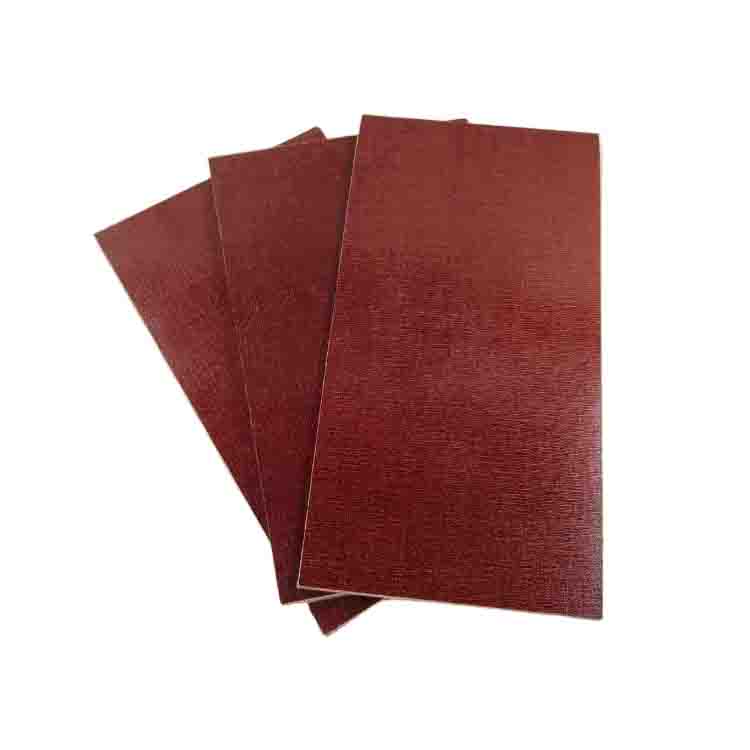

Fabric Based Phenolic Laminates

Basic Information:

