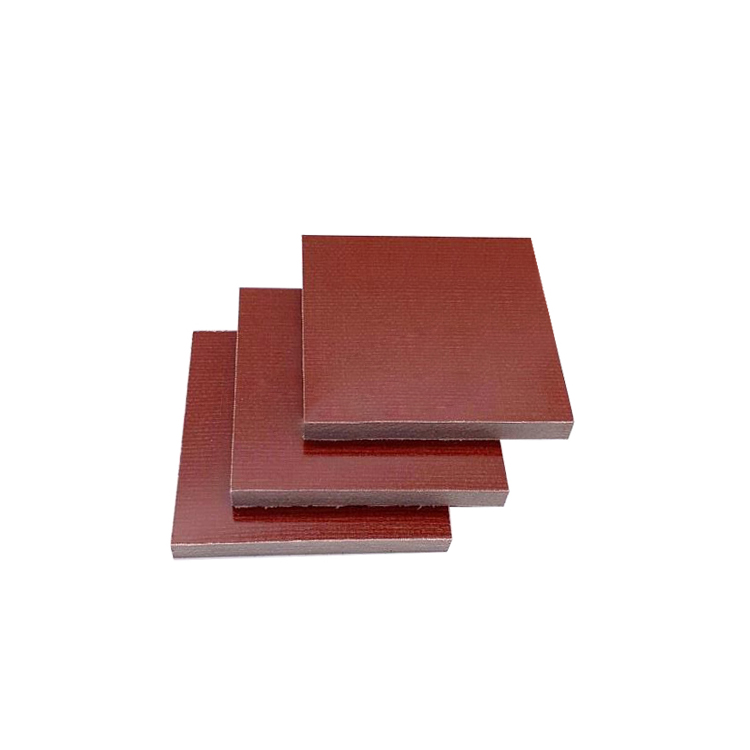

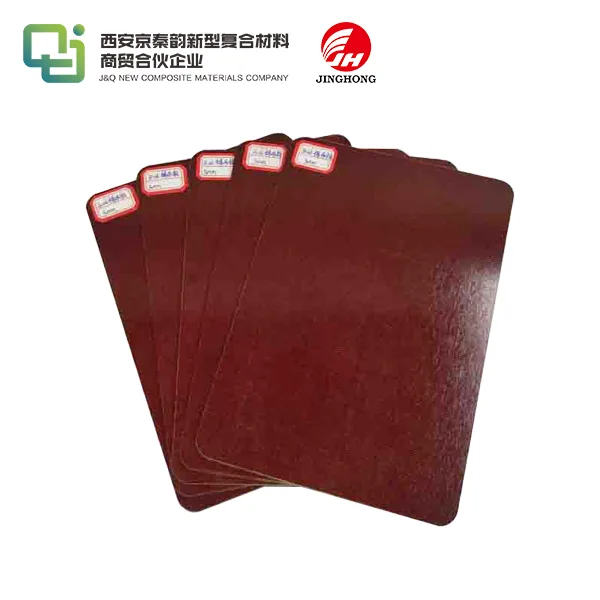

Phenolic Cotton Laminates

Basic Information:

