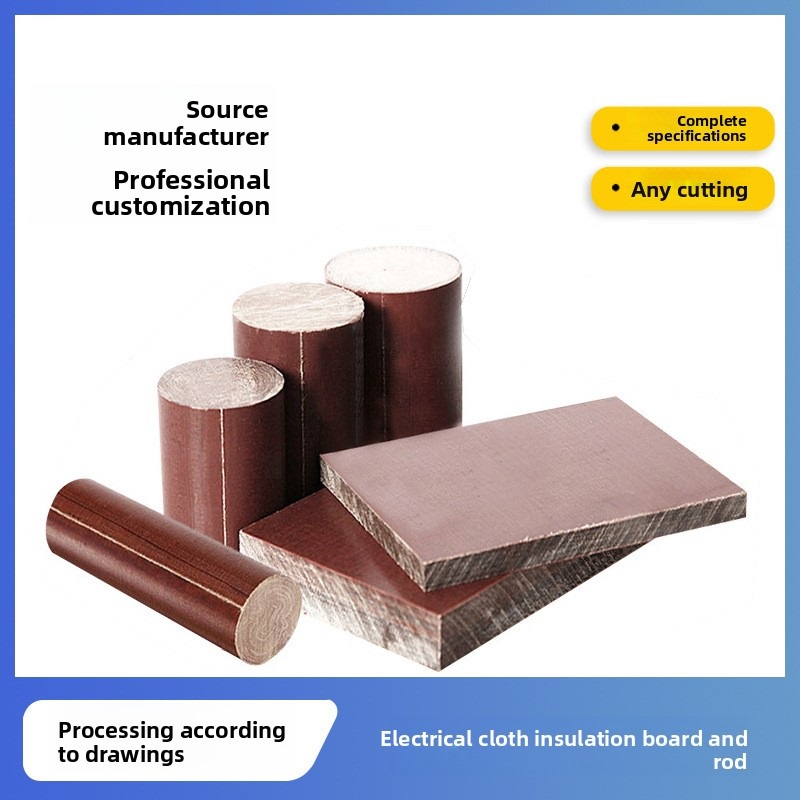

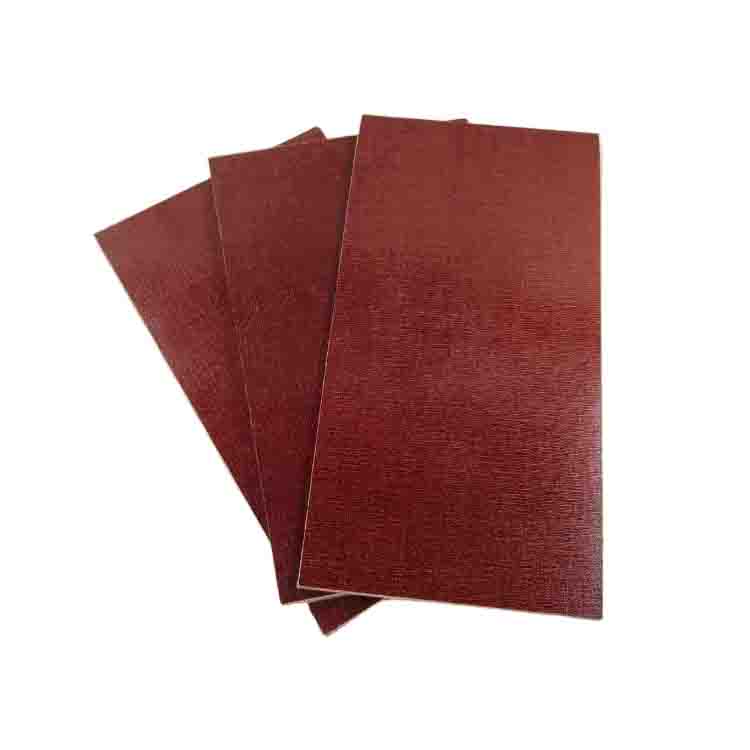

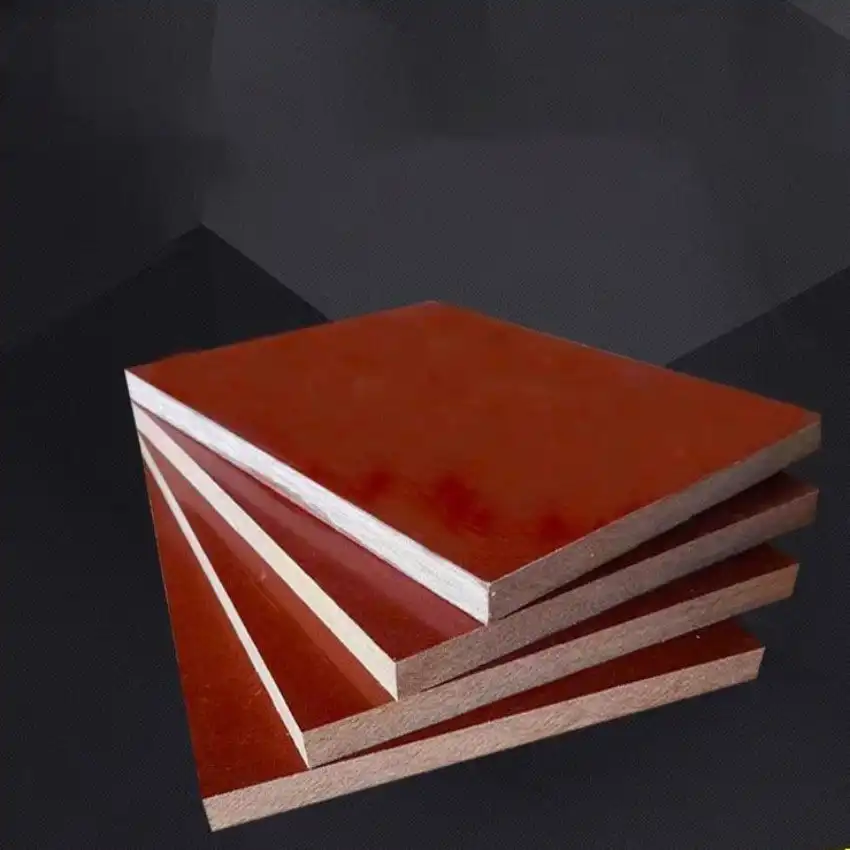

