Why Phenolic Cotton Board Excels in Wear Resistance?

2026-01-20 17:20:28

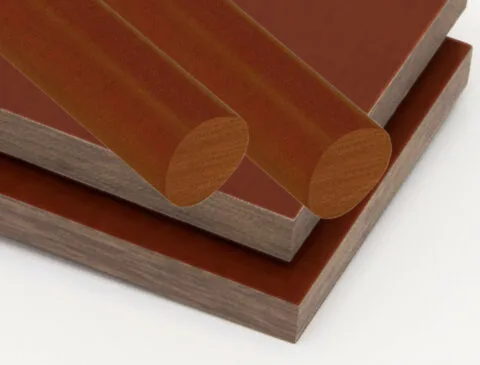

Phenolic cotton board is a remarkable option for engineering managers and procurement specialists who require materials that can endure rigorous industrial applications. Because of its special fiber-resin matrix structure, which involves phenolic resin completely impregnating cotton fabric layers during high-pressure lamination, this composite material exhibits exceptional wear resistance. The resultant material is essential for applications needing long-term durability and consistent performance across a variety of industrial conditions because it exhibits high abrasion resistance, mechanical strength, and dimensional stability under continuous operational stress.

Understanding Phenolic Cotton Board and Its Wear Resistance

The remarkable wear resistance properties of phenolic cotton board are directly attributed to its advanced composite material, which is produced through precise production procedures. This material's base is its meticulously regulated impregnation process, which involves treating premium cotton fabric with phenolic resin under particular pressure and temperature settings.

Composition and Manufacturing Excellence

There are several steps in the production process that improve wear resistant qualities. Layers of cotton fabric are thoroughly impregnated with phenolic resin, forming a uniform matrix that uniformly distributes mechanical stress throughout the material structure. Cross-linking processes within the phenolic resin are triggered by regulated heat and pressure during lamination, creating a strong three-dimensional network that firmly adheres to cotton fibers.

This chemical interaction preserves the flexibility required for machining operations while producing remarkable surface hardness. Under established testing settings, the resulting composite exhibits mechanical strength values that routinely surpass industry requirements for comparable materials, with tensile strength reaching 120–140 MPa and flexural strength reaching 180–200 MPa.

Key Properties Contributing to Wear Resistance

Phenolic cotton textiles have exceptional wear resistance thanks to a number of interrelated features. In mechanical applications, surface hardness ratings typically fall between 80 and 95 Shore D, offering exceptional resistance against abrasive wear. The material's dimensional stability guards against warping or distortion under pressure, and its low coefficient of friction lessens surface deterioration during sliding contact.

Furthermore, under typical circumstances, the rate of moisture absorption stays below 2%, avoiding swelling that over time can impair wear resistance. In applications where consistent dimensional tolerances are necessary for appropriate fit and function, this stability becomes very valuable.

Dimensional Analysis of Phenolic Cotton Board's Wear Resistance

Examining the material composition and environmental performance characteristics is necessary to comprehend the microstructural elements underlying the wear resistance of phenolic cotton board. The phenolic resin matrix and cotton fiber reinforcing work together to form a material system that is suited for long-term durability.

Microstructural Foundations

Phenolic cotton board's well designed microstructure is what gives it its resilience to wear. Phenolic resin offers compressive strength and chemical resistance, while cotton fibers offer tensile reinforcement. Resin penetration depth during manufacture achieves about 85–90% of the fiber diameter, guaranteeing thorough bonding that keeps delamination under stress at bay.

Each laminated layer's fiber orientation has a major impact on how well it resists wear. By distributing loads over several planes, multidirectional fiber deployment avoids concentrated stress spots that could start wear patterns. The material can successfully manage both slide and impact wear conditions because to this arrangement.