Brand: JingHong

Grade: 3025,3026,CE

Color: Brown,Black

Thickness: 2mm --- 100mm

Material: Cotton Fabric + Phenolic Resin

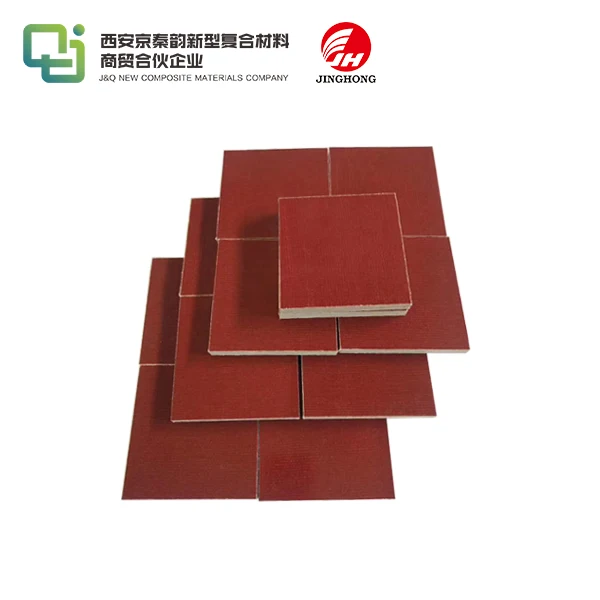

Regular Size:1020mm*2020mm,1220mm*2440mm

Packaging: Regular packing, Protect by Pallet

Productivity: 30000 Tons per year

Transportation: Ocean, Land, Air

Payment:T/T

MOQ:500KG

- Fast Delievery

- Quality Assurance

- 24/7 Customer Service

Product Introduction

Phenolic Cotton Laminates - Premium Industrial Insulation Solution

Phenolic Cotton Laminates offer extraordinary mechanical quality and warm steadiness for your mechanical applications. Made from high-quality cotton texture impregnated with phenolic gum, these covers provide exceptional execution in engines, electrical gear, and mechanical structures. Our JingHong brand materials meet strict industry guidelines whereas giving fabulous esteem for your fabricating needs. With thickness alternatives from 2mm to 100mm, you can discover the culminate arrangement for your particular requirements.

Product Description

Our premium cotton texture phenolic covers combine toughness with flexibility. These composite materials highlight cotton texture support reinforced with phenolic tar through progressed fabricating forms. Accessible in brown and dark colors, they offer fabulous dimensional soundness and steady quality over all thickness ranges.

Product Availability

| Attribute | Details |

|---|---|

| Available Grades | 3025, 3026 |

| Color Options | Brown, Black |

| Thickness Range | 2mm - 100mm |

| Standard Sizes | 1020mm × 2020mm, 1220mm × 2440mm |

| Minimum Order | 500KG |

| Annual Capacity | 30,000 tons |

| Payment Terms | T/T accepted |

Key Features

- Superior Mechanical Quality - Amazing load-bearing capacity for basic applications

- Outstanding Electrical Separator - Solid dielectric properties for electrical components

- Thermal Solidness - Keeps up execution over wide temperature ranges

- Chemical Resistance - Withstands introduction to oils, solvents, and mechanical chemicals

- Dimensional Accuracy - Reliable thickness and levelness for accuracy manufacturing

- Easy Machining - Cuts, drills, and shapes cleanly without delamination

Standards Compliance

Our cotton phenolic covers accommodate to worldwide quality guidelines guaranteeing reliable execution and unwavering quality. Each bunch experiences thorough testing to confirm mechanical properties, electrical characteristics, and dimensional accuracy.

Table 1:Performance index of phenolic cotton cloth laminate

|

Serial No. |

Project name |

Unit |

Test method |

Targets |

||

| 3025 | 3026 | |||||

|

1 |

Density |

g/cm |

GB/T5130 |

1.30~1.40 |

- |

|

|

2 |

Absorbent |

mg |

GB/T5130 |

Refer to table 2 | Refer to table 3 | |

|

3 |

Vertical Layer Bending Strength Longitudinal |

Mpa |

GB/T5130 (Q/JBQP51-2001) |

≥100 |

≥140 |

|

|

4 |

Tensile Strengths |

Mpa |

GB/T5130中 |

≥(80) |

≥98 |

|

|

5 |

bonding strength |

N |

JB886-75 |

≥(5390) |

||

|

6 |

Compression strength Vertical Layer Parallel Layer |

MPa |

GB/T5130 |

- - |

≥245 ≥147 |

|

|

7 |

Notched impact strength (simply supported beams) Parallel Layer |

kJ/m |

GB/T5130 |

≥8.8 |

≥6.8 |

|

|

8 |

Parallel layerwise insulation resistance After immersion in water |

Ω |

GB/T5130 |

≥1.0×10 |

- |

|

|

9 |

Parallel layer breakdown voltage In transformer oil at (90+2)°C |

kV |

GB/T5130 |

≥10 |

- |

|

|

10 |

Vertical laminar electrical strength In transformer oil at (90+2)°C |

kV/mm |

GB/T5130 |

Refer to Table4 |

- |

|

Table 2:Water absorption of phenolic cotton cloth laminate

|

Average thickness(mm) |

absorbency(mg) |

Average thickness(mm) | absorbency(mg) | Average thickness(mm) | absorbency(mg) |

