solvents, acids, and alkalis, safeguarding against corrosion in industrial milieus like chemical processing plants. Such resistance extends service life, reducing maintenance needs and operational downtimes.

Applications Revolutionizing Industries with Epoxy Glass Fiber Sheet

The versatility of epoxy glass fiber sheet propels it into diverse sectors, where it addresses specific challenges with tailored solutions. From powering renewable sources to fortifying aerospace assemblies, its adoption underscores a shift toward advanced materials that prioritize performance and safety.

Empowering Renewable Energy Systems

In solar and wind energy setups, this sheet insulates inverters and control panels, shielding against environmental stressors like humidity and UV exposure. Its lightweight yet robust nature facilitates efficient energy conversion, minimizing weight in turbine nacelles while ensuring electrical isolation. As global push for sustainable power intensifies, epoxy glass fiber sheet supports scalable installations, enhancing grid stability and reducing carbon footprints through reliable, long-lasting components.

Advancing Aerospace and Defense Technologies

Aerospace demands materials that endure extreme conditions, and epoxy glass fiber sheet delivers by insulating radar systems and avionics. Its high strength-to-weight ratio aids in constructing lightweight yet durable enclosures, crucial for fuel efficiency in aircraft. In defense, it protects sensitive electronics from electromagnetic interference, maintaining operational integrity during missions. Innovations in flame-retardant variants further align with stringent safety protocols, fostering advancements in unmanned aerial vehicles and satellite hardware.

Enhancing Consumer Electronics and Automotive Sectors

Everyday gadgets benefit immensely, with this sheet forming the backbone of printed circuit boards in smartphones and laptops. It provides stable substrates that resist thermal expansion, ensuring consistent performance. In automobiles, particularly electric vehicles, it insulates battery management systems, preventing thermal runaway and boosting range. As electrification accelerates, epoxy glass fiber sheet enables compact, efficient designs that integrate seamlessly into modern vehicles, promoting safer and more reliable transportation.

Why Choose J&Q for Your Epoxy Glass Fiber Sheet Needs?

With over two decades honing expertise in insulating sheets and a decade navigating international trade, J&Q stands as a trusted partner for global manufacturers. Our collaborations with myriad domestic and overseas entities refine our service ethos, delivering precision and reliability.

Proven Expertise and Manufacturing Excellence

Our legacy in producing epoxy glass fiber sheet reflects meticulous craftsmanship, employing state-of-the-art lamination techniques to achieve uniform thickness and optimal resin saturation. This expertise translates to products that meet international standards like UL and RoHS, ensuring compliance across markets. Clients appreciate our ability to customize formulations, adjusting fiber orientations for specific tensile requirements or incorporating additives for enhanced UV stability.

Comprehensive Global Supply Chain

Leveraging extensive trade networks, we source premium raw materials worldwide, guaranteeing consistency in every batch. This global reach facilitates swift deliveries, even for bespoke orders, minimizing lead times for urgent projects. Our partnerships foster innovation, allowing us to integrate feedback from diverse industries into product development, such as eco-friendly resins that align with sustainability goals.

Unmatched Customer Support and Services

Beyond supply, we offer technical consultations to optimize material selection, drawing on our vast experience to troubleshoot application challenges. Our team provides detailed datasheets and testing protocols, empowering clients with knowledge for informed decisions. Commitment to after-sales support ensures ongoing assistance, from installation guidance to performance evaluations, building enduring relationships that drive mutual success.

Conclusion

Epoxy glass fiber sheet represents a pivotal advancement in electrical insulation, merging dielectric excellence with mechanical prowess to meet evolving industrial demands. Its applications span renewable energy, aerospace, and consumer electronics, underscoring its role in fostering innovation and safety. As technologies advance, this material's adaptability positions it as an indispensable ally for future-proof designs. J&Q's dedication, backed by decades of experience, ensures access to top-tier products that elevate projects worldwide. Embracing this composite not only enhances efficiency but also contributes to sustainable progress in electrical engineering.

Contact Us

For deeper insights or to explore how epoxy glass fiber sheet can transform your operations, reach out to us at info@jhd-material.com. We're here to provide tailored solutions and expert guidance.

References

1. "Composite Materials Handbook" by Mel M. Schwartz.

2. "Electrical Insulation for Rotating Machines" by Greg C. Stone et al.

3. "Handbook of Polymer Composites for Engineers" edited by Leonard Hollaway.

4. "Advanced Composites Manufacturing" by Timothy G. Gutowski.

5. "Dielectric Materials for Electrical Engineering" by Juan Martinez-Vega.

6. "Fiberglass and Glass Technology" edited by Frederick T. Wallenberger and Paul A. Bingham.

_1732777843529.webp)

_1740986340093.webp)