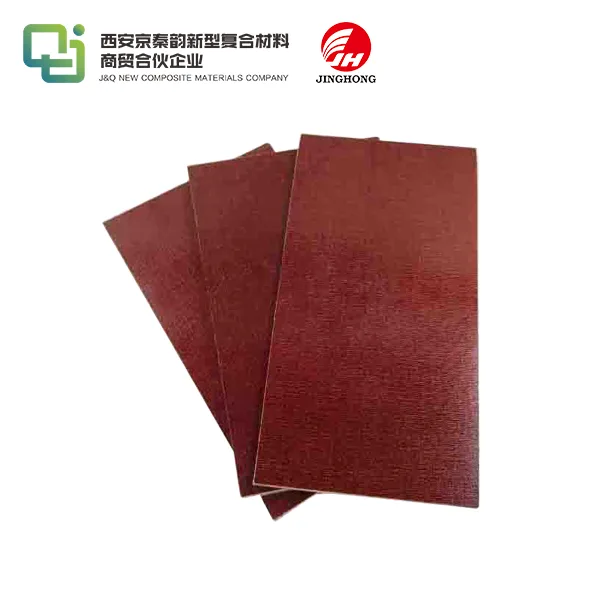

Fabric Reinforced Phenolic Sheet

Basic Information:

Brand: JingHong

Grade: 3025,3026

Color: Brown,Black

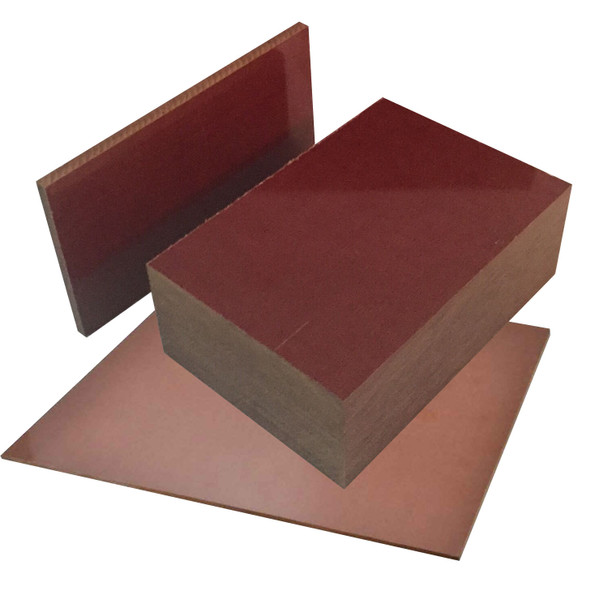

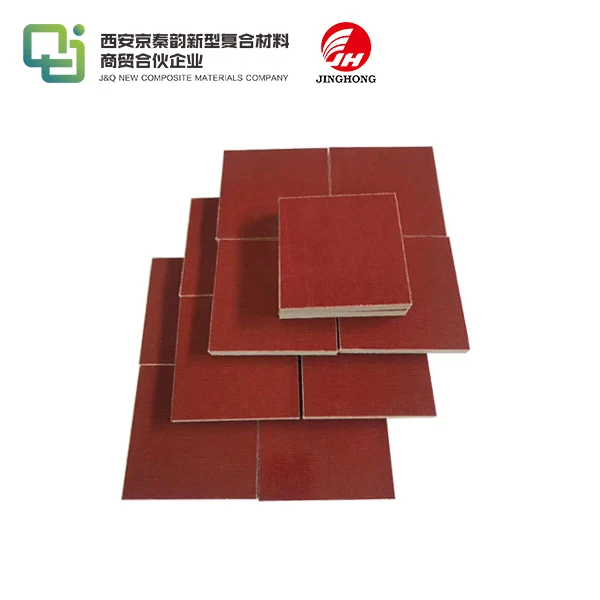

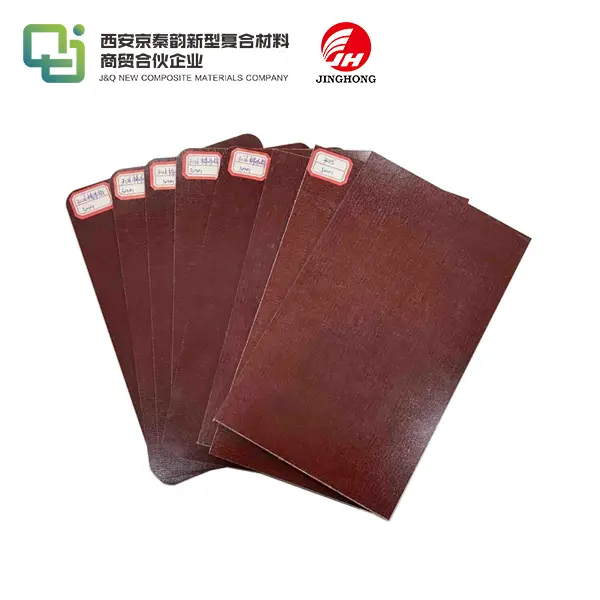

Thickness: 2mm --- 100mm

Material: Cotton Fabric + Phenolic Resin

Regular Size:1020mm*2020mm,1220mm*2440mm

Packaging: Regular packing, Protect by Pallet

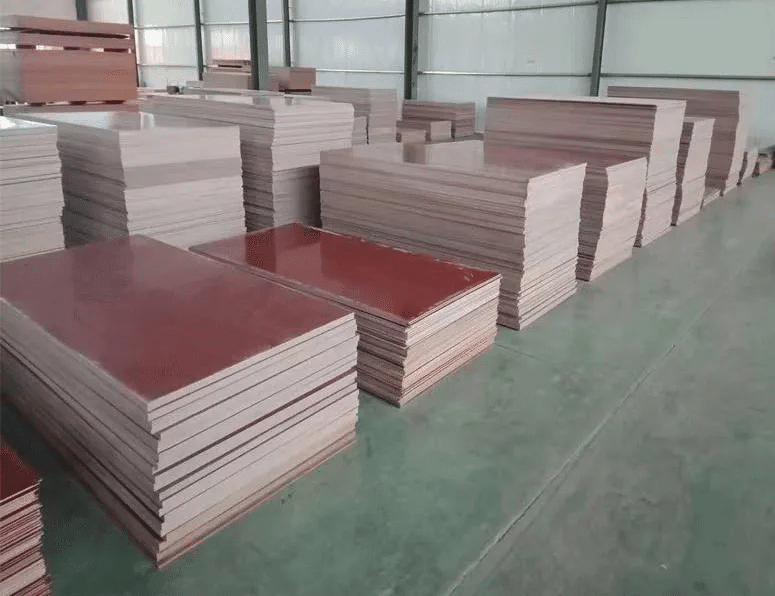

Productivity: 30000 Tons per year

Transportation: Ocean, Land, Air

Payment:T/T

MOQ:500KG

- Fast Delievery

- Quality Assurance

- 24/7 Customer Service

Product Introduction

Fabric Reinforced Phenolic Sheet - Premium Industrial Insulation Material

Our Fabric Reinforced Phenolic Sheet cotton texture fortification with high-quality phenolic gum to convey remarkable execution. This composite fabric offers exceptional electrical cover, mechanical quality, and warm soundness. Whether you require fabric for electrical hardware, car components, or specialized mechanical applications, our phenolic sheets give the toughness and unwavering quality you require for requesting environments.