Brand: JingHong

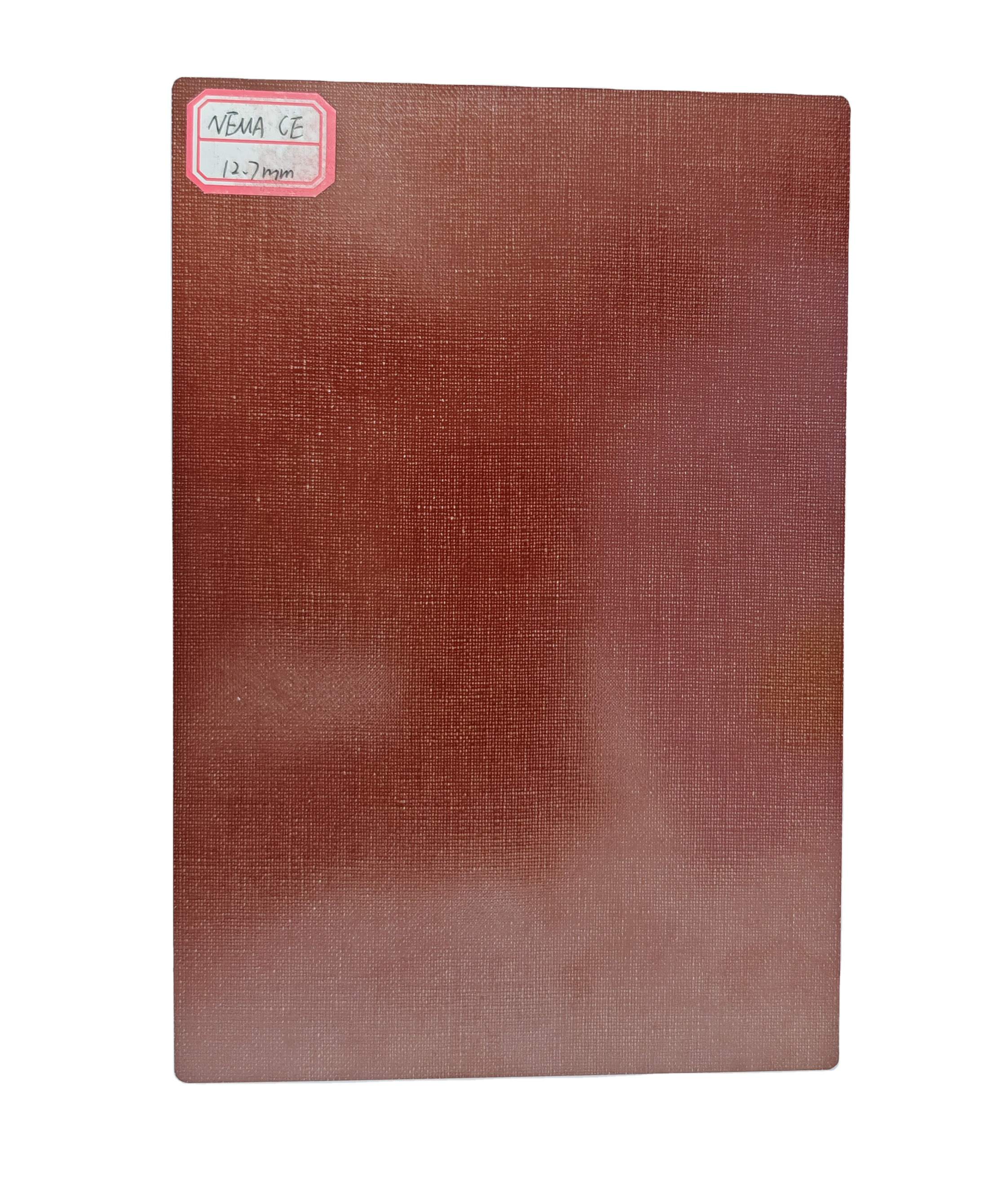

Grade: 3025,3026,CE

Color: Brown,Black

Thickness: 2mm --- 100mm

Material: Cotton Fabric + Phenolic Resin

Regular Size:1020mm*2020mm,1220mm*2440mm

Packaging: Regular packing, Protect by Pallet

Productivity: 30000 Tons per year

Transportation: Ocean, Land, Air

Payment:T/T

MOQ:500KG

- Fast Delievery

- Quality Assurance

- 24/7 Customer Service

Product Introduction

Fabric Based Phenolic Laminates - Premium Industrial Insulation Solutions

When you require solid electrical separator materials for requesting mechanical applications, Fabric Based Phenolic Laminates from J&Q New Composite Materials Company Fabric Bunch convey remarkable execution. Our JingHong brand covers combine cotton texture fortification with phenolic gum to make strong materials that withstand extraordinary conditions. These flexible composite materials offer prevalent mechanical quality, fabulous electrical properties, and exceptional chemical resistance for your most challenging projects.

Product Descriptions from the Supplier

JingHong Brand Specifications:

| Attribute | Details |

|---|---|

| Grades Available | 3025, 3026 |

| Color Options | Brown, Black |

| Thickness Range | 2mm - 100mm |

| Core Materials | Premium Cotton Fabric + High-Grade Phenolic Resin |

| Standard Dimensions | 1020mm × 2020mm, 1220mm × 2440mm |

| Annual Production | 30,000 tons capacity |

| Minimum Order | 500KG |

Product Availability

Our phenolic cotton cloth sheets are promptly accessible for quick shipping. We keep up considerable stock levels to meet your critical venture prerequisites. You can select from numerous transportation choices counting sea cargo, arrive transport, and discuss shipping based on your conveyance timeline needs.

Ordering Details:

- Payment Terms: T/T (Transmitted Transfer)

- Packaging: Proficient bed assurance for secure delivery

- Custom sizes accessible upon request

- Flexible conveyance scheduling

Key Features

Superior Electrical Performance

- Dielectric quality ≥15kV/mm guarantees dependable electrical insulation

- Stable operation in transformer oil environments

- Excellent bend resistance properties

Outstanding Mechanical Properties

- High malleable and flexural quality from cotton texture reinforcement

- Superior affect resistance for requesting applications

- Excellent dimensional solidness over temperature ranges

Chemical & Environmental Resistance

- Outstanding oil resistance for petroleum-based applications

- Heat diversion temperature ≥145℃ for high-temperature performance

- Moisture resistance in muggy working conditions

Standards

Our fabricating forms comply with worldwide quality benchmarks guaranteeing reliable item execution. Each bunch experiences thorough testing for electrical, mechanical, and warm properties. Quality control measures incorporate dielectric quality testing, warm avoidance investigation, and dimensional precision verification.