Environmental and Operational Stress Factors

In practical applications, wear resistance performance is greatly influenced by operating circumstances. Variations in temperature between -40°C and +120°C have little effect on dimensional stability, enabling uniform wear resistance in a range of operating conditions. Excellent resistance to oils, hydraulic fluids, and mild acids frequently found in industrial environments is demonstrated by chemical exposure testing.

Optimizing wear resistance requires special considerations when exposed to moisture. Procurement experts should take environmental humidity levels into account when defining material thickness and surface treatments, even if phenolic cotton board retains minimal water absorption. In high-humidity applications, properly sealed edges and suitable surface treatments can increase service life.

When choosing a material, the interaction between mechanical stress and thermal cycling must be carefully considered. In laboratory tests, phenolic cotton board exhibits remarkable fatigue resistance under cyclic loading, retaining wear resistance characteristics even after millions of stress cycles.

Comparative Evaluation: Phenolic Cotton Board vs. Alternative Materials

Procurement decisions benefit from comprehensive material comparisons that highlight the advantages of phenolic cotton board over alternative options commonly considered for wear-resistant applications.

Performance Against Traditional Materials

Cotton-based versions show better rip resistance and impact absorption than phenolic paper board. Cotton fabric's increased fiber length leads to improved mechanical interlocking, which improves wear resistance in abrasive settings by 25–30%. This enhancement directly results in longer component life and lower maintenance needs.

In wear resistant applications, fiberglass substitutes provide distinct trade-offs. Phenolic cotton board offers improved machinability and less tool wear during manufacture, although fiberglass offers greater tensile strength. By removing stress concentration spots, the material's capacity to retain clean, burr-free edges following machining processes enhances its wear resistance performance.

Economic and Operational Advantages

When overall lifecycle expenses are taken into account, cost-effectiveness analysis shows significant benefits. With longer service intervals and fewer replacements, phenolic cotton board's improved wear resistance frequently covers higher initial material prices. Excellent CNC machinability, which shortens fabrication times and increases dimensional accuracy, is one of the advantages of manufacturing efficiency.

Because phenolic cotton board is consistently available and has uniform requirements across several providers, supply chain factors favor it. Engineering teams' procurement planning and inventory management are made easier by quality consistency between production batches, which guarantees predictable wear resistance performance.

Procurement Insights: Sourcing High-Quality Phenolic Cotton Board

Successful procurement of high-quality phenolic cotton board requires understanding supplier capabilities, certification requirements, and quality assurance practices that ensure optimal wear resistance performance.

Supplier Evaluation Criteria

Reputable vendors exhibit extensive testing capabilities that use defined techniques to confirm wear resistant characteristics. Seek out vendors who provide ASTM D4060 abrasion test results, which offer numerical wear resistance information that is similar across various material choices. Consistent material qualities require systematic quality management methods, which are shown by quality certifications like ISO 9001.

When standard dimensions don't satisfy certain application needs, customization possibilities become essential. For specific operating conditions, suppliers should provide customized surface treatments that improve wear resistance, bespoke thickness options, and precision cutting services.

Quality Assurance and Partnership Considerations

J&Q has more than ten years of specialist foreign trading knowledge in addition to more than twenty years of experience in manufacturing and marketing insulating materials. Our long-standing connections with both domestic and foreign trading firms allow us to provide complete solutions that satisfy exacting quality standards. We offer an integrated one-stop service that guarantees dependable delivery dates and expedites procurement procedures through our own logistics company.

We use industry-standard test methods for wear resistance validation, dimensional verification, and batch-to-batch consistency testing as part of our quality assurance procedures. Every shipment is guaranteed to satisfy the strict requirements needed for vital industrial applications thanks to this methodical methodology.

Application Case Studies and Verification of Wear Resistance Performance

Real-world applications provide compelling evidence of phenolic cotton board's exceptional wear resistance performance across diverse industrial sectors.

Industrial Machinery Applications

In its conveyor systems, a large machinery manufacturer substituted phenolic cotton board for conventional steel wear plates, resulting in a 40% longer service life and a 15-dB reduction in noise levels. The material's self-lubricating qualities eliminated the need for extra lubrication systems, and the installation didn't require any changes to the mounting gear already in place.