Product Description from JingHong

JingHong specializes in fabricating premium composite materials with over decades of involvement. Our fabric-reinforced phenolic sheets are designed utilizing progressed cover forms that bond cotton texture layers with phenolic tar. This makes a vigorous fabric that keeps up its properties beneath stretch and temperature variations.

We offer steady quality over all our items, guaranteeing you get materials that meet your correct details each time.

Product Availability

| Attribute | Details |

|---|---|

| Brand | JingHong |

| Grades Available | 3025, 3026 |

| Color Options | Brown, Black |

| Thickness Range | 2mm to 100mm |

| Standard Sizes | 1020mm × 2020mm, 1220mm × 2440mm |

| Minimum Order | 500KG |

| Annual Capacity | 30,000 Tons |

| Custom Sizes and Thicknesses | Available upon request to meet your specific project requirements |

Key Features

- Superior Cover Properties: Great electrical resistance for secure operation

- High Mechanical Quality: Withstands stretch and affect without cracking

- Temperature Resistance: Keeps up steadiness at raised temperatures

- Chemical Resistance: Stands up to debasement from oils, solvents, and gentle acids

- Dimensional Solidness: Negligible shrinkage and extension beneath shifting conditions

- Easy Machining: Can be cut, bored, and molded utilizing standard tools

- Long Benefit Life: Tough development guarantees amplified operational lifespan

Standards

Our fabricating forms comply with worldwide quality standards:

- IEC 60893 (Worldwide Electrotechnical Commission)

- NEMA Measures for Mechanical Laminates

- ISO 9001 Quality Administration System

These measures guarantee reliable fabric properties and solid execution over all applications.

Technical Features: Product Safety Control

Physical Properties:

- Density: 1.30–1.45 g/cm³

- Flexural Quality: Tall resistance to twisting stress

- Impact Resistance: Amazing stun assimilation capabilities

Electrical Properties:

- High dielectric quality for electrical isolation

- Low dampness retention anticipating electrical failures

- Consistent separator resistance over time

Thermal Properties:

- Operating temperature extend reasonable for mechanical environments

- Low warm extension coefficient

- Excellent warm scattering characteristics

Our quality control forms incorporate thorough testing at each generation arrange to guarantee each Fabric Reinforced Phenolic Sheet meets specified parameters.

Table 1:Performance index of phenolic cotton cloth laminate

|

Serial No. |

Project name |

Unit |

Test method |

Targets |

||

| 3025 | 3026 | |||||

|

1 |

Density |

g/cm |

GB/T5130 |

1.30~1.40 |

- |

|

|

2 |

Absorbent |

mg |

GB/T5130 |

Refer to table 2 | Refer to table 3 | |

|

3 |

Vertical Layer Bending Strength Longitudinal |

Mpa |

GB/T5130 (Q/JBQP51-2001) |

≥100 |

≥140 |

|

|

4 |

Tensile Strengths |

Mpa |

GB/T5130中 |

≥(80) |

≥98 |

|

|

5 |

bonding strength |

N |

JB886-75 |

≥(5390) |

||

|

6 |

Compression strength Vertical Layer Parallel Layer |

MPa |

GB/T5130 |

- - |

≥245 ≥147 |

|

|

7 |

Notched impact strength (simply supported beams) Parallel Layer |

kJ/m |

GB/T5130 |

≥8.8 |

≥6.8 |

|

|

8 |

Parallel layerwise insulation resistance After immersion in water |

Ω |

GB/T5130 |

≥1.0×10 |

- |

|

|

9 |

Parallel layer breakdown voltage In transformer oil at (90+2)°C |

kV |

GB/T5130 |

≥10 |

- |

|

|

10 |

Vertical laminar electrical strength In transformer oil at (90+2)°C |

kV/mm |

GB/T5130 |

Refer to Table4 |

- |

|

Table 2:Water absorption of phenolic cotton cloth laminate

|

Average thickness(mm) |

absorbency(mg) |

Average thickness(mm) | absorbency(mg) | Average thickness(mm) | absorbency(mg) |

|

0.8 |

≤201 |

3.0 |

≤249 |

12.0 |

≤336 |

|

1.0 |

≤206 |

4.0 |

≤262 |

14.0 |

≤354 |

|

1.2 |

≤211 |

5.0 |

≤275 |

16.0 |

≤371 |

|

1.6 |

≤220 |

6.0 |

≤284 |

20.0 |

≤406 |

|

2.0 |

≤229 |

8.0 |

≤301 |

25.0 |

≤450 |

|

2.5 |

≤239 |

10.0 |

≤319 |

One-sided processing to 22.5 |

≤540 |

Table 3:Water absorption of phenolic cotton cloth laminate

| Average thickness(mm) |

absorbency(mg) |

Average thickness(mm) |

absorbency(mg) |

Average thickness(mm) |

absorbency(mg) |

|

0.4 |

≤186 |

2.0 |

≤229 |

10 |

≤319 |

|

0.5 |

≤190 |

2.5 |

≤239 |

12 |

≤336 |

|

0.6 |

≤194 |

3.0 |

≤249 |

14 |

≤354 |

|

0.8 |

≤201 |

4.0 |

≤262 |

16 |

≤371 |

|

1.0 |

≤206 |

5.0 |

≤275 |

20 |

≤406 |

|

1.2 |

≤211 |

6.0 |

≤284 |

25 |

≤450 |

|

1.6 |

≤220 |

8.0 |

≤301 |

One-sided processing to 22.5 |

≤540 |

Table 4:Electrical strength of phenolic cotton fabric laminates

| Average thickness(mm) |

Electrical Strength(kV/mm) |

Average thickness(mm) | Electrical Strength(kV/mm) | Average thickness(mm) | Electrical Strength(kV/mm) |

|

0.8 |

≥0.89 |

1.6 |

≥0.72 |

2.6 |

≥0.56 |

|

0.9 |

≥0.84 |

1.8 |

≥0.69 |

2.8 |

≥0.53 |

|

1.0 |

≥0.82 |

2.0 |

≥0.65 |

3.0 |

≥0.50 |

|

1.2 |

≥0.80 |

2.2 |

≥0.61 |

||

|

1.4 |

≥0.76 |

2.4 |

≥0.58 |

Product Applications

Electrical Industry:

- Switchgear components and control panels

- Motor housings and transformer parts

- Circuit breaker assemblies

Automotive Sector:

- Brake linings and clutch components

- Heat shields and gaskets

- Electrical connector housings

Industrial Equipment:

- Bearing retainers and wear strips

- Jigs, fixtures, and tooling applications

- Chemical processing equipment components

Specialized Uses:

- Tea tray manufacturing (food-safe applications)

- Marine equipment components

- Aerospace interior fittings

OEM Service

We give comprehensive OEM administrations custom fitted to your requirements:

- Custom Measuring: Cut to your correct dimensions

- Special Grades: Defined for particular applications

- Surface Medications: Different wrapping up choices available

- Packaging Arrangements: Custom bundling for your dissemination needs

- Technical Back: Building help for fabric selection

Our experienced group works closely with you to create arrangements that coordinate your specialized and commercial requirements.

Certification

Frequently Asked Questions

Q: What makes fabric reinforcement important in phenolic sheets?

A: Cotton fabric reinforcement provides mechanical strength and dimensional stability. It prevents cracking and improves impact resistance compared to unreinforced materials.

Q: Can these sheets be used in food-related applications?

A: Yes, certain grades are suitable for food-contact applications like tea trays. The thermosetting properties ensure stability at elevated temperatures without releasing harmful substances.

Q: What machining considerations should I keep in mind?

A: Use sharp cutting tools and moderate speeds to prevent chipping. Dust collection is recommended during machining operations.

Q: How should I store these materials?

A: Store in dry conditions away from direct sunlight. Proper storage maintains the product properties over extended periods.

Contact Us

Ready to discuss your material requirements? Our technical team is here to help you select the right Fabric Reinforced Phenolic Sheet for your application.

Email: info@jhd-material.com

Contact us nowadays for point by point specialized determinations, estimating data, or to ask tests. We're committed to giving you with high-quality materials and extraordinary benefit back.

Send Inquiry