Table 1:Performance index of phenolic cotton cloth laminate

|

Serial No. |

Project name |

Unit |

Test method |

Targets |

||

| 3025 | 3026 | |||||

|

1 |

Density |

g/cm |

GB/T5130 |

1.30~1.40 |

- |

|

|

2 |

Absorbent |

mg |

GB/T5130 |

Refer to table 2 | Refer to table 3 | |

|

3 |

Vertical Layer Bending Strength Longitudinal |

Mpa |

GB/T5130 (Q/JBQP51-2001) |

≥100 |

≥140 |

|

|

4 |

Tensile Strengths |

Mpa |

GB/T5130中 |

≥(80) |

≥98 |

|

|

5 |

bonding strength |

N |

JB886-75 |

≥(5390) |

||

|

6 |

Compression strength Vertical Layer Parallel Layer |

MPa |

GB/T5130 |

- - |

≥245 ≥147 |

|

|

7 |

Notched impact strength (simply supported beams) Parallel Layer |

kJ/m |

GB/T5130 |

≥8.8 |

≥6.8 |

|

|

8 |

Parallel layerwise insulation resistance After immersion in water |

Ω |

GB/T5130 |

≥1.0×10 |

- |

|

|

9 |

Parallel layer breakdown voltage In transformer oil at (90+2)°C |

kV |

GB/T5130 |

≥10 |

- |

|

|

10 |

Vertical laminar electrical strength In transformer oil at (90+2)°C |

kV/mm |

GB/T5130 |

Refer to Table4 |

- |

|

Table 2:Water absorption of phenolic cotton cloth laminate

|

Average thickness(mm) |

absorbency(mg) |

Average thickness(mm) | absorbency(mg) | Average thickness(mm) | absorbency(mg) |

|

0.8 |

≤201 |

3.0 |

≤249 |

12.0 |

≤336 |

|

1.0 |

≤206 |

4.0 |

≤262 |

14.0 |

≤354 |

|

1.2 |

≤211 |

5.0 |

≤275 |

16.0 |

≤371 |

|

1.6 |

≤220 |

6.0 |

≤284 |

20.0 |

≤406 |

|

2.0 |

≤229 |

8.0 |

≤301 |

25.0 |

≤450 |

|

2.5 |

≤239 |

10.0 |

≤319 |

One-sided processing to 22.5 |

≤540 |

Table 3:Water absorption of phenolic cotton cloth laminate

| Average thickness(mm) |

absorbency(mg) |

Average thickness(mm) |

absorbency(mg) |

Average thickness(mm) |

absorbency(mg) |

|

0.4 |

≤186 |

2.0 |

≤229 |

10 |

≤319 |

|

0.5 |

≤190 |

2.5 |

≤239 |

12 |

≤336 |

|

0.6 |

≤194 |

3.0 |

≤249 |

14 |

≤354 |

|

0.8 |

≤201 |

4.0 |

≤262 |

16 |

≤371 |

|

1.0 |

≤206 |

5.0 |

≤275 |

20 |

≤406 |

|

1.2 |

≤211 |

6.0 |

≤284 |

25 |

≤450 |

|

1.6 |

≤220 |

8.0 |

≤301 |

One-sided processing to 22.5 |

≤540 |

Table 4:Electrical strength of phenolic cotton fabric laminates

| Average thickness(mm) |

Electrical Strength(kV/mm) |

Average thickness(mm) | Electrical Strength(kV/mm) | Average thickness(mm) | Electrical Strength(kV/mm) |

|

0.8 |

≥0.89 |

1.6 |

≥0.72 |

2.6 |

≥0.56 |

|

0.9 |

≥0.84 |

1.8 |

≥0.69 |

2.8 |

≥0.53 |

|

1.0 |

≥0.82 |

2.0 |

≥0.65 |

3.0 |

≥0.50 |

|

1.2 |

≥0.80 |

2.2 |

≥0.61 |

||

|

1.4 |

≥0.76 |

2.4 |

≥0.58 |

Technical Features: Product Safety Control

Quality Assurance Process:

- Raw fabric assessment and certification

- In-process observing amid lamination

- Final item electrical testing at ≥15kV/mm

- Heat diversion temperature confirmation at ≥145℃

- Surface quality assessment for defects

Safety Specifications:

- Non-toxic phenolic gum formulation

- Low smoke era amid warm exposure

- Stable execution in oil-immersed applications

- Consistent electrical properties over thickness variations

Product Applications

Electrical Industry Applications

- Transformer cover sheets for control dissemination systems

- Switchgear components requiring tall dielectric strength

- Electrical board backing materials

Mechanical Engineering Solutions

- Machine instrument vibration damping shims for exactness equipment

- Bearing underpins in high-vibration environments

- Structural components requiring oil resistance

Specialized Industrial Uses

- Oil-immersed transformer cover components

- Chemical handling gear parts

- Automotive electrical cover applications

These Fabric Based Phenolic Laminates exceed expectations in situations where conventional materials fall flat, giving solid execution over assorted mechanical sectors.

OEM Service

We offer comprehensive OEM fabricating administrations custom fitted to your particular necessities. Our designing group works closely with you to create custom definitions, measurements, and execution characteristics. Whether you require special thickness details, extraordinary surface medicines, or altered electrical properties, we can oblige your extend needs.