|

0.8 |

≤201 |

3.0 |

≤249 |

12.0 |

≤336 |

|

1.0 |

≤206 |

4.0 |

≤262 |

14.0 |

≤354 |

|

1.2 |

≤211 |

5.0 |

≤275 |

16.0 |

≤371 |

|

1.6 |

≤220 |

6.0 |

≤284 |

20.0 |

≤406 |

|

2.0 |

≤229 |

8.0 |

≤301 |

25.0 |

≤450 |

|

2.5 |

≤239 |

10.0 |

≤319 |

One-sided processing to 22.5 |

≤540 |

Table 3:Water absorption of phenolic cotton cloth laminate

| Average thickness(mm) |

absorbency(mg) |

Average thickness(mm) |

absorbency(mg) |

Average thickness(mm) |

absorbency(mg) |

|

0.4 |

≤186 |

2.0 |

≤229 |

10 |

≤319 |

|

0.5 |

≤190 |

2.5 |

≤239 |

12 |

≤336 |

|

0.6 |

≤194 |

3.0 |

≤249 |

14 |

≤354 |

|

0.8 |

≤201 |

4.0 |

≤262 |

16 |

≤371 |

|

1.0 |

≤206 |

5.0 |

≤275 |

20 |

≤406 |

|

1.2 |

≤211 |

6.0 |

≤284 |

25 |

≤450 |

|

1.6 |

≤220 |

8.0 |

≤301 |

One-sided processing to 22.5 |

≤540 |

Table 4:Electrical strength of phenolic cotton fabric laminates

| Average thickness(mm) |

Electrical Strength(kV/mm) |

Average thickness(mm) | Electrical Strength(kV/mm) | Average thickness(mm) | Electrical Strength(kV/mm) |

|

0.8 |

≥0.89 |

1.6 |

≥0.72 |

2.6 |

≥0.56 |

|

0.9 |

≥0.84 |

1.8 |

≥0.69 |

2.8 |

≥0.53 |

|

1.0 |

≥0.82 |

2.0 |

≥0.65 |

3.0 |

≥0.50 |

|

1.2 |

≥0.80 |

2.2 |

≥0.61 |

||

|

1.4 |

≥0.76 |

2.4 |

≥0.58 |

Technical Features: Product Safety Control

Quality Affirmation Process:

- Raw fabric review and certification

- In-process observing amid lamination

- Final item testing for all key properties

- Batch traceability documentation

- Controlled capacity and taking care of procedures

Safety Standards:

- Non-toxic detailing reasonable for mechanical use

- Low smoke emanation properties

- Stable execution beneath typical working conditions

Product Applications

Electrical Industry:

- Motor insulation components

- Distribution cabinet partitions

- Transformer parts

- Circuit breaker components

- Electrical panel assemblies

Mechanical Applications:

- Gear shaft bearings

- Structural support elements

- Machine tool components

- Industrial fixtures and jigs

Specialized Uses:

- Automotive electrical systems

- Marine equipment insulation

- Railway electrical components

The versatility of Phenolic Cotton Laminates makes them perfect for applications requiring both mechanical quality and electrical cover properties.

OEM Service

We give comprehensive OEM arrangements custom fitted to your specifications:

- Custom Measuring - Cut to your correct dimensions

- Special Grades - Definitions for particular applications

- Surface Medicines - Upgraded wraps up when required

- Technical Bolster - Building help for fabric selection

- Quality Documentation - Total certification packages

- Flexible Bundling - Alternatives to meet your taking care of requirements

Transportation & Packaging

Packaging: Standard defensive bundling with bed back guarantees secure delivery

Shipping Choices: Sea cargo, arrive transport, and discuss cargo available

Global Reach: Around the world conveyance capabilities

Frequently Asked Questions

Q: What's the contrast between grades 3025 and 3026?

A: Review 3025 offers standard execution for common applications, whereas 3026 gives upgraded properties for requesting mechanical uses.

Q: Can you provide custom thickness options?

A: Yes, we can manufacture materials within our 2mm-100mm range to meet your specific requirements.

Q: How do cotton phenolic laminates compare to fiber-reinforced alternatives?

A: Cotton-based materials offer excellent mechanical strength ideal for structural and electrical applications, while maintaining cost-effectiveness.

Q: What's your typical lead time for standard sizes?

A: Standard sizes are typically available from stock, with delivery times depending on quantity and destination.

Q: Do you provide technical data sheets?

A: Complete technical documentation including property data and application guidelines is available upon request.

Contact Us

Ready to enhance your manufacturing with high-quality Phenolic Cotton Laminates? Our technical team is here to help you select the right material for your application.

Email: info@jhd-material.com

Get in touch nowadays for nitty gritty details, estimating data, or specialized discussion. We're committed to giving arrangements that meet your correct prerequisites whereas conveying remarkable esteem and execution.

Send Inquiry