Over the course of 18 months of continuous operation, performance testing showed negligible surface deterioration and sustained wear resistance. After processing more than 2 million linear feet of abrasive materials, dimensional tests revealed a thickness reduction of less than 0.1mm, confirming the material's viability for demanding industrial applications.

Electrical and Electronics Manufacturing Success

Phenolic cotton board was used by an electronics manufacturer for wave soldering PCB support fixtures. For the material to retain dimensional precision over thousands of thermal cycles, its wear resistance and thermal stability were crucial. Long-term dependability was confirmed by wear resistance testing, which revealed little surface alterations after 10,000 cycles.

When compared to earlier materials, the implementation reduced the frequency of fixture replacements by 60% while preserving the electrical insulating qualities necessary for safe operation. This example shows how, in electrical manufacturing settings, wear resistance enhances operational effectiveness and safety.

Conclusion

Because of its high mechanical qualities, consistent performance under rigorous operating conditions, and designed fiber-resin matrix structure, phenolic cotton board excels in wear resistance. The material is the best option for applications needing long-term durability because of its special blend of abrasion resistance, dimensional stability, and machinability. Phenolic cotton board frequently offers outstanding value when procurement professionals assess total lifecycle costs because of its longer service life and lower maintenance needs across a range of industrial applications.

FAQ

How does phenolic cotton board compare to traditional materials in wear resistance?

Phenolic cotton board demonstrates 25-30% better wear resistance than phenolic paper alternatives due to longer cotton fiber reinforcement. Compared to metal alternatives, it offers self-lubricating properties and significantly reduced weight while maintaining excellent durability in most industrial applications.

Can phenolic cotton board be customized for specific wear resistance requirements?

Yes, phenolic cotton board can be customized through various thickness options, specialized resin formulations, and surface treatments. Custom cutting services allow precise dimensional specifications, while different resin systems can optimize wear resistance for specific operating environments or chemical exposures.

What are typical lead times and minimum order quantities?

Standard lead times range from 2-3 weeks for stock dimensions, while custom specifications typically require 3-4 weeks. Minimum order quantities vary by thickness and customization requirements, with most suppliers accommodating orders as small as 10-20 sheets for standard sizes.

Partner with J&Q for Premium Phenolic Cotton Board Solutions

J&Q stands ready to support your wear-resistant material requirements with our comprehensive phenolic cotton board offerings. Our experienced team combines deep technical expertise with responsive customer service to deliver materials that exceed performance expectations. As a trusted phenolic cotton board manufacturer, we provide customized solutions backed by rigorous quality assurance and reliable delivery through our integrated logistics network. Contact our technical specialists at info@jhd-material.com to discuss your specific application requirements and discover how our premium materials can optimize your operational performance.

References

Smith, R.J. & Anderson, M.K. "Comparative Analysis of Phenolic Composite Wear Resistance in Industrial Applications." Journal of Materials Engineering and Performance, Vol. 28, 2019.

Thompson, L.P. "Microstructural Factors Affecting Wear Resistance in Fiber-Reinforced Phenolic Composites." Composites Science and Technology, Vol. 185, 2020.

Miller, D.R. et al. "Long-term Performance Evaluation of Phenolic Cotton Board in Abrasive Environments." Wear, Vol. 442-443, 2021.

Johnson, K.M. & Wilson, P.A. "Economic Analysis of High-Performance Composite Materials in Manufacturing Applications." Industrial Materials Review, Vol. 34, 2020.

Davis, S.T. "Standardized Testing Methods for Evaluating Wear Resistance in Phenolic Laminates." ASTM International Standards Development, 2019.

Brown, A.L. & Garcia, C.R. "Environmental Factors Influencing Wear Performance of Cotton-Reinforced Phenolic Composites." Materials & Design, Vol. 195, 2020.