Custom Services Include:

- Modified gum formulations

- Special dimensional requirements

- Custom color matching

- Performance optimization for particular applications

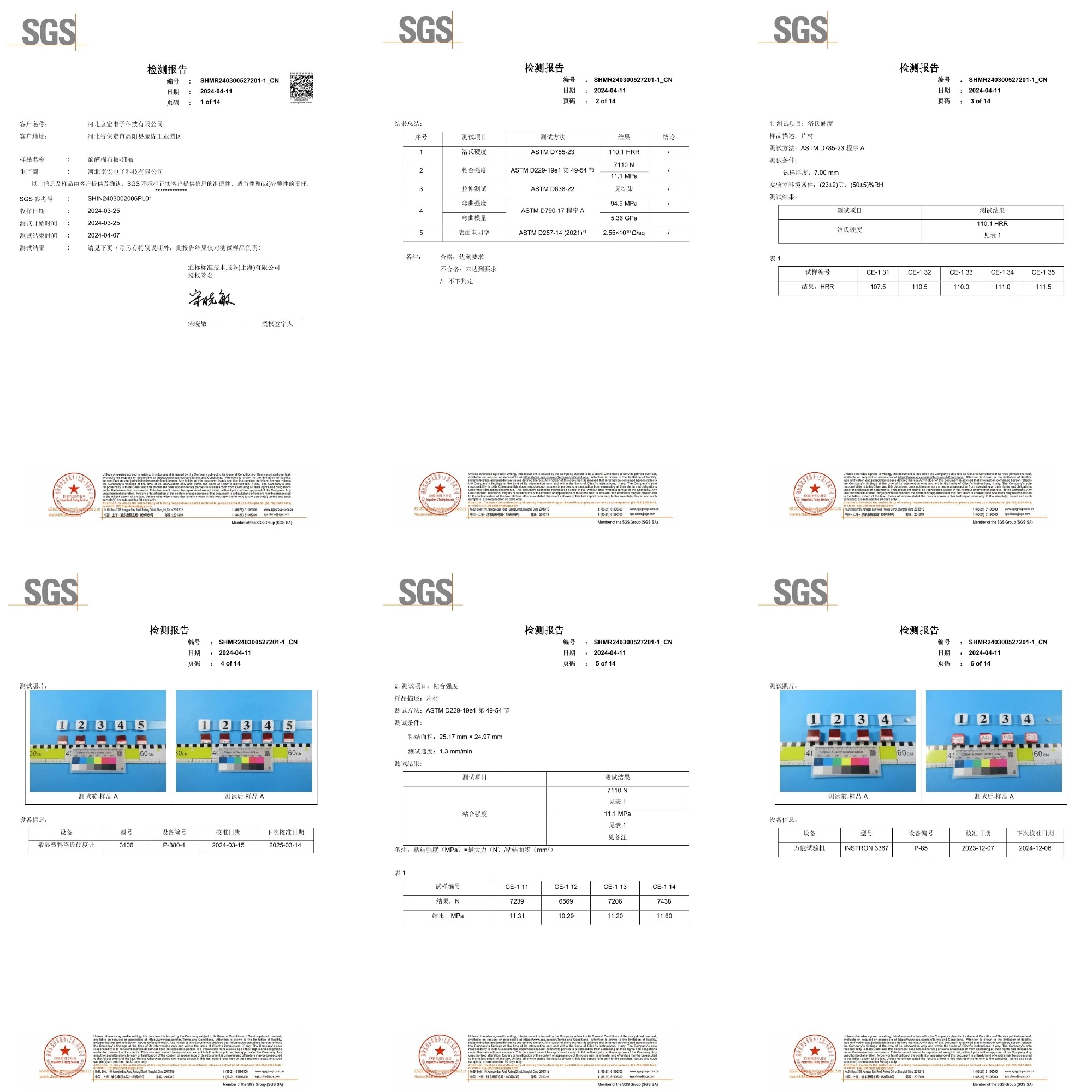

Certification

FAQ

Q: What thickness options are available for phenolic cotton cloth boards?

A: We offer thicknesses from 2mm to 100mm to accommodate various application requirements.

Q: Can these laminates operate in transformer oil environments?

A: Yes, our product are specifically designed for stable operation in transformer oil with excellent chemical compatibility.

Q: What is the commonplace lead time for standard sizes?

A: Standard measurements are ordinarily accessible for quick shipment from our inventory.

Q: Do you offer specialized bolster for fabric selection?

A: Our specialized group gives comprehensive application back to offer assistance you select the ideal review and specifications.

Q: What quality documentation do you provide?

A: Each shipment includes detailed test certificates verifying electrical, mechanical, and thermal properties.

Contact Us

Ready to discuss your Fabric Based Phenolic Laminates requirements? Our specialized pros are here to offer assistance you select the culminate arrangement for your application needs. Contact us nowadays for point by point determinations, custom cites, or specialized consultation.

Email: info@jhd-material.com

Let us offer assistance you discover the perfect phenolic cover arrangement for your another venture. Our experienced group guarantees you get materials that meet your correct execution necessities whereas keeping up competitive estimating and solid conveyance plans.

Send Inquiry

You May